Fold-free bending die applied to plate

A technology for bending molds and plates, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., and can solve the problems that bending molds cannot complete bending, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

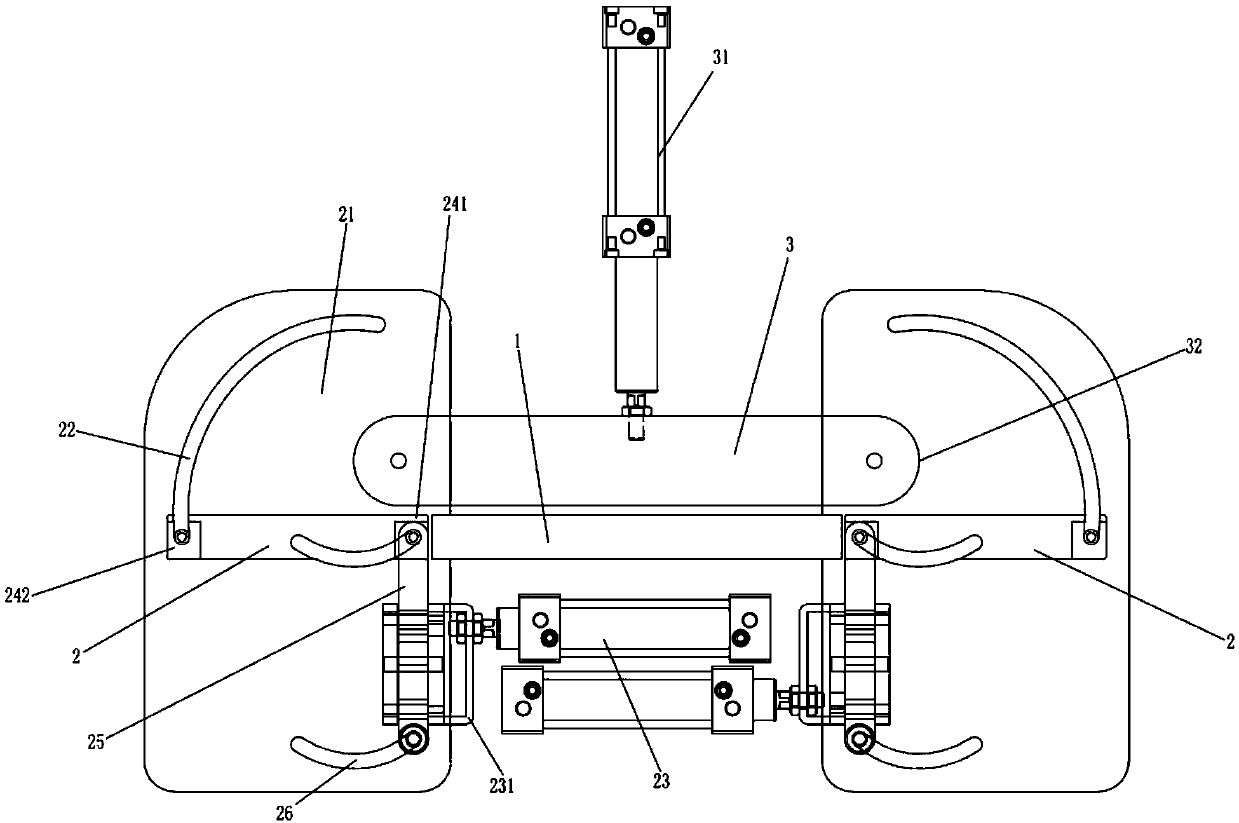

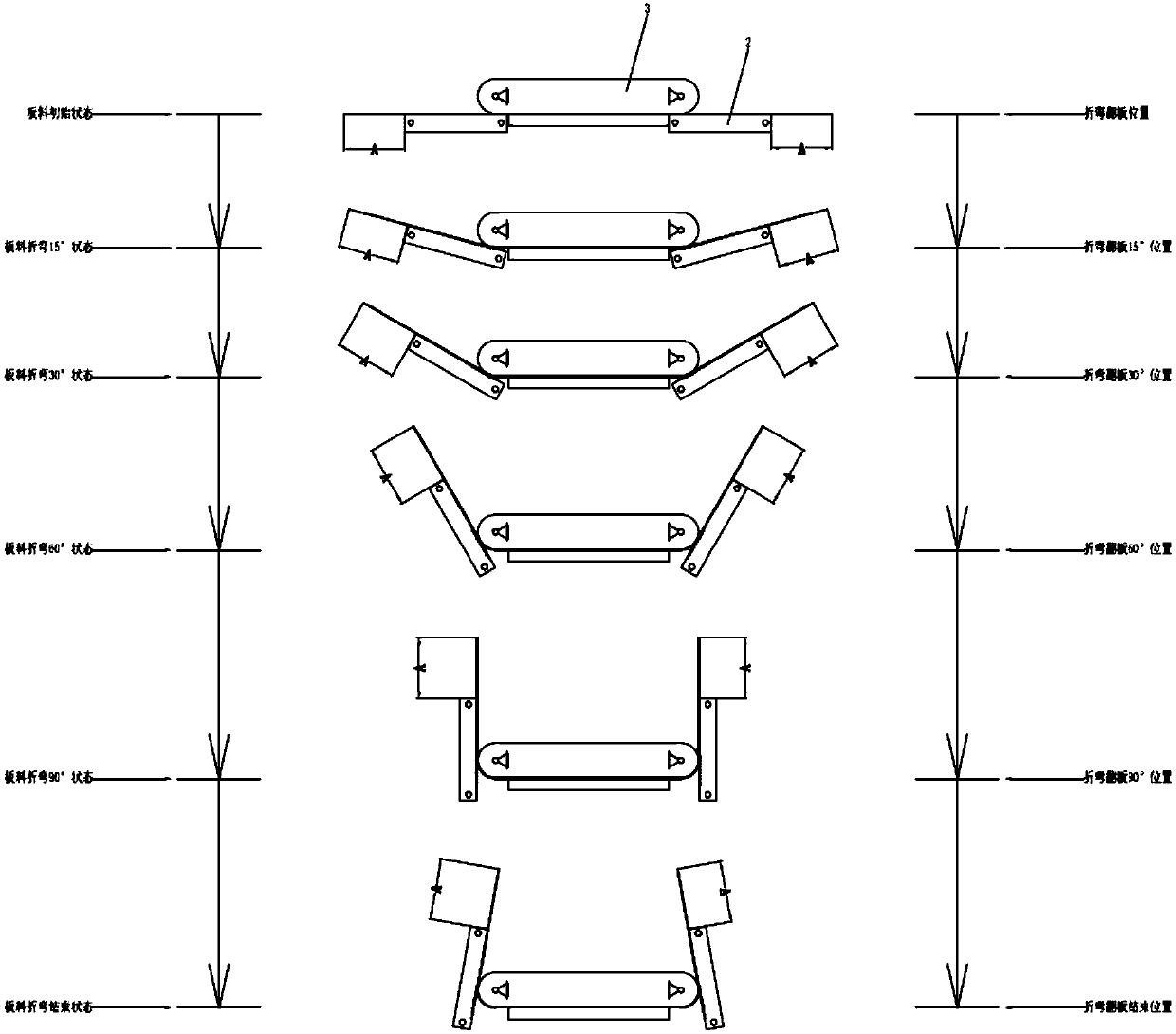

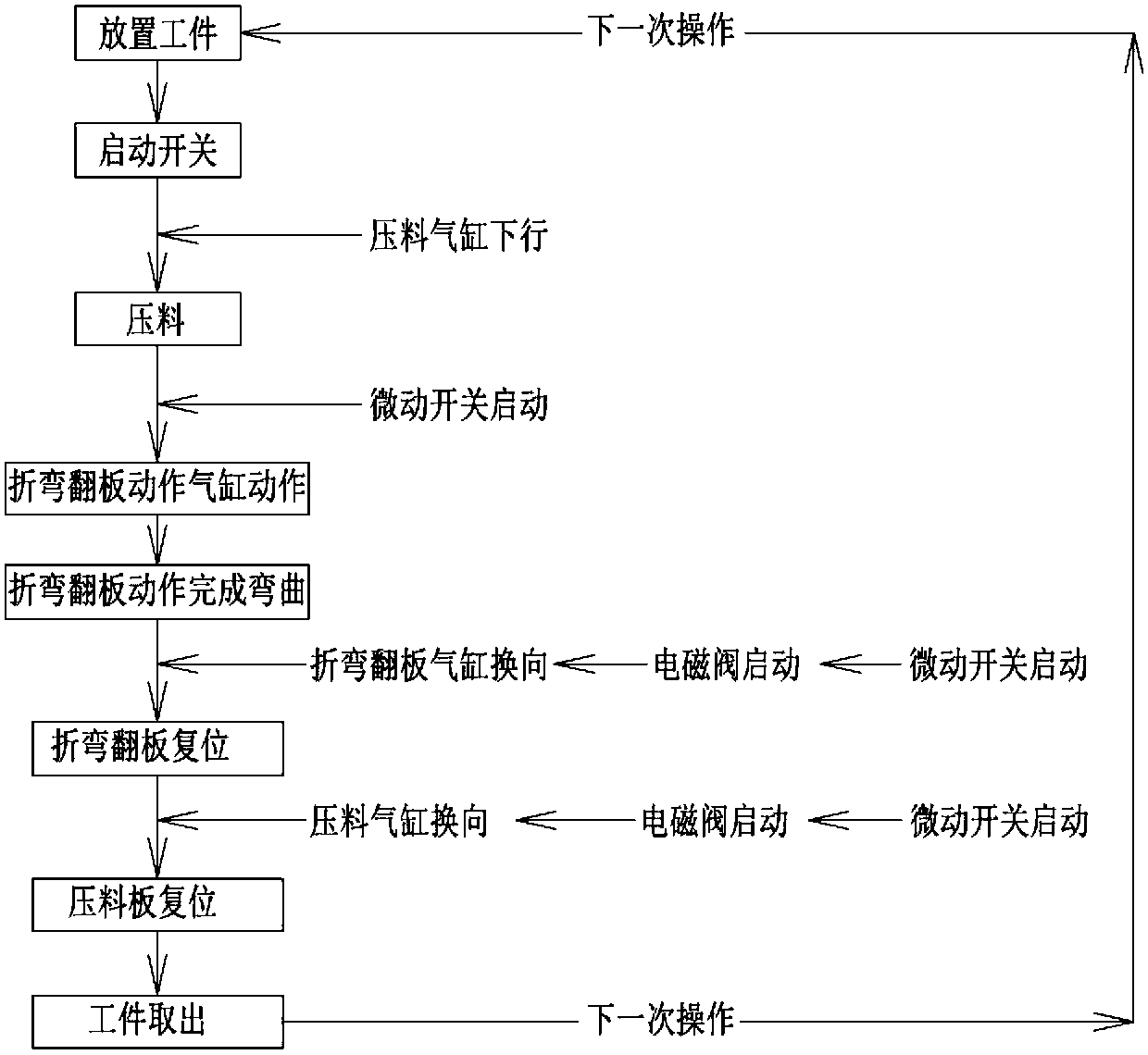

[0023] see Figure 1 to Figure 3 , the figure shows a non-marking bending die applied to plates provided by Embodiment 1 of the present invention, which includes: a clamping plate 1; two bending parts 2, which are symmetrically arranged, and the bending parts 2 are specifically It can be a bent plate, and the two bent parts 2 are respectively arranged outside the opposite ends of the clamping plate 1. The first end 241 of the bent part 2 is hinged on the guide plate 21, and the opposite second end 242 is slidably connected. In the first arc-shaped guide rail 22, the first arc-shaped guide rail 22 is fixedly installed on the guide plate 21, and the bending part 2 is fixedly connected to the first driving part 23 at the same time, and the first driving part 23 drives the bending part 2 to move back and forth; The material plate 3 is installed on the top of the clamping plate 1, the top of the pressure material plate 3 is fixedly connected with a second driving part 31, and the s...

Embodiment 2

[0026] see Figure 1 to Figure 3 , the figure shows a non-marking bending die applied to panels provided by Embodiment 2 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: folding The first end 241 of the curved part 2 is hinged on the end of the guide rod 25, and the guide rod 25 is fixedly connected to the first driving part 23; the guide plate 21 is also fixedly equipped with two parallel second arc guide rails 26, and the guide rod The two opposite ends of 25 are respectively slidably connected in two second arc-shaped guide rails 26 . Through the setting of the above structure, the first end of the bending part can be bent along the arc track to form the end of the product by using the guiding function of the two second arc-shaped guide rails, and the bending force can be effectively controlled. Guaranteed non-marking effect.

Embodiment 3

[0028] see Figure 1 to Figure 3 , the figure shows a non-marking bending die applied to panels provided by Embodiment 3 of the present invention. On the basis of the above embodiments, this embodiment further makes the following technical solutions as improvements: the first A driving component 23 (specifically, an air cylinder) is connected to the bending component 2 through a U-shaped connecting plate 231 . Through the arrangement of the above structure, the U-shaped connecting plate can be used to expand the force application range and force application area of the first driving part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com