Weaving equipment

A kind of equipment and steam channel technology, applied in the field of weaving, can solve the problems of easy creases, affecting the appearance of cloth, etc., and achieve the effect of crease elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

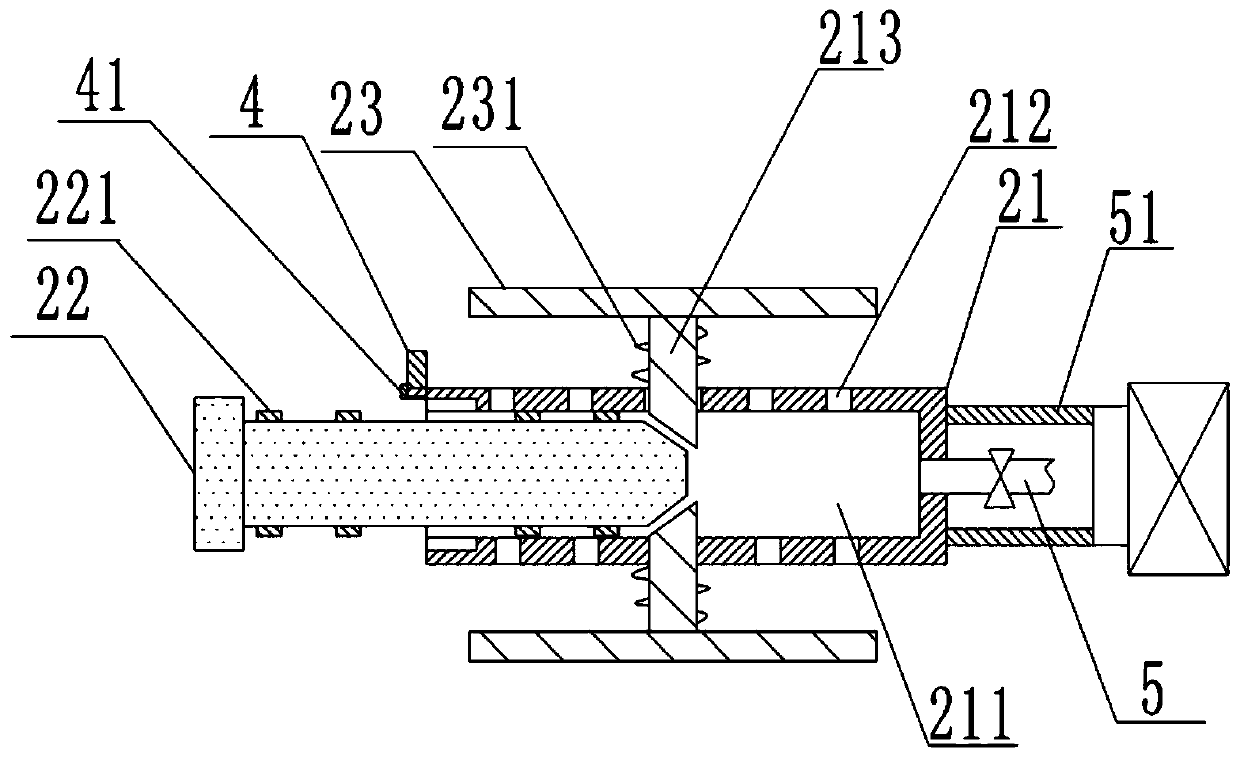

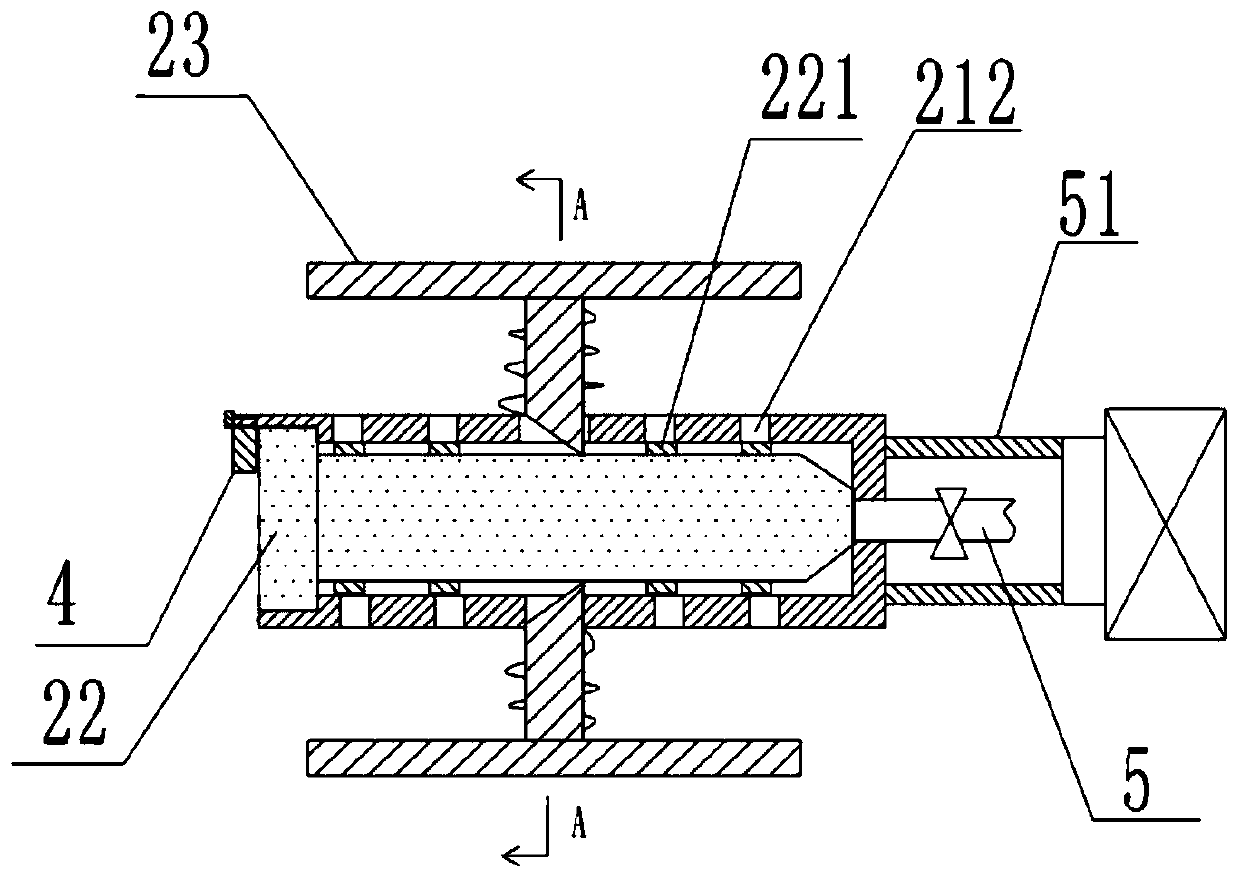

[0022] The reference numerals in the accompanying drawings of the description include: transmission table 1, transmission roller 2, roller body 21, air outlet 212, sliding rod 213, pressing column 22, blocking column 221, caressing platform 23, spring 231, arc-shaped surface 232, Steam channel 211, winding roller 3, rotating bar 4, rotating shaft 41, steam pipe 5, fixed shaft 51.

[0023] In order to achieve the above object, the basic scheme of the present invention is as follows:

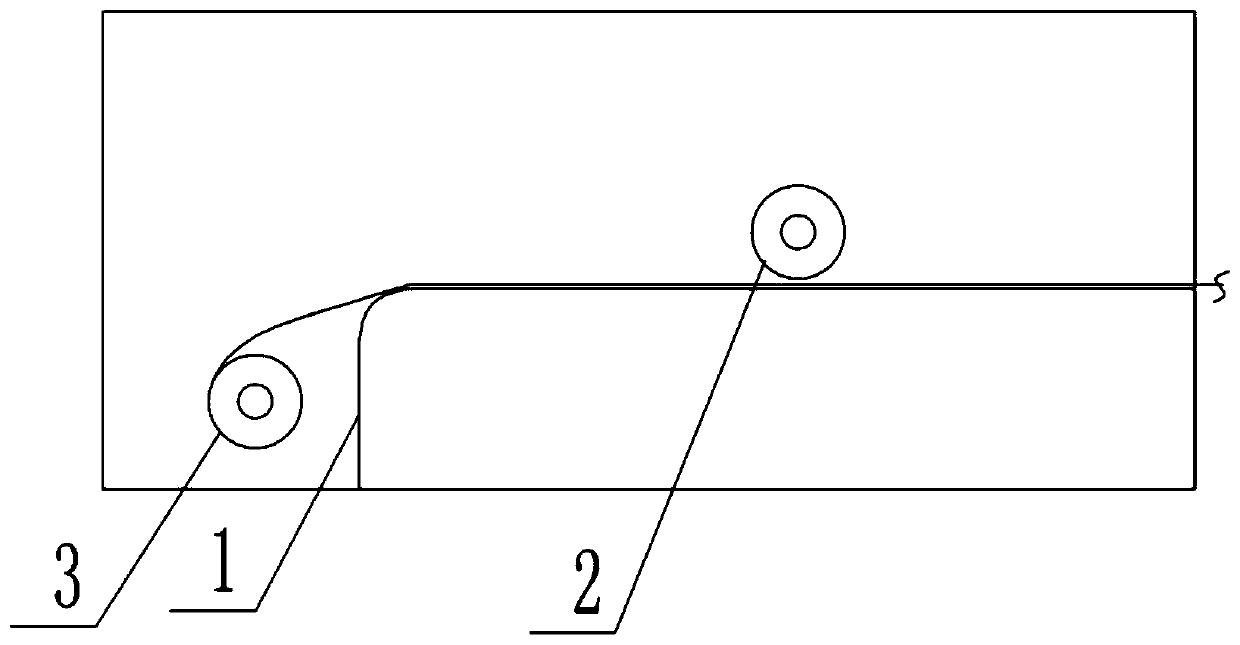

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the weaving equipment includes a transmission platform 1, a transmission roller 2 for transmitting the cloth on the transmission platform 1, and a winding roller 3 for winding the cloth; the winding roller 3 is located at the discharge end of the transmission platform 1 , and the winding roller 3 is driven by a motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com