Patents

Literature

37results about How to "Improve cloth quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing process for denim garment

ActiveCN104532592ANo effect on air qualityReduce storage pressureBiochemical fibre treatmentDry-cleaning apparatus for textilesChemical oxygen demandRoom temperature

The invention relates to a washing process for a denim garment. The washing process comprises the following steps: performing bio-enzyme de-sizing treatment in an amylase solution after performing denim garment fabric pre-treatment; performing enzyme washing by neutral enzyme powder; dehydrating and drying after cleaning with clean water; performing monkey wash on the fabric surface; performing neutralization treatment on the fabric which is subjected to monkey wash; adding a softening agent to perform softening treatment on the fabric; cooling the denim garment fabric to room temperature after dehydrating and drying, thereby completing washing on the denim garment. Compared with the prior art, the washing process has the advantages of quickly removing residual manganese ions, shortening the processing time, removing the color of a bleaching liquid, reducing the cleaning frequency, being low in sewage COD (chemical oxygen demand), and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

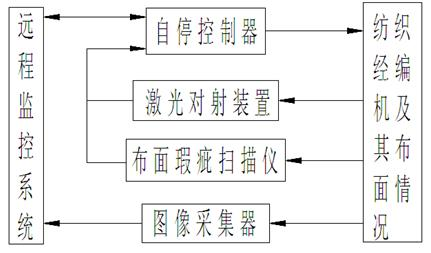

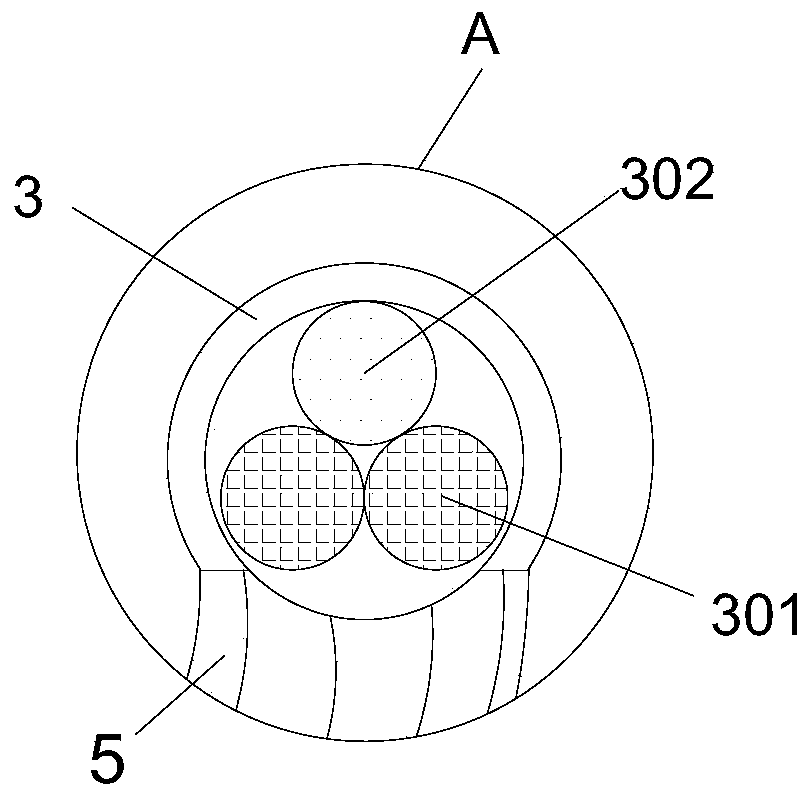

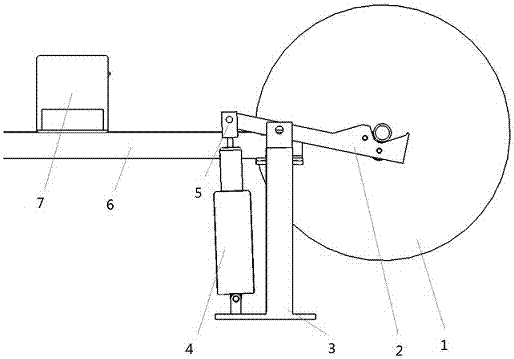

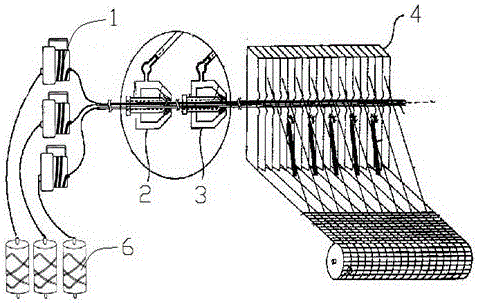

Remote monitoring automatic thread stop system for textile tricot machine

The invention relates to a remote monitoring automatic thread stop system for a textile tricot machine. The system comprises (1) an image acquisition unit, (2) a remote monitoring system, (3) a cloth cover defect scanner, (4) a laser correlation device and (5) an automatic stop controller. The cloth cover defect scanner and the laser correlation device scan and monitor a broken yarn of the textile tricot machine, and are matched with the automatic stop controller to realize automatic stop when a yarn is broken, the image acquisition unit acquires the quality of a cloth cover of the textile tricot machine and transmits the quality to the remote monitoring system, a monitoring worker monitors the working condition of the textile tricot machine and the quality of the cloth cover, and if the cloth cover defect scanner and the laser correlation automatic control device miss detection, the remote monitoring worker can locate cloth cover defects through the monitoring system and send a stop instruction. The system can automatically detect and monitor the yarn breaking condition, reduce the labor intensity of a knitter, improve labor productivity, remove the harm of noise and dust, and ensure that the productivity of the machine and the quality of the cloth cover are greatly improved.

Owner:CHANGLE MAIYE JINGBIAN FITTINGS MFG

Cation viscose vortex spun woven fabric and preparation method thereof

The invention relates to a preparation method of a cation viscose vortex spun woven fabric, which comprises the following steps of: drawing polyester fibers with cations, and viscose fibers in a ratio on a drawing frame to obtain cation viscose drawn slivers; spinning cation viscose vortex spun single yarns at a certain vehicle speed, warping, warp-rebeaming, and sizing to obtain the cation viscose vortex spun single yarns serving as the warp beams of the cation viscose vortex spun woven fabric; weaving the cation viscose vortex spun single yarns serving as warp yarns and other raw materials serving as weft yarns into a whole according to different tissue requirements by using a single-warp beam weaving machine; and performing secondary light desizing and secondary dyeing, and drying to obtain the dyed cation viscose vortex spun woven fabric. The cation viscose vortex spun woven fabric prepared by the method is suitable for a clothing fabric, and has a bright and clean surface, soft handfeel, high pilling resistance, washing fastness and hygroscopicity, and higher face quality and lower cost compared with the common polyester viscose fabric, energy consumed in the process of double-twisting into plied yarns is saved, various index requirements of the fabric are improved while the cost is reduced, and the method is suitable for processing and weaving fabrics on a large scale.

Owner:HANGZHOU AOHUA TEXTILE

Water washing process for denim clothes

InactiveCN106968102AReduce storage pressureQuick removalDry-cleaning apparatus for textilesBiochemical treatment with enzymes/microorganismsHigh concentrationDenim

The invention provides a water washing process for denim clothes. The water washing process comprises the following steps: performing pretreatment, enzyme washing, ferment washing, water washing, primary dewatering, primary drying, monkey washing, neutralization treatment, softening, secondary dewatering and secondary drying on the denim clothes, and obtaining a water-washed finished product. The water washing process has the beneficial effects that no odor is generated during neutralizing reduction, so that the air quality in a working environment is not affected; by the use of a high-concentration product, the use amount is small, and the warehousing pressure of a factory is relieved; residual manganese ions can be quickly removed, and thetreatment time is shortened; the color of bleaching liquid can be removed; the number of cleaning times is reduced, and the sewage treatment pressure is relieved; the sewage COD is low; the sand level is clear, and the class of the denim clothes is improved.

Owner:FANCHANG QINGXIN WASHING CO LTD

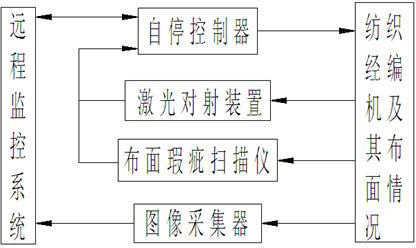

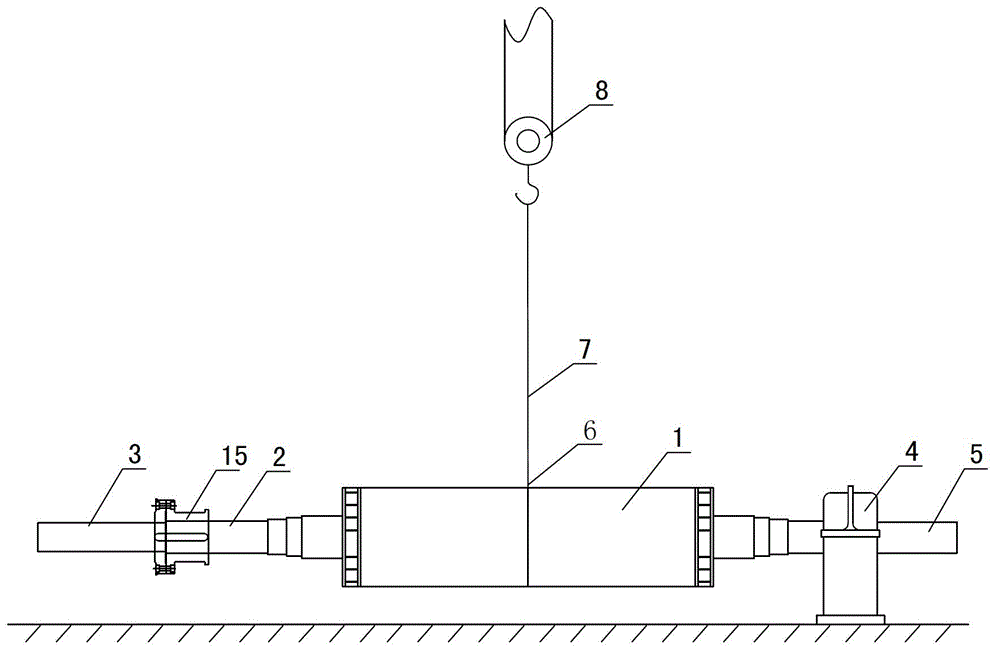

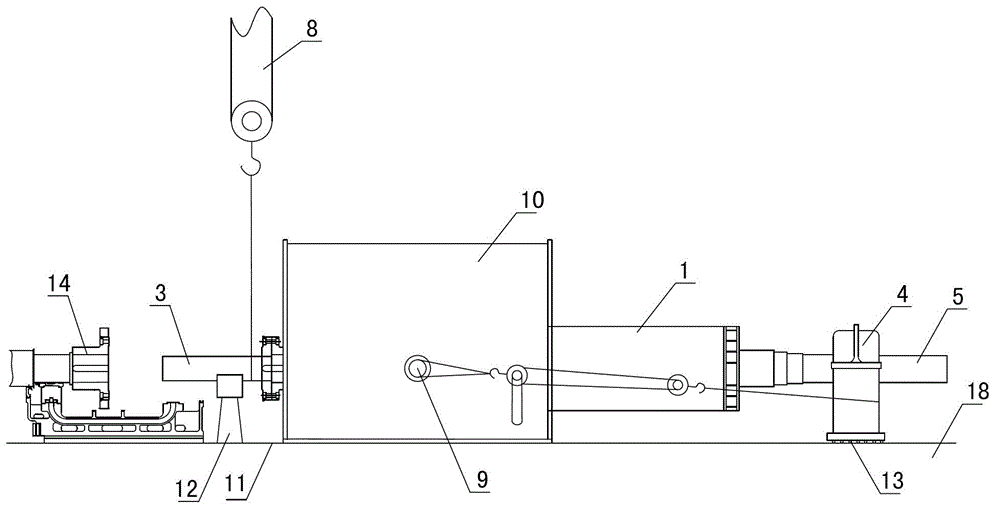

Method for inserting generator rotor of gas-filling condensing steam turbine unit

InactiveCN102744588ALow construction costShorten the construction periodMetal working apparatusSocial benefitsCoupling

The invention relates to the field of steam turbine units, and in particular relates to a method for inserting a generator rotor of a gas-filling condensing steam turbine unit. The method is characterized in that a connecting shaft is arranged at the steam end of the generator rotor and a balance weight is hanged at the exciter end. The method comprises the operation steps of: (1), connecting the connecting shaft with the steam end of the generator rotor, and hanging a rear bearing base of a generator on a shaft neck of the exciter to be used as the balance weight; (2), lifting the rotor to be in a horizontal state; (3) slowing inserting the steam end into a stator; (4) moving a lifting point to the root part of the connecting shaft until the connecting shaft end is close to a back wheel of the steam turbine; (5) moving the lifting point to the steam end of the rotor; (6), continuously drafting the rotor by using a chain block until a shaft coupler at the steam end is close to the back wheel, and connecting the steam end with the back wheel of the steam turbine; and (7) rotating the rotor after the rotor is in position. Compared with the prior art, the method has the beneficial effects of stability, efficiency, safety, good social benefit and economic benefit; and moreover, the operation skills are easy to manage.

Owner:ANGANG CONSTR CONSORTIUM

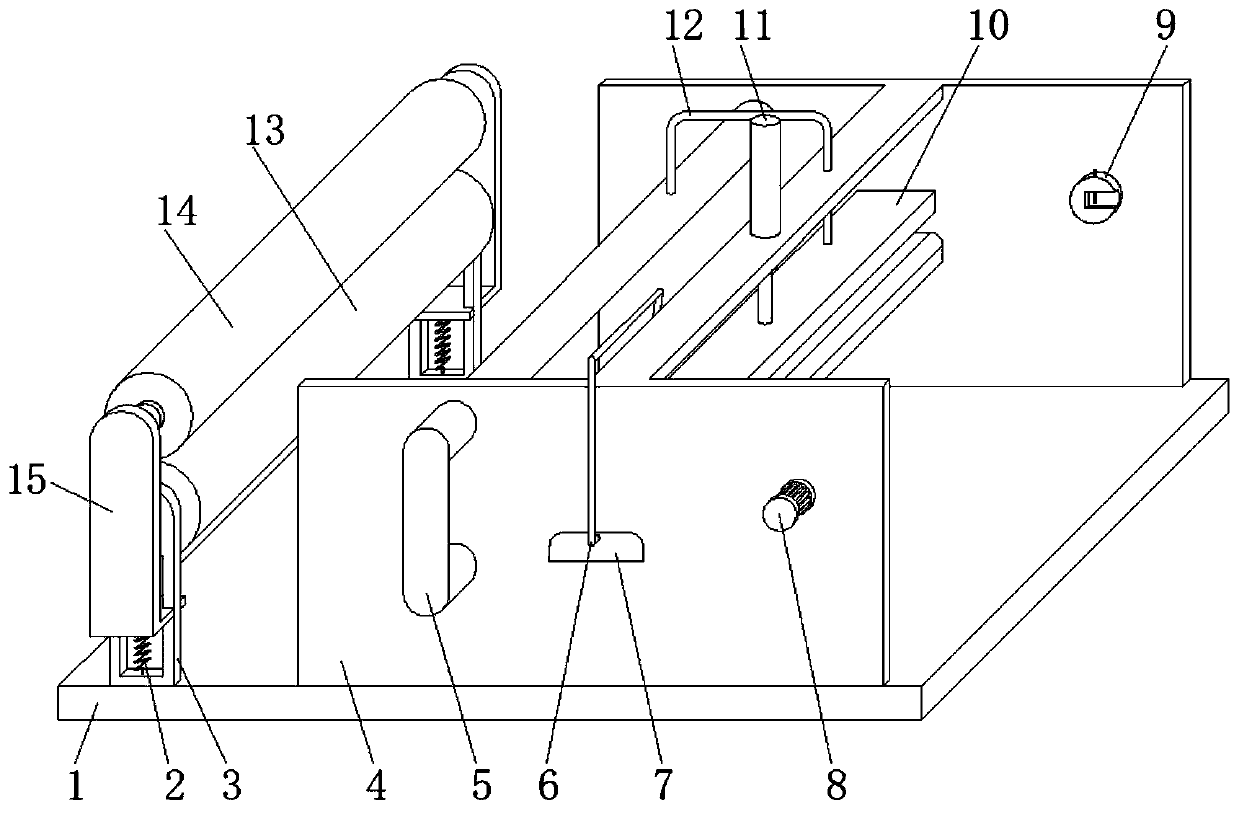

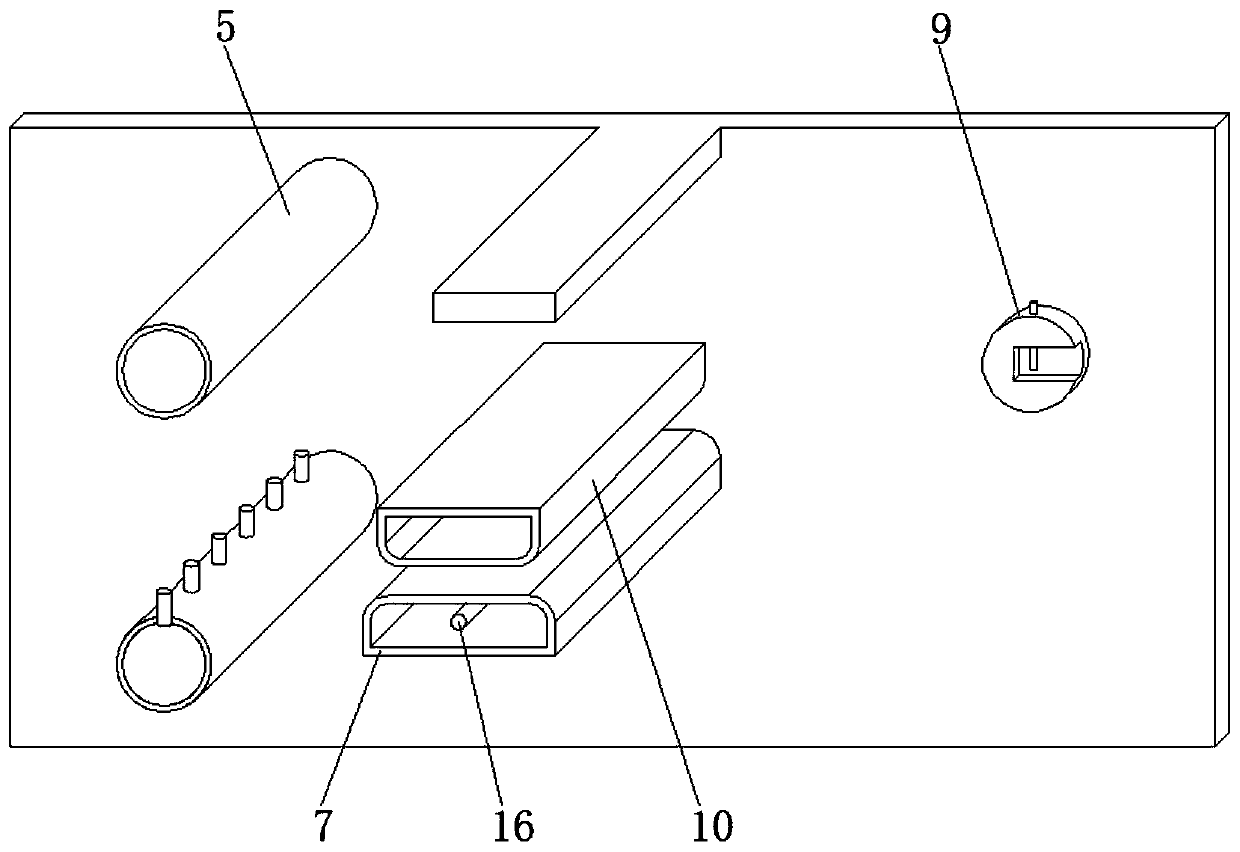

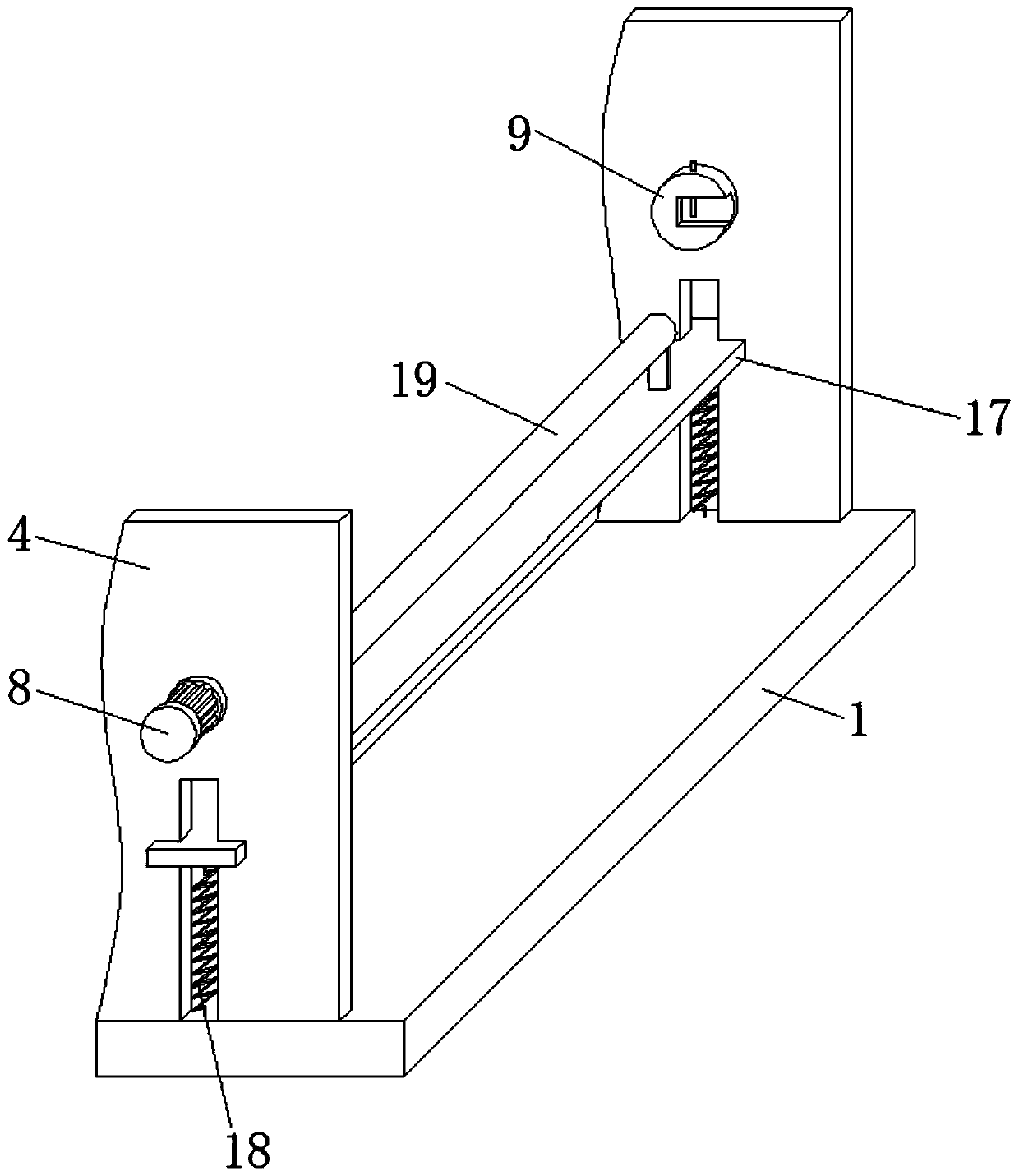

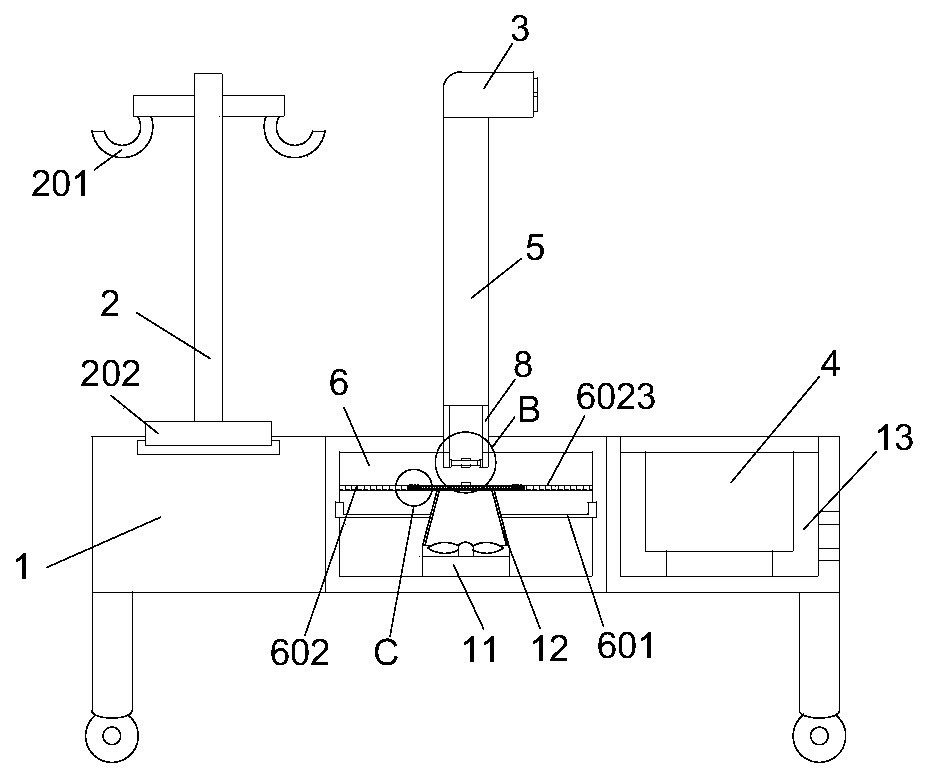

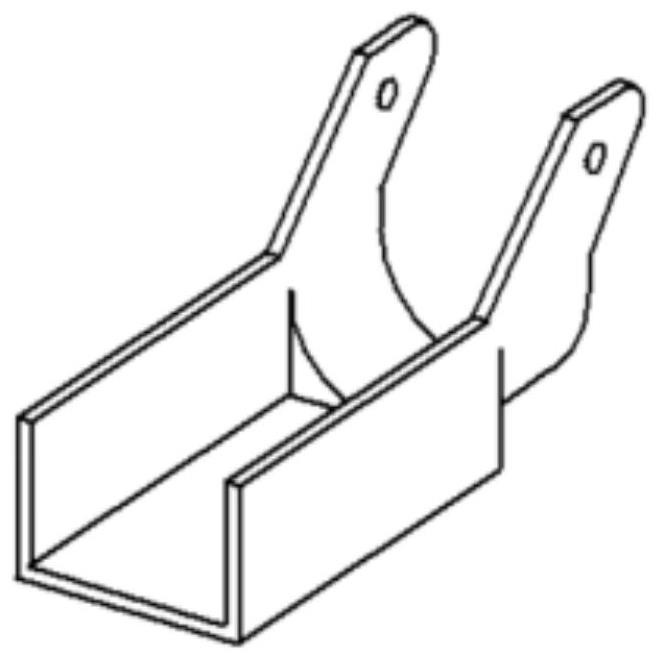

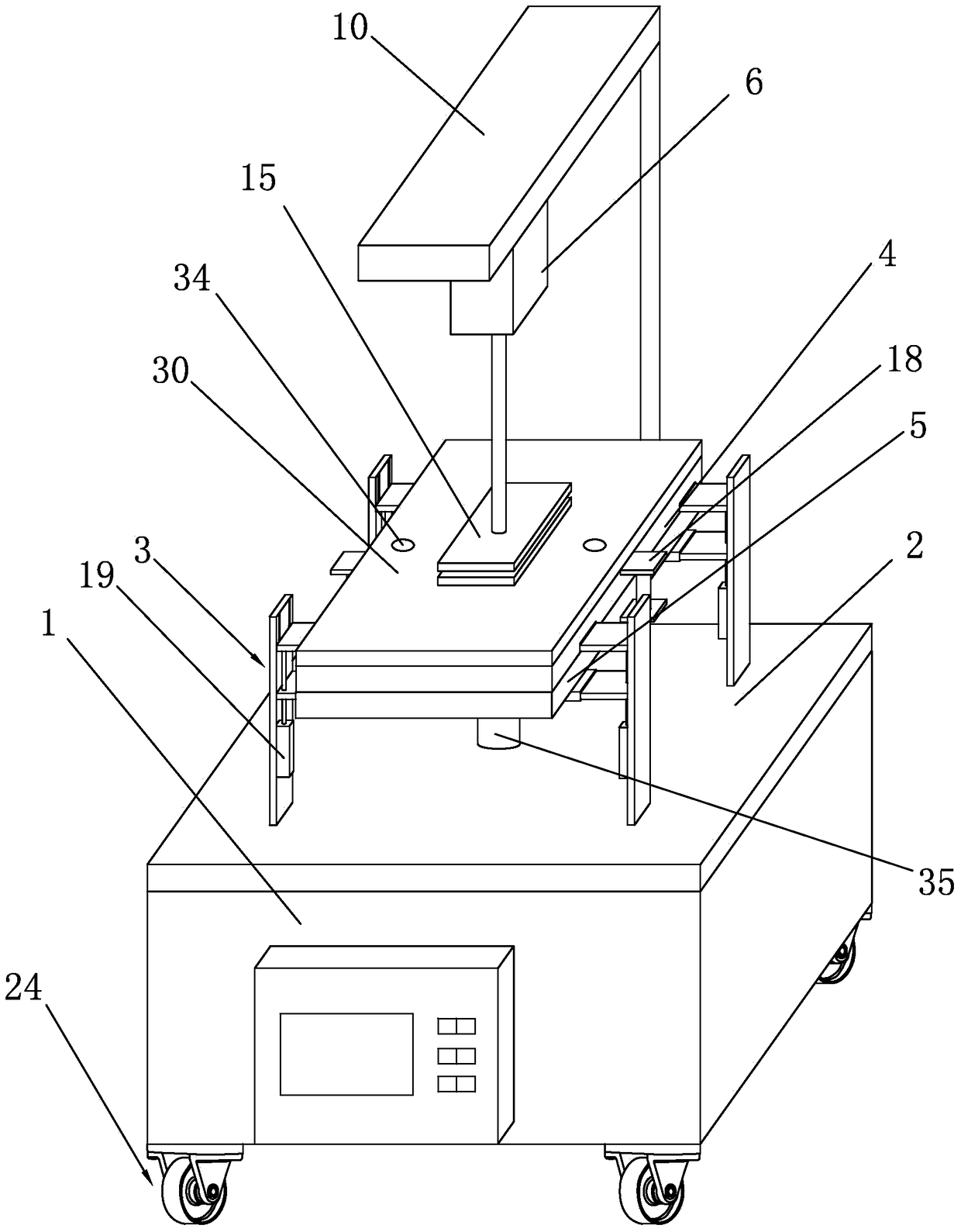

Cloth winding device for garment making

The invention discloses a cloth winding device for garment making. The cloth winding device comprises a base. A fixed rack and a mounting rack are welded to the two sides of the outer wall of the topof the base correspondingly, and a pressing mechanism is arranged in the fixed rack. A U-shaped pipe mounting hole is formed in the outer wall of one side of the fixed rack, and a U-shaped pipe is connected to the inner wall of the U-shaped pipe mounting hole in an inserted manner. Air spray holes are formed in the top inner wall and the bottom inner wall of the U-shaped pipe. Air spray nozzles are connected to the inner walls of the air spray holes in an inserted manner. An ironing box is fixed to the middle of the inner wall of the mounting rack through screws, a hydraulic cylinder is fixedto the outer wall of the top of the mounting rack through screws, and a press plate is fixed to the bottom end of a piston rod of the hydraulic cylinder through screws. According to the cloth windingdevice, humidity of cloth can be increased, the cloth is ironed through the ironing box and the press plate, water in the cloth is removed through drying, folds of the cloth can be eliminated, the cloth quality can be improved easily, the tension degree of the cloth between a pressing roller and a connecting roller can be guaranteed, and the winding quality can be improved easily.

Owner:天门市丰煜服饰有限公司

Polyester vortex spun woven fabric and preparation method thereof

The invention relates to a preparation method of a polyester vortex spun woven fabric, which comprises the following steps of: drawing polyester fiber carded slivers with cations on a drawing frame to obtain polyester fiber drawn slivers; spinning polyester vortex spun single yarns at a certain vehicle speed, warping, warp-rebeaming, and sizing to obtain the polyester vortex spun single yarns serving as the warp beams of the polyester vortex spun woven fabric; weaving the polyester vortex spun single yarns serving as warp yarns and other raw materials serving as weft yarns into a whole according to different requirements by using a single-warp beam weaving machine; and performing secondary light desizing, performing disperse dyeing, and drying to obtain the polyester vortex spun woven fabric. The polyester vortex spun woven fabric woven by the preparation method is suitable for a clothing fabric, and has a bright and clean surface, soft handfeel, high pilling resistance, washing fastness and hygroscopicity, and higher face quality and lower cost compared with the common polyester viscose fabric, energy consumed in the process of double-twisting into plied yarns is saved, various index requirements of the fabric are improved while the cost is reduced, and the method is suitable for processing and weaving fabrics on a large scale.

Owner:HANGZHOU AOHUA TEXTILE

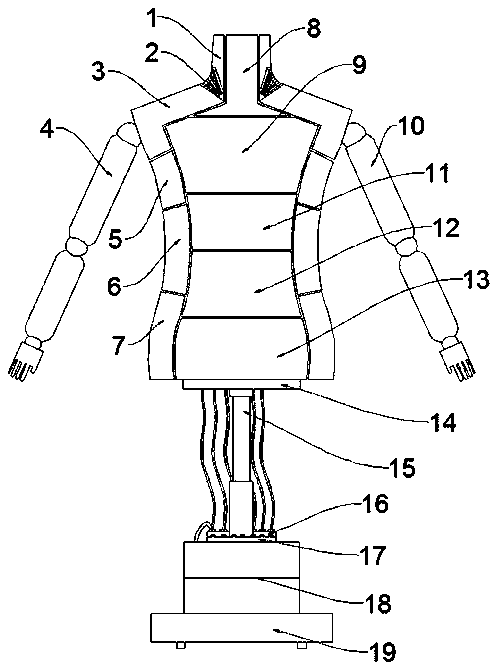

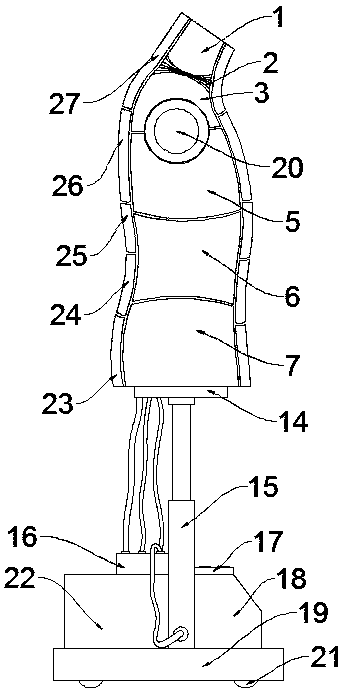

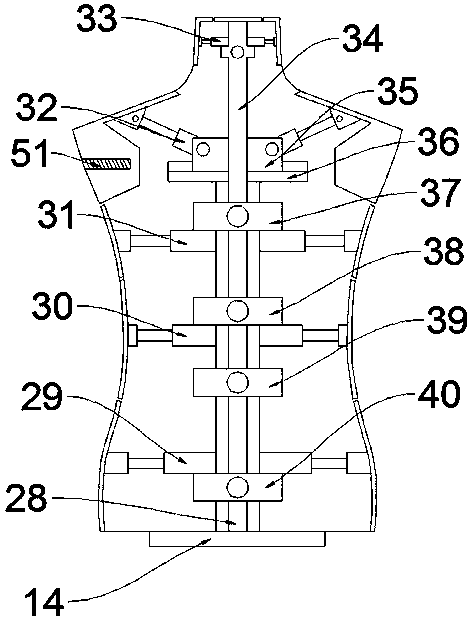

Cloth support mannequin for clothing design

The invention discloses a cloth support mannequin for clothing design, and relates to the technical field of support brackets of the clothing design. In order to solve the problem that in the prior art, the fat and thin condition cannot be changed, the idea of clothing designers is fixed, and movement is troublesome, four casters are installed on the lower end face of a base, a support hydraulic arm is installed on the upper end face of the base, a compressor is installed on one side of the support hydraulic arm, a hydraulic shunt is installed on the upper end face of the compressor, a machinebox is installed on the other side of the support hydraulic arm, and a hydraulic control button is installed on the upper end face of the machine box; a bearing supporting plate is installed at one end of the support hydraulic arm, a first support skeleton is installed on the upper end face of the bearing support plate, first side hydraulic rods are installed on the two sides of the first supporthydraulic arm respectively, a lower waist piece is installed at one end of each first side hydraulic rod, and a second side hydraulic rod is installed on the upper portion of each side hydraulic rod.

Owner:IANGSU COLLEGE OF ENG & TECH

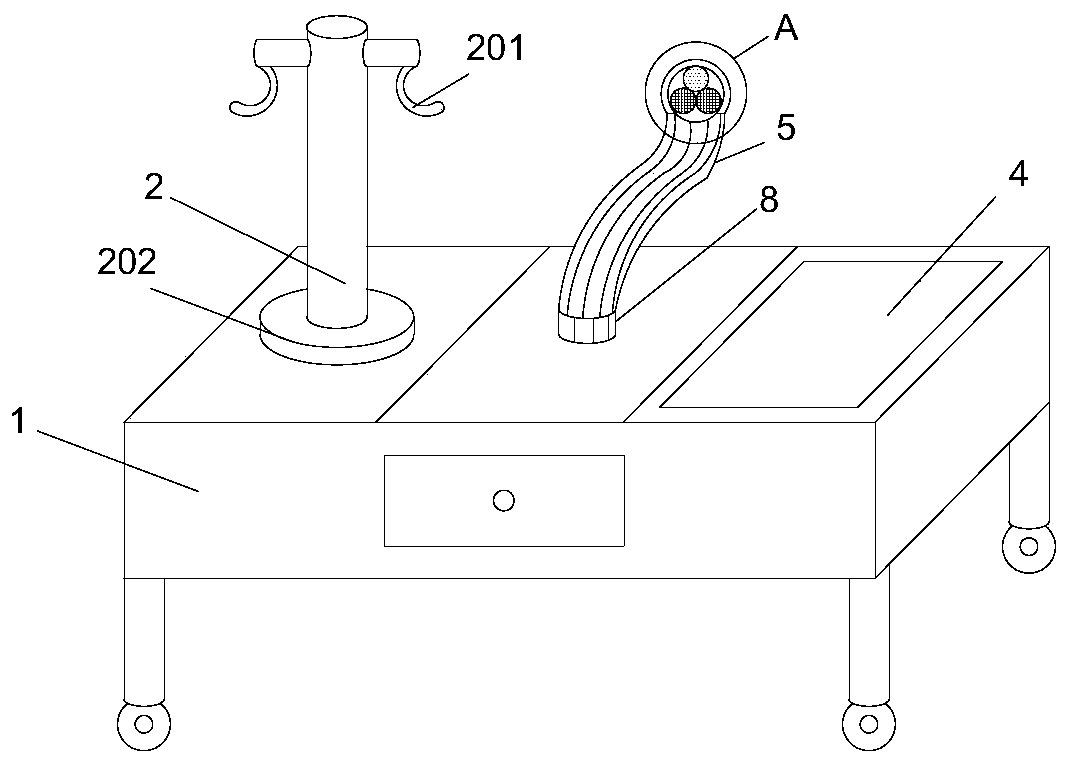

Burr trimming equipment used after cutting textile clothing cloth

ActiveCN110938959AAchieve absorptionAchieve vibrationMechanical cleaningPressure cleaningFan bladeKnife blades

The invention relates to the technical field of textile equipment, and discloses burr trimming equipment used after cutting textile clothing cloth. The burr trimming equipment comprises a table body;the top of the table body is provided with a clothes rail, a trimmer and a heating device in order from left to right; a dust collection bin is configured at the middle of the table body; and the heating device is arranged at the right side of the table body. According to the burr trimming equipment used after cutting the textile clothing cloth provided by the invention, through the work of a vacuum cleaner, the vacuum cleaner absorbs burrs and thread residues trimmed by a trimmer blade, and the burrs and the thread residues enter the filter screen layer; at the same time, the work of the vacuum cleaner enables a fan blade to rotate; the fan blade drives a second magnet to rotate to change the magnetic pole; when the second magnet and a first magnet have opposite magnetic poles, the firstmagnet is attracted to drive the filter screen layer to move to the upper side, so that the burrs and the thread residues falling on the top of the filter screen layer move towards dust outlet layerson the two sides, and finally enter a dust collection box, so that when clothes are trimmed, the thread residues and the burrs are absorbed while being trimmed.

Owner:青岛威达生物科技有限公司

Cation viscose vortex spun woven fabric and preparation method thereof

The invention relates to a method for manufacturing a cationic vortex spinning woven fabric. The cationic vortex is spun out at a certain speed by drawing cationic polyester fibers and viscose fibers on a drawing frame according to the ratio. Spun single yarn, after warping, paralleling, and sizing, obtain the catabolic vortex spun single yarn as the warp beam of the cationic vortex spun woven fabric, and use the single warp beam loom to make the above-mentioned cathodic vortex spun single yarn Warp threads and other raw materials are used as weft threads, which are woven into one according to the requirements of different tissues. After secondary light desizing, secondary dyeing and drying, the dyed cathodic eddy current woven fabric is obtained. The cathodic vortex woven fabric prepared by this method is suitable for clothing fabrics, with smooth surface, soft hand feeling, excellent anti-pilling, washability and hygroscopicity, which is better than ordinary polyester-viscose fabrics in surface quality. Improvement, cost reduction, saving the energy consumption of two-for-one twisted strands, improving the various index requirements of fabrics, suitable for large-scale fabric processing and weaving.

Owner:HANGZHOU AOHUA TEXTILE

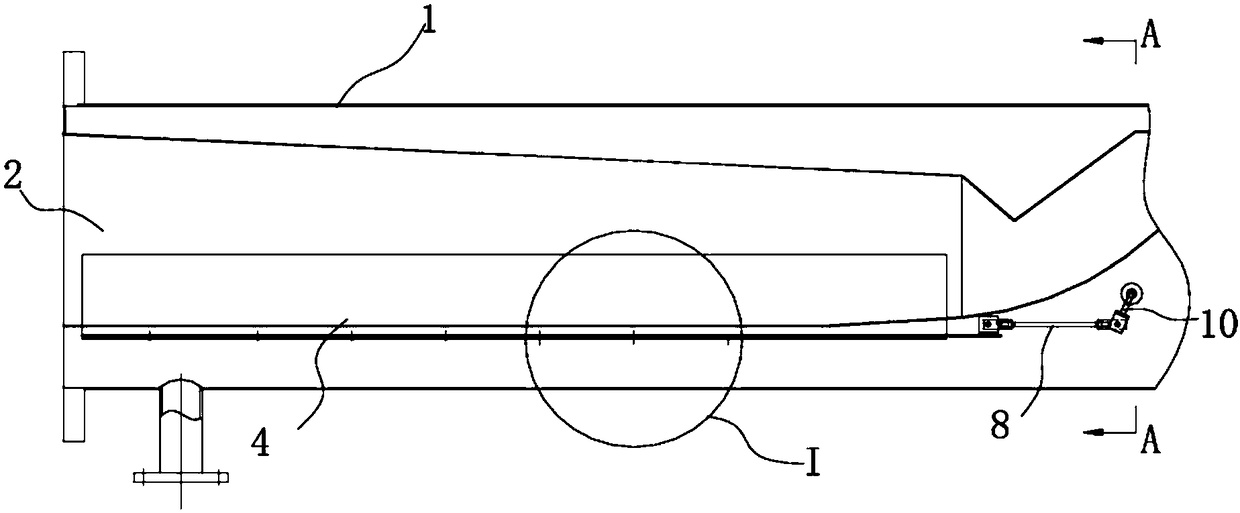

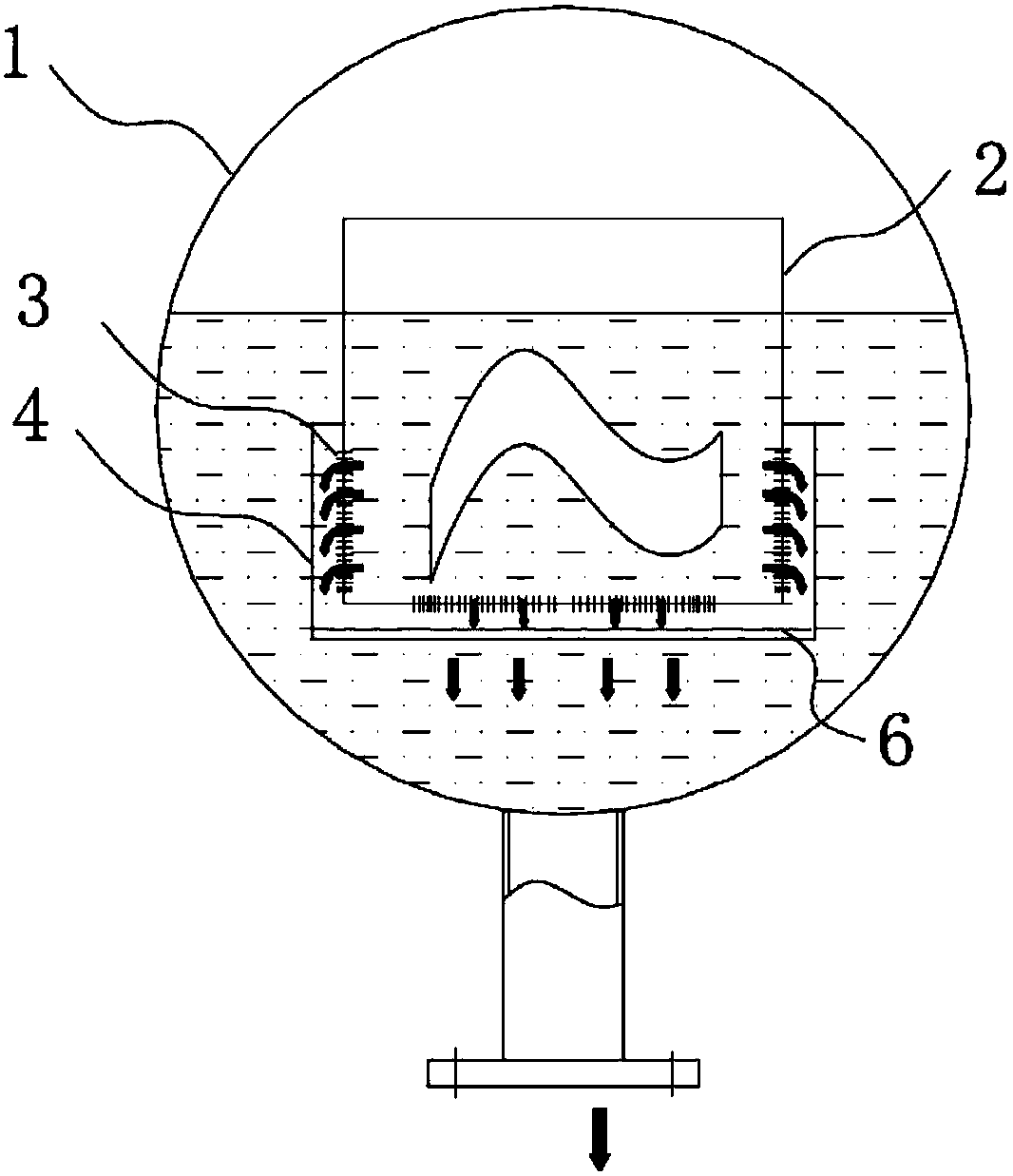

Remote monitoring automatic thread stop system for textile tricot machine

The invention relates to a remote monitoring automatic thread stop system for a textile tricot machine. The system comprises (1) an image acquisition unit, (2) a remote monitoring system, (3) a cloth cover defect scanner, (4) a laser correlation device and (5) an automatic stop controller. The cloth cover defect scanner and the laser correlation device scan and monitor a broken yarn of the textile tricot machine, and are matched with the automatic stop controller to realize automatic stop when a yarn is broken, the image acquisition unit acquires the quality of a cloth cover of the textile tricot machine and transmits the quality to the remote monitoring system, a monitoring worker monitors the working condition of the textile tricot machine and the quality of the cloth cover, and if the cloth cover defect scanner and the laser correlation automatic control device miss detection, the remote monitoring worker can locate cloth cover defects through the monitoring system and send a stop instruction. The system can automatically detect and monitor the yarn breaking condition, reduce the labor intensity of a knitter, improve labor productivity, remove the harm of noise and dust, and ensure that the productivity of the machine and the quality of the cloth cover are greatly improved.

Owner:CHANGLE MAIYE JINGBIAN FITTINGS MFG

Dyeing and finishing process of elastic soft chinlon fabric

PendingCN111472125AEliminate retractionImprove cloth qualitySucessive textile treatmentsChemical fixing of textilesChemistryProcess engineering

The invention discloses a dyeing and finishing process of an elastic soft chinlon fabric and belongs to the technical field of fabric dyeing and finishing. The dyeing and finishing process of the elastic soft chinlon fabric comprises the following steps of feeding the elastic chinlon fabric in hot water for desizing, then conducting presetting, immersing the elastic chinlon fabric into hot water of 30-40 DEG C, adding a refining degreasing agent and a penetrating agent, conducting heating and then heat preservation for 10-20 min, conducting water washing and cooling, feeding the elastic chinlon fabric into an overflow dyeing machine, adding dye and an acid leveling agent for dyeing, feeding the elastic chinlon fabric in a soaping agent for soaping for 15-20 min, feeding the elastic chinlonfabric in a color fixation solution for color fixation, conducting soft finishing and drying, feeding the elastic chinlon fabric in a heat-setting machine for heat setting to enable the setting to be2-3 cm wider than that of a finished product. The dyeing and finishing process of the elastic soft chinlon fabric is good in color fixation performance and capable of effectively maintaining the elasticity of the fabric and effectively improving the sweat absorption and moisture discharge performance.

Owner:晋江市七彩狐服装织造有限公司

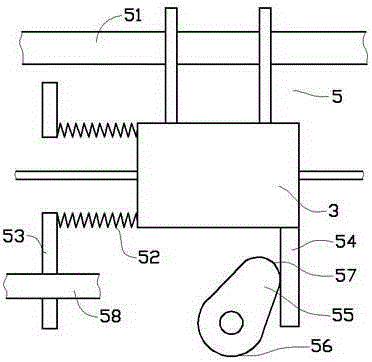

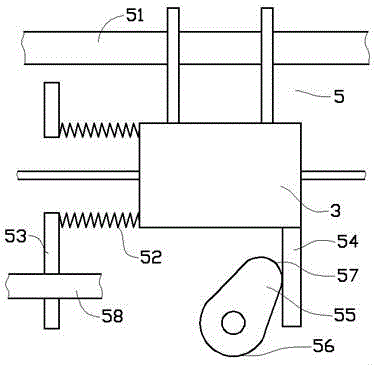

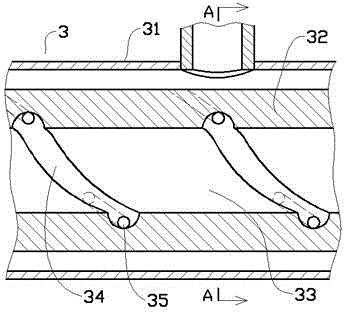

Double-spray-nozzle multi-yarn weaving device

The invention provides a double-spray-nozzle multi-yarn weaving device. The double-spray-nozzle multi-yarn weaving device comprises weft storage units, a main spray nozzle, a secondary spray nozzle, a heald frame and a sliding module; the secondary spray nozzle is arranged between the main spray nozzle and the warp opening position; the sliding module comprises a sliding rail, springs and an active block, the secondary spray nozzle is assembled on the horizontal sliding rial in a sliding mode, the secondary spray nozzle is connected with the active block through the springs, the active block is assembled on a rack, the lower portion of the secondary spray nozzle is designed with a knocking plate which perpendicularly extends downwards, the front part of the knocking plate is designed with a cam which rotates around the axis, and the cam is designed with a near end and a far end; the far end of the cam can knock on the knocking plate during rotating. In this way, the secondary spray nozzle can greatly increase the jet velocity of weft yarn; meanwhile, simultaneous conveying capacity to a single weft yarn and multiple weft yarns is greatly improved, and the cloth cover quality of gray fabric is improved.

Owner:JIANGSU MINGYUAN TEXTILE

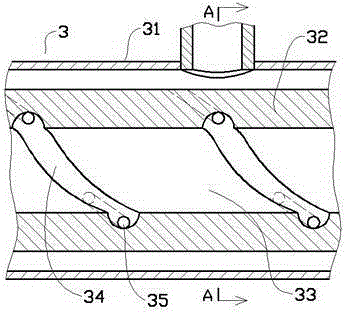

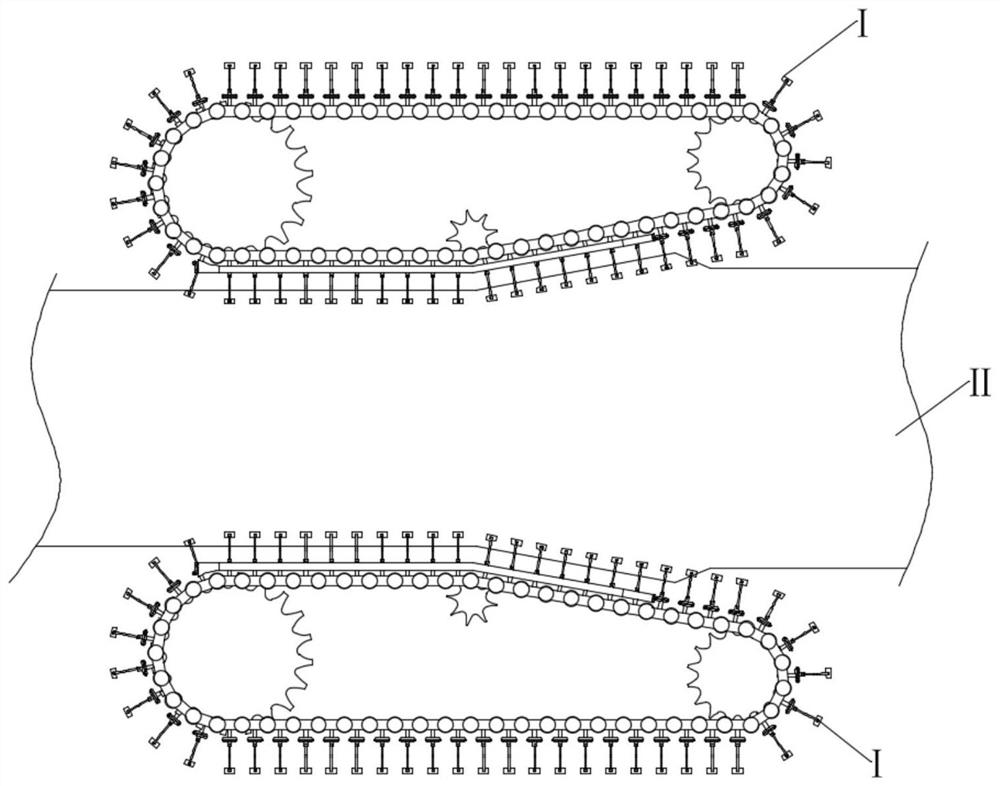

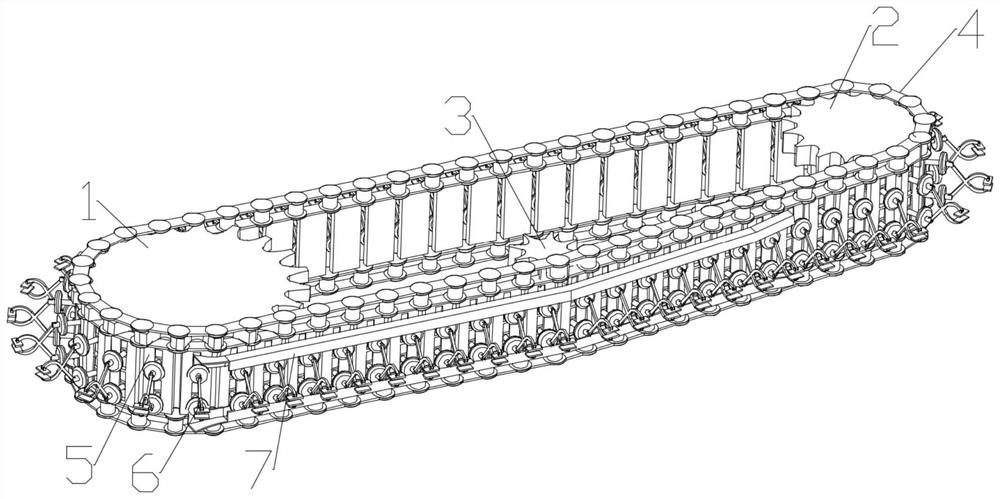

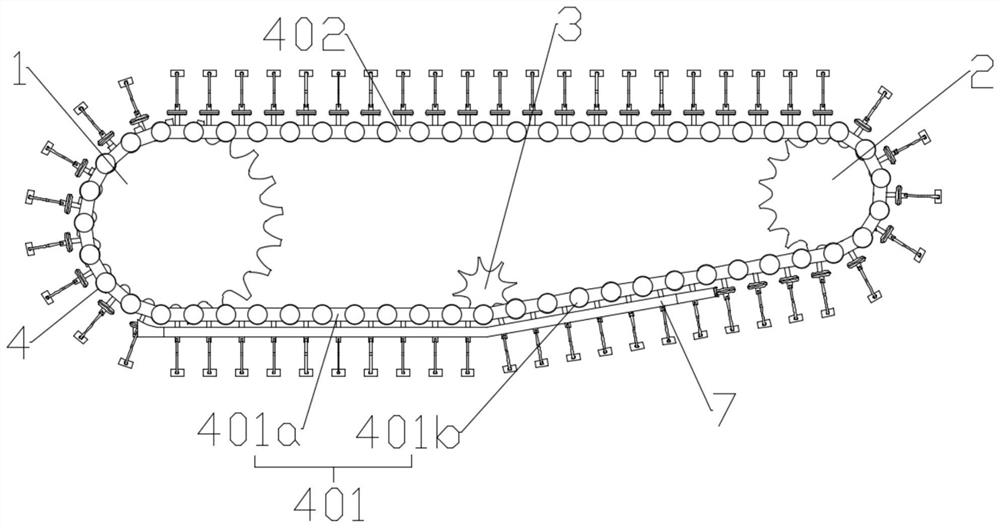

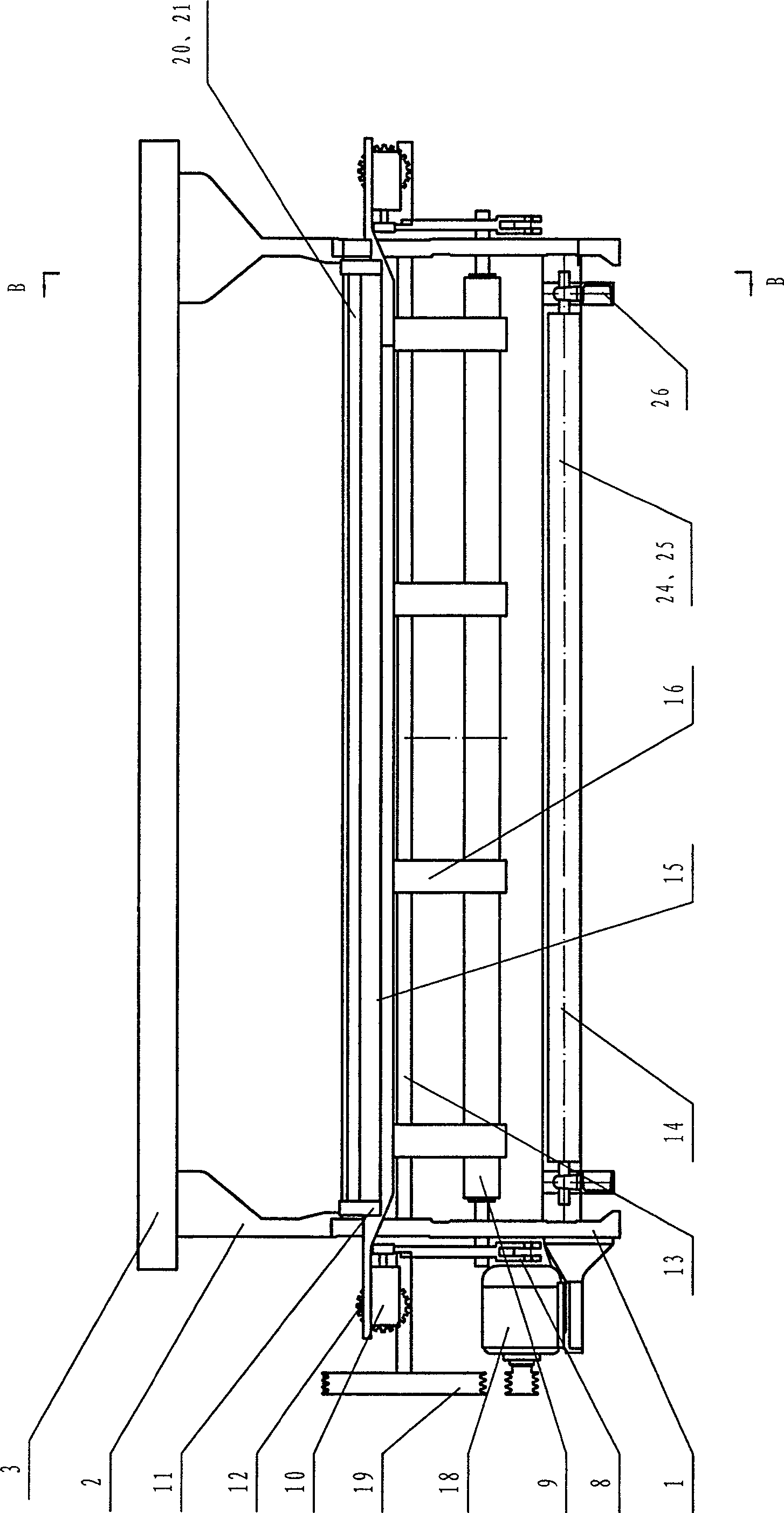

Cloth tensioning mechanism

The invention relates to a cloth tensioning mechanism. The cloth tensioning mechanism comprises a first chain wheel set, a second chain wheel set, a guide chain wheel set, chains and chain plates; the first chain wheel set and the second chain wheel set are arranged in a spaced mode; the chains surround the first chain wheel set and the second chain wheel set by a circle in a closed mode; each chain comprises a first chain part and a second chain part, and the guide chain wheel set is located on the first chain parts; each first chain part comprises a cloth pressing part and a cloth tensioning part, and the guide chain wheel set is located at the connecting positions of the cloth pressing parts and the corresponding cloth tensioning parts; and the number of the chains is at least two, the chain plates are located between the chains, the two ends of the chain plates are fixedly connected with the corresponding chains, and a clamping assembly is arranged on each chain plate. According to the mechanism, the cloth can be tensioned in the width direction, the problem that the cloth cannot be continuously stretched in the width direction in the cloth advancing process in the prior art is solved, the tensioning efficiency is improved, and the cloth quality is improved.

Owner:清远市诚鸿纺织有限公司

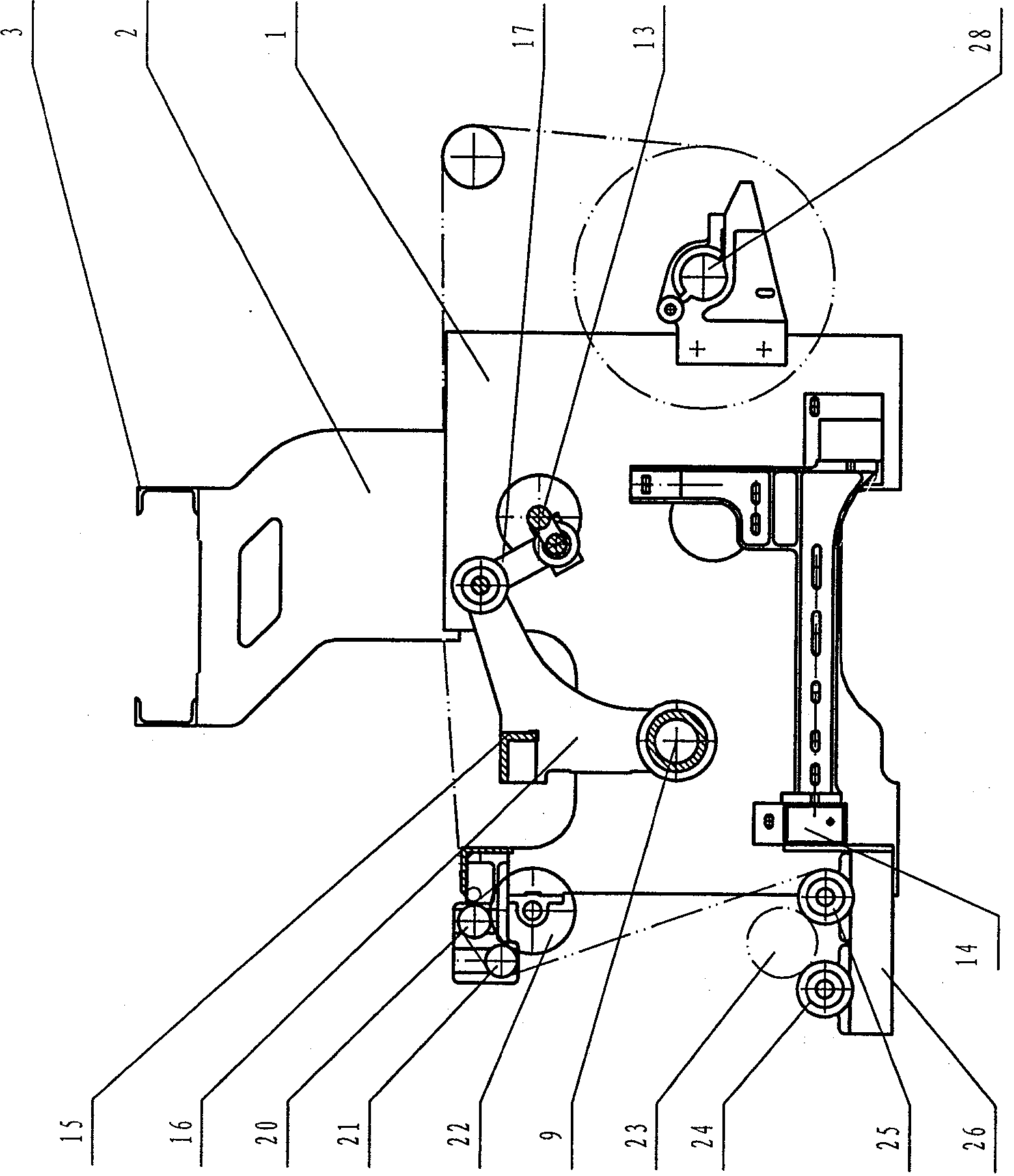

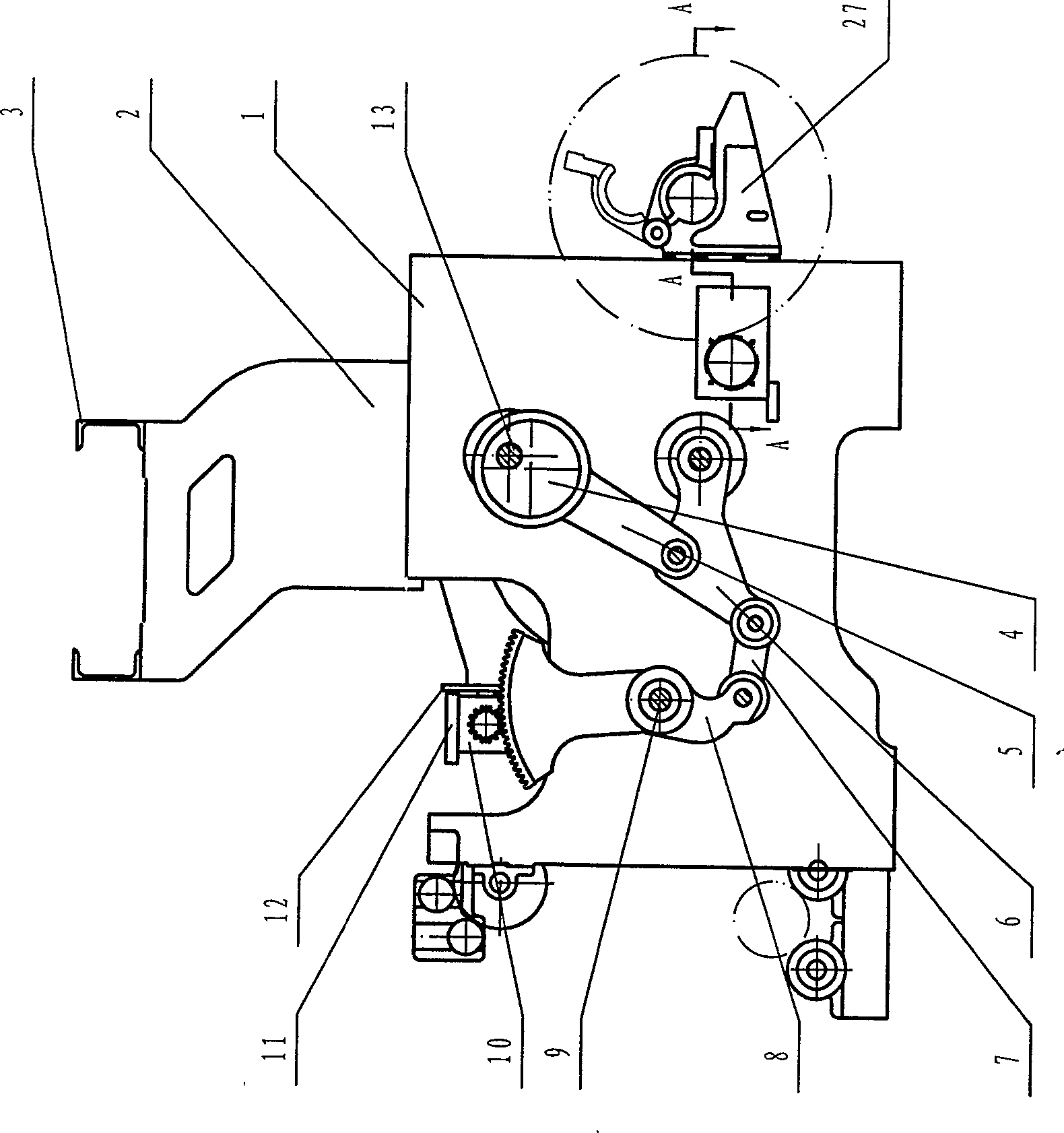

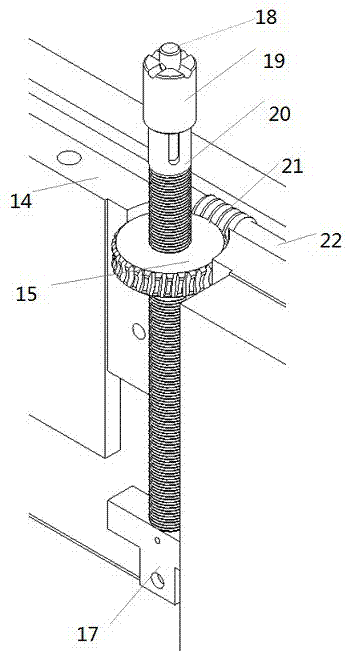

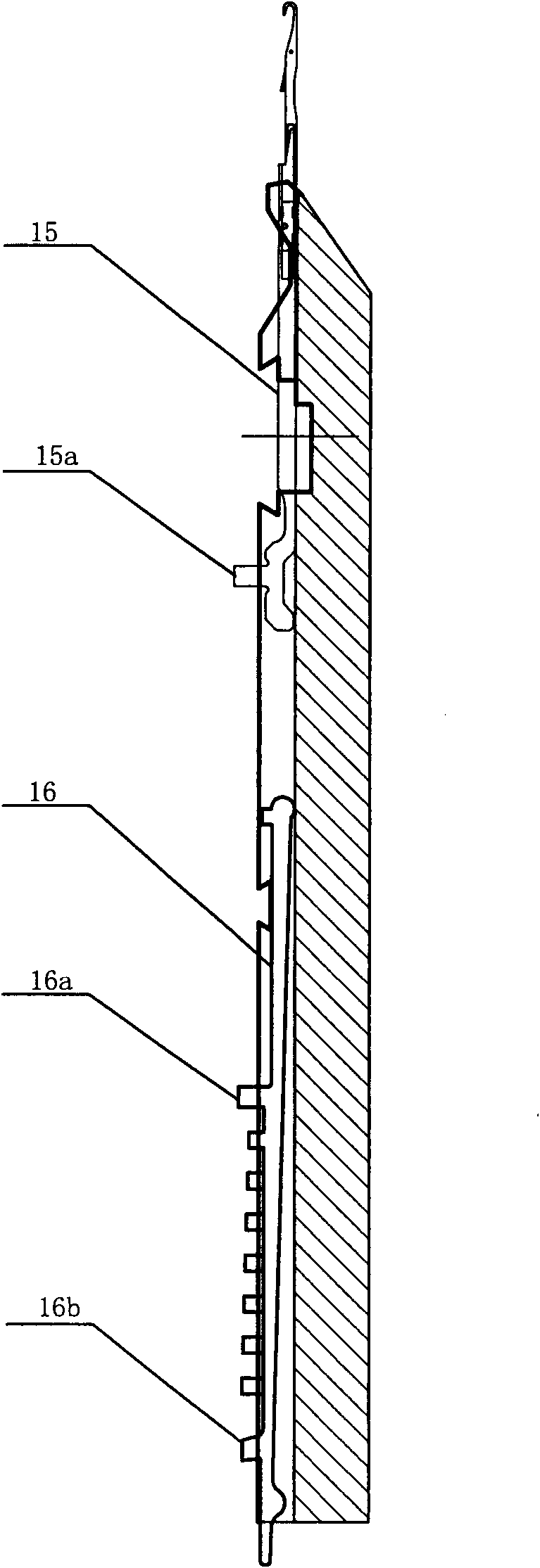

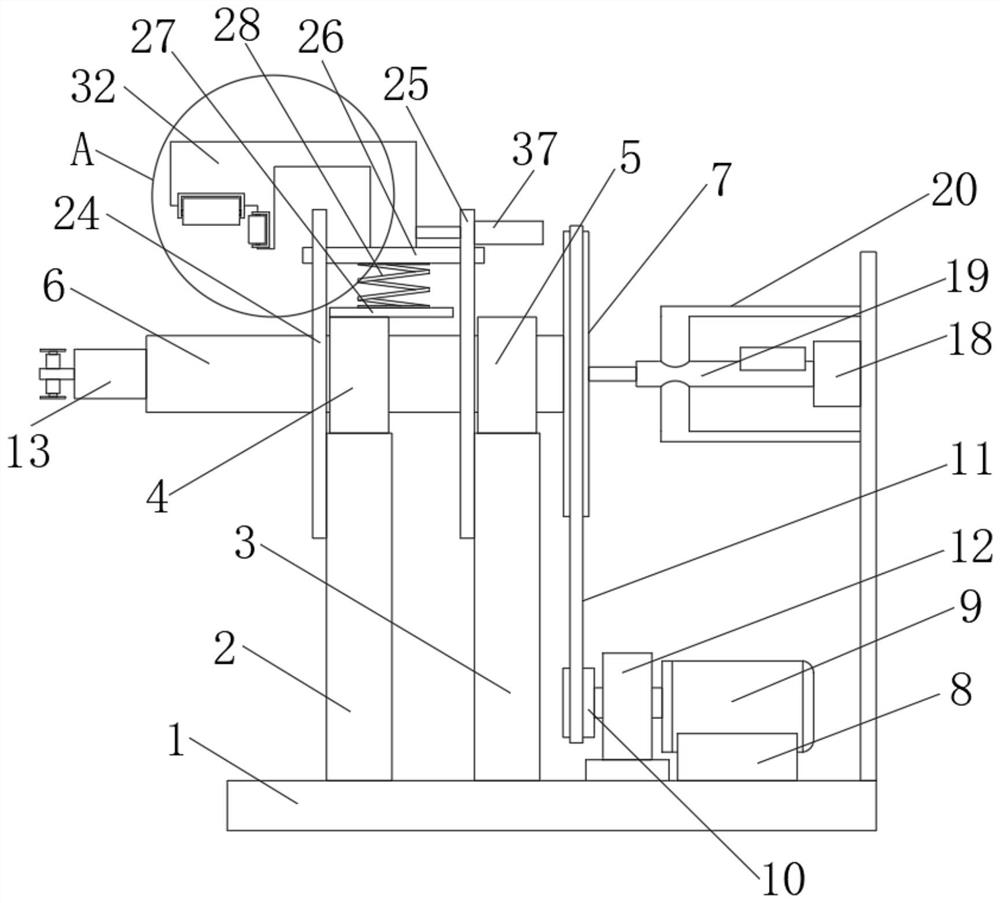

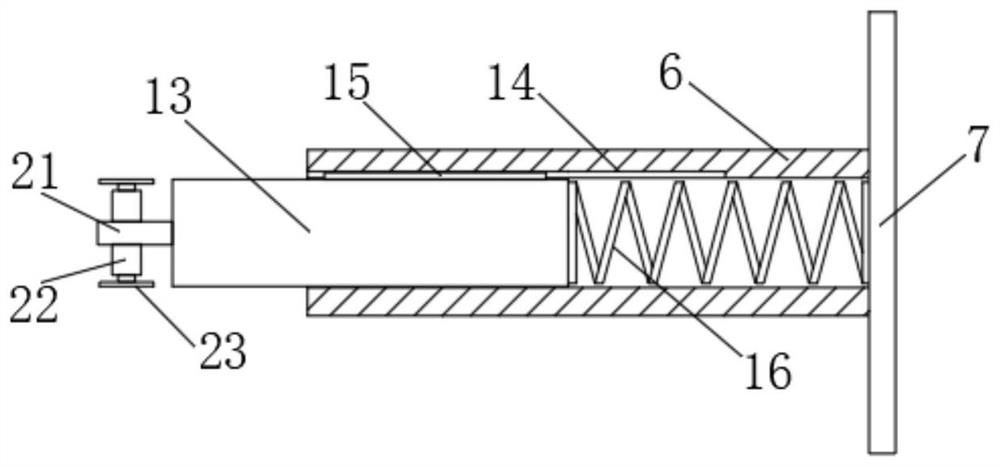

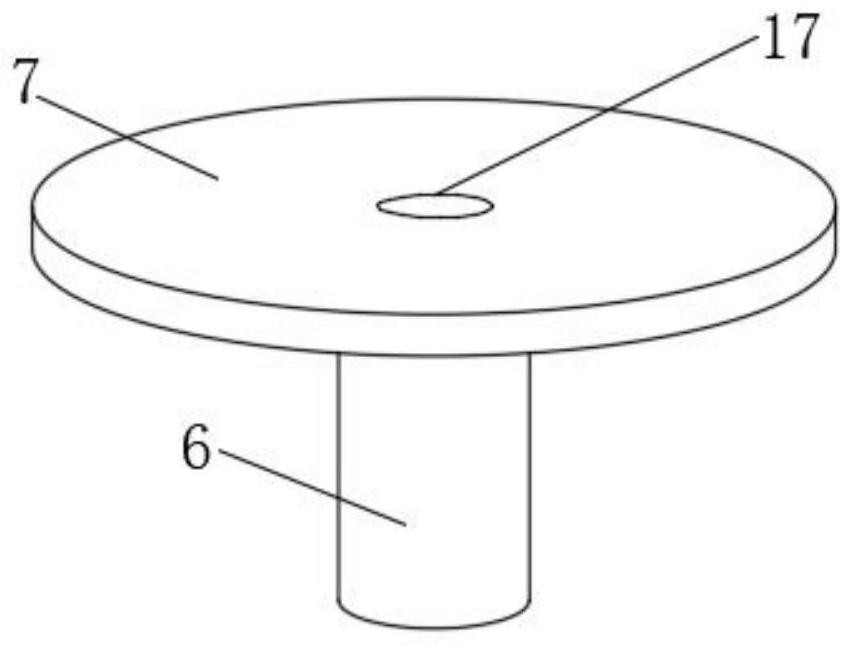

Novel gripper loom

A new type 736 rapier loom, belonging to the technical field of weaving equipment manufacturing, including left and right wall panels (1), a crankshaft (13), a worm wheel (30), a worm (29), a driving gear (32), a driven gear (33), warp beam (28), flip-type warp beam support foot (27), etc. constitute the warp let-off mechanism, which is arranged side by side by the deburring roller (22) with two pressure cloth rollers (20), (21) The take-up mechanism composed of two roll cloth transmission rollers (24), (25) etc., the beating-up mechanism composed of sley (15), rocking shaft (9), sley foot (16), hand in hand (17) etc. The mechanism consists of an eccentric wheel (4) with a long connecting rod (5), a triangular swing arm (6), a short connecting rod (7), a fan-shaped tooth arm (8), a rocker shaft (9), and a sword The weft insertion mechanism that wheel (12) etc. constitutes. The utility model has reasonable overall design, relatively good performance and price, wide application range and stable performance, and can effectively improve the surface quality of the fabric and the working efficiency of the loom.

Owner:SHAOXING TEXTILE MACHINERY GRP +1

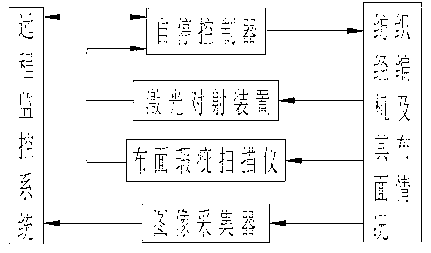

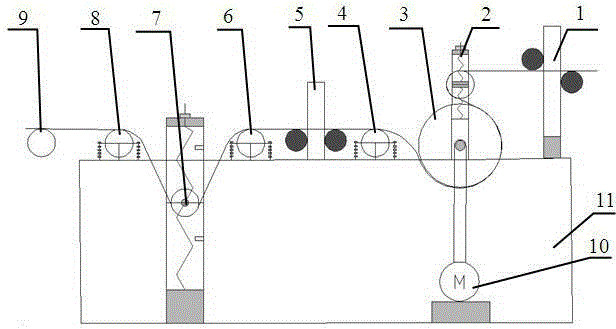

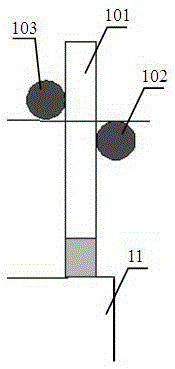

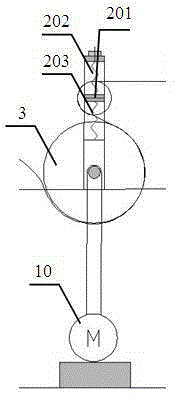

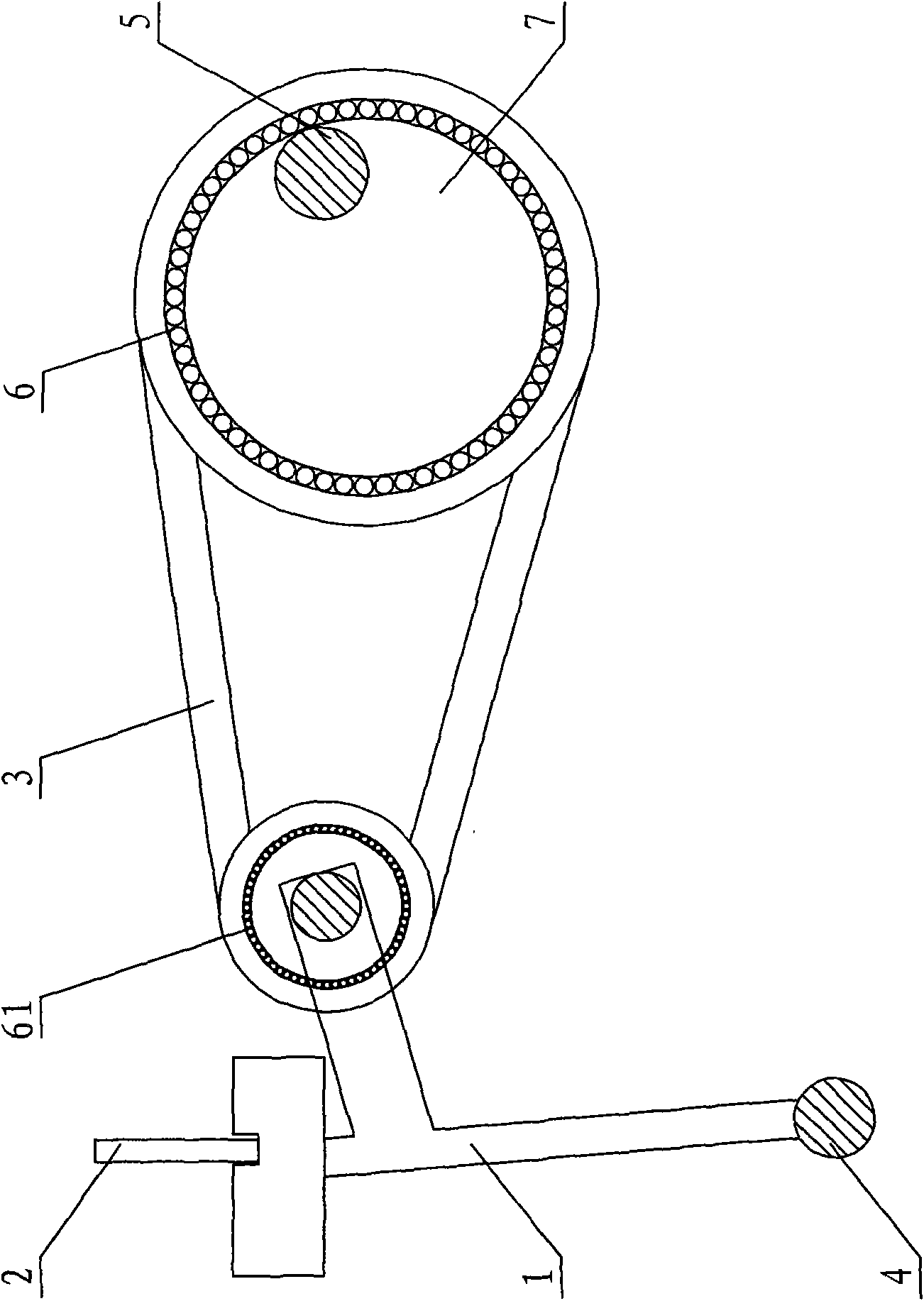

Active continuous let-off system for carbon fiber weaving

The invention provides an active continuous warp feeding system for carbon fiber weaving. The active continuous warp feeding system comprises a frame, a first reed combination, an upper yarn guide roller combination, a rubber guide roller, a first stainless steel yarn guide roller, a second reed combination, a second stainless steel yarn guide roller, a tension balance device, a third stainless steel yarn guide roller and a fourth stainless steel yarn guide roller. A motor drives the rubber guide roller to rotate at a constant speed, a certain quantity of fibers are fed into the tension balance device due to the friction force between the rubber guide roller and the fibers, the warp tension is finely adjusted through lubrication of the vertical positions of the yarn guide rollers, and it is guaranteed that warp yarns can be fed to the weaving process at even and constant tension. The active continuous warp feeding system avoids the problems that a passive warp feeding device feeds warp yarns to a weaving machine through a winding mechanism, the winding mechanism is seriously abraded, and the quality of cloth is deteriorated.

Owner:HENGSHEN

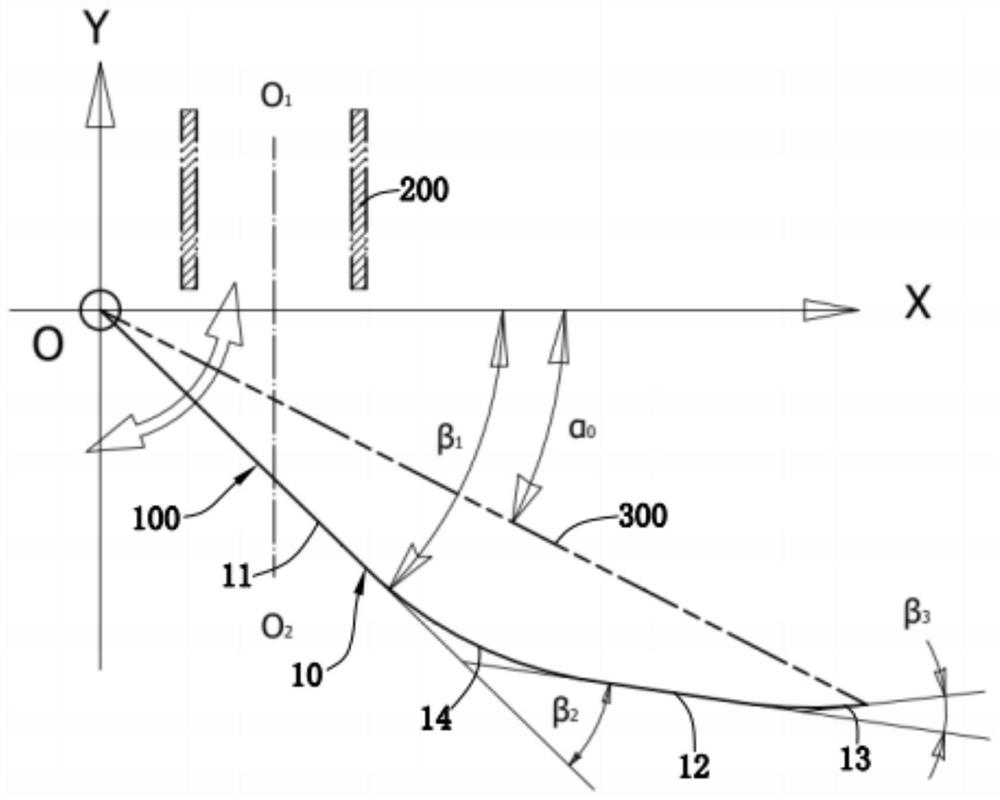

Novel straight-shaft beating-up mechanism

The invention relates to a novel straight-shaft beating-up mechanism comprising a sley component, a reed, a beating-up connecting rod, a swinging shaft and a beating-up shaft. The sley component is connected with the swinging shaft and is provided with the reed; the beating-up shaft is a straight shaft, and an eccentric cam is fixed on the beating-up shaft; the eccentric cam is connected with one end of the beating-up connecting rod via a bearing, and the other end of the beating-up connecting rod is connected with the sley component. The mechanism adopts the straight shaft to drive the sley component via the eccentric cam to beat up, has high beating-up precision, little wearing, large beating-up force, difficult deformation in large-torque transmission, long service life, no gap of beating-up and high cloth quality, is convenient for a weaving machine to accelerate and has high adaptability.

Owner:王勇

Smart multilayer fabric divider

PendingCN107201620AImprove cloth qualityQuality improvementDouble pile fabrics splittingEngineeringMechanical engineering

The invention discloses a smart multilayer fabric divider. The smart multilayer fabric divider comprises a cloth conveying transmission device and a pile cutting device, wherein the cloth conveying transmission device comprises a plurality of cloth conveying guide rollers and a metal detection device; the cloth conveying guide rollers are used for conveying grey cloth to the front of the metal detection device, detecting whether needle breakage occurs in the grey cloth or not, and conveying the grey cloth to a tape knife cutting position; the pile cutting device is used for cutting the grey cloth into two parts from the middle with a tape cutter, wherein the two parts serve as a side A and a side B respectively; on the side A and the side B, cloth is delivered along the same direction through a side A cloth delivery guide roller assembly and a side B cloth delivery guide roller assembly; a visual detection device for detecting the height of lint on the side A and the side B and a servo control device for controlling the height of the lint on the side A and side B are arranged in cloth delivery paths of the side A and the side B along the same direction. By adopting the smart multilayer fabric divider, the technical level of workers is lowered, the whole production flow is simplified, the machining time is shortened, and the production efficiency is increased; meanwhile, single-layer lint having higher cloth quality can be obtained.

Owner:CHANGZHOU WUJIN WUYANG TEXTILE MACHINERY

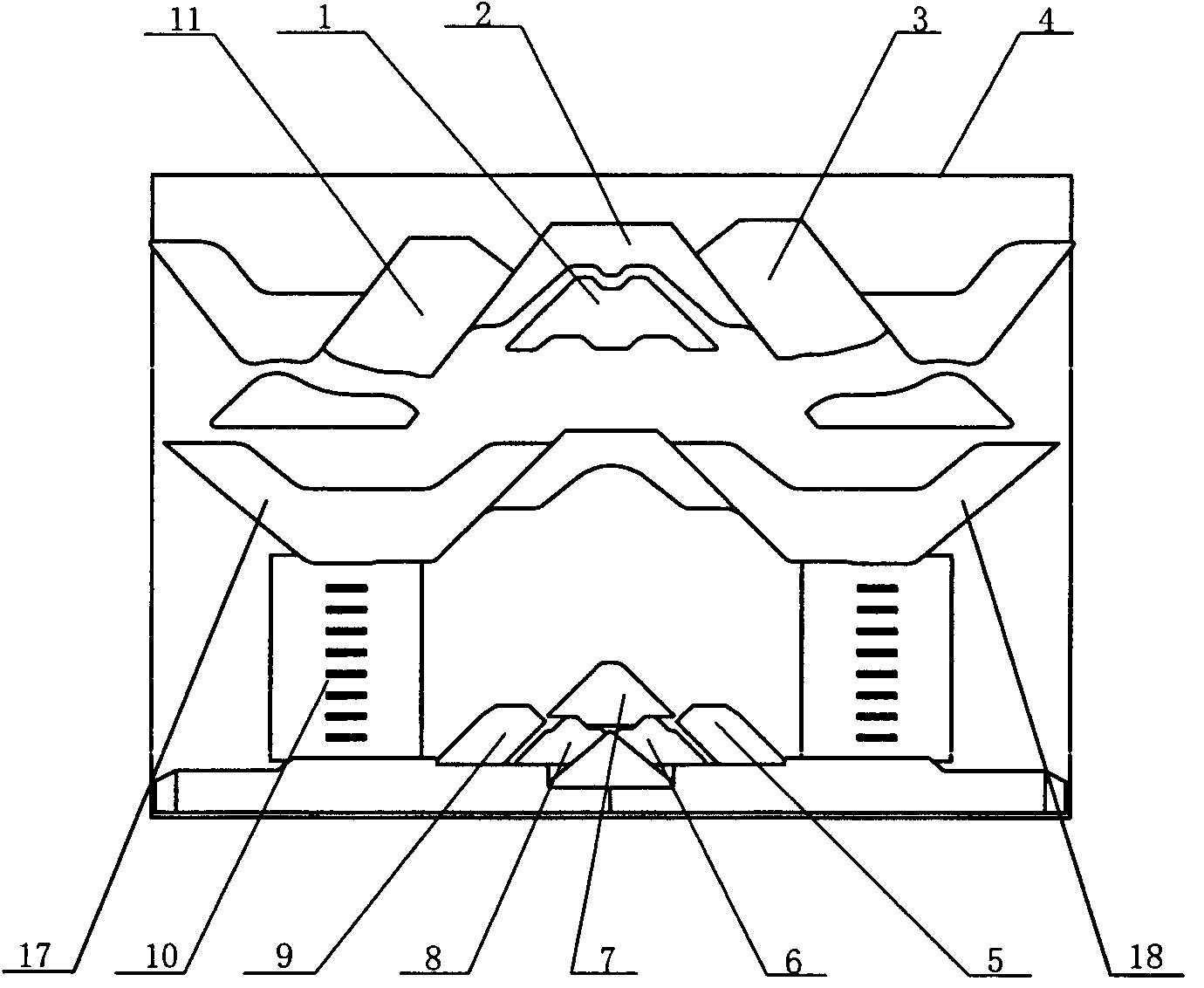

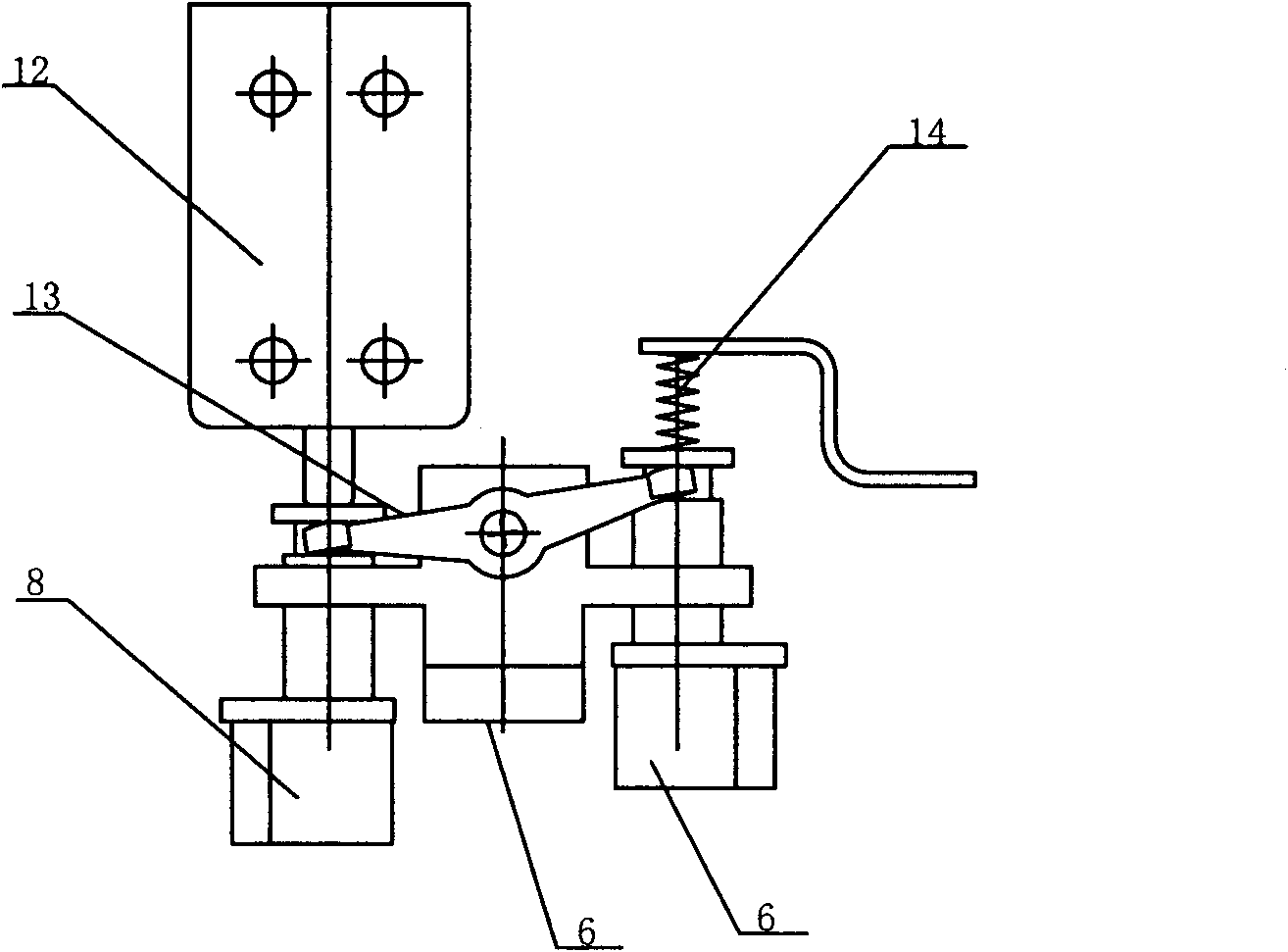

Cam running-needle control mechanism of flat knitting machine

InactiveCN101892554AWith minute needle knitting functionExpanded capabilities for knitting patternsWeft knittingMechanical equipmentEngineering

The invention relates to a cam running-needle control mechanism of a flat knitting machine, belonging to the technical field of textile mechanical equipment. The cam running-needle control mechanism comprises a flat knitting machine cam plate, a needle-selecting unit which is arranged on a base in a matching way, a knitting needle control mechanism and a jacquard needle control mechanism, wherein the knitting needle control mechanism comprises a herringbone cam, a transfer cam, a left stitch cam and a right stitch cam which are used for running the knitting needle; and the jacquard needle control mechanism comprises a cast-off cam which is used for running the jacquard needle and is fixedly connected with the flat knitting machine cam plate, and a left receiving cam, a left raising cam, a right raising cam and a right receiving cam which are movable and are respectively arranged at both sides of the cast-off cam in a matching way. By using the scheme to manufacture the cam running-needle control mechanism of the flat knitting machine, the invention enables a direct-selection automatic flat knitting machine to have a divided knitting function, and enhances the pattern-knitting capability of the machine. Besides, the up-run distance of the knitting needle in the receiving process is decreased, and the friction between a transfer needle and a receiving needle in the transfer process is reduced, thus the needle consumption is reduced, the cloth is smoother, and the cloth quality of the textile is improved.

Owner:唐永生

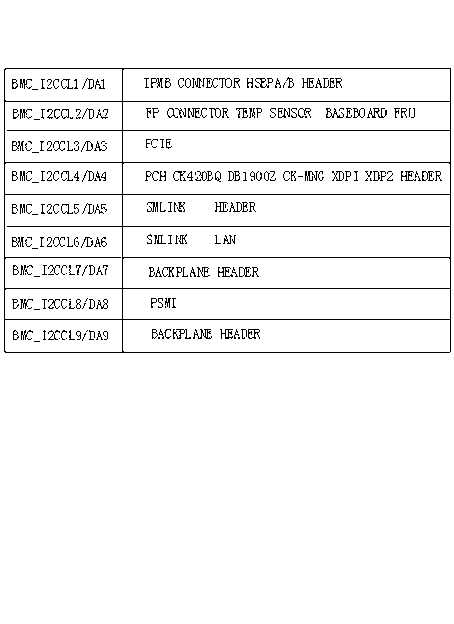

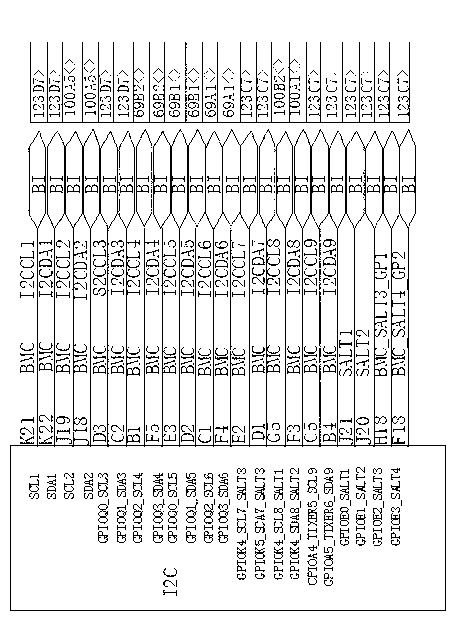

Method for designing signal wire pull-up resistor according to length of signal wire

InactiveCN103106303ASimple processImprove cloth qualitySpecial data processing applicationsWire widthElectrical resistance and conductance

The invention provides a method for designing a signal wire pull-up resistor according to the length of a signal wire. In the design of detail circuits of 12Cs and in the layout design, firstly ensuring capacity of wires adopted in the design circuit, due to the fact that design topologies are different, the layout design lengths of the 12Cs are different, so that in actual design computation, the width of the wires of the 12Cs maintain 10miles, the capacity of the wires is computed according to the capacity of 3.3pf / inch. After the actual layout design is finished, a distance calculator of the layout is used for specific measurement of the lengths of the wires of the 12Cs. According to the design requirements, a specific pull-up resistor matched with the 12Cs is designed at an output end of a block multiplexer channel (BMC). Through modification, measurement values of the 12Cs can meet product requirements in subsequent tests.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Fabric woven by rayon vortex spinning machine and preparation method thereof

The invention relates to a textile, in particular to a preparation method of fabric woven by a rayon vortex spinning machine, which is widely used in garment fabric. The fabric is interwoven by warp and weft, the warp is rayon vortex spun single yarn and the weft is polyester silk or wrap silk with combination of the polyester silk and spandex. The preparation method comprises the steps of drawing, vortex spinning, batch warping, re-beaming, sizing, drafting and reeding, weaving, pretreatment of dyeing and finishing, dyeing and setting. The fabric woven by the rayon vortex spinning machine is suitable for the garment fabric, smooth in surface, flabby in hand feeling and excellent in anti-pilling property, washing fastness and moisture absorption; compared with ordinary polyester-viscose fabric, the cloth surface quality is improved, the cost is relatively reduced, the energy consumption for double-twisting for forming the twisted yarn is saved and the index requirements in multiple aspects can be improved while reducing the cost.

Owner:HANGZHOU AOHUA TEXTILE

A kind of denim garment washing treatment process

ActiveCN104532592BNo effect on air qualityReduce storage pressureBiochemical fibre treatmentDry-cleaning apparatus for textilesChemical oxygen demandRoom temperature

The invention relates to a washing process for a denim garment. The washing process comprises the following steps: performing bio-enzyme de-sizing treatment in an amylase solution after performing denim garment fabric pre-treatment; performing enzyme washing by neutral enzyme powder; dehydrating and drying after cleaning with clean water; performing monkey wash on the fabric surface; performing neutralization treatment on the fabric which is subjected to monkey wash; adding a softening agent to perform softening treatment on the fabric; cooling the denim garment fabric to room temperature after dehydrating and drying, thereby completing washing on the denim garment. Compared with the prior art, the washing process has the advantages of quickly removing residual manganese ions, shortening the processing time, removing the color of a bleaching liquid, reducing the cleaning frequency, being low in sewage COD (chemical oxygen demand), and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

Energy-saving multi-purpose printing and dyeing machine

The invention relates to an energy-saving multi-purpose printing and dyeing machine capable of controlling the amount of water flowing through mesh holes and further fine-adjusting to control the effect cloth piling so as to better improve the quality of the dyed cloth. The machine comprises a net cage installed in a tail casing of the printing and dyeing machine, the net cage comprises a cage body, wherein the cage body is provided with a plurality of mesh holes; the machine also comprises a cage body sleeve with an opening upper end and a closed lower end, the cage body sleeve sleeves outside the cage body, the upper edge of the cage body sleeve is higher than the mesh holes, and the upper edge of the cage body sleeve is lower than the liquid level in the tail shell, a plurality of waterpassing holes are arranged on the cage body sleeve, a water passing adjustment device is arranged on the cage body sleeve.

Owner:望江硕丰汇锦科技有限公司

Dyeing and finishing process of superfine fiber fabric capable of quickly wicking sweat

PendingCN112281517AEliminate retractionImprove cloth qualityDyeing processMicrofiberProcess engineering

The invention relates to the technical field of elastic fabric, in particular to a dyeing and finishing process of a superfine fiber fabric capable of quickly wicking sweat. The process comprises thefollowing steps: weaving the superfine fiber fabric, presetting, immersing in hot water at 30-40 DEG C, adding a refining degreasing agent and a penetrating agent, heating to 80 DEG C, keeping the temperature for 10-20 minutes, washing with water, cooling to 20-25 DEG C, conveying the fabric into an overflow dyeing machine, adding 2-3 g / L of dye and 0.4-0.8 g / L of an acidic leveling agent for dyeing, soaping in a soaping agent for 15-20 minutes, then putting the fabric into a color fixing solution for color fixing for 20-40 minutes, dehydrating, drying at the temperature of 110-120 DEG C, andputting the fabric into a heat setting machine for heat setting, wherein the heat setting temperature is 135-140 DEG C, the fabric conveying speed is 25-30 m / min, the set width is 2-3 cm wider than the width of the finished fabric. The process has the advantages that the color fixing property is good, and the moisture absorption and draining properties of the fabric are effectively enhanced.

Owner:FUJIAN LIANFENGSHENG DYEING FLOCKING

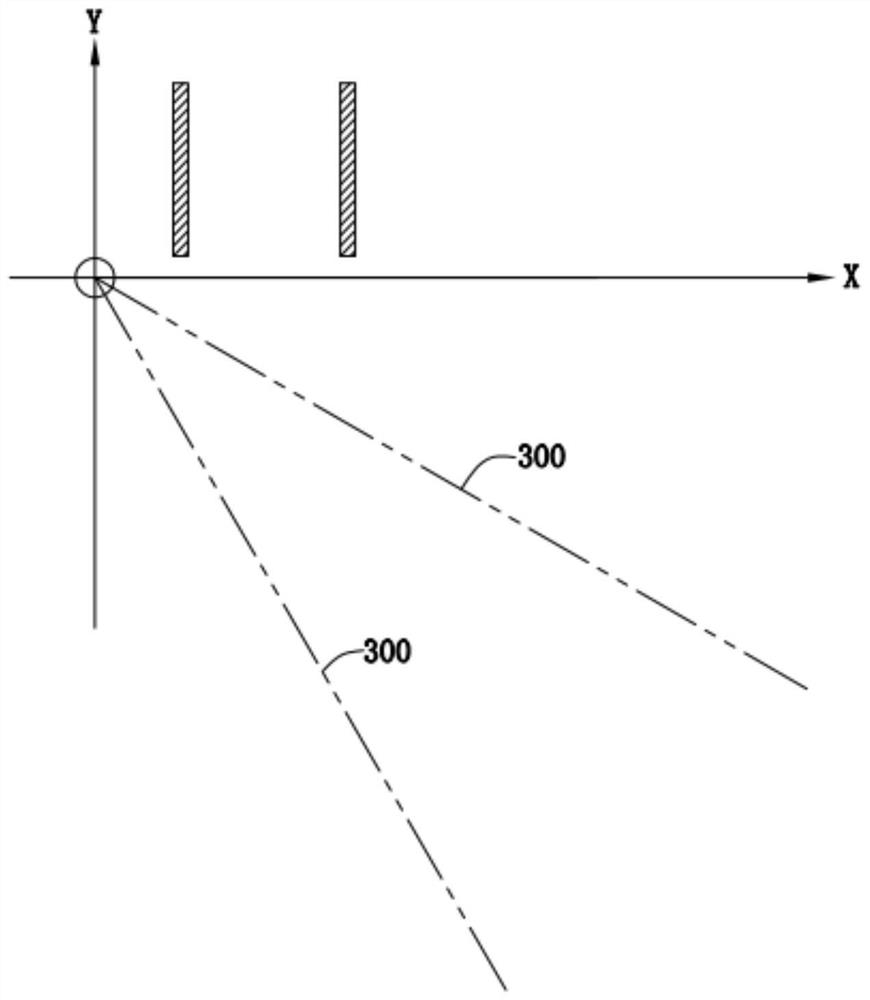

Blast furnace material distribution folding chute and blast furnace material distribution equipment

PendingCN113846201AReduced force and kinetic energy lossImprove cloth qualityBell-and-hopper arrangementStructural engineeringNozzle

The invention provides a blast furnace material distribution folding chute. The blast furnace material distribution folding chute comprises a chute body with a material distribution cavity, the chute body comprises a first straight line section, a second straight line section and a tilting nozzle section, and the first straight line section is used for receiving materials falling from a central throat pipe; in the length direction of the chute body, the second straight line section is arranged at the discharging end of the first straight line section, and the second straight line section is obliquely arranged towards the inner side relative to the first straight line section; and in the length direction of the chute body, the tilting nozzle section is arranged at the end, away from the first straight line section, of the second straight line section, and the tilting nozzle section is obliquely arranged towards the inner side relative to the second straight line section. Meanwhile, the invention provides blast furnace material distribution equipment which comprises the blast furnace material distribution folding chute. Compared with the prior art, the blast furnace material distribution folding chute and the blast furnace material distribution equipment provided by the invention have the advantages that the material impact force and kinetic energy loss can be reduced, the material distribution quality is improved, and the wear-resistant life of the chute is prolonged.

Owner:湖南德尚源耐磨工业有限公司

Double nozzle multi-yarn weaving device

The invention provides a double-nozzle multi-yarn weaving device, which includes a weft feeder, a main nozzle, a sub-nozzle, a heald frame, and a sliding module; the sub-nozzle is placed between the main nozzle and the warp opening; the The sliding module includes a sliding track, a spring, and a movable block. The auxiliary nozzle is slidably assembled on the horizontal sliding track. The auxiliary nozzle is connected to the movable block through a spring. The movable block is assembled on the frame. The lower part is designed with a knocking plate extending vertically downwards, and the front part of the knocking plate is designed with a cam that rotates from the axis, and a proximal end and a distal end are designed on the cam; the far end of the cam rotates Can be tapped onto the pad. In this way, the sub-nozzle can greatly increase the injection speed of the weft yarn, and also greatly improve the simultaneous conveying capacity of single or multiple weft yarns, and improve the surface quality of the gray cloth.

Owner:JIANGSU MINGYUAN TEXTILE

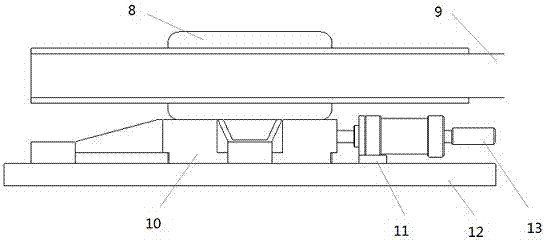

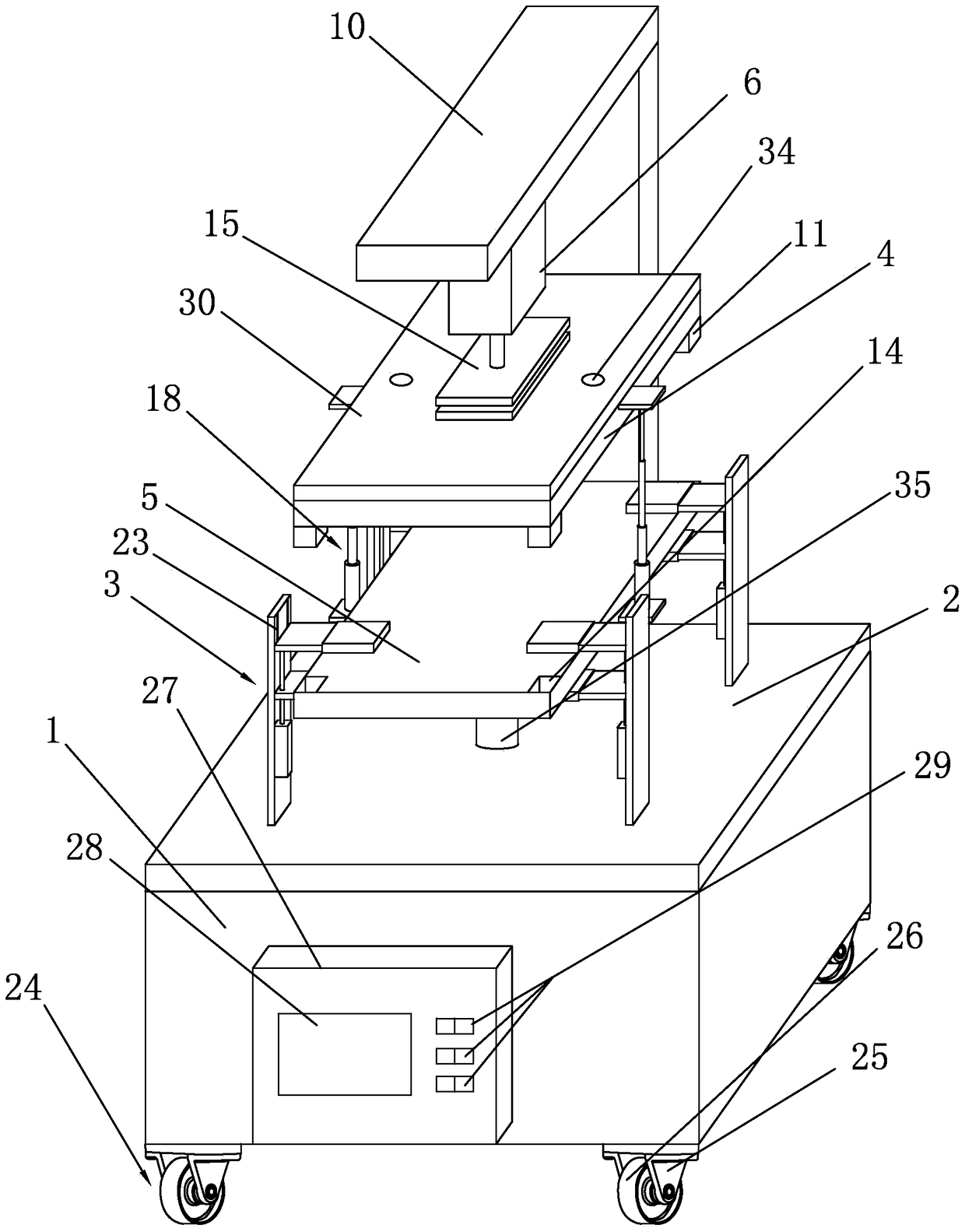

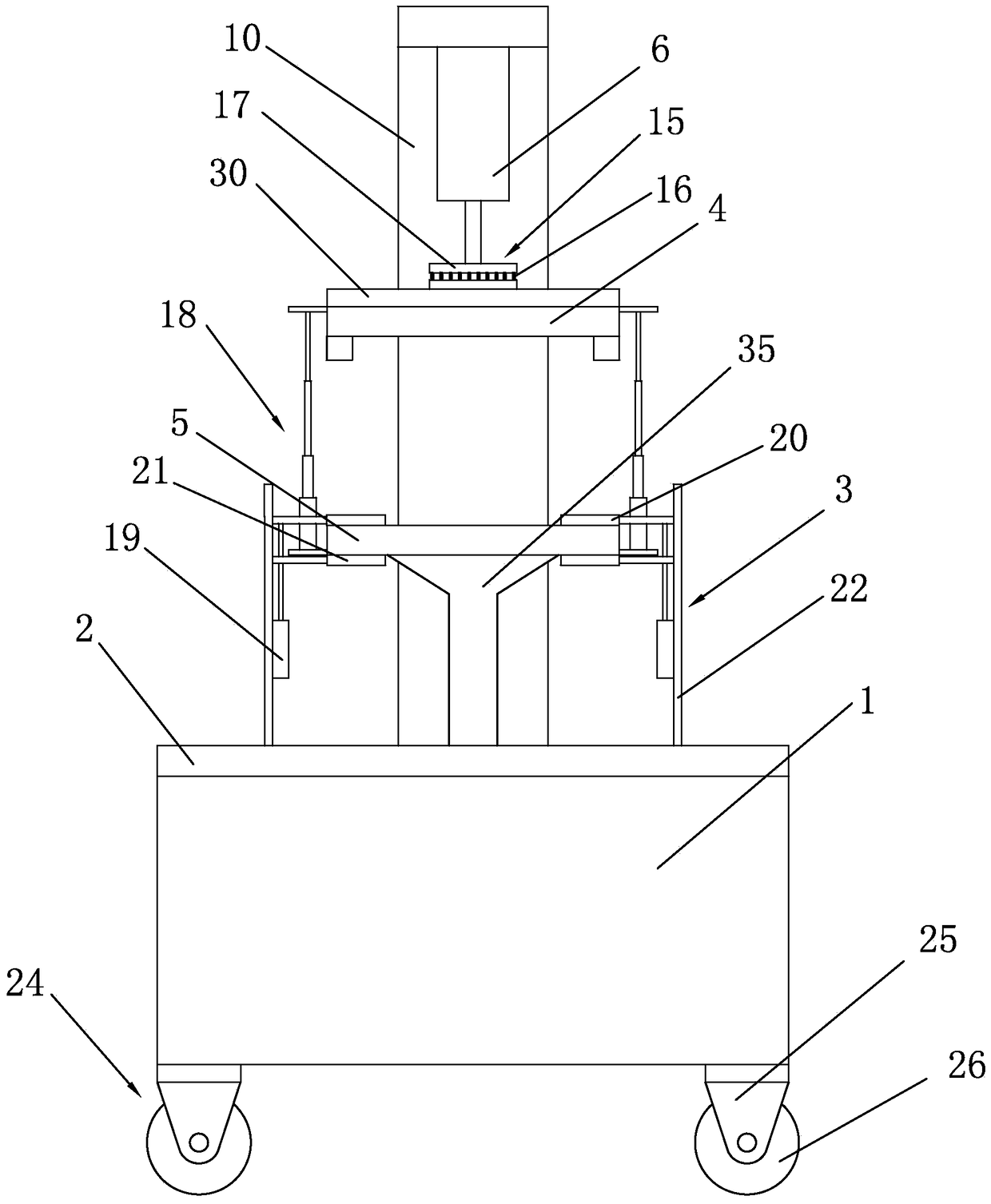

A pneumatic pressing machine for clothing printing and ironing

InactiveCN105177958BEvenly heatedReduce lossesIroning apparatusTextile decorationEngineeringMechanical engineering

The invention discloses a pneumatic pressing and ironing machine for clothing printing and ironing. The pneumatic pressing and ironing machine comprises a rack, a pressing and ironing table, a pressing and ironing device and a clamping device. The pressing and ironing device comprises an upper pressing and ironing plate, a lower pressing and ironing plate and a pressing and ironing air cylinder. The bottom face of the upper pressing and ironing plate is provided with a limiting protruding block, a clamping groove and an air outlet hole. A guiding device is arranged between the upper pressing and ironing plate and the lower pressing and ironing plate. The clamping device comprises a clamping air cylinder, an upper air clamp and a lower air clamp. The pneumatic pressing and ironing machine is simple in structure and high in practicality; by means of design of the guiding device, pressing precision between the upper pressing and ironing plate and the lower pressing and ironing plate is higher, and the quality of clothing pressing and ironing is improved; meanwhile, as the limiting protruding block and the limiting groove are matched, the situation that the two pressing and ironing plates are dislocated can be prevented, the production efficiency of the pressing and ironing machine is improved by means of the clamping device, the lower air clamp can have effects of fixing and supporting the lower pressing and ironing plate, the parallelism between the lower pressing and ironing plate and the upper pressing and ironing plate is guaranteed, and comprehensive utilization efficiency is improved.

Owner:无锡市和田服饰有限公司

Polyester vortex spun woven fabric and preparation method thereof

The invention relates to a method for manufacturing polyester vortex spun fabrics. The raw slivers of polyester fibers with cations are drawn on a drawing frame to obtain cooked slivers of polyester fibers, and the polyester vortex spun single yarns are spun at a certain speed, and are finished. Warp, parallel, and sizing to obtain polyester vortex spun single yarn as the warp beam of polyester vortex spun fabric, use single warp beam loom to use polyester vortex spun single yarn as warp, and other raw materials as weft, according to different requirements. As a whole, the polyester vortex woven fabric is obtained through secondary light desizing, disperse dyeing and drying; the polyester vortex woven fabric woven by this manufacturing method is suitable for clothing fabrics, with smooth surface and soft hand feeling. It has excellent anti-pilling, washability and moisture absorption. Compared with ordinary polyester-viscose fabrics, the surface quality is improved, the cost is reduced, and the energy consumption of the process of twisting into strands is saved. It is suitable for fabric processing and weaving in large quantities.

Owner:HANGZHOU AOHUA TEXTILE

Pretreatment process of chemical fiber fabric

PendingCN112176731ASoft and plumpSpeed up thermal motionSynthetic fibresBiochemical treatment with enzymes/microorganismsProcess engineeringEnvironmental geology

The invention discloses a pretreatment process of chemical fiber fabric. The process comprises the following operation steps of a, carrying out cloth turning and sewing on the chemical fiber fabric toobtain a product A; B, singeing the product A to obtain a product B; C, padding the product B in an enzyme solution, and performing thermal stacking at the stacking temperature of 55-65 DEG C to obtain a product C; and D, enabling the product C to be sequentially subjected to water washing in a water washing box, soaking in a working solution tank and steaming washing in a tight steaming box, enabling the speed of the tight steaming box to be 45-55m / min, the cloth containing amount to be 140-160m, and the steaming time to 2-4min, then enabling the product C to be subjected to water washing inthe water washing steaming box, and obtaining a finished product. The process has the characteristics that the technological process is shortened, the production efficiency is high, water can be saved, sewage discharge is reduced, and the product quality is improved.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

Thermocompression bonding and unwinding mechanism for processing long-fiber non-woven fabric

InactiveCN113086697AFully AutoclavedThere will be no thermal dead angleNon-woven fabricsWebs handlingEngineeringStructural engineering

The invention relates to the technical field of non-woven fabric equipment, and discloses a thermocompression bonding and unwinding mechanism for processing a long-fiber non-woven fabric. The thermocompression bonding and unwinding mechanism comprises a mounting base; the top end of the mounting base is fixedly connected with a first mounting frame and a second mounting frame; a first shaft sleeve is mounted at the top end of the first mounting frame, and a second shaft sleeve is mounted at the top end of the second mounting frame; a rotating cylinder is rotatably connected to the inner walls of the first shaft sleeve and the second shaft sleeve; a transmission disc is fixedly connected to one end of the rotating cylinder; a servo motor is arranged on one side of the top end of the mounting base; a driving disc is fixedly connected to an output end of the servo motor; and a transmission belt is arranged between the driving disc and the side wall of the transmission disc. According to the thermocompression bonding and unwinding mechanism for processing the long-fiber non-woven fabric provided by the invention, it is guaranteed that no hot-pressing dead angle exists on the non-woven fabric on a cloth roller, the non-woven fabric can be evenly subjected to hot-pressing treatment, and the situation that lines on the end face of the non-woven fabric on the cloth roller are loose can be avoided in the high-speed rotating and hot-pressing state of the cloth roller.

Owner:周秀恒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com