Novel gripper loom

A rapier loom, a new type of technology, applied in the field of weaving equipment manufacturing, can solve the problems of high manufacturing cost, low efficiency, and high price, and achieve the effect of increasing speed, improving work efficiency, and stabilizing warp tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

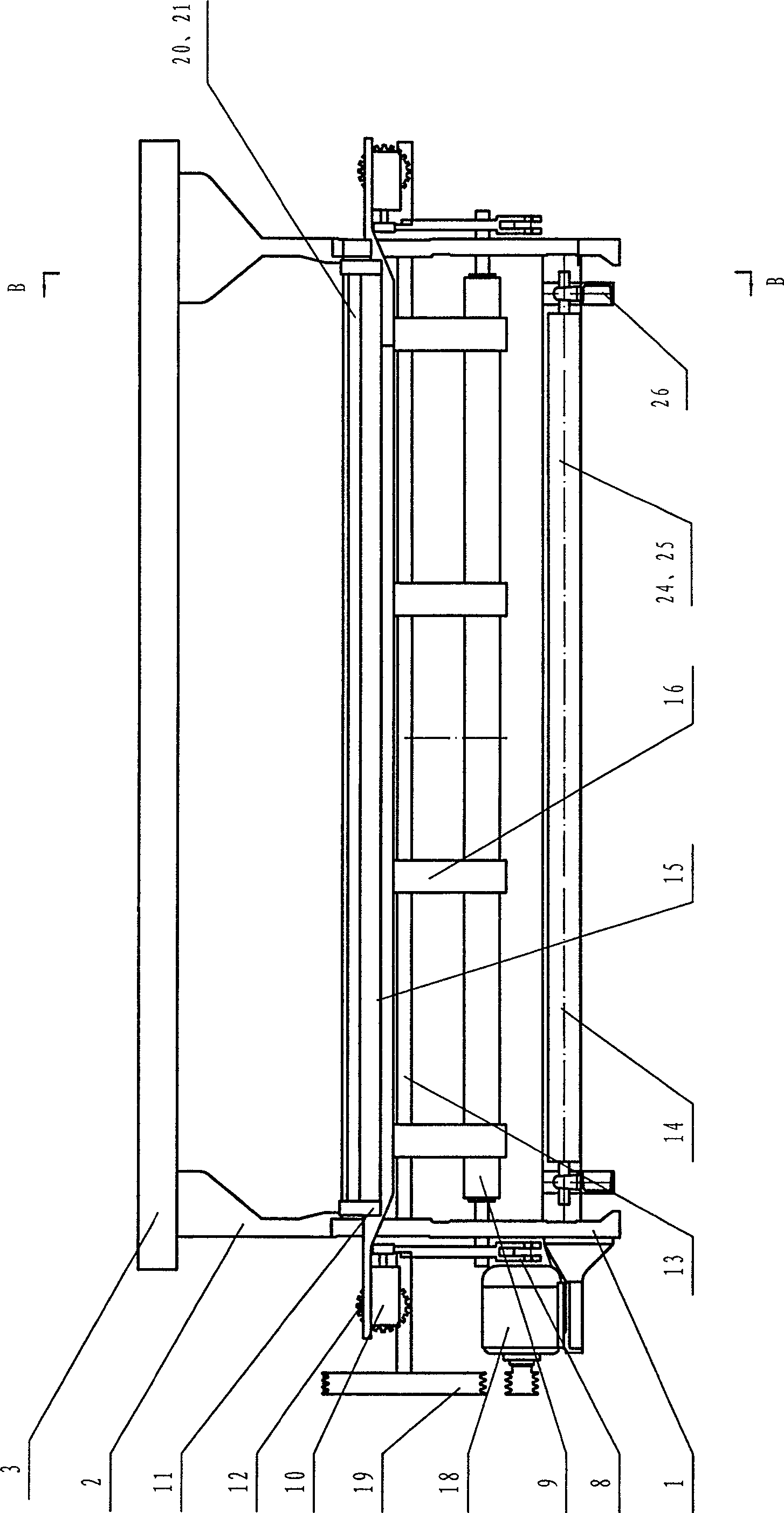

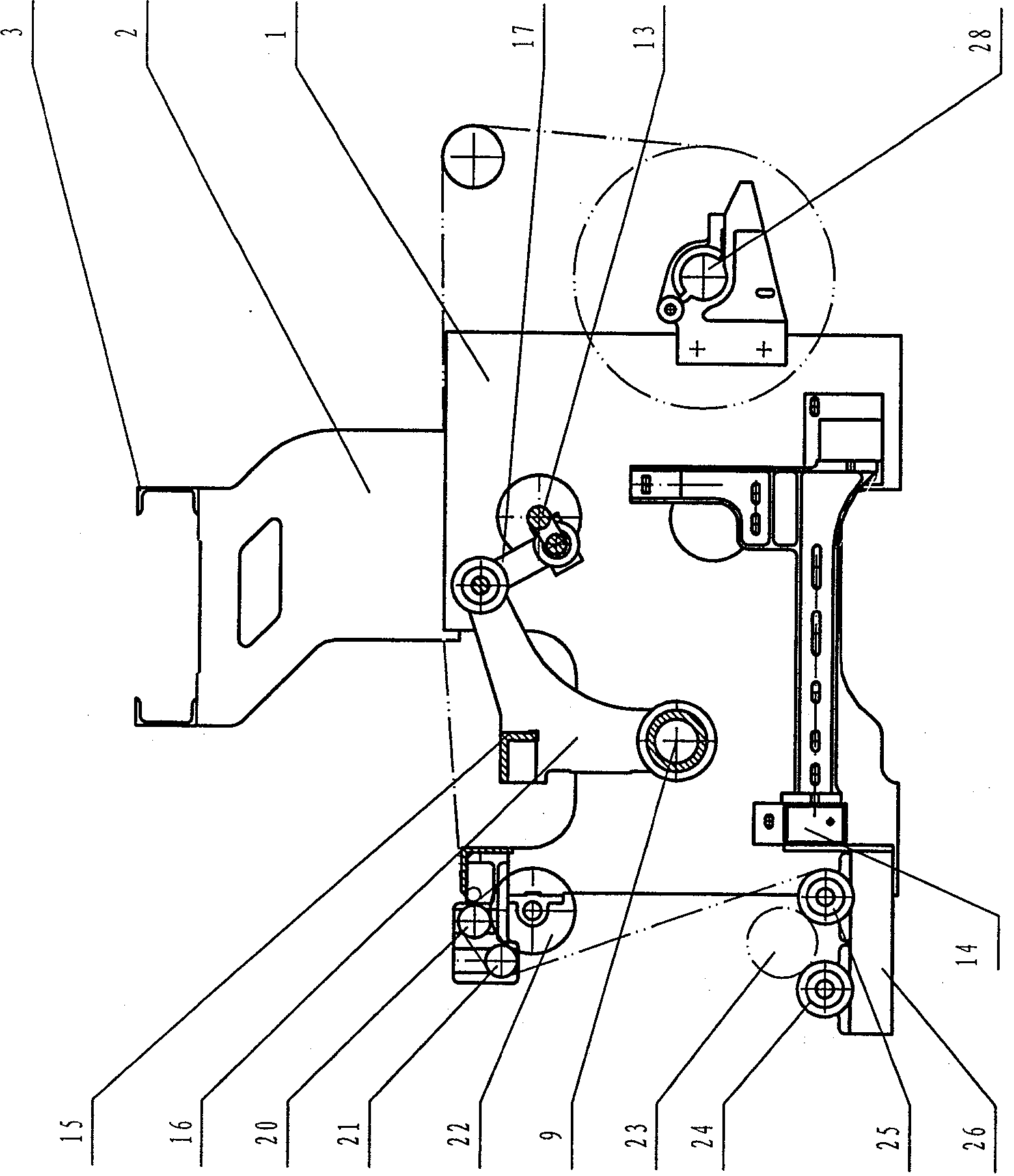

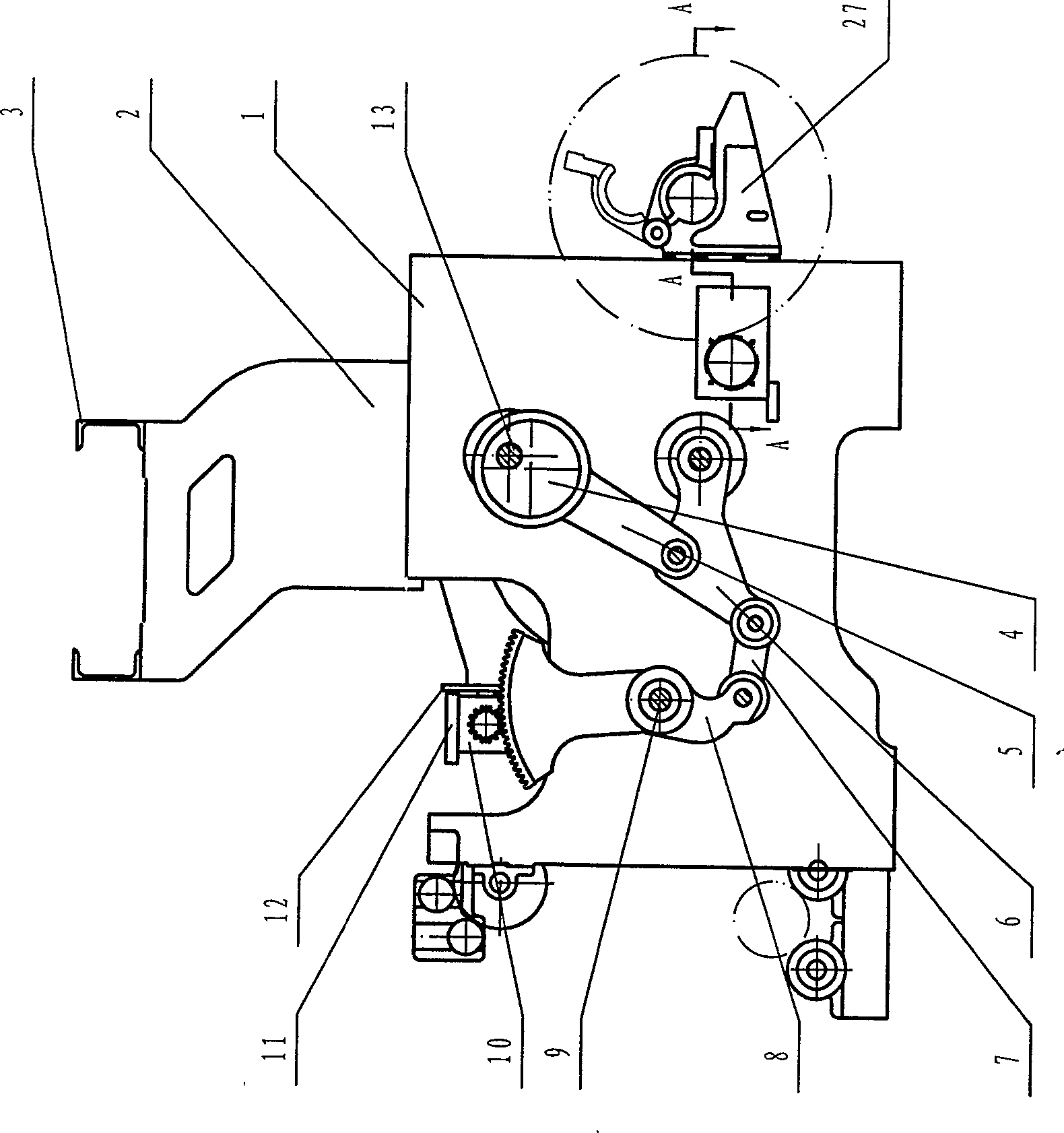

[0020] The present invention mainly comprises the left and right wall panels 1 with the left and right upper wall panels 2, the sley 15 placed between the left and right wall panels 1, the rocking shaft 9, the front and rear beams 14, the front and rear upper beams placed between the left and right upper wall panels 2 3. The motor 18 with pulley 19 placed on one side of the left and right wall panels 1, the crankshaft 13 coaxial with the pulley 19 placed between the left and right wall panels 1, weft beating mechanism, weft insertion mechanism, warp let-off mechanism, coiling mechanism, etc. part.

[0021] The warp let-off mechanism consists of a worm gear box 31 with a worm 29 and a worm gear 30 inside, a driving gear 32 coaxial with the worm gear 30, a driven gear 33 with a warp shaft 28 meshed with the driving gear 32, and a clamshell type fixed on the left and right wall panels 1. Warp shaft supporting foot 27 etc. are formed. Drive the worm gear 30 through the worm screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com