Economical knitting controlling mechanism of computer flat-bed knitting machine

A technology of a flat knitting machine and a control mechanism, which is applied in the directions of weft knitting, knitting, textiles and paper making, can solve the problems of large size of triangular base plate, high production cost and large size of the machine head, and achieves reduced size and less consumables. , the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention and its advantages will be further described below in conjunction with the accompanying drawings and embodiments.

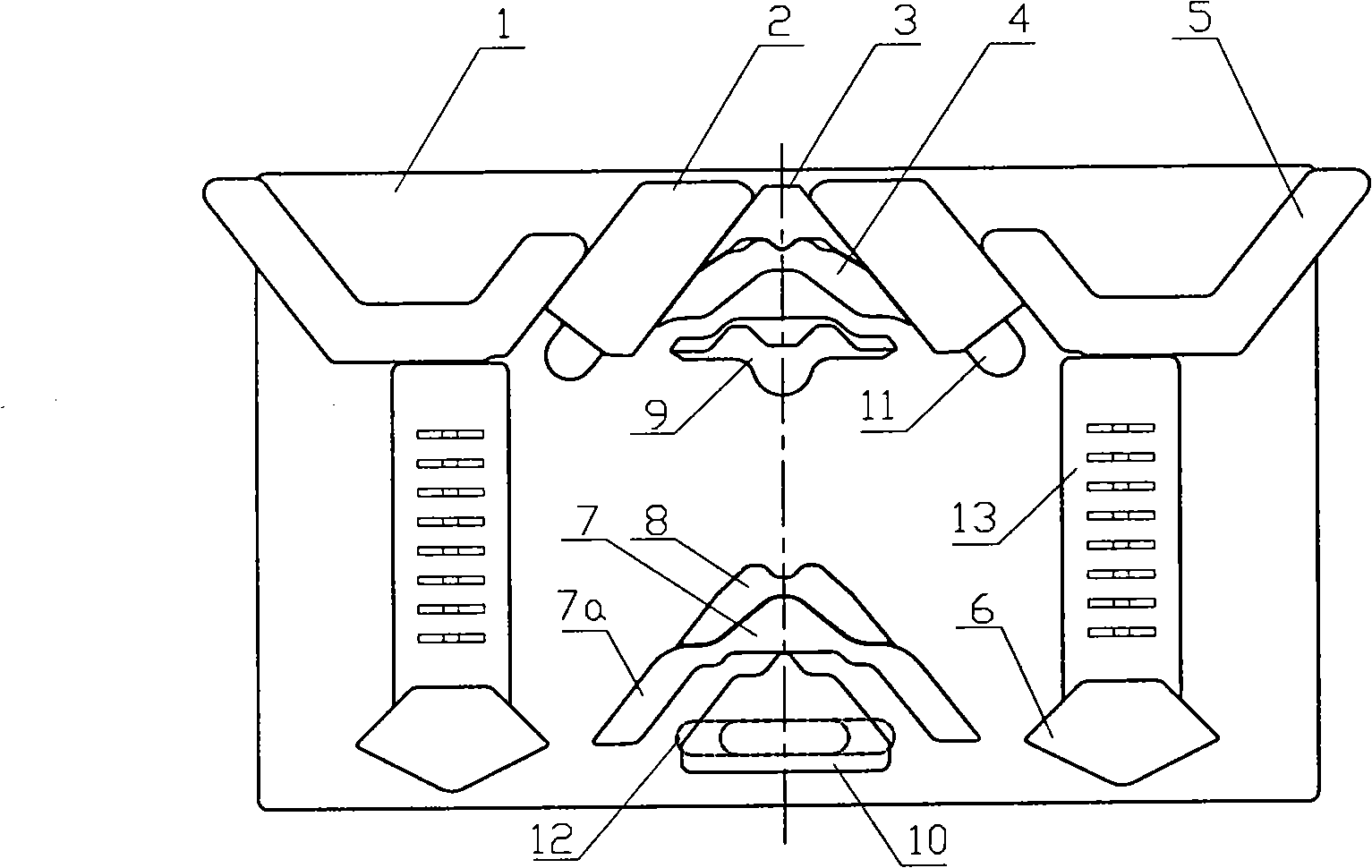

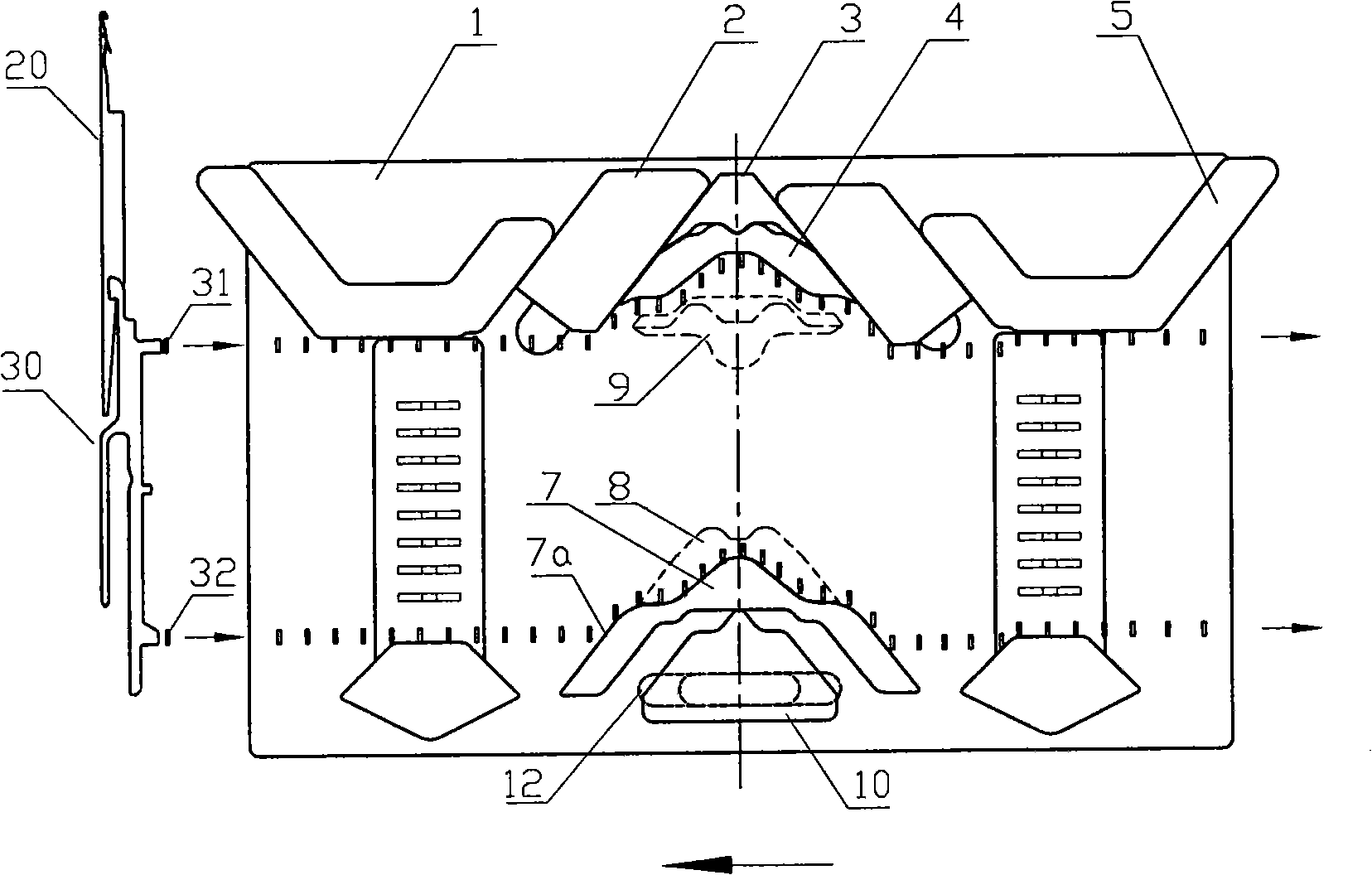

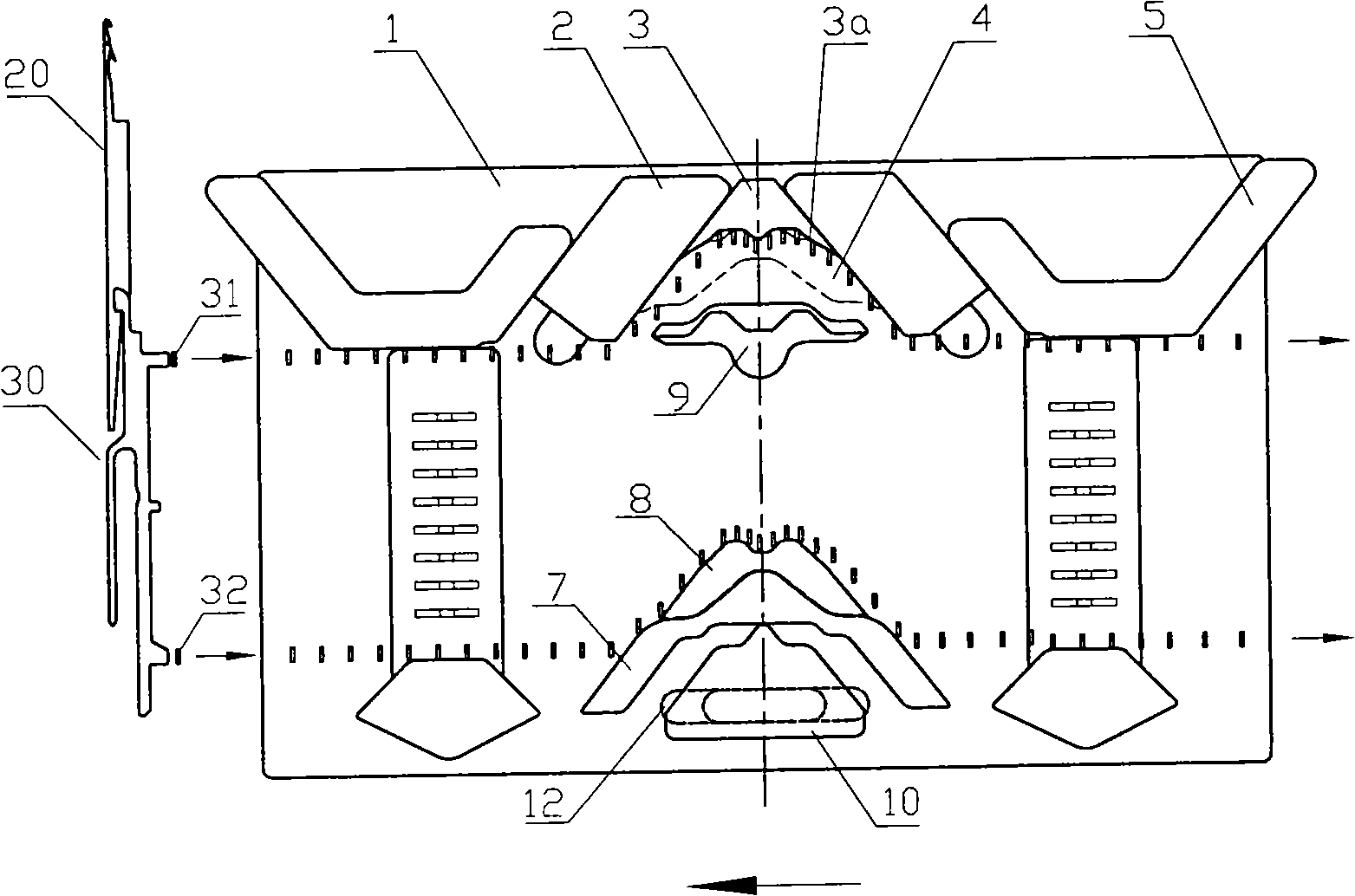

[0021] figure 1 It is a knitting control mechanism with a knitting unit. On the cam bottom plate 1, there are needle stop cam 5, loop transfer cam 3, needle press cam 2, loop receiving cam 9, loop transfer cam 8, and loop forming cam 7. Form a weaving area with the weaving triangles such as tuck triangles 10. In the upper part of this area, there are needle-blocking triangles 5 and needle-pressing triangles 2 symmetrically distributed. Needle selectors 13 are placed on both sides symmetrically in the middle of the area. A needle selection cam 6 and a needle raising cam 7a are symmetrically distributed in the lower part of the area, and the two stitching cams 7a and the knitting cam 7 are integrated. On the top of the center line of symmetry in this knitting area, there are transfer ring and stop needle triangle 3, eyebrow triangle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com