Novel three-dimensional orthogonal woven hybrid puncture-proof clothes

A stab-resistant clothing, three-dimensional technology, applied in the direction of fabrics, textiles, clothing, etc., can solve the problems of increasing the weight of stab-resistant clothing, affecting comfort, limiting applications, etc., to achieve excellent stab-resistant performance, easy to absorb impact energy, initial mold low volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of the new three-dimensional orthogonal weaving hybrid stab-resistant clothing will be described below in conjunction with the accompanying drawings.

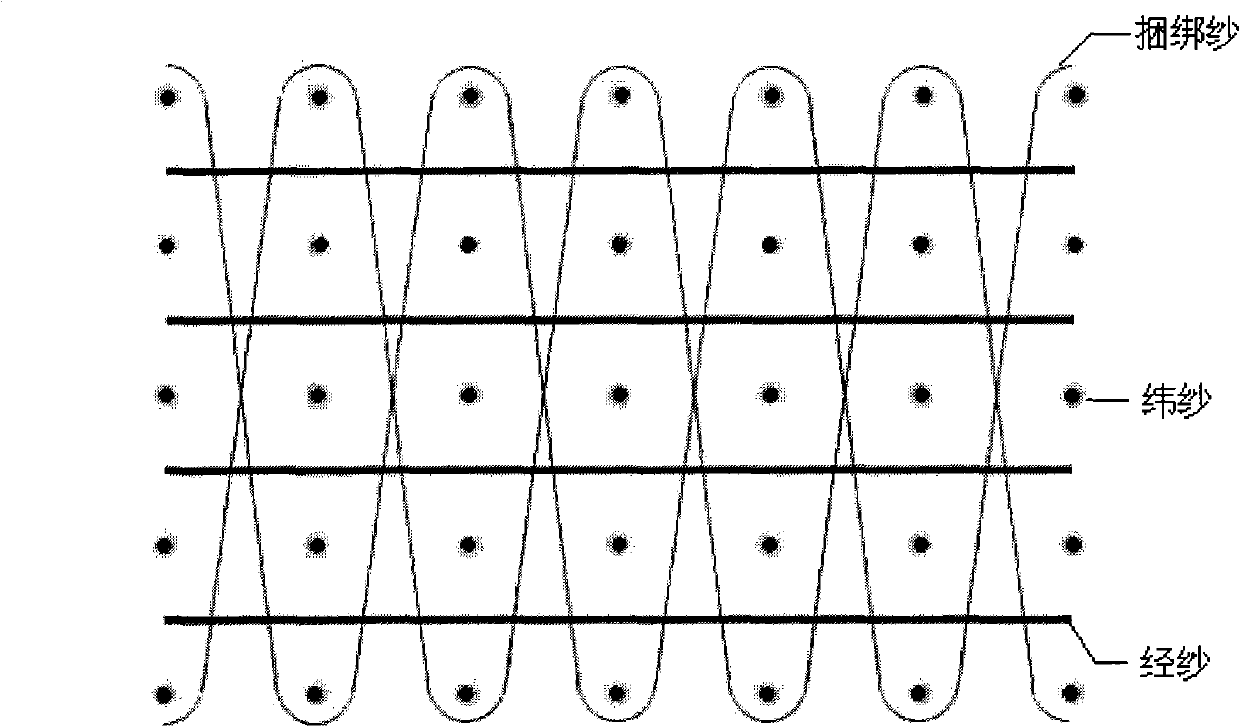

[0015] combined with figure 1 , which is a schematic diagram of the warp direction of the new three-dimensional orthogonally woven hybrid stab-resistant fabric. ① Let-off system. Since the three-dimensional orthogonal structure has three systems of yarns (yarns in the warp and weft directions and binding yarns in the Z direction), two let-off systems are required to complete the warp let-off, one supplying the warp yarns and the other supplying the binding yarns. ② Opening system. Since the three-dimensional orthogonal reinforcement material is a multi-layer three-dimensional fabric, it is necessary to form multi-layer openings; at the same time, the binding yarn needs to be opened with a large stroke and interwoven with the weft yarn. ③ Weft insertion system. After the multi-layer opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com