Active continuous let-off system for carbon fiber weaving

A carbon fiber, active technology, applied in textiles, papermaking, textile, looms, etc., can solve problems such as the inability to ensure the tension of the sheet yarn into the weaving process, the uniformity of the warp tension without adjustment, and the inability to guarantee the quality of the carbon fiber fabric surface, etc. , to achieve the effect of lightening the load, improving the quality of the cloth surface, and improving the quality of the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

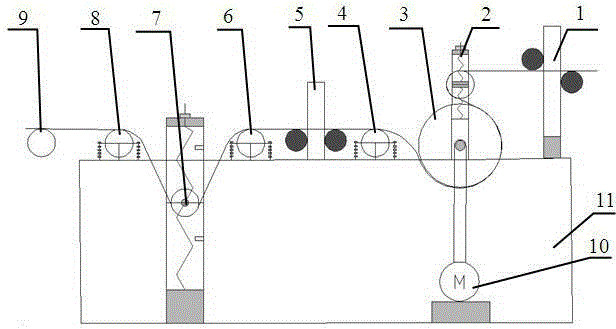

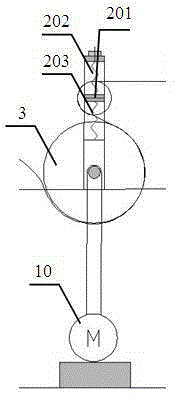

[0029] An active continuous warp let-off system for carbon fiber weaving, comprising frame 11, steel reed combination 1, upper guide roller combination 2, rubber guide roller 3, stainless steel guide roller 1 4, steel reed combination 2 5, stainless steel yarn guide Roller two 6, tension balance device 7, stainless steel guide roller three 8, stainless steel guide roller four 9, such as figure 1 ; Reed combination 1, upper guide roller combination 2, rubber guide roller 3, stainless steel guide roller 1 4, reed combination 2 5, stainless steel guide roller 2 6, tension balance device 7, stainless steel guide roller 3 8 4. Stainless steel guide rollers 9 are sequentially arranged on the frame 11; rubber guide rollers 3 are driven by motor 10.

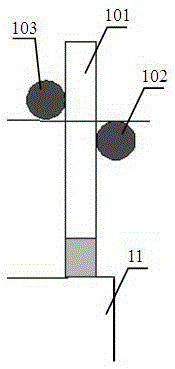

[0030] Steel reed combination one 1 comprises the first steel reed 101, the first guide roller 102, the second guide roller 103, as figure 2 , the upper surface of the first guide roller 102 and the lower surface of the second guide ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com