Energy-saving multi-purpose printing and dyeing machine

A printing and dyeing machine and multi-purpose technology, applied in the field of printing and dyeing machines, can solve the problems of inability to fine-tune, affect the adaptability of cloth and the quality of dyed cloth, and achieve the effects of convenient and reliable adjustment, expanded gram weight range, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

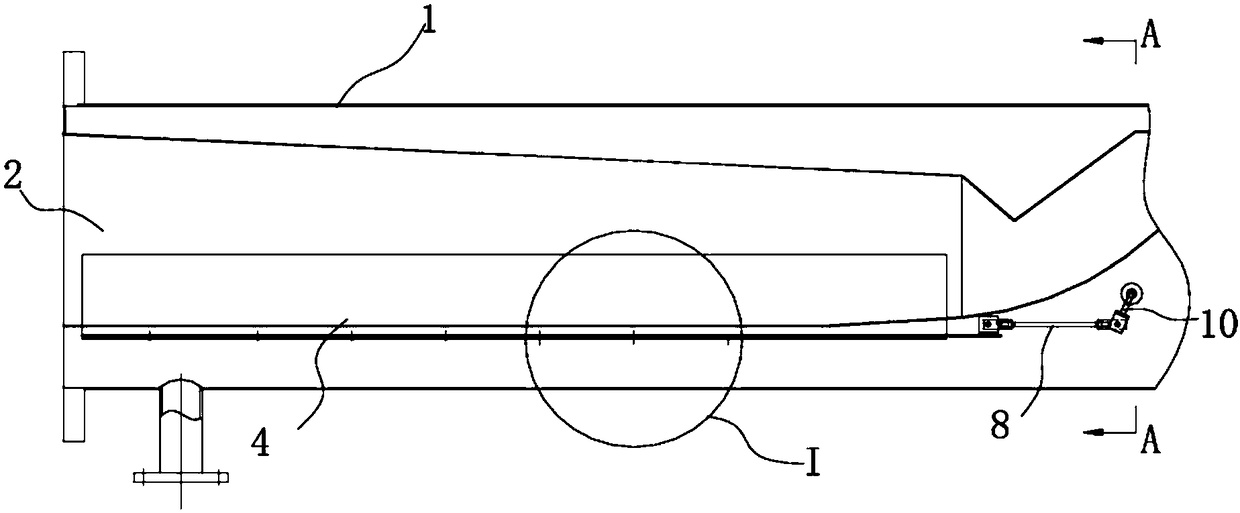

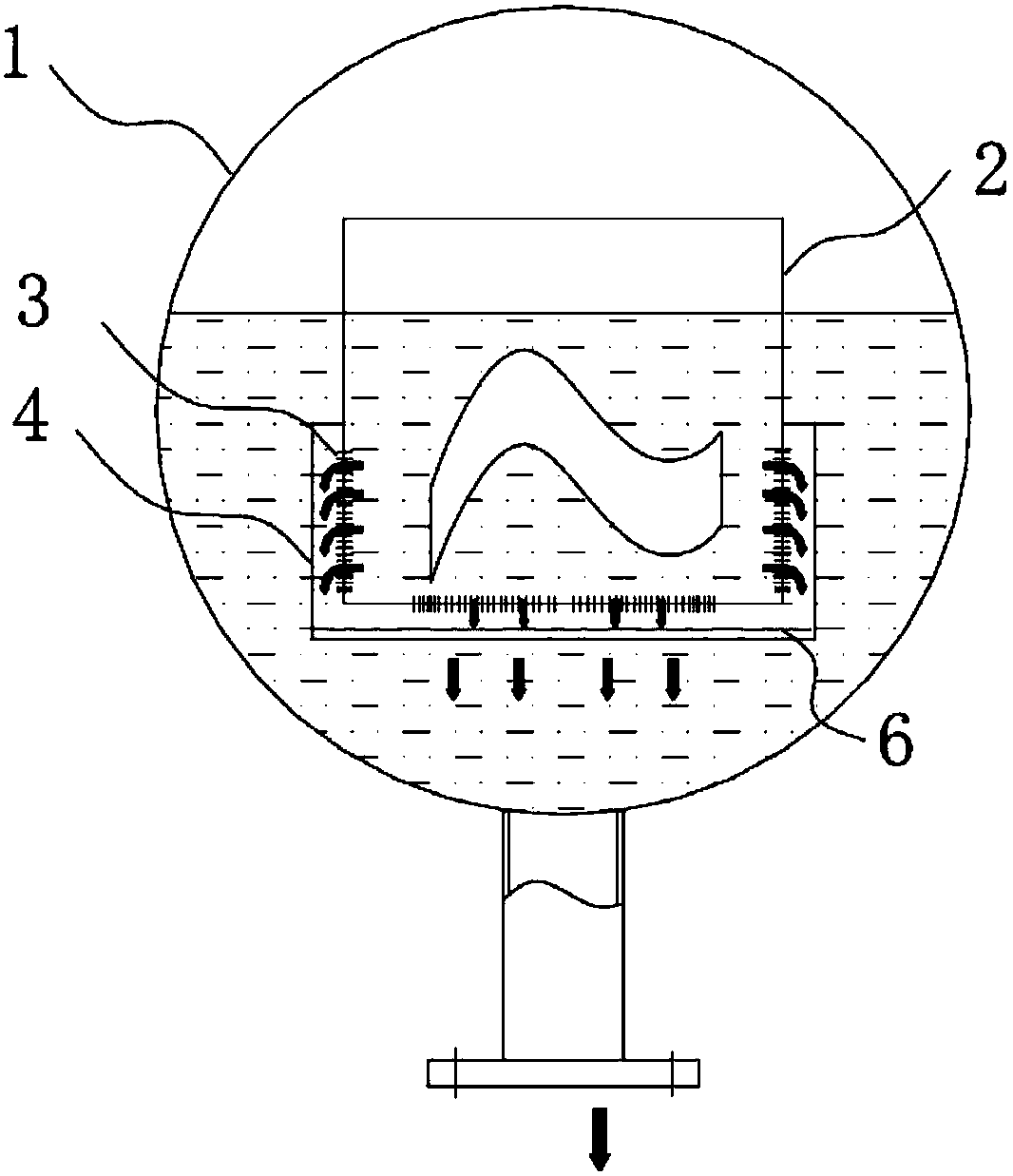

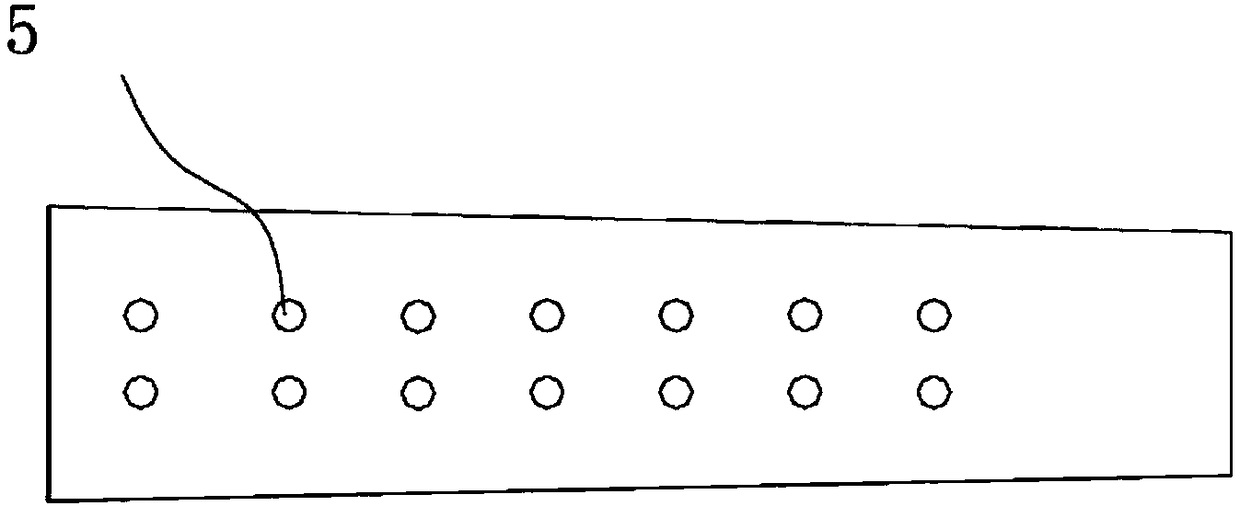

[0021] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 As shown, the energy-saving multi-purpose printing and dyeing machine includes a net cage installed in the tail housing 1 of the printing and dyeing machine, the net cage includes a box body 2, and the box body 2 is provided with a plurality of mesh holes 3; it also includes A box cover 4 with an open upper end and a closed lower end, the box cover 4 is set outside the box body 2, the upper edge of the box cover 4 is higher than the mesh 3 and the upper edge of the box cover 4 The edge is lower than the liquid level in the tail casing 1 , and the box cover 4 is provided with a plurality of water hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com