Double-spray-nozzle multi-yarn weaving device

A dual-nozzle and sub-nozzle technology, used in textiles, looms, textiles and papermaking, can solve the problems of difficult weft threading, unstable airflow, and easy wear of the cloth surface, so as to improve the simultaneous conveying capacity and improve the quality of the cloth. The effect of improving the surface quality and increasing the jetting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described:

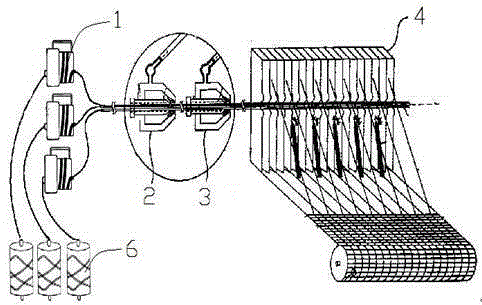

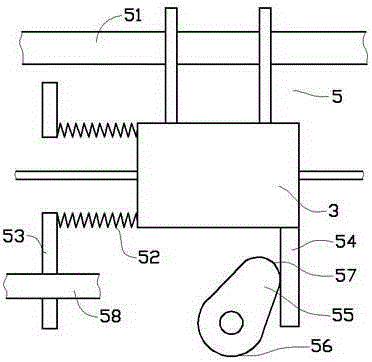

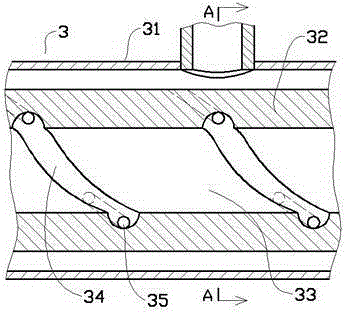

[0016] Such as figure 1 and figure 2 As shown in the embodiment, the double-nozzle multi-yarn weaving device includes a weft feeder 1, a main nozzle 2, a sub-nozzle 3, a heald frame 4, and a sliding module 5; The corresponding structures on the machine are similar, and will not be described in detail here. The weft feeder 1 extracts the yarn from the spindle 6 used for weaving and stores it first, and the main nozzle 2 is designed with a yarn guide, and the weft yarn is wound on the weft feeder 1, and the weft feeder 1 is weaving. When the machine opens, the weft yarns are released at the same time, and all the weft yarns enter the main nozzle 2 under the traction of the airflow; after passing through the main nozzle 2, the pulse current of the solenoid valve controls the injection of compressed air in the swing nozzle to ensure the smooth flight of the yarn.

[0017] The weft feeder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com