Internal combustion engine

A technology of internal combustion engine and combustion chamber, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

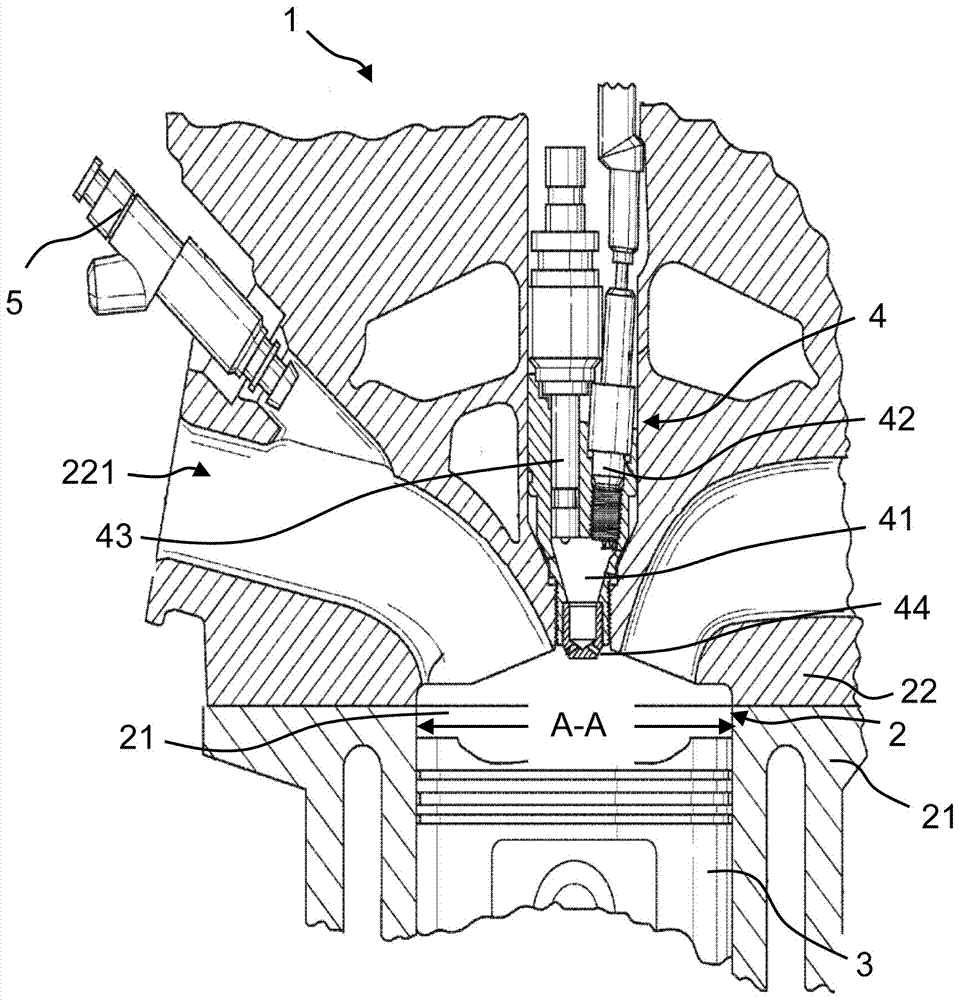

[0026] figure 1 An internal combustion engine 1 comprising one cylinder 2 (for example four) is shown. The cylinder 2 is formed in an engine block 21, and a cylinder head 22 is arranged on the cylinder. An inlet 221 having a separate main fuel injector 5 and an outlet 222 for discharging combustion products are arranged in the cylinder head 21 . A piston 3 is supported (at the crankshaft - not shown) for repeated reciprocating movement in the cylinder 2 so as to define (together with the cylinder head) a combustion chamber 21 having an engine bore diameter (AA ).

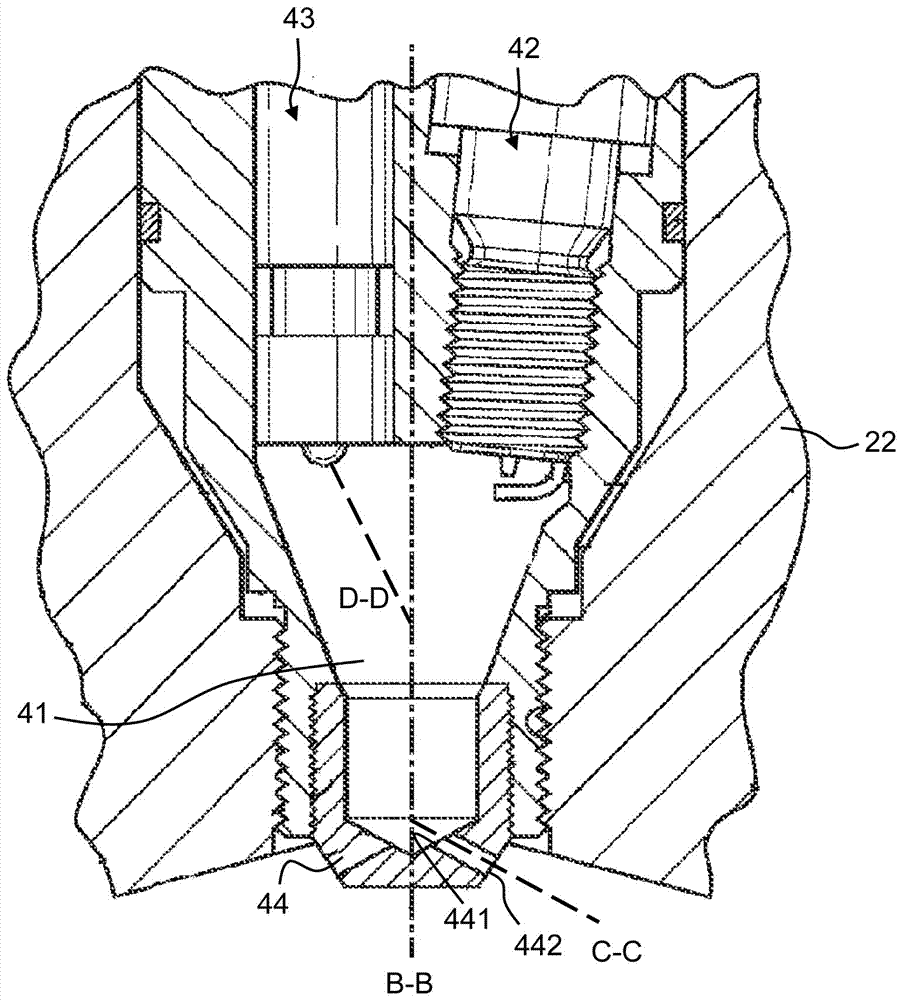

[0027] The internal combustion engine 1 also comprises an ignition device 4 (for turbulent injection ignition) arranged in said cylinder 2, said ignition device 4 having an igniter portion 42 and a fuel injector 43 (separate from the main fuel injector), both facing A pre-chamber 41 is arranged. The pre-chamber 41 includes in the example shown six holes 44 for providing fluid communication from the interior of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com