Tail gas purification device

An exhaust gas purification device and air bag technology, applied in chemical instruments and methods, dispersed particle separation, use of liquid separation agents, etc., can solve problems such as short contact time between exhaust gas and water, and achieve improved purification effect, efficiency, and purification. The effect of efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

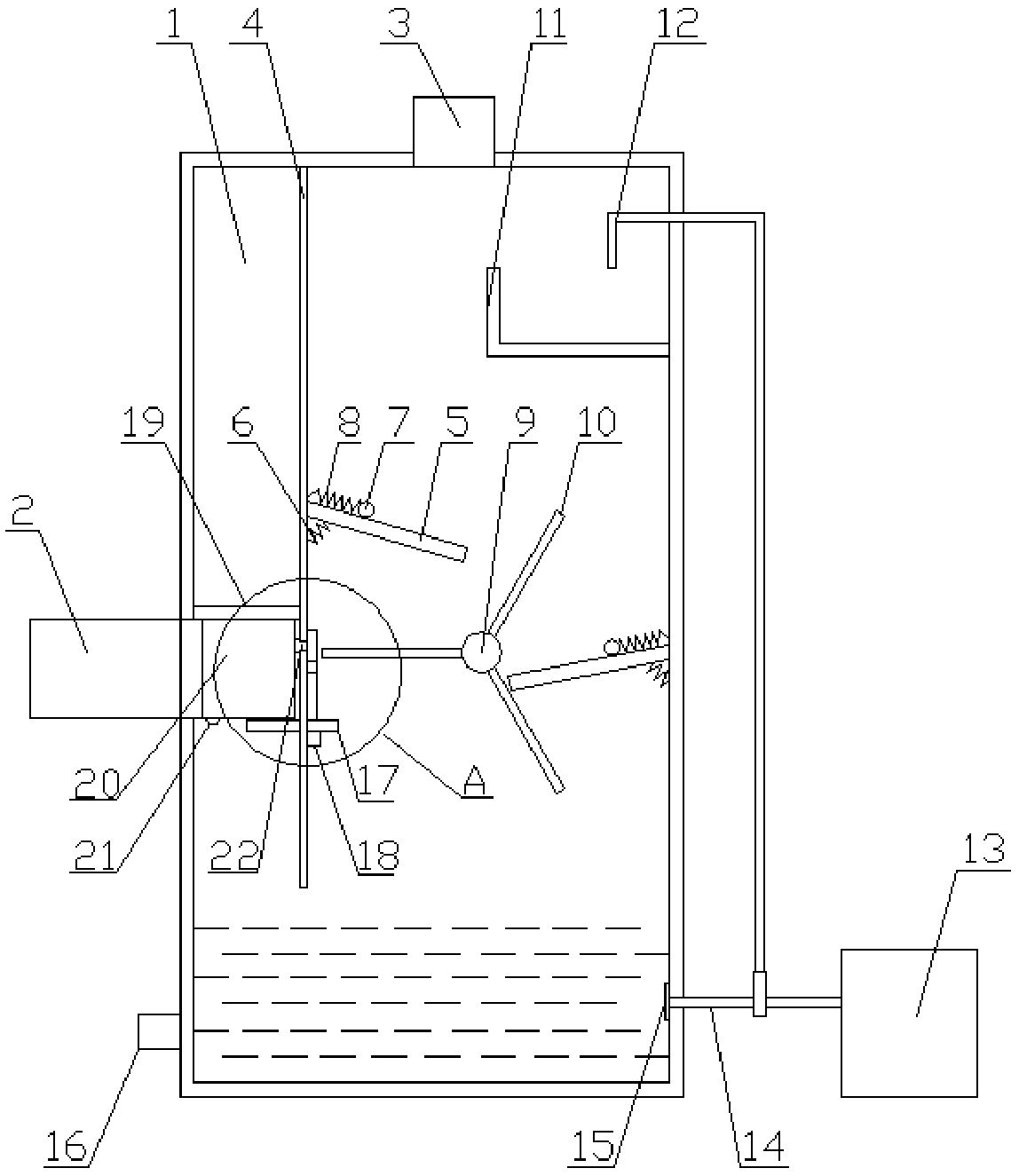

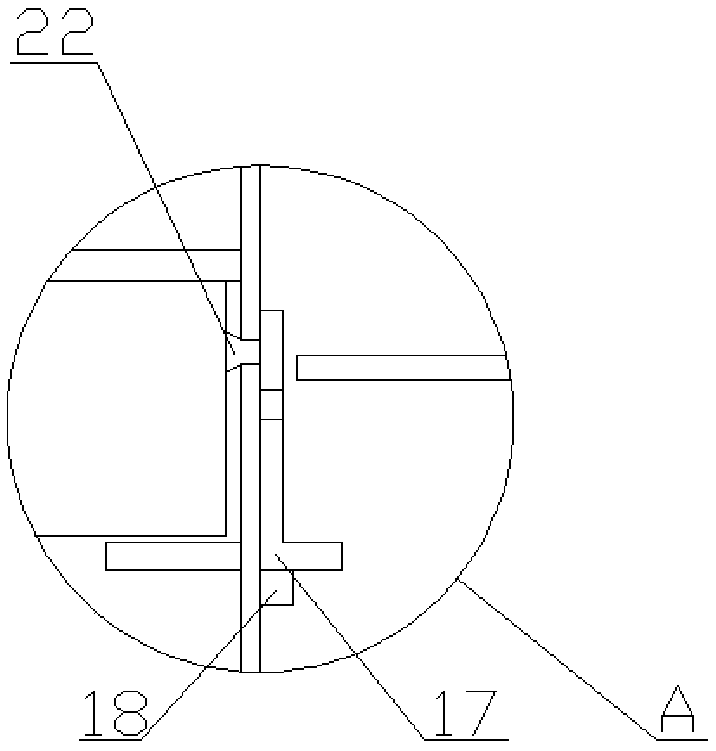

[0020] The reference signs in the drawings of the description include: box body 1, air inlet 2, air outlet 3, buffer plate 4, inclined plate 5, first spring 6, rebound ball 7, second spring 8, rotating shaft 9, blade 10. Water collection tank 11, water inlet pipe 12, water pump 13, circulating water pipe 14, filter screen 15, drain pipe 16, push plate 17, limit column 18, stop plate 19, air bag 20, first nozzle 21, second nozzle 22 .

[0021] The embodiment is basically as attached figure 1 And attached figure 2 As shown: the exhaust gas purification device includes a hollow box body 1 with an air inlet 2 and an air outlet 3 on the box body 1, and a drain pipe 16 is welded at the bottom of the box body 1, which can circulate more water in the box body 1 After the second time, drain the water and replace it, so as to prevent the impurities in the water from reaching sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com