Welding device used for copper craft production

A technology of copper handicrafts and welders, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., and can solve problems such as welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

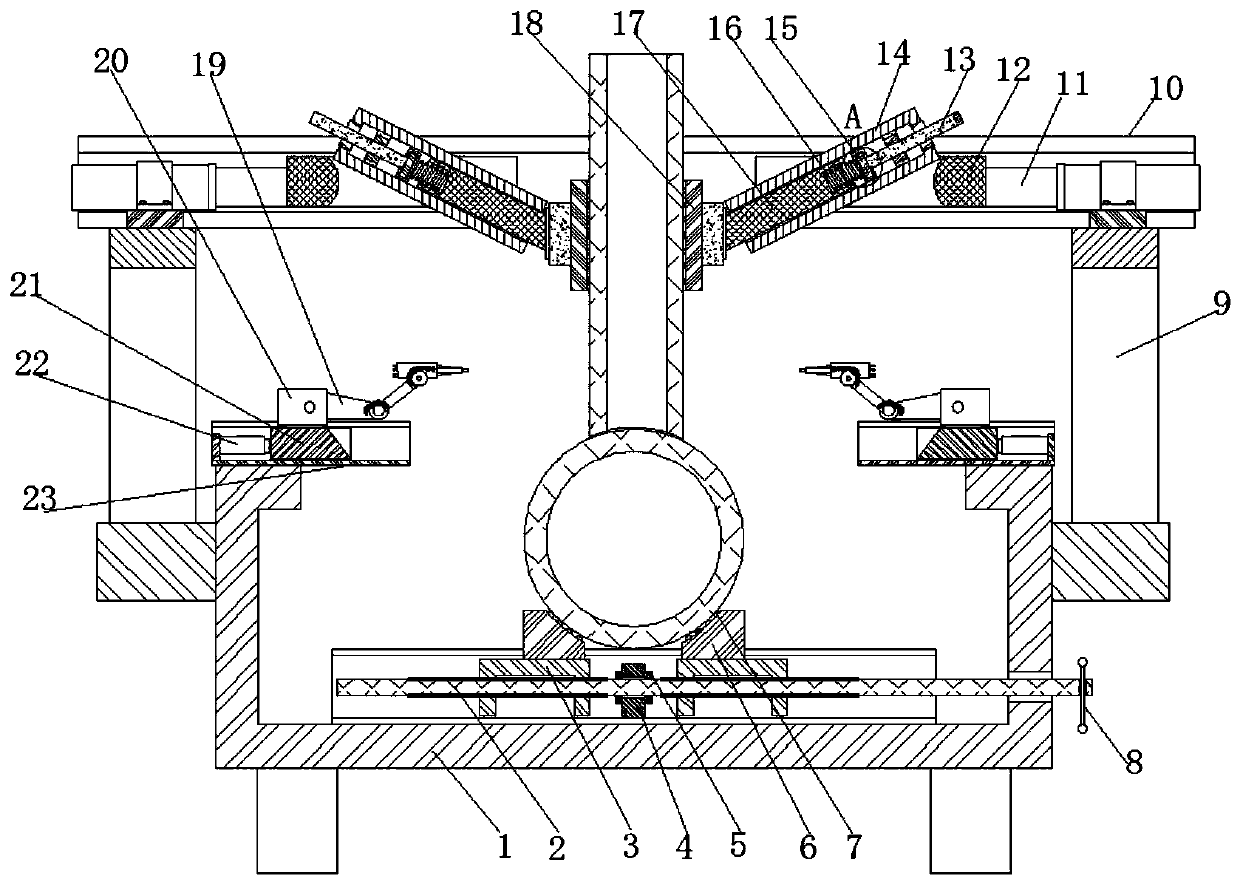

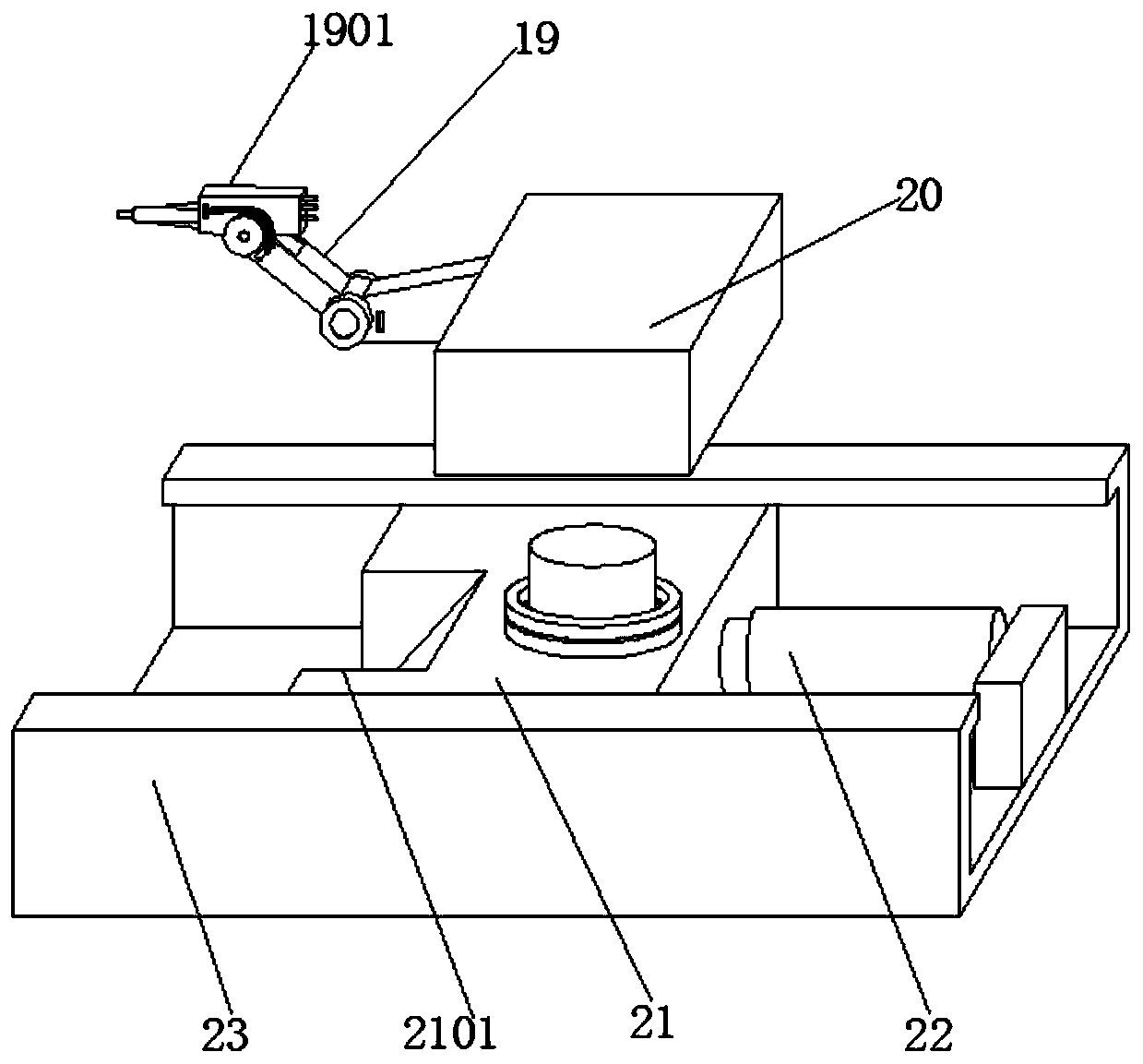

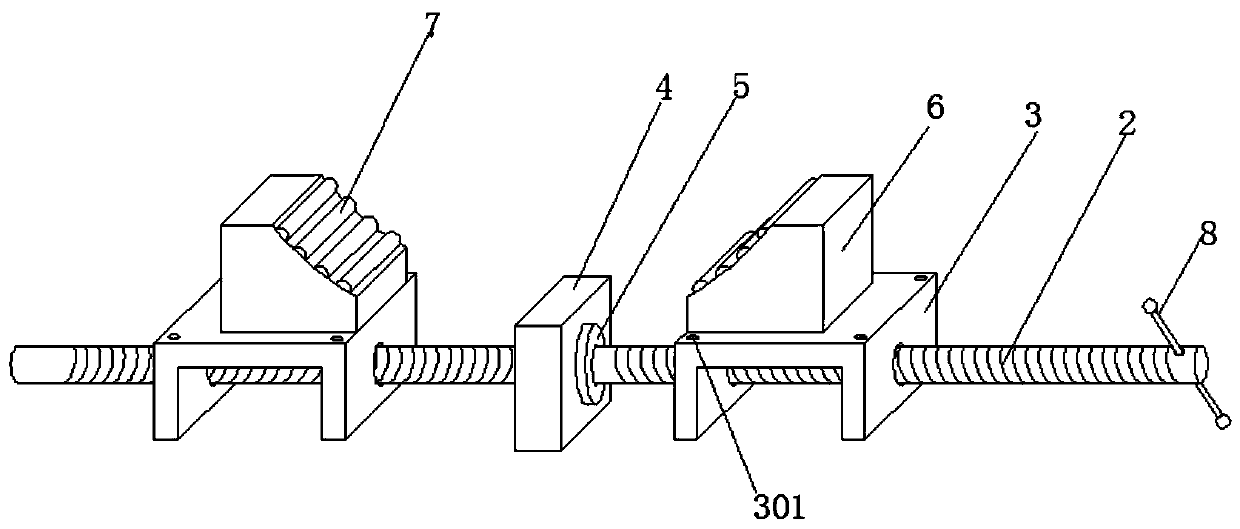

[0029] refer to Figure 1-5 , a welder for the production of copper handicrafts, including a base 1 with an upward opening in a groove-shaped structure, a C-shaped steel slide rail with an upward opening is fixed in the middle of the bottom of the base 1, and a stopper is fixed in the middle of the groove bottom of the C-shaped steel slide rail. Plate 4, the middle of baffle plate 4 is connected with two-way screw rod 2 for rotation, and the two ends of two-way screw rod 2 are sleeved with sliding blocks 3 respectively, and the tops of two sliding blocks 3 are respectively fixed with mutually symmetrical arc push plates 6, tube The seat is fixed between two arc-shaped push plates 6, and support frames 9 are fixed on opposite sides of the base 1, and two channel steel beams 10 with opposite openings and parallel to each other are fixed on the top of the two support frames 9. Two channel steel beams 10 are slidably connected with two C-shaped clamping blocks 12 with opposite ope...

Embodiment 2

[0039] refer to Figure 1-2 , a welder for the production of copper handicrafts. Compared with Embodiment 1, this embodiment also includes sockets that are equidistantly distributed on the side of the channel steel beam 10, and a C-shaped clamping block 12 is close to the socket. The side is embedded with an electric control positioning pin.

[0040] When the C-shaped clamping block 12 is moved into place during use, the electronically controlled positioning pin is activated to position it, preventing the C-shaped clamping block 12 from being forced to slide backwards and ensuring the stability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com