Main blowing system for weft insertion

A technology of weft insertion and main nozzle, used in textile, textile and papermaking, looms, etc., can solve the problems of accelerating weft yarn, lowering, high jetting speed, etc., to achieve high airflow jetting speed, improved ability, and increased pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

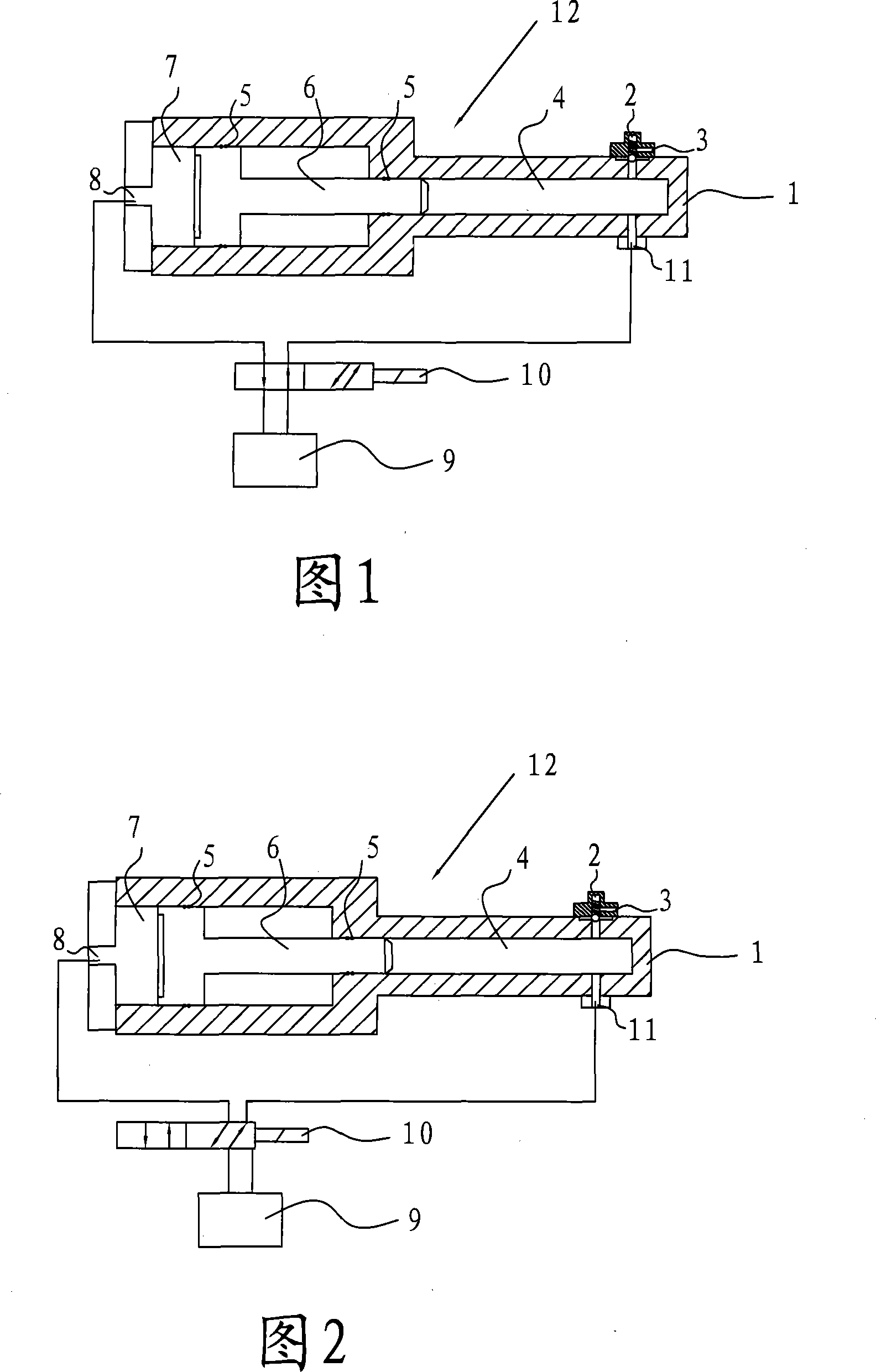

[0012] A main air injection system for weft insertion, including an air storage tank 9 for containing high-pressure gas, a main nozzle 3 for injecting high-speed air flow, and a solenoid valve connecting the air storage tank 9 and the main nozzle 3 and used to control the on-off of the air flow 10. In order to increase the air supply pressure of the main nozzle 3, a supercharger 12 is arranged between the solenoid valve 10 and the main nozzle 3 in the present invention. The piston 6 inside the device body 1 and can slide along the inner cavity of the supercharger body 1, the inner cavity of the supercharger body 1 is divided into the first air chamber 4 and the second air chamber 7 by the piston 6, in order to increase the piston 6 and the booster The tightness of the pressurizer body 1, in this embodiment, an O-ring 5 is used to seal between the piston 6 and the inner cavity of the booster body 1 . The cross-sectional area of the first air chamber 4 is smaller than the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com