Patents

Literature

39results about How to "To achieve the purpose of anti-glare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

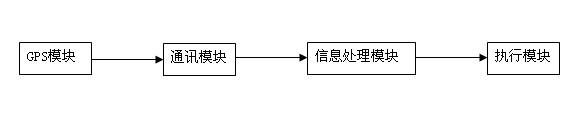

Glare control system based on Internet of vehicles and control method of glare control system

InactiveCN102592442AIncrease labor intensityImprove efficiencyRoad vehicles traffic controlOptical signallingInformation processingIn vehicle

The invention relates to a glare control system based on Internet of vehicles and a control method of the glare control system. The system comprises a GPS (global positioning system) module used for judging the current position of a vehicle; a communication module connected with the GPS module for realizing data transmission among the vehicles; an information processing module connected with the communication module for processing the received information and information of the vehicle to judge whether meeting or whether the meeting is finished and send a corresponding command to an executing module; and the executing module connected with the information processing module for executing the command sent by the information processing module. The system and the method provided by the invention have accurate data transmission and sensitive reaction in an operation process, the vehicle-mounted glare control system can automatically switch a high beam and a dipped headlight according to the distance among the vehicles within a preset range so as to achieve the anti-glare purposes and effectively reduce safety accidents.

Owner:CHERY AUTOMOBILE CO LTD

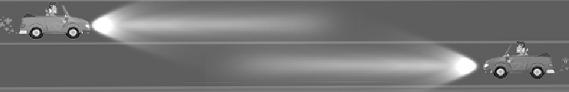

Anti-glare flame-retardant polycarbonate material, and preparation method and application thereof

The invention discloses an anti-glare flame-retardant polycarbonate material which comprises the following components by weight percent: 85-95 percent of polycarbonate, 2-12 percent of flame retardant, 0.1-1 percent of flame-retardant synergist, 0.1-5 percent of anti-glare agent, 0.3-2 percent of anti-ultraviolet agent, 0.05-3 percent of blue light absorbent, 0.2-3 percent of antioxidant and 0.2-2 percent of lubricating agent. The anti-glare flame-retardant polycarbonate material not only has an excellent anti-glare function, but also has higher light transmittance, and is capable of absorbing the blue wave band of the LED lighting spectrum at the same time. The invention further discloses a preparation method of the anti-glare flame-retardant polycarbonate material, which comprises the following steps: firstly preparing flame-retardant masterbatches, organic silicon microbead anti-glare masterbatches and blue light absorption masterbatches, and then preparing the anti-glare flame-retardant polycarbonate material, so that the performance anti-glare flame-retardant polycarbonate material is improved. The anti-glare flame-retardant polycarbonate material is particularly suitable for preparing an optical housing for LED lighting.

Owner:CGN JUNER NEW MATERIALS +1

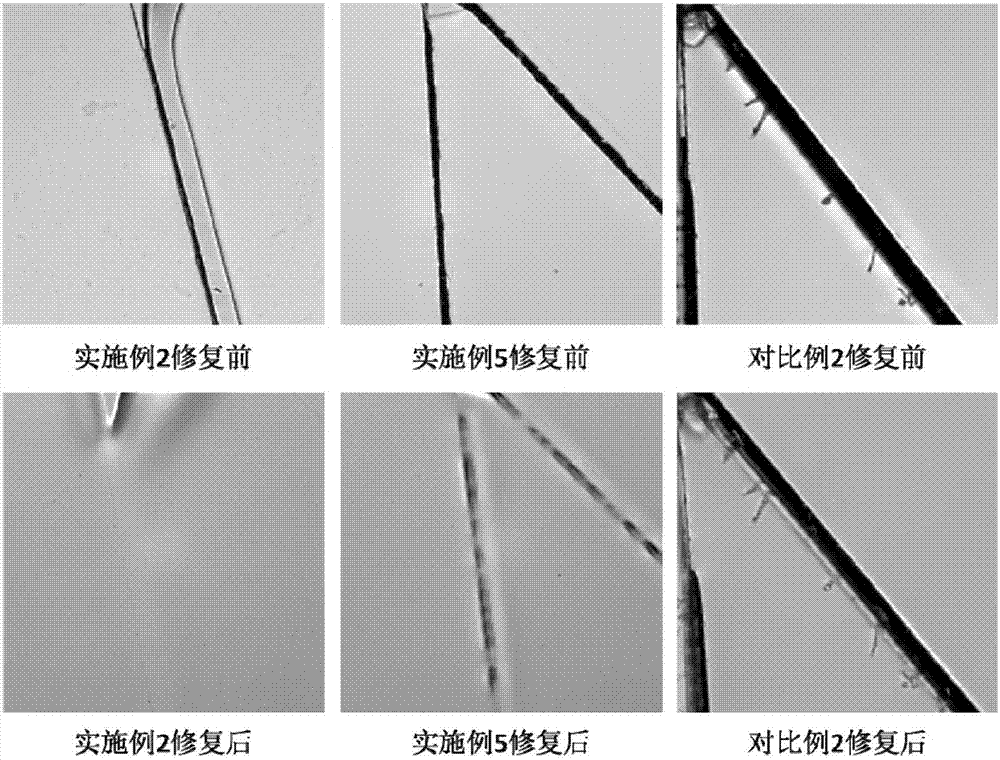

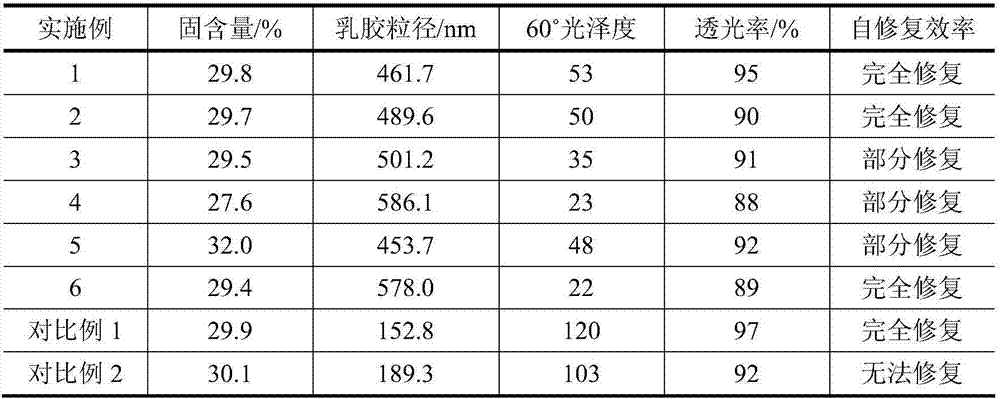

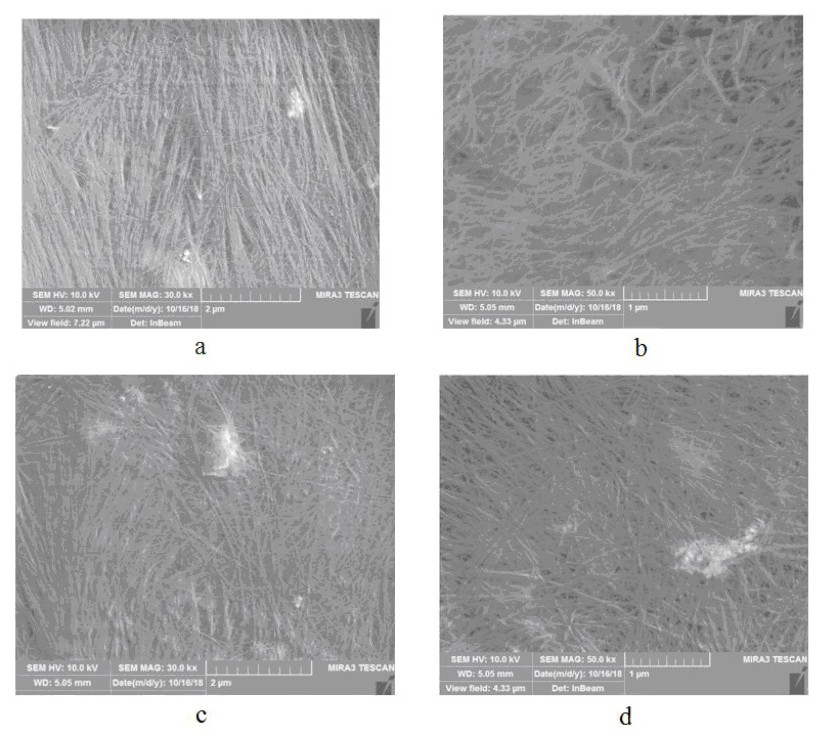

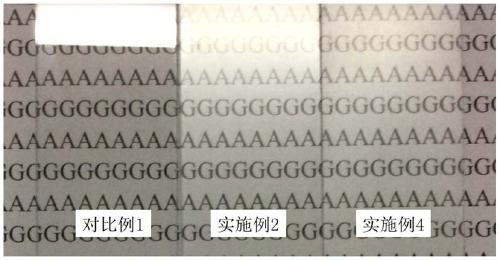

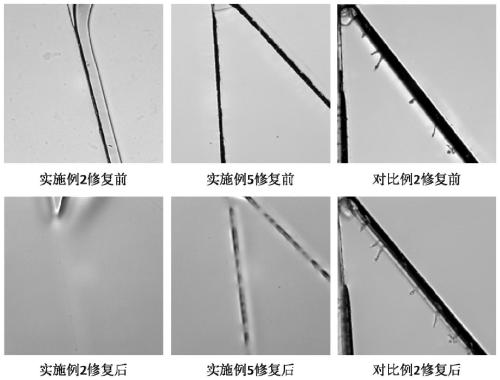

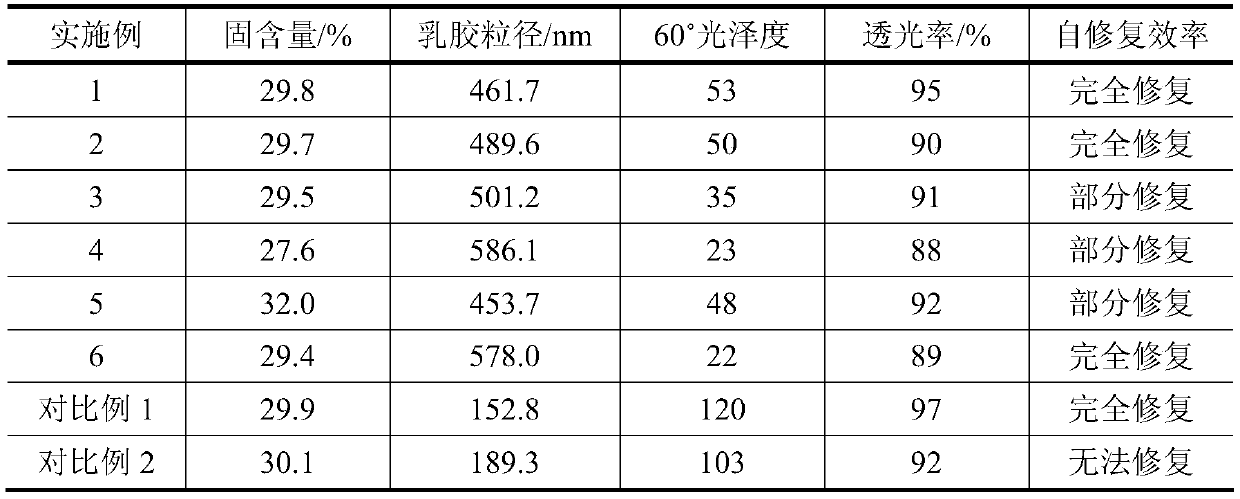

Self-repairing anti-glare waterborne polyurethane paint and preparation method thereof

ActiveCN106867388AGuaranteed transmission throughTo achieve the purpose of anti-glarePolyurea/polyurethane coatingsPolymer scienceCopolymer

The invention discloses anti-glare waterborne polyurethane paint with a self-repairing function and a preparation method thereof. The preparation method is characterized in that aliphatic polyether glycol subjected to dehydration treatment and diisocyanate are subjected to prepolymerization under the effect of organic tin catalyst; then, the aliphatic polyether glycol subjected to dehydration treatment is added to generate a segmented copolymer; primary chain extension is performed through dimethylolpropionic acid; neutralization is performed to form salt; deionized water and sodium sulfamate type chain extenders are subjected to emulsification and chain extension; sulfonic acid groups are introduced at a hard chain section; then, aliphatic diamine type or hydrazine chain extenders with higher reactivity is added, so that the rest isocyanate completely reacts; finally, the proper amount of auxiliary agents is mixed to obtain the waterborne polyurethane paint. The paint coating film has good diffusion performance and high transmissivity; the excellent anti-glare effect can be achieved without adding additional auxiliary agents or performing surface treatment; the coating film has the self repairing capability through a large number of reversible hydrogen bonds and sulfonic acid groups in polyurethane.

Owner:QINGYUAN YAKOO CHEM CO LTD

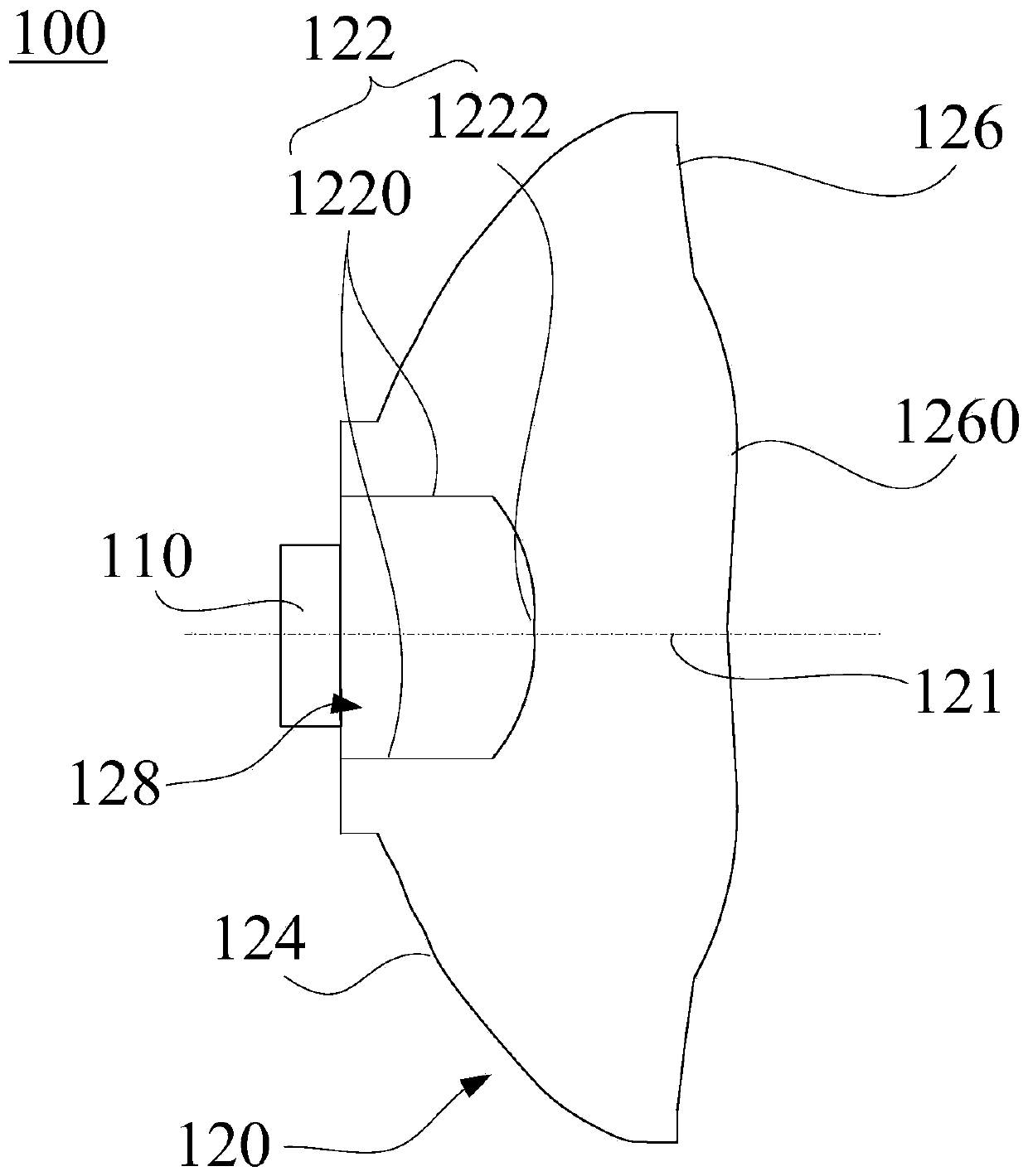

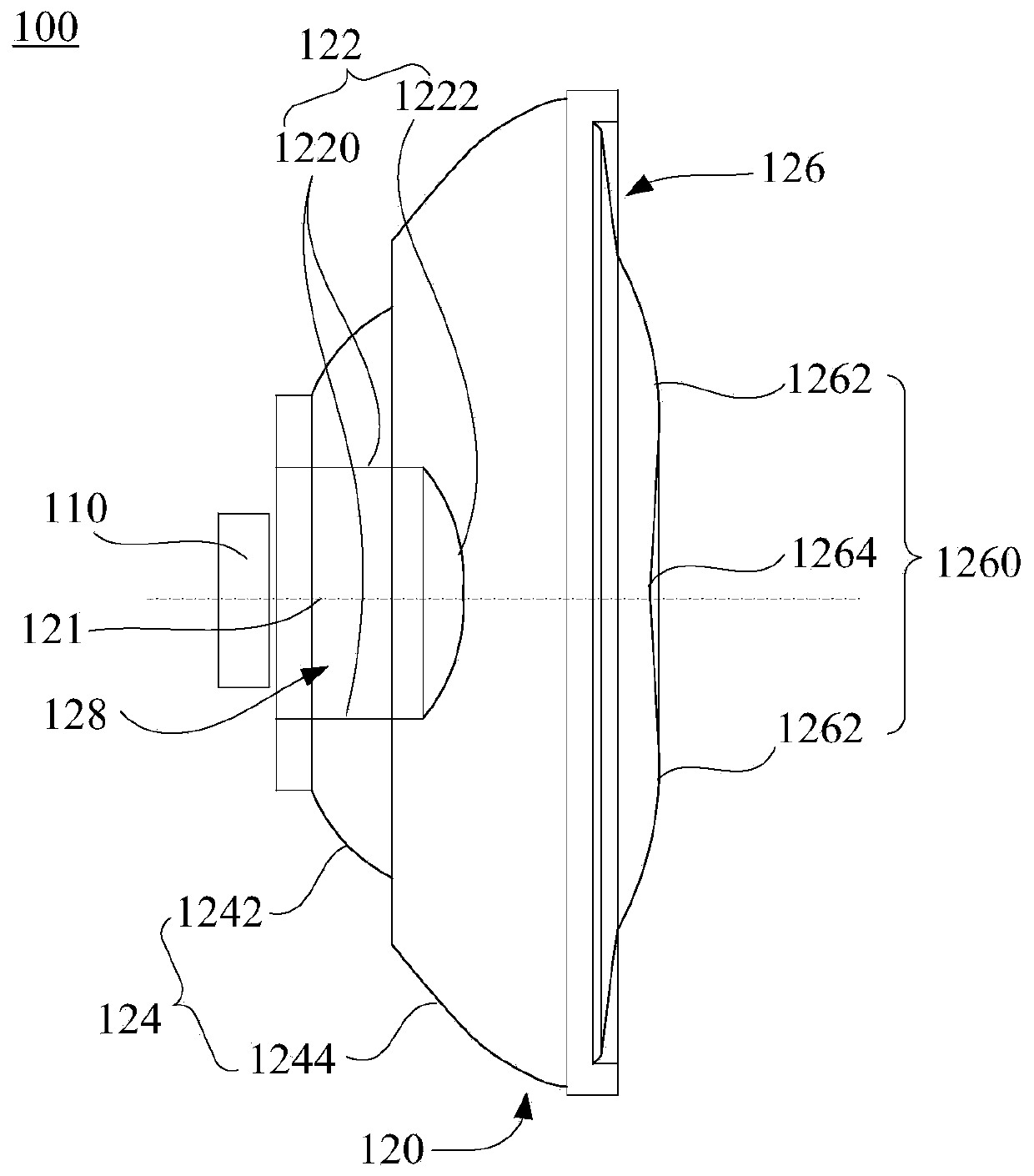

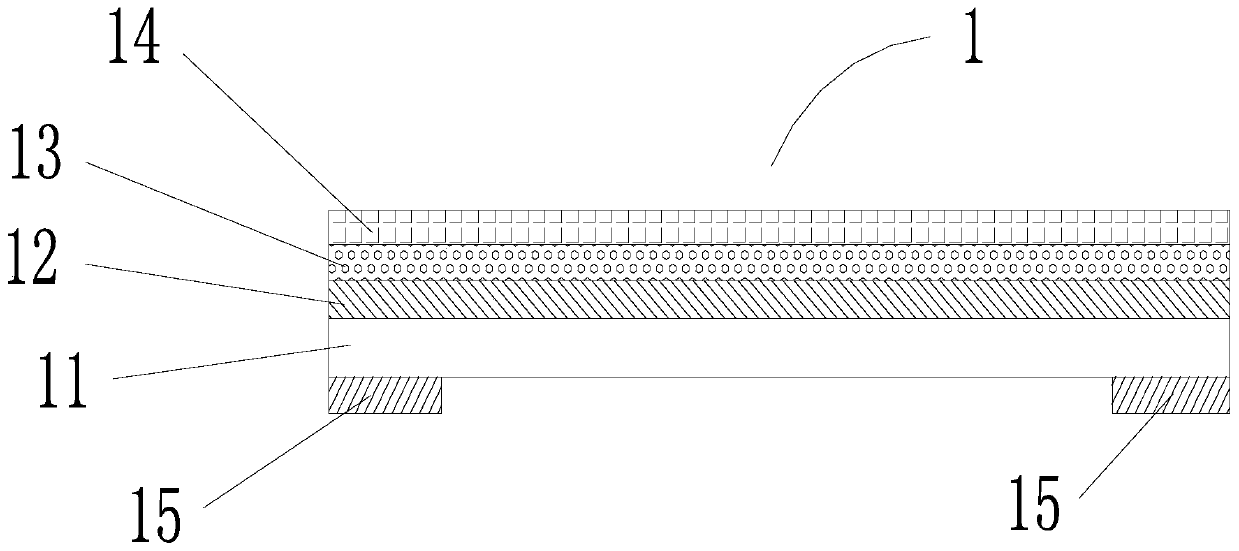

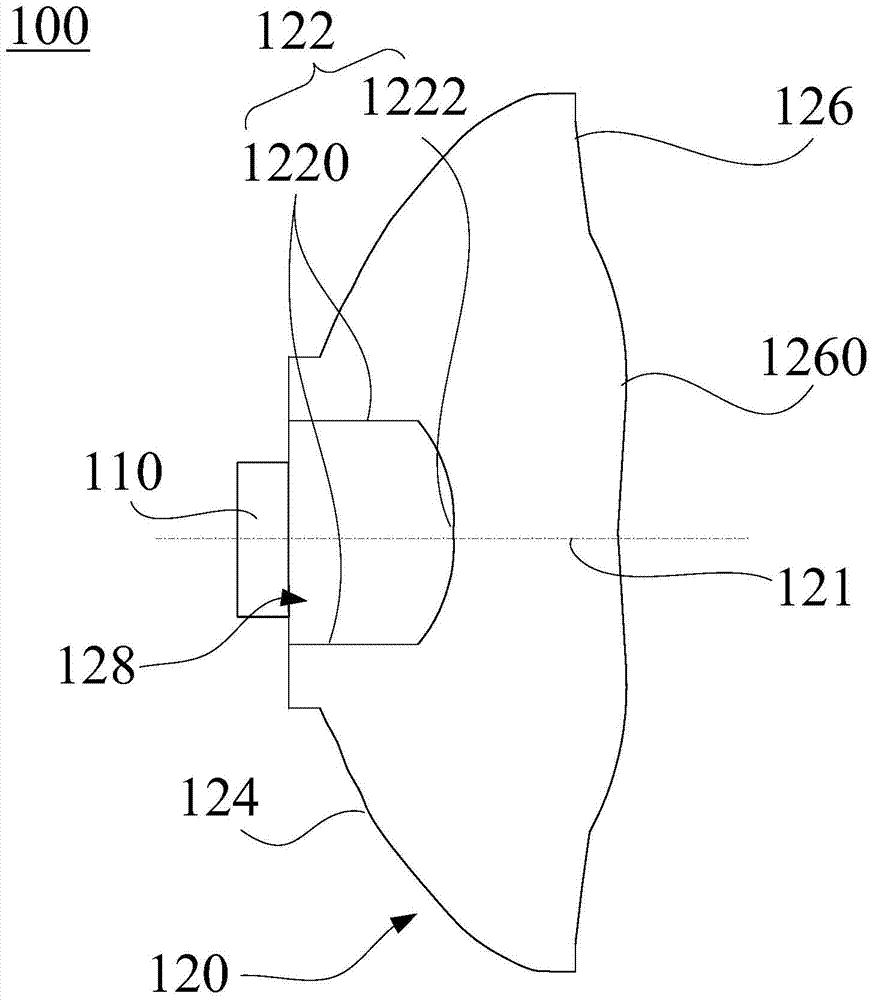

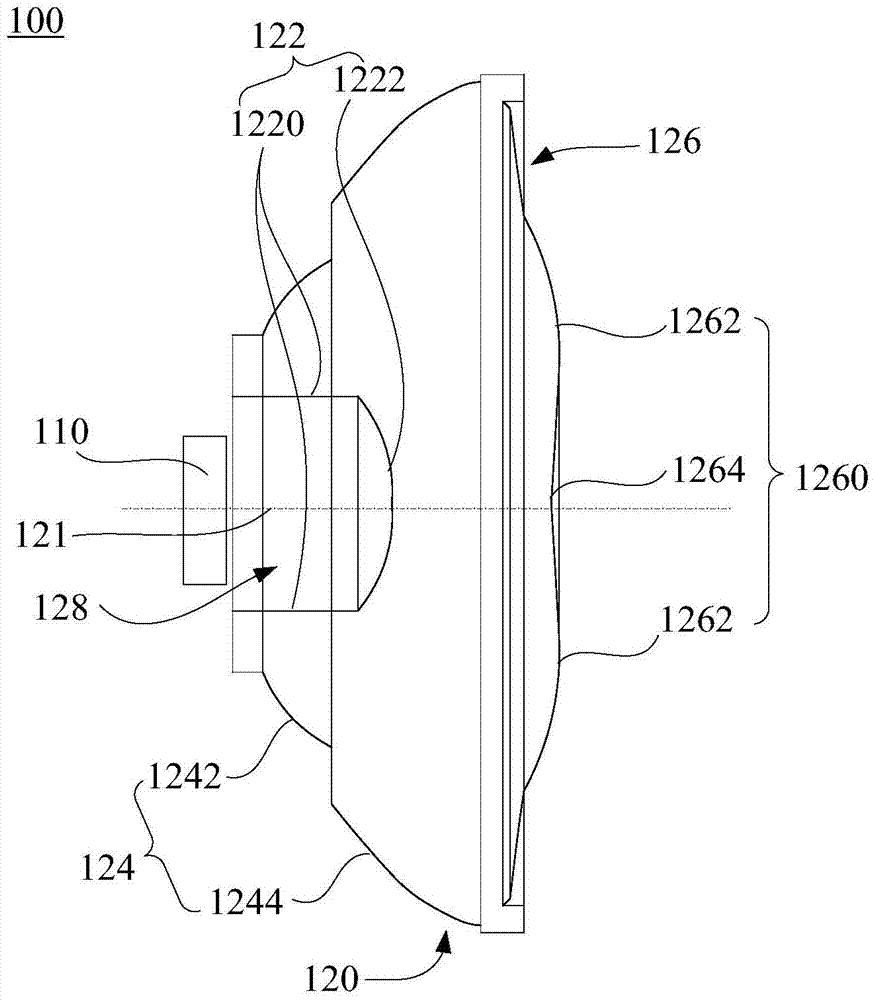

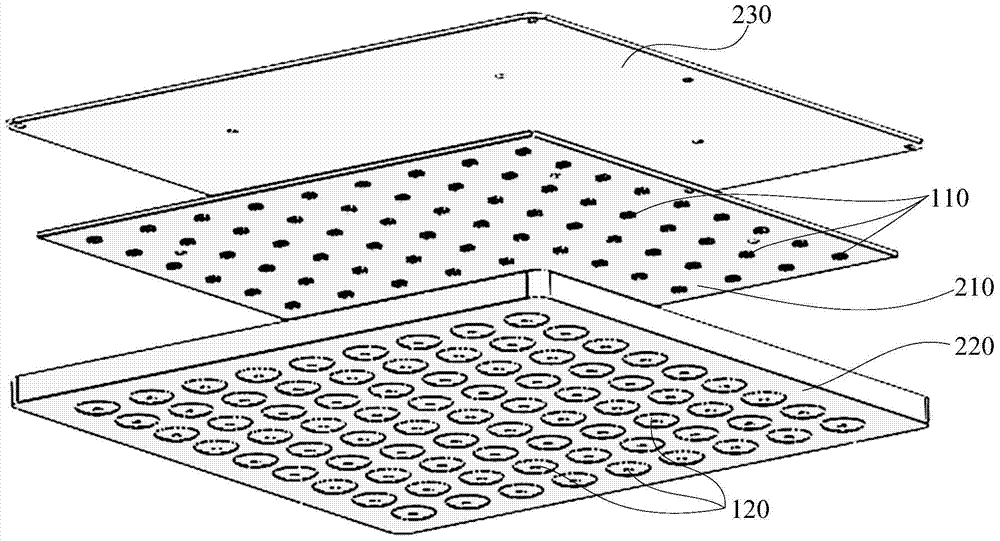

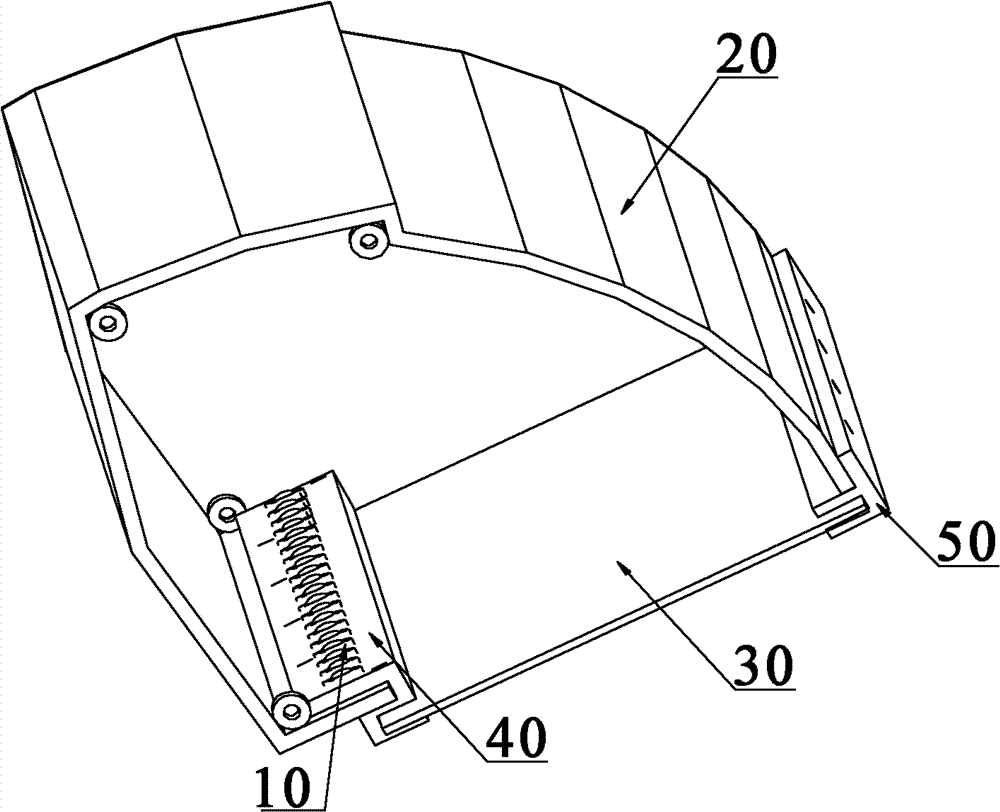

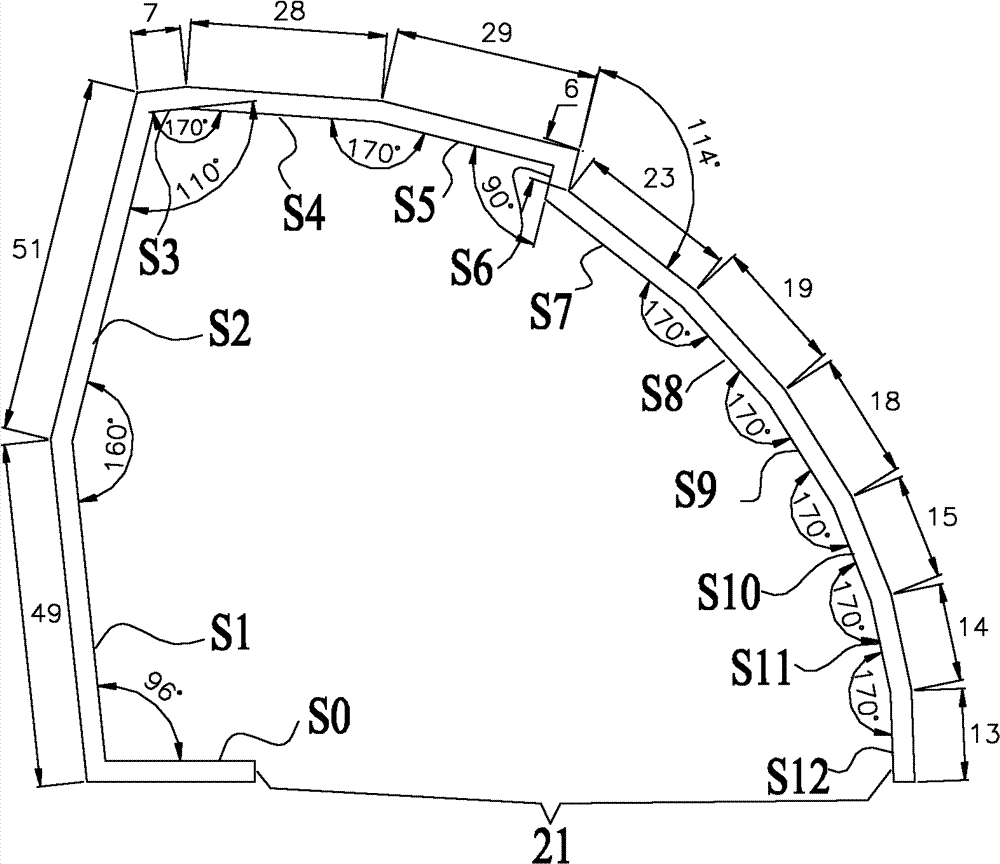

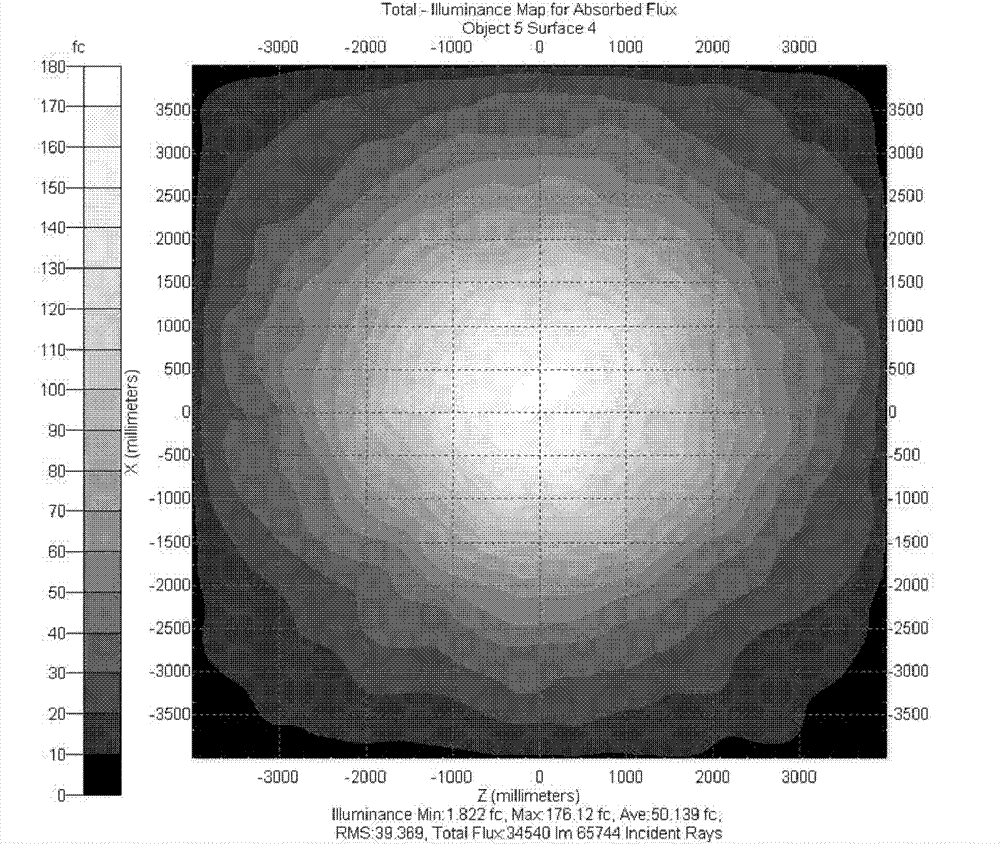

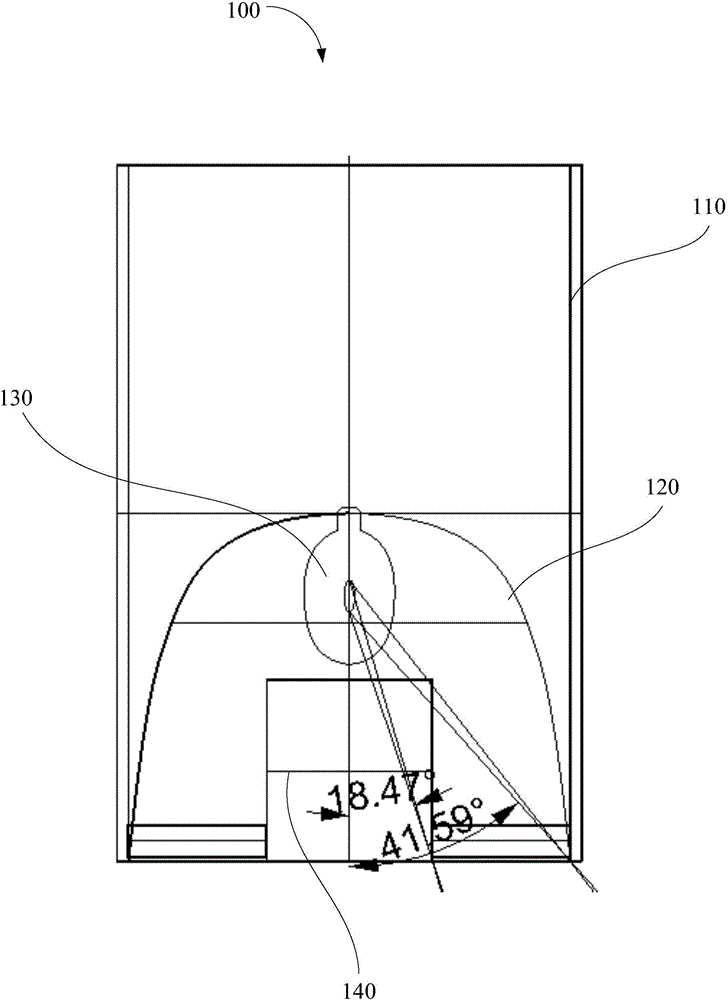

LED optical system and lamp

ActiveCN103994395AIncrease light emitting areaSufficient optical utilizationPlanar light sourcesElectric lightingPoint light sourceOptoelectronics

An LED optical system comprises a light emitting element and an anti-glare substrate. The anti-glare substrate comprises a light entering surface, a reflecting surface and a light emitting surface. The light entering surface faces the light emitting element, the reflecting surface is located between the light entering surface and the light emitting surface, and the orthographic projection, towards the light emitting surface, of the light entering surface and the orthographic projection, towards the light emitting surface, of the light emitting surface are located on the light emitting surface. The light emitting surface comprises a light emitting sub-surface which is a curved surface, and the light emitting sub-surface is located on the central region of the light emitting surface and protrudes away from the light entering surface. The light emitting surface comprises the light emitting sub-surface which is the curved surface, the light emitting sub-surface is located on the central region of the light emitting surface and protrudes away from the light entering surface, and therefore light located on the central region can be scattered and emitted and light nearby the central axis is weakened. Light emitted out of the light emitting surface after being reflected by the reflecting surface can compensate for the light nearby the central axis, a point light source is converted into a multi-surface light source to be emitted under the premise that the optical utilization rate is sufficient, the anti-glare purpose is achieved, and reliability is high.

Owner:SHENZHEN INST FOR INNOVATIVE DESIGN CO LTD

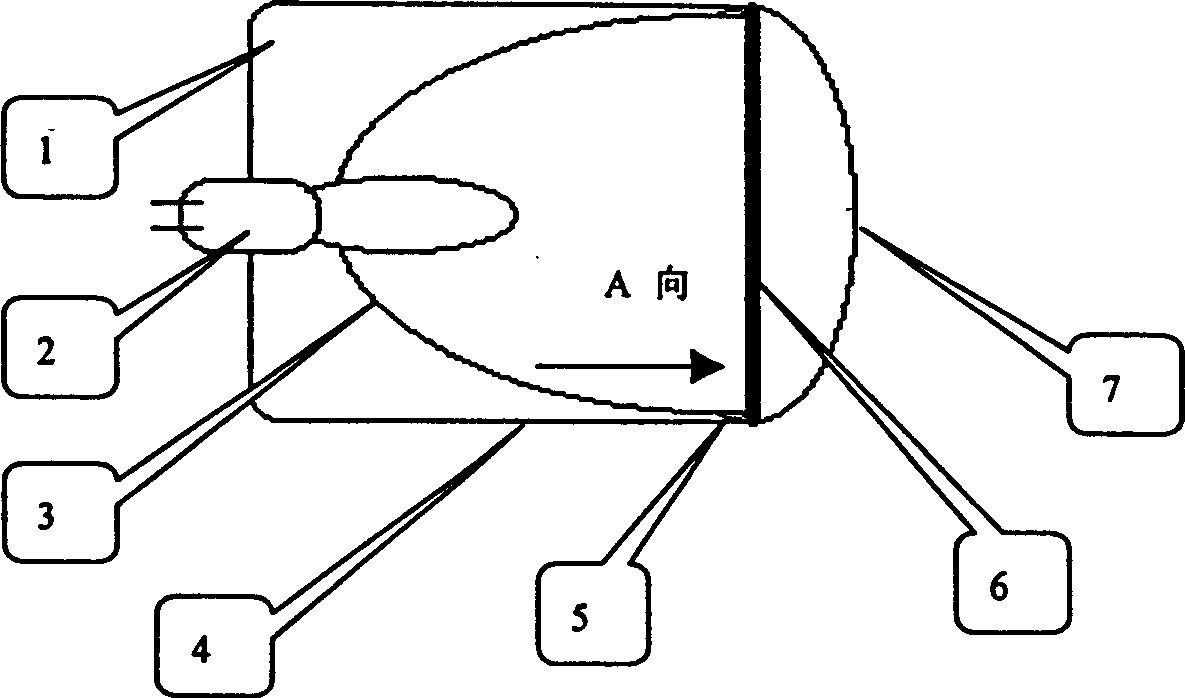

Liquid crystal glasses

InactiveCN105607284ASave electricityTo achieve the purpose of anti-glareStatic indicating devicesOptical partsLiquid-crystal displayGray level

The invention discloses liquid crystal glasses which can selectively reduce the highlight brightness during car meeting at night. The liquid crystal glasses comprise a glasses frame, lenses and a head band; an image collecting unit is arranged at the center of the position right ahead of the head band, and a CCD chip, a liquid crystal drive circuit, a microprocessor, a buffer, a power supply, an image recognizing unit, an image processing unit, an information extracting unit and a gray level data generating unit are arranged in the head band.

Owner:侯绪华

Processing technology of etching-free anti-dazzle cover plate

PendingCN111170652AThe processing technology is convenient and fastIncrease productivityCoatingsSilicone resinFogging

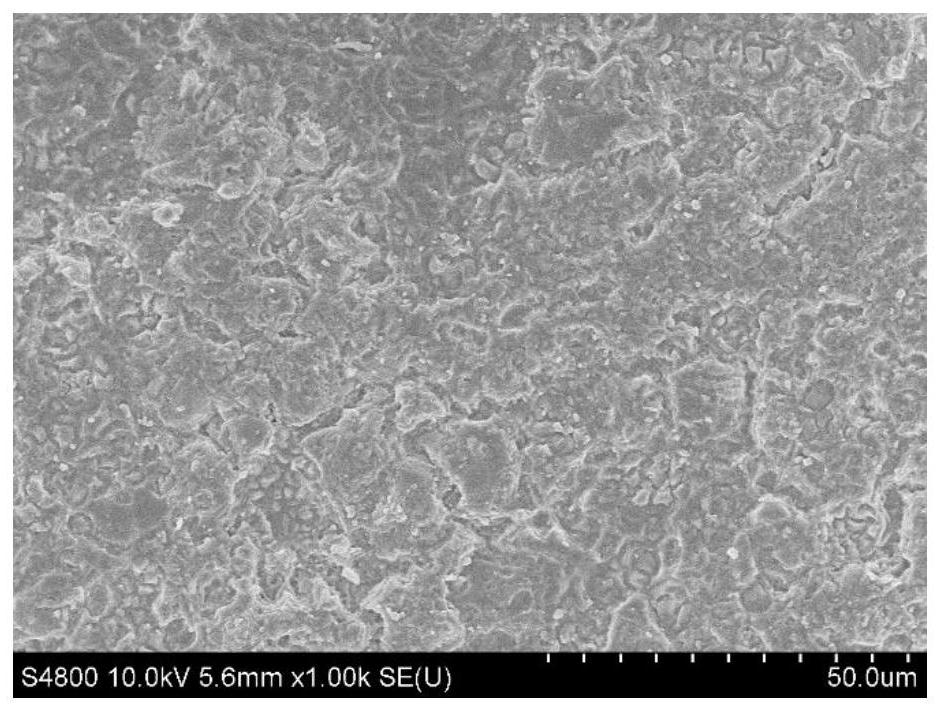

The invention relates to processing technology of etching-free anti-dazzle cover plate. The processing technology comprises the following steps of: putting cleaned front cover glass on a vacuum adsorption jig in a way that the outer surface of the front cover glass is upward, and carrying out vacuum adsorption Plasma beating treatment; spraying an anti-dazzle film solution on the front cover glass; carrying out atomization and mist treatment through a spray gun; spraying the anti-dazzle film solution uniform and fine fog drops; at the moment, carrying out scanning using the spray gun at a specific height back and forth at a constant speed, and heating the front cover glass on a platform, and advancing in an inching manner, so that the anti-dazzle film solution can uniformly cover the glassin a crossed manner, silicon resin in the solution and hydroxyl OH on the glass are subjected to condensation reaction to form silicon-oxygen bonding, and the silicon-oxygen bonding is attached to the surface of the glass; and carrying out high-temperature solid baking on the front cover glass sprayed with the anti-dazzle film solution to form an AG anti-dazzle protective film layer. The problemsthat existing chemical etching AG is not environmentally friendly, the surface hardness of a coating AG is low, and the hand feeling is poor are solved.

Owner:BIEL OPTIC HUIZHOU

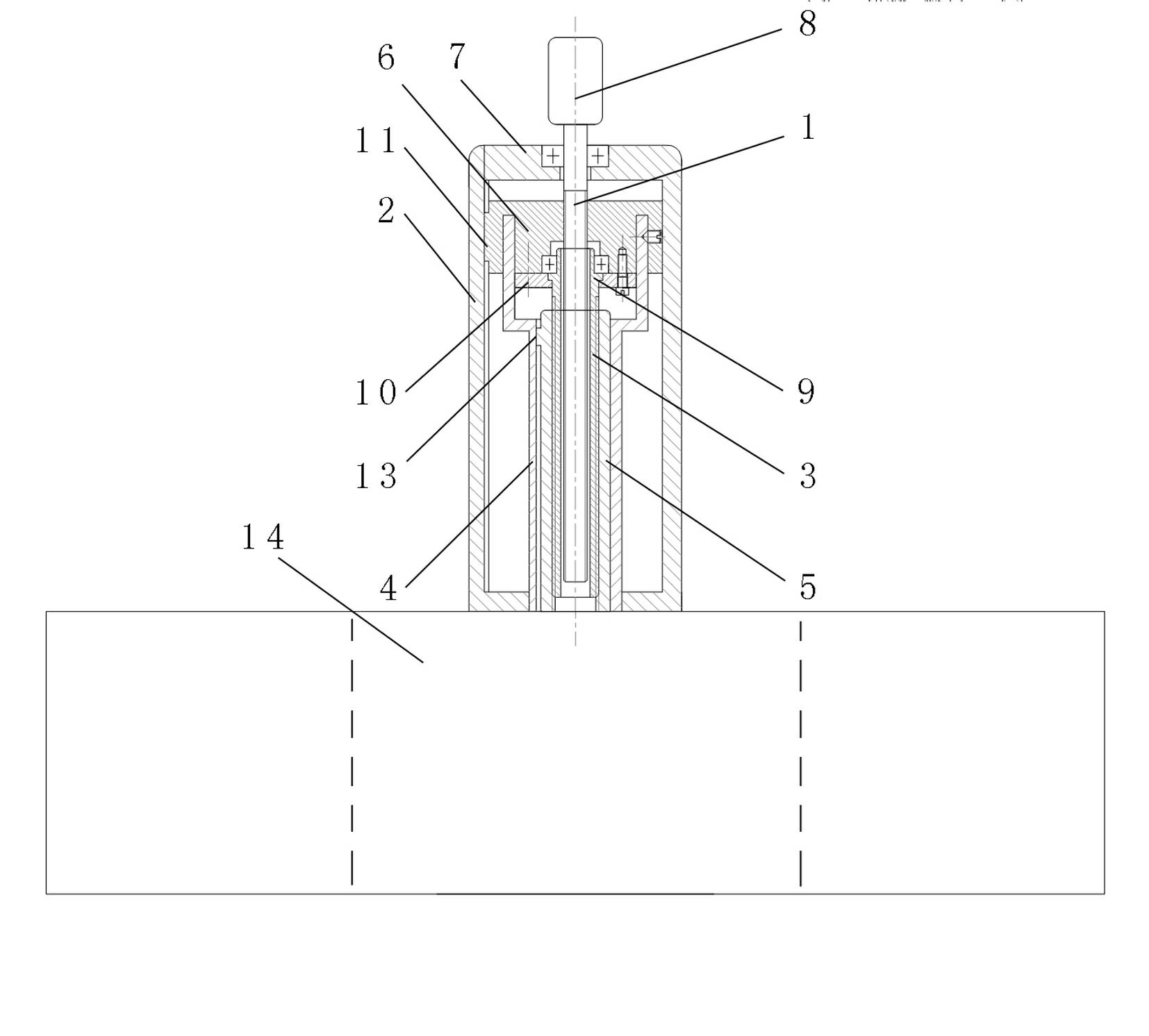

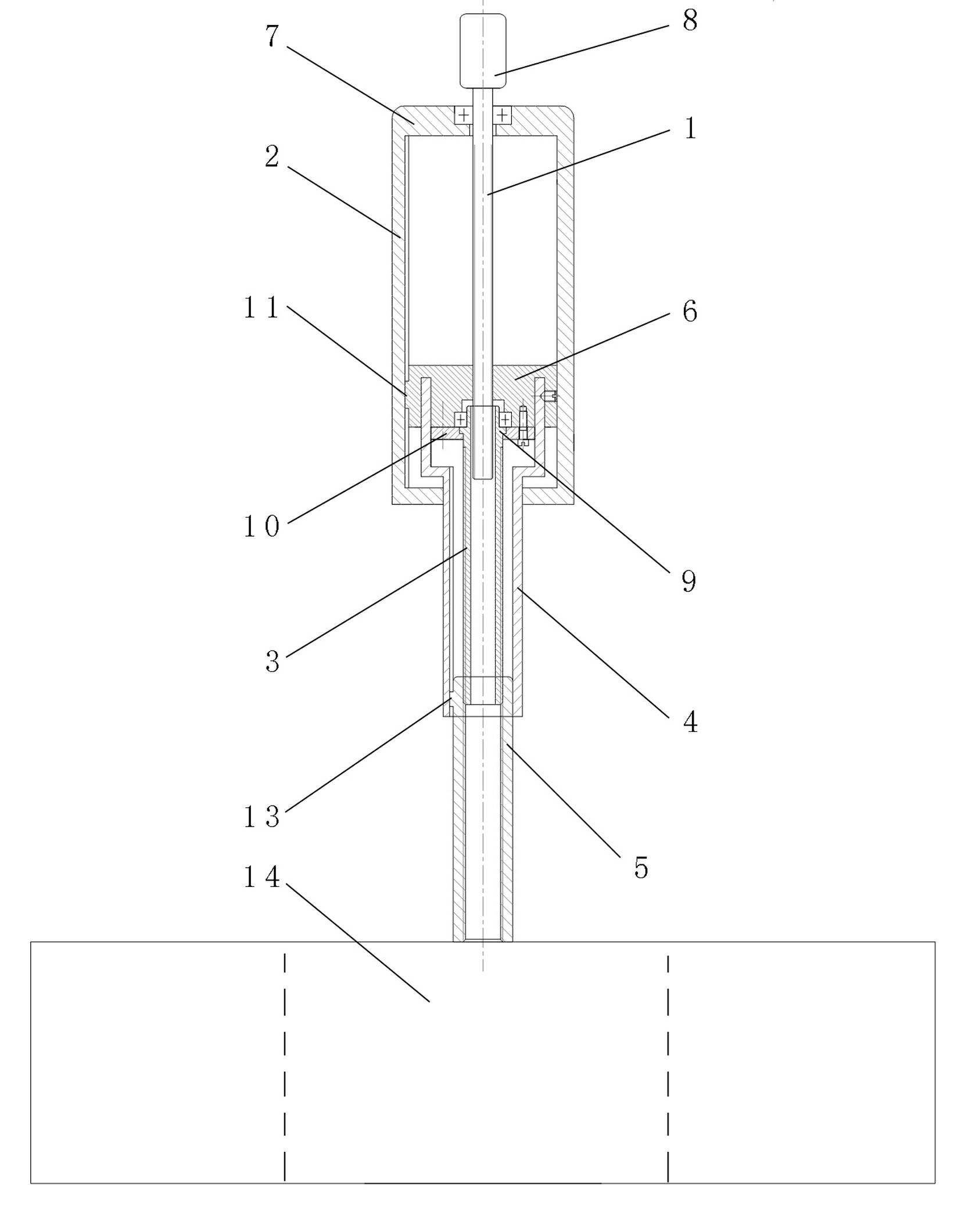

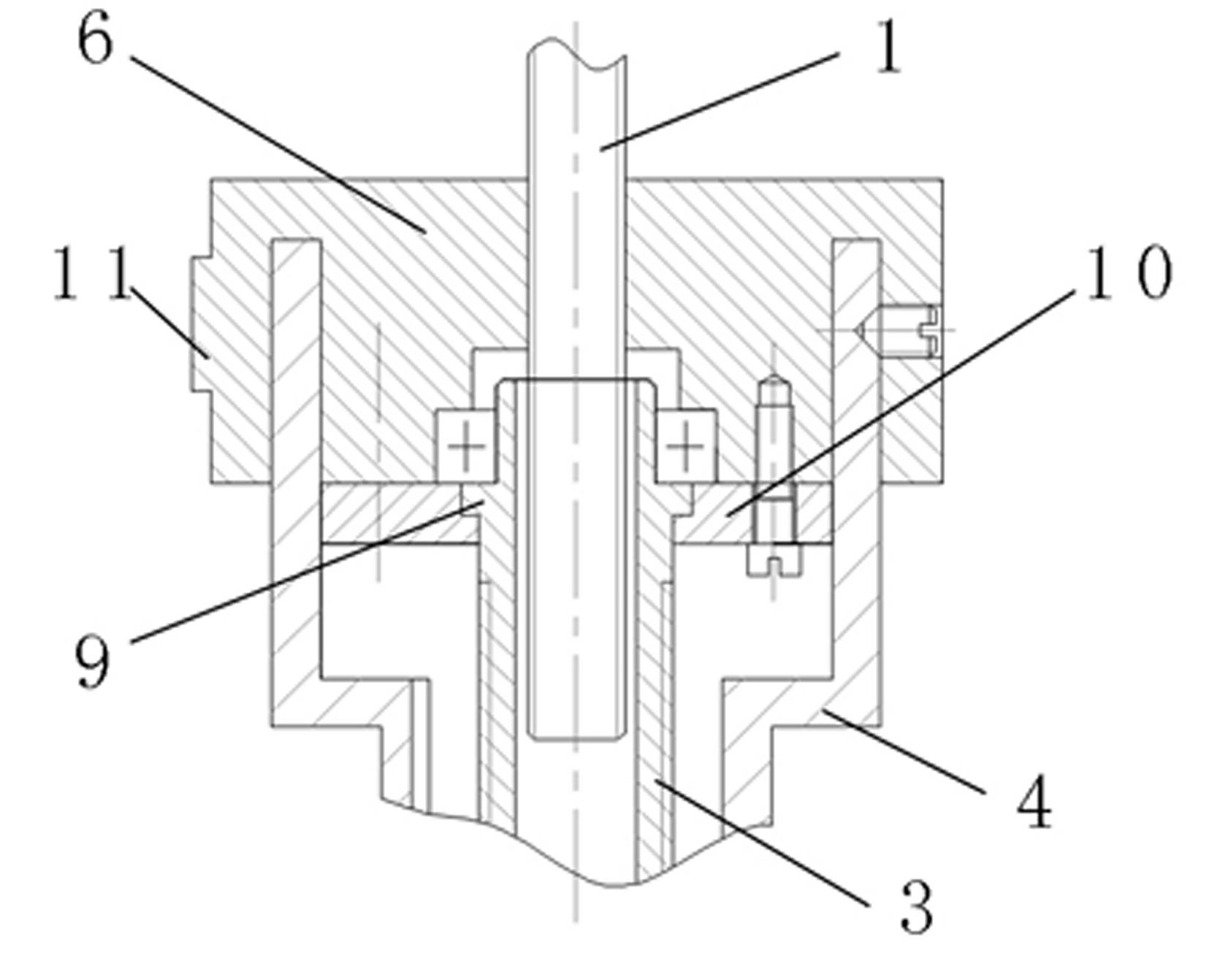

Shading tool for vehicle driving

InactiveCN102501745ATo achieve the purpose of anti-glareTo achieve the purpose of shadingAntiglare equipmentMotor driveElectric machinery

The invention discloses a shading tool for vehicle driving. The shading tool comprises a motor, an electric lifting device and a shading plate; the motor drives the electric lifting device; the electric lifting device is connected with the shading plate; the shading tool is characterized in that: the electric lifting device comprises multiple sections of casings which are sleeved into each other; the innermost layer of each casing is provided with a top pipe; and the tail end of each top pipe is connected with the shading plate through a connection device. Compared with the prior art, the shading tool has the characteristics of wide application range, simple structure, low cost and convenience in popularization.

Owner:董建书

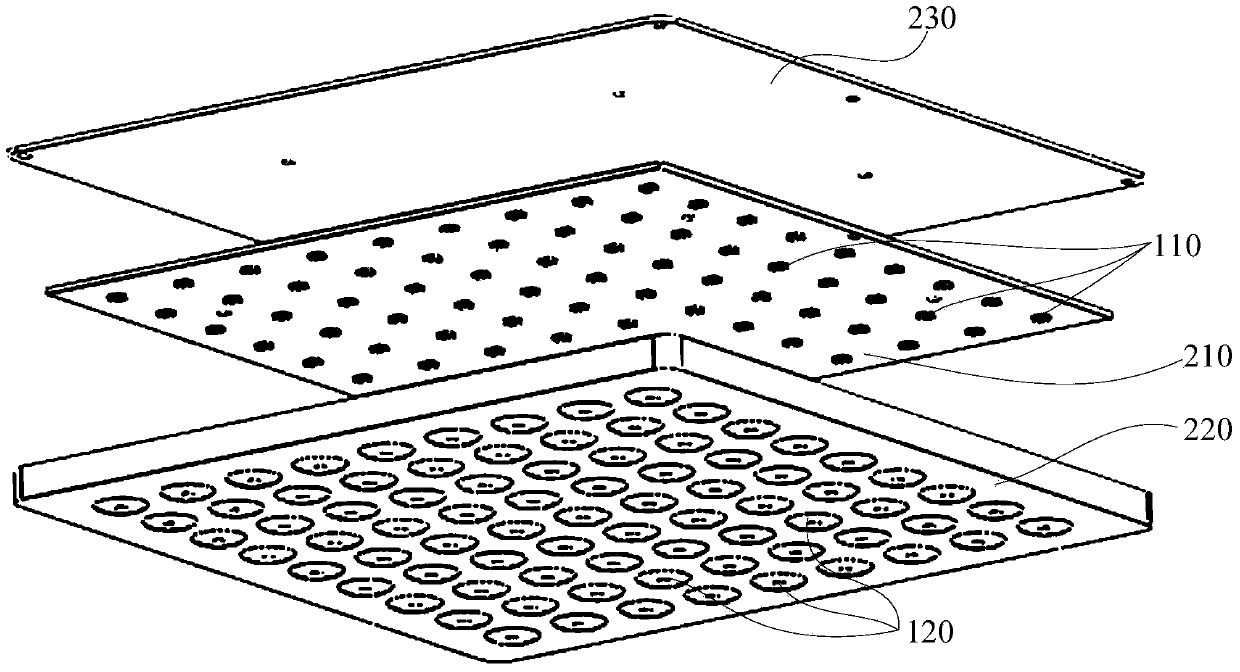

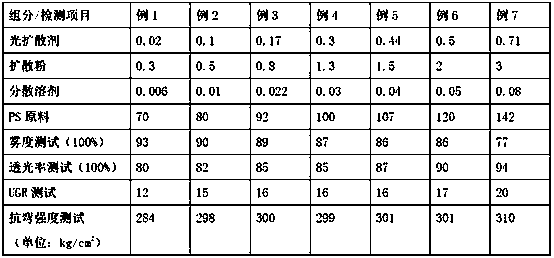

Preparation process of anti-dazzle diffusion plate

InactiveCN108873127AImprove experienceGlare suppressionDiffusing elementsOptical articlesHoneycombHoneycomb like

The invention relates to the technical field of illumination, in particular to a preparation process of an anti-dazzle diffusion plate. The preparation process comprises the steps of the steps of selecting 80 -120 parts of PS raw materials in parts by weight, adding a 0.1 to 0.5 parts light diffusant in parts by weight into the PS raw material, stirring and mixing 0.5 to 2 parts of diffusion powder and 0.01 to 0.05 part of a dispersing agent in parts by weight to form a mixture; adopting an extrusion process, adding the mixture into an extrusion forming machine to be extruded to form a diffusion plate; carrying out embossing on the diffusion plate by adopting an embossing roller with the pattern as convex polygons to make a honeycomb-shaped diffusion plate with a concave polygon pattern, and selecting cutter for cutting the diffusion plate. The honeycomb-shaped diffusion plate can shield light rays in all directions, glare can be effectively inhibited when a user sees from all directions, and the purpose of preventing glare can be achieved. When the anti-dazzle diffusion plate manufactured by adopting the process and the formula is applied to practical application, the light sourceis comfortable and soft, light transmission is uniform, glare is effectively controlled, and user experience is better.

Owner:DONGGUAN XINJU OPTRONICS INC

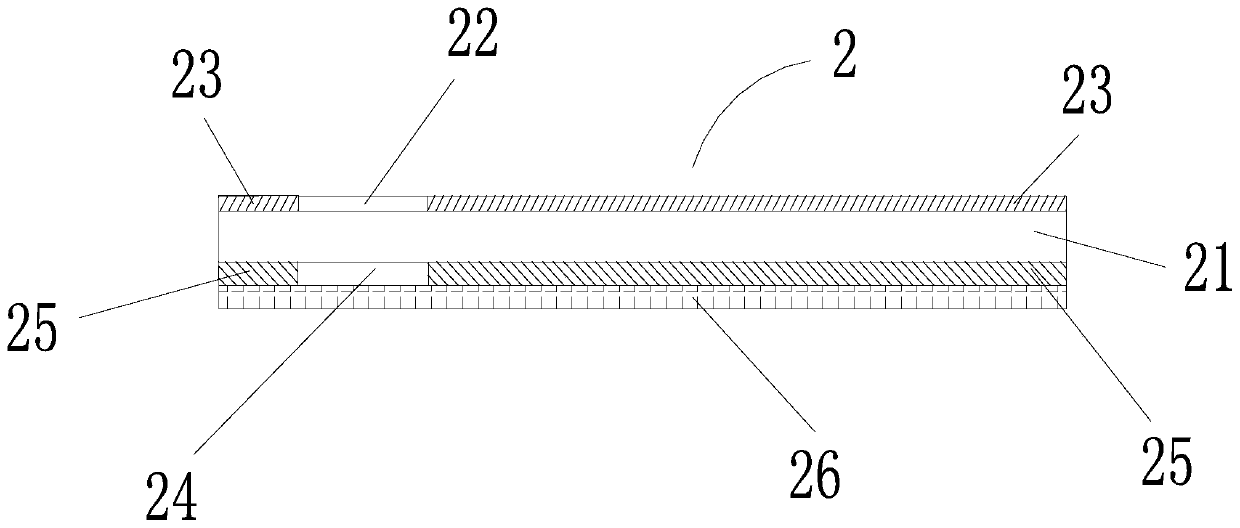

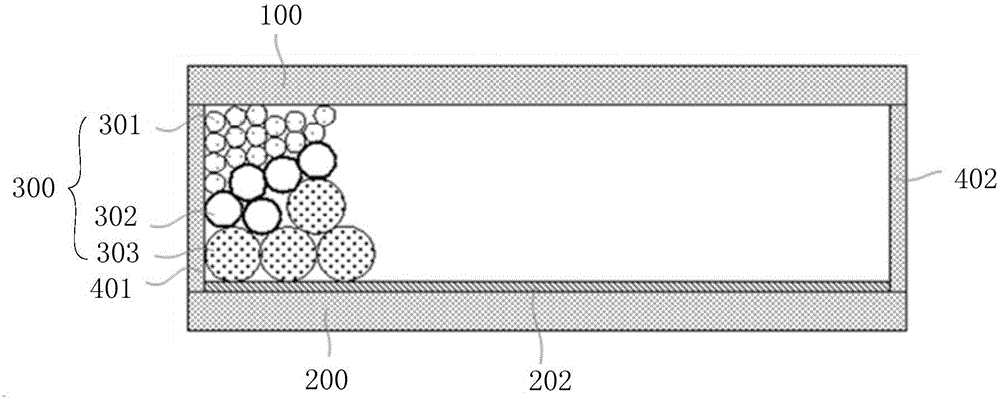

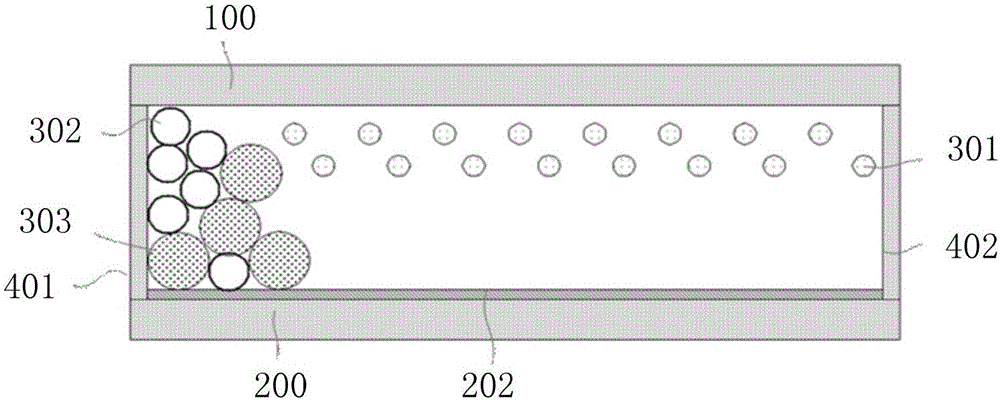

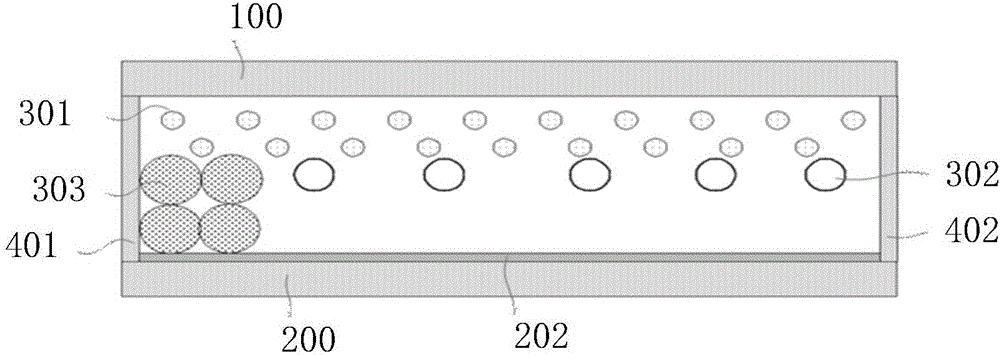

Anti-dazzling structure, anti-dazzling rearview mirror and vehicle

ActiveCN106427792AReduce light intensityTo achieve the purpose of anti-glareOptical viewingOptoelectronicsField of view

The invention provides an anti-dazzling structure, an anti-dazzling rearview mirror and a vehicle. The anti-dazzling structure comprises a first light-transmitting substrate, a second substrate for reflecting light transmitted from the first substrate, multiple micro capsules and a control mechanism capable of controlling the motion direction of the multiple micro capsules, wherein the second substrate and the first substrate are arranged oppositely and form a cavity, and the multiple micro capsules are arranged in the cavity, can move in the cavity and have a first state and a second state. In the first state, the micro capsules move in the direction in which an edge zone of the first substrate and an edge zone of the second substrate are located under the control of the control mechanism and are gathered in the edge zone of the first substrate and the edge zone of the second substrate. In the second state, at least partial micro capsules move to a middle zone of the first substrate and a middle zone of the second substrate under the control of the control mechanism. The anti-dazzling structure can provide multiple functional applications, has wide display purpose and does not affect a running view field.

Owner:BOE TECH GRP CO LTD +1

High performance antiglare film

InactiveCN105062328AStrong adhesionGood weather resistancePolyurea/polyurethane coatingsEpoxy resin coatingsALUMINUM STEARATESPolymer science

The invention discloses a high performance antiglare film. The raw materials include: a fluorine-containing epoxy acrylate oligomer, a fluorine-containing polyurethane acrylate oligomer, polycarbonate, styrene, hydroxyethyl methacrylate, N-vinyl pyrrolidone, pentaerythritol triarylate, glycerol monostearate, sorbitol, polyethylene glycol, nano-titanium dioxide, nano-silica, aluminum stearate, aluminum-doped zinc oxide, vinyl-tri(2-methoxyethoxy)silane, sodium dodecyl benzene sulfonate, 1-hydroxycyclohexyl phenyl ketone, triphenylphosphine oxide, phenolic resin, amino resin, an additive, and a solvent. The high performance antiglare film provided by the invention has high adhesion with the substrate, good scratch resistance, and excellent anti-static, antiglare and anti-radiation effects.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

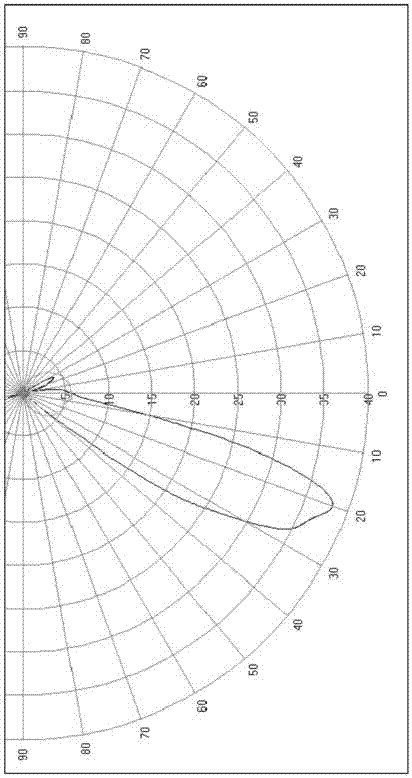

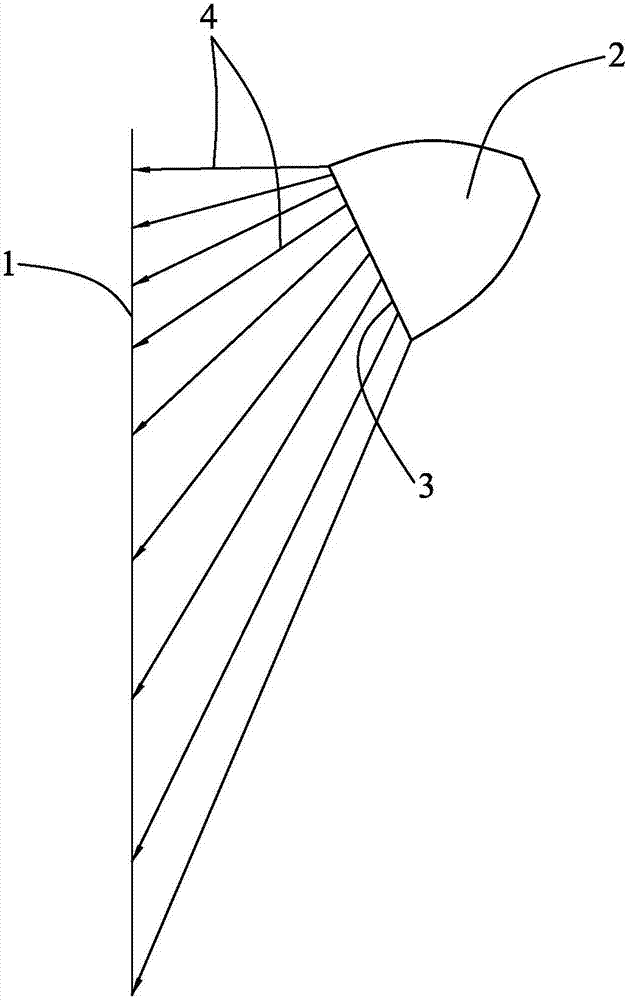

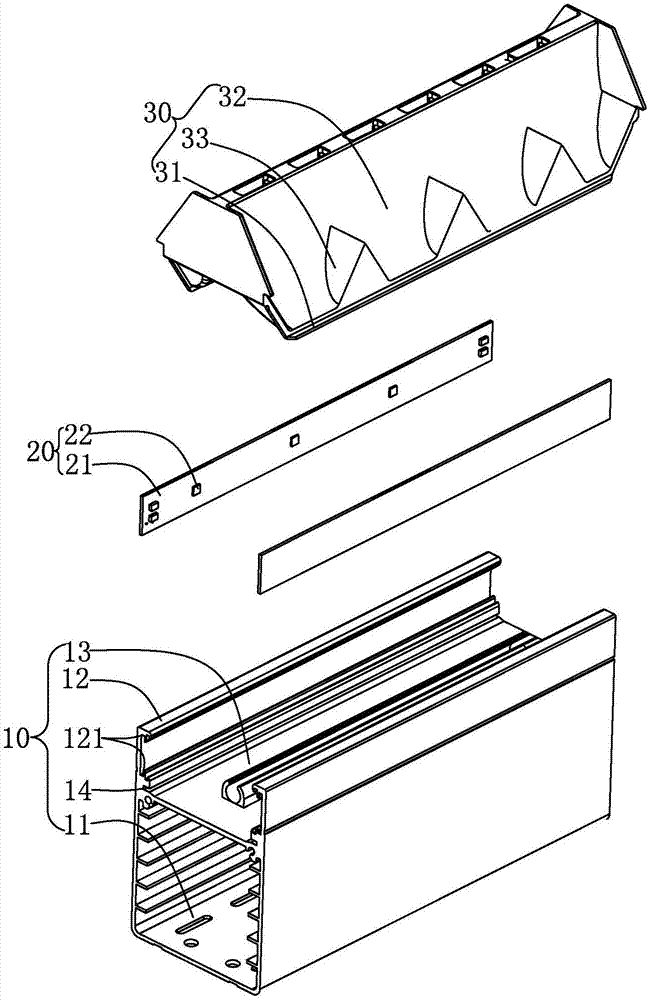

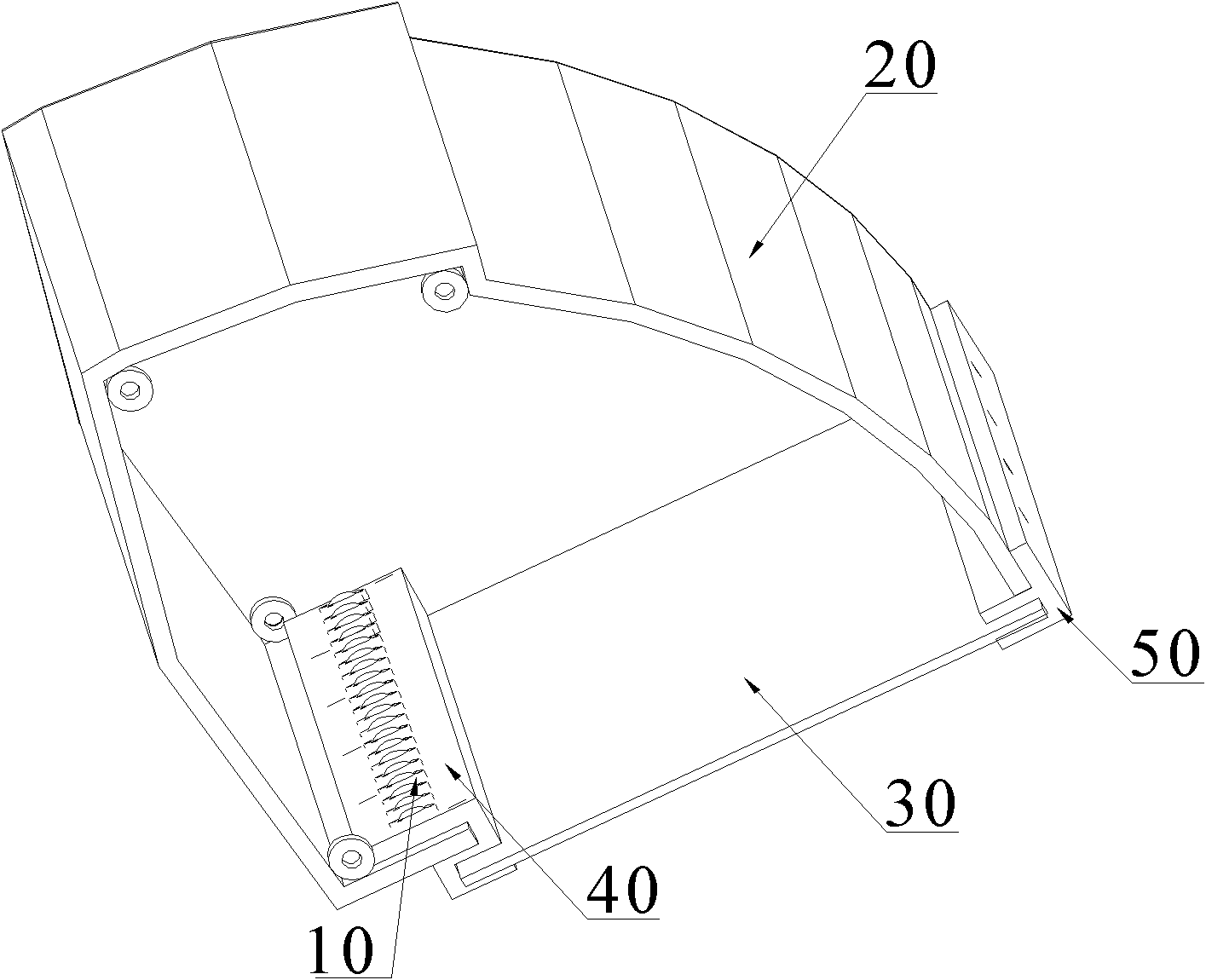

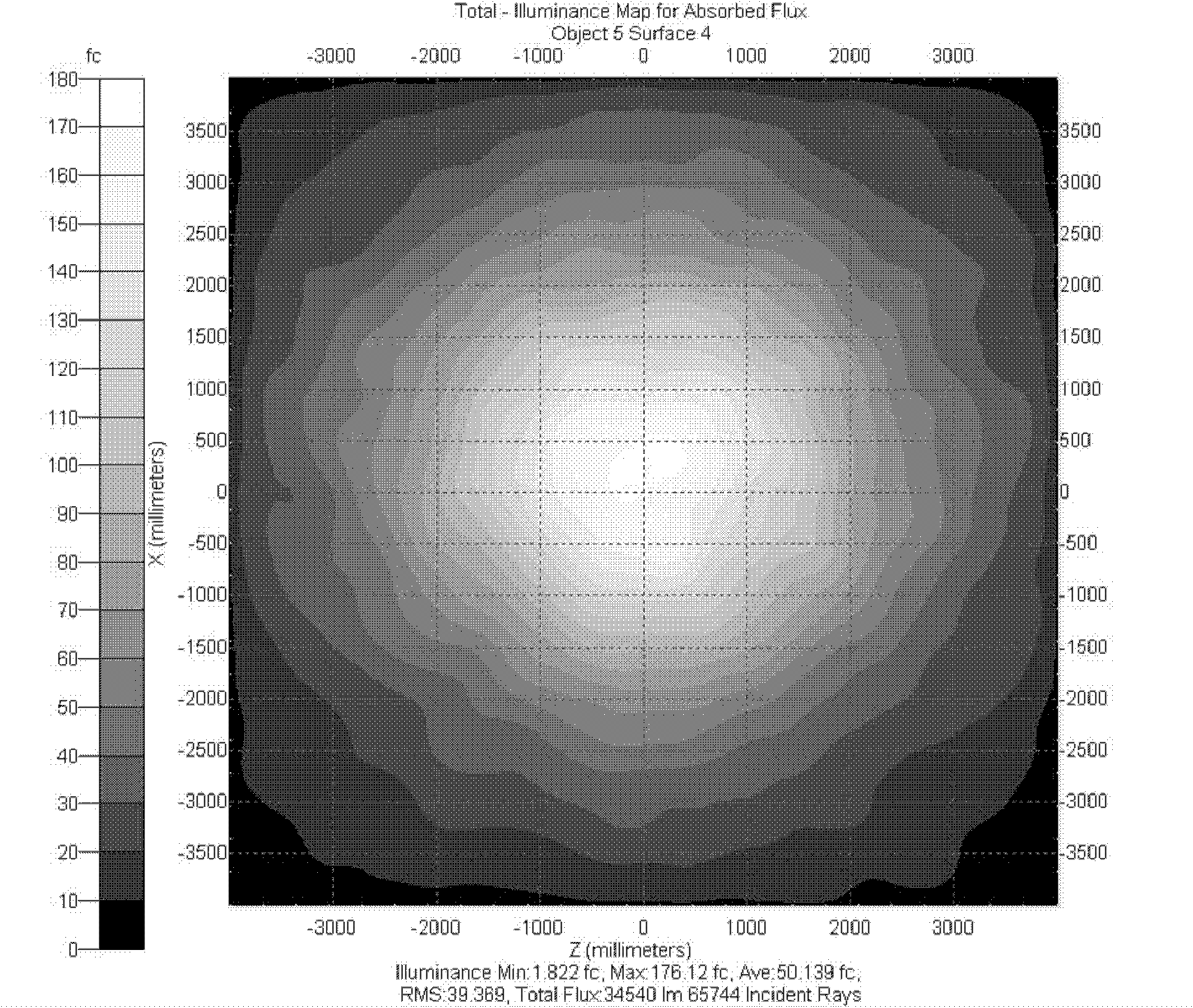

Light distribution system for strip-shaped LED lamp

PendingCN107091420AImprove lighting experienceIncrease desire to shopLighting applicationsMechanical apparatusIlluminanceShortest distance

The invention discloses a light distribution system for a strip-shaped LED lamp. The light distribution system for the strip-shaped LED lamp comprises a light source module, a light-reflecting device and an irradiated surface. The light source module comprises at least one LED chip. The light-reflecting device comprises a front light-reflecting surface, the front light-reflecting surface comprises a ground irradiation section used for irradiating the ground, a long-distance section and a short-distance section, and the optical axis is intersected with the contour line of the long-distance section. The ground irradiation section comprises a first curvature, the long-distance irradiation section comprises a second curvature, the short-distance irradiation section comprises a third curvature, the first curvature is greater than the second curvature, and the second curvature is greater than the third curvature. According to the light distribution system for the strip-shaped LED lamp, the main irradiated surface can obtain the basically same illuminance in the vertical direction thereof under the mutual matching of the long-distance irradiation section and the short-distance irradiation section of the light-reflecting device, so that the light use experience of a user can be greatly improved, and the shopping desire of the user is increased.

Owner:SELF ELECTRONICS CO LTD

Anti-dazzle film special for anti-dazzle glass

InactiveCN105038523AGood adhesion and weather resistanceHigh light transmittancePolyurea/polyurethane coatingsEpoxy resin coatingsChemistryBenzene

The invention discloses an anti-dazzle film special for anti-dazzle glass. The anti-dazzle film comprises epoxy acrylate oligomer, urethane acrylate oligomer, polycarbonate, styrene, methyl methacrylate, trimethylolpropane triacrylate, polyethylene glycol, tri-isopropylphenyl phosphate, nano-titanium dioxide, nanosilicon dioxide, aluminum stearate, fluorine-doped tin oxide, ethyl acetate, glycerol, ethanediol, toluene, 1,3-bis(trifluoromethyl)-benzene, silane coupling agent, sodium dodecyl benzene sulfonate, 1-hydroxyl cyclohexyl phenyl ketone, benzophenone, amino resin and auxiliaries. The anti-dazzle film special for anti-dazzle glass is high in adhesion with a substrate, does not drop easily in the using process and is good in scratch resistance and high in transparency, and the yield of the anti-dazzle glass prepared from the anti-dazzle film is high.

Owner:ANHUI HERUN SPECIAL GLASS CO LTD

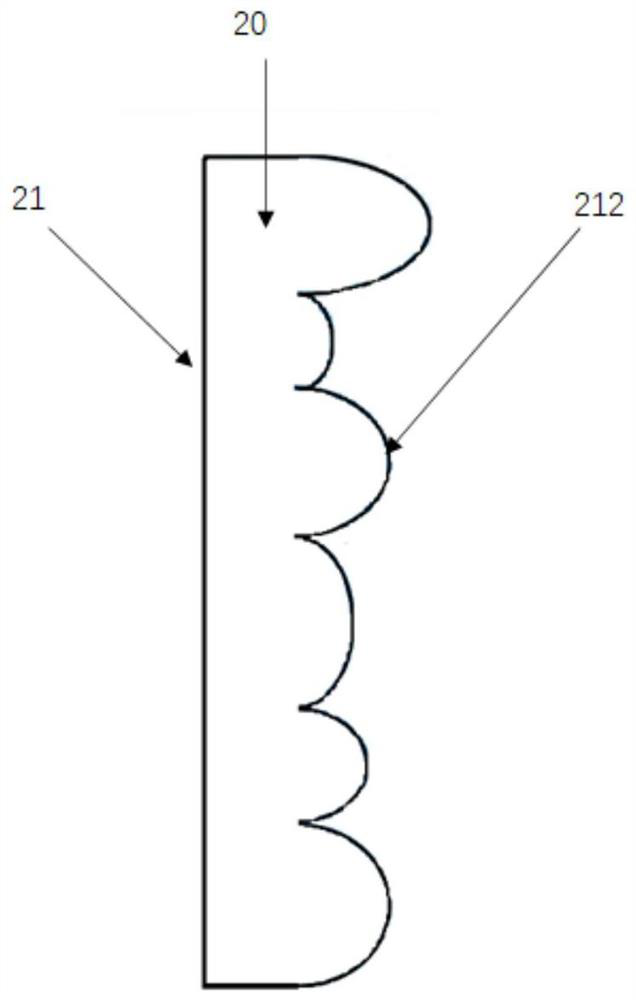

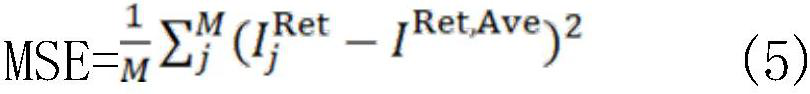

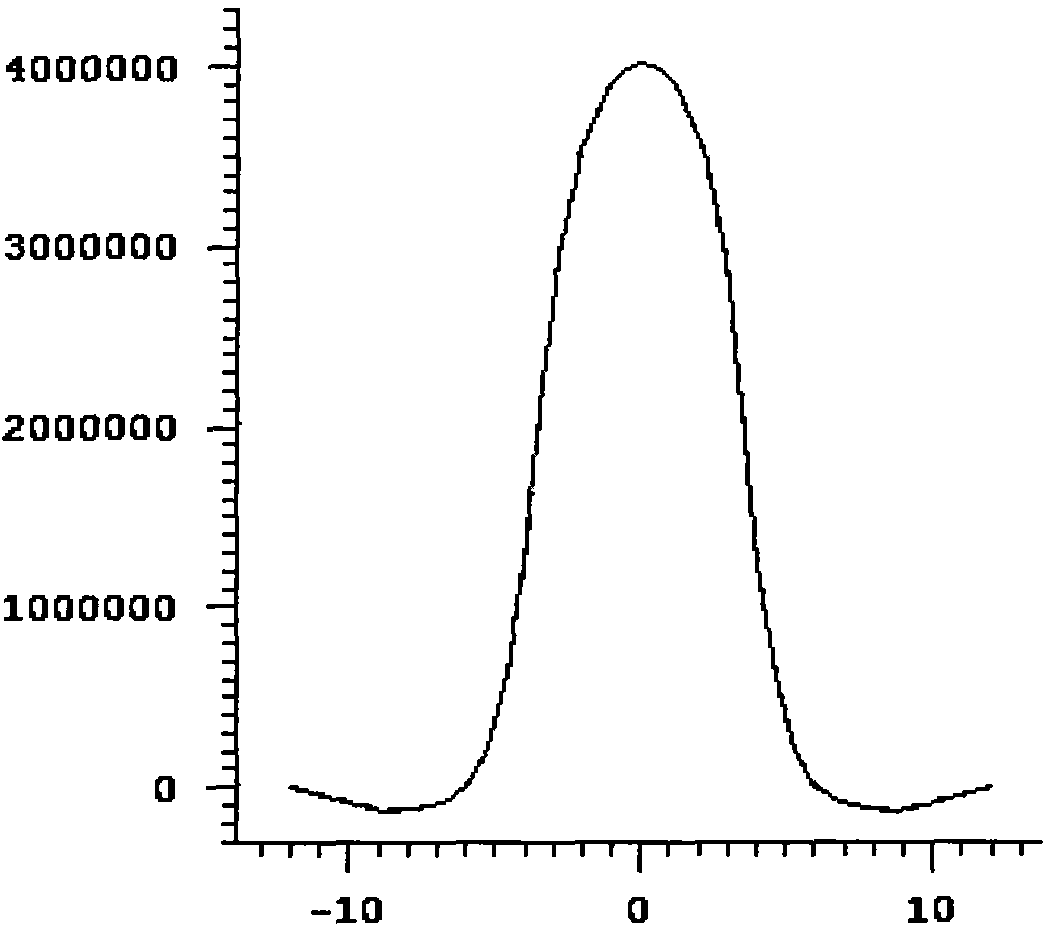

Transparent optical element and method for adjusting light field to penetrate through transparent optical element

The invention provides a transparent optical element and a method for adjusting a light field penetrating through the transparent optical element. The adjusting method comprises the following steps: S1, carrying out light field tracing on incident light entering a micro-lens array of the transparent optical element; s2, performing light field tracing on the first incident light field through emergent light of a micro-lens array of the transparent optical element; s3, the second incident light field penetrates through the crystalline lens of the observer and forms emergent light, the emergent light is tracked, and the emergent light passes through the retina of the observer and forms a projection light field; s4, obtaining the intensity of a light field distributed on the retina of the observer; and S5, according to the light field intensity distributed on the retina of the observer, obtaining the mean square error of the pixel intensity distribution of the retina of the observer, and performing optimization by taking the minimum value of the mean square error as a target. According to the invention, the randomly distributed micro-lens array is utilized to realize glare elimination based on the reflection principle, and a light field passes through the surfaces of the micro-lenses, so that the mirror reflection energy is greatly reduced, and the anti-glare effect is achieved.

Owner:深圳市雕拓科技有限公司

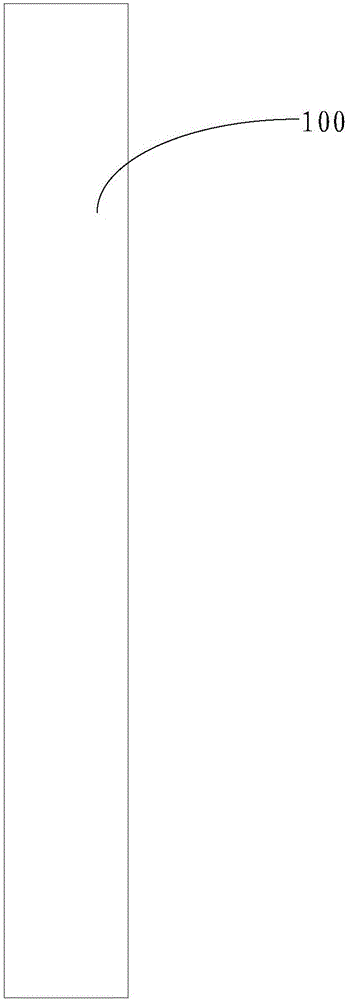

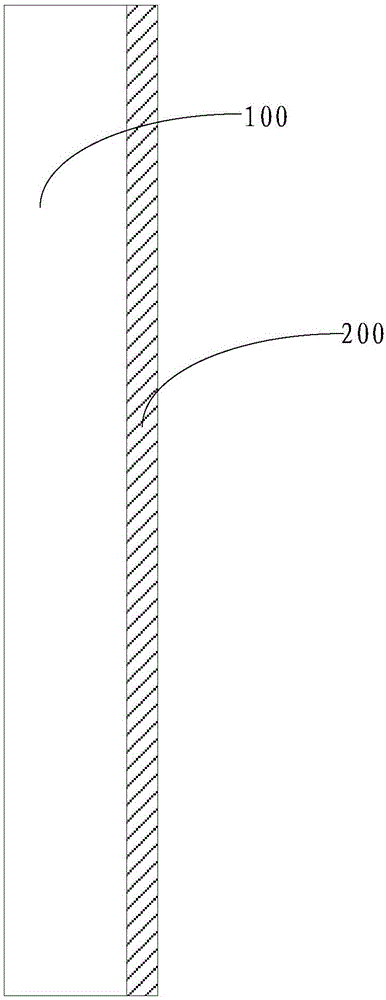

Cover plate for intelligent terminal, manufacturing method thereof, and intelligent terminal

InactiveCN107182180AExtended service lifeTo achieve the purpose of anti-glareCasings/cabinets/drawers detailsEngineeringColor film

The invention discloses a cover plate for an intelligent terminal, a manufacturing method thereof, and an intelligent terminal. The manufacturing method includes providing a cover plate body; forming an AG processing layer on the surface at one side of the cover plate body; forming a pattern layer at one side, far from the cover plate body, of the AG processing layer; plating a color film layer at one side, far from the cover plate body, of the pattern layer; and forming a protective film layer at one side, far from the cover plate body, of the color film layer. From the above, the technical scheme of the invention, different requirements of people for the exterior are met by preparing different pattern layers and different color film layers; the color film layer can be prevented from being damaged by arranging the protective layer at one side, far from the cover plate, of the color film layer, and the service life of the cover plate is prolonged; and the different requirements of people for the exterior are further satisfied by preparing the AG processing layer, and the purpose of anti-dazzle of the cover plate can be achieved.

Owner:TRULY OPTO ELECTRONICS

led optical system and lamps

ActiveCN103994395BIncrease light emitting areaSufficient optical utilizationPlanar light sourcesSemiconductor devices for light sourcesOptoelectronicsPoint light source

An LED optical system comprises a light emitting element and an anti-glare substrate. The anti-glare substrate comprises a light entering surface, a reflecting surface and a light emitting surface. The light entering surface faces the light emitting element, the reflecting surface is located between the light entering surface and the light emitting surface, and the orthographic projection, towards the light emitting surface, of the light entering surface and the orthographic projection, towards the light emitting surface, of the light emitting surface are located on the light emitting surface. The light emitting surface comprises a light emitting sub-surface which is a curved surface, and the light emitting sub-surface is located on the central region of the light emitting surface and protrudes away from the light entering surface. The light emitting surface comprises the light emitting sub-surface which is the curved surface, the light emitting sub-surface is located on the central region of the light emitting surface and protrudes away from the light entering surface, and therefore light located on the central region can be scattered and emitted and light nearby the central axis is weakened. Light emitted out of the light emitting surface after being reflected by the reflecting surface can compensate for the light nearby the central axis, a point light source is converted into a multi-surface light source to be emitted under the premise that the optical utilization rate is sufficient, the anti-glare purpose is achieved, and reliability is high.

Owner:SHENZHEN INST FOR INNOVATIVE DESIGN CO LTD

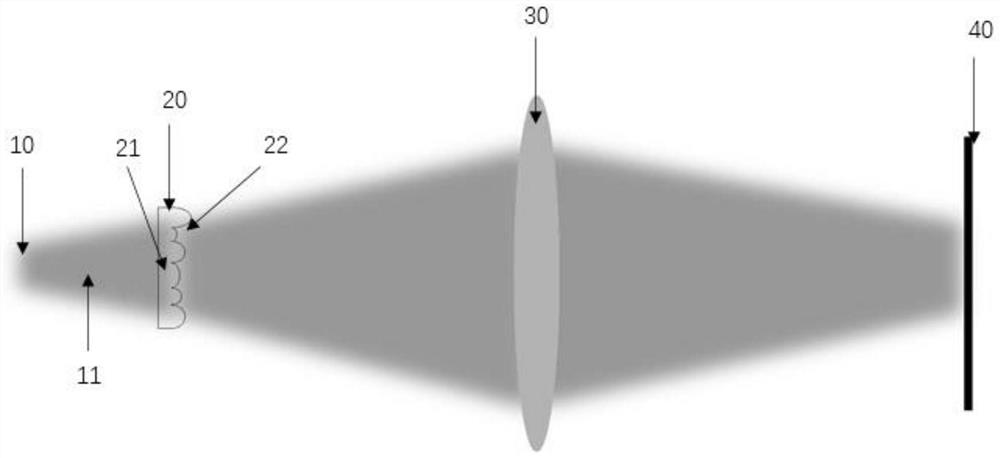

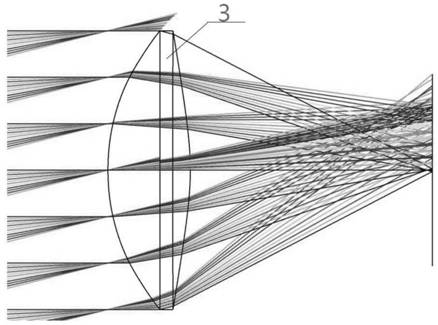

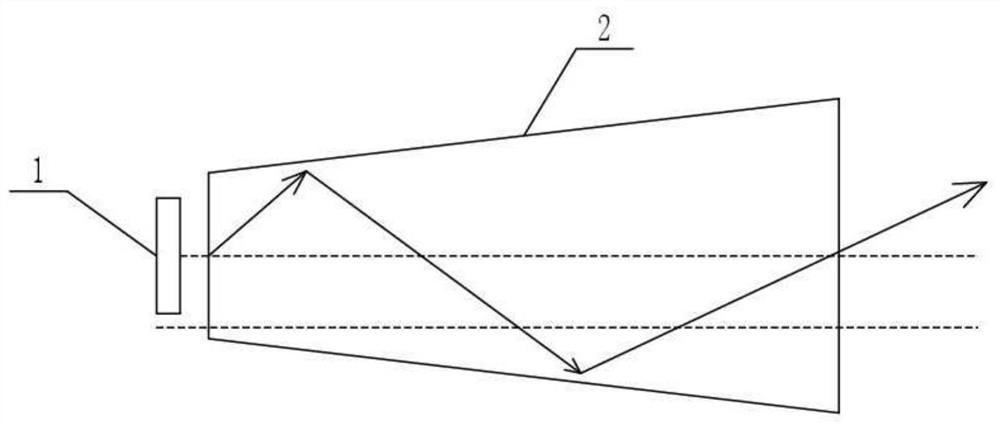

An anti-dazzle LED illuminating lamp and reflection structure thereof

InactiveCN102042492AGuaranteed lighting efficiencyCompact structurePoint-like light sourceElectric lightingOptoelectronicsLight source

The invention relates to an anti-dazzle LED illuminating lamp and a reflection structure thereof. The LED illuminating lamp comprises a reflector and a LED light source which is positioned at the bottom of the reflector; wherein, a beam splitter which can divide a light beam emitted from the LED light source into a transmitted light beam and a reflected light beam between which the light intensity ratio is predetermined; the reflected light is reflected again by the reflector to illuminate together with the transmitted light. According to the invention, the beam splitter is employed to decrease the center intensity of the light source of the lamp, then the reflector is employed to distribute light beams, so that not only can the objective of dazzle prevention be realized to allow people to feel comfortable without being dazzled when they stare directly at the LED illuminating lamp, but also the illumination efficiency of the lamp can be ensured, meanwhile, the integral lamp can have a compact structure.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Anti-dazzle self-repairing mobile phone screen protection film

The invention discloses an anti-dazzle self-repairing mobile phone screen protection film. The anti-dazzle self-repairing mobile phone screen protection film is prepared from the following raw materials: a self-repairing polyurethane elastomer, low-density polyethylene, PMMA (Polymethyl Methacrylate), nano silicon oxide, an ultraviolet light absorber, a surfactant, an antioxidant, a flame retardant, a cross-linking agent and a flatting agent. The obtained anti-dazzle self-repairing mobile phone screen protection film has excellent anti-dazzle and self-repairing capabilities and long service life, the ultimate tensile strength of the anti-dazzle self-repairing mobile phone screen protection film reaches 11.5 MPa, the elongation at break of the anti-dazzle self-repairing mobile phone screen protection film can reach 374%, a mobile phone screen can be effectively protected and prevented from being broken, and the anti-dazzle self-repairing mobile phone screen protection film has good light permeability and clear display effect while preventing dazzle.

Owner:赵敏

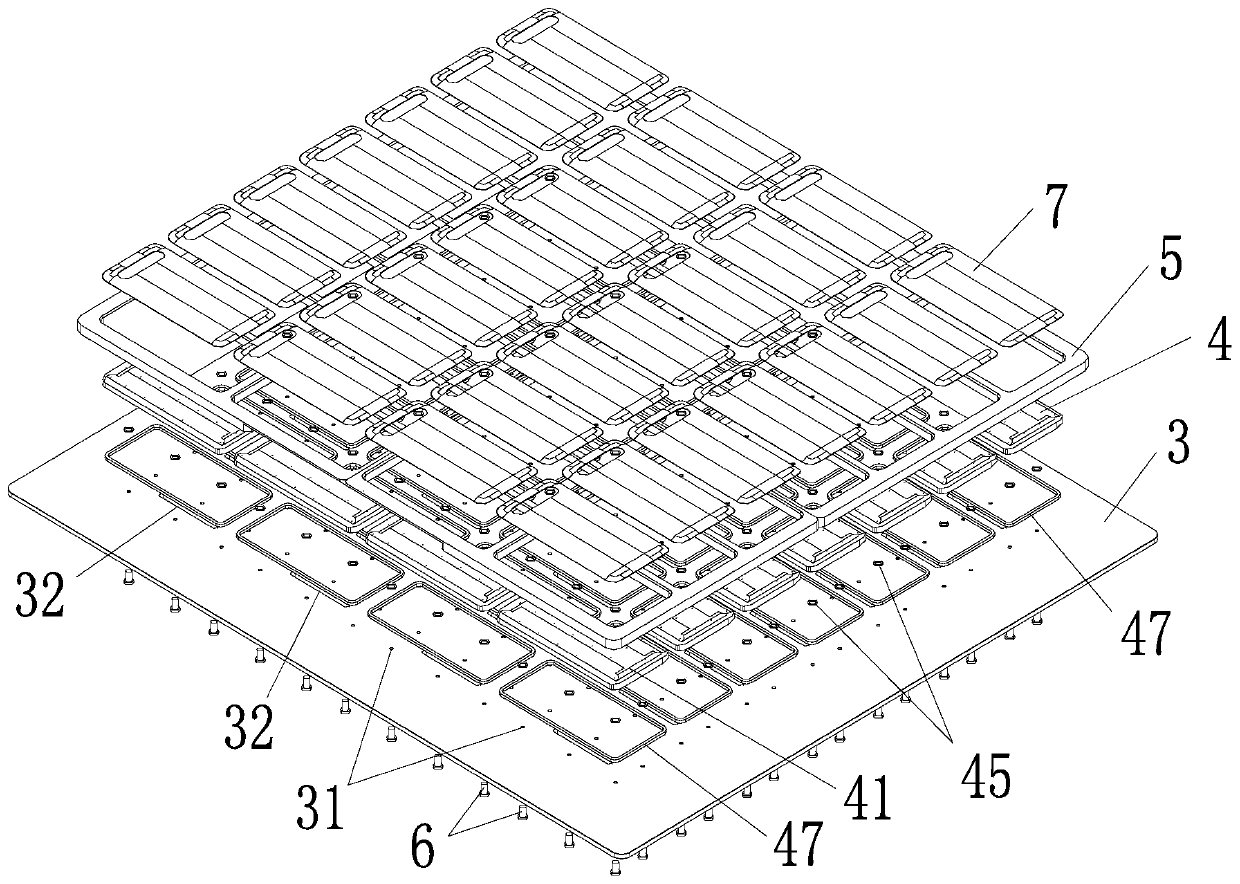

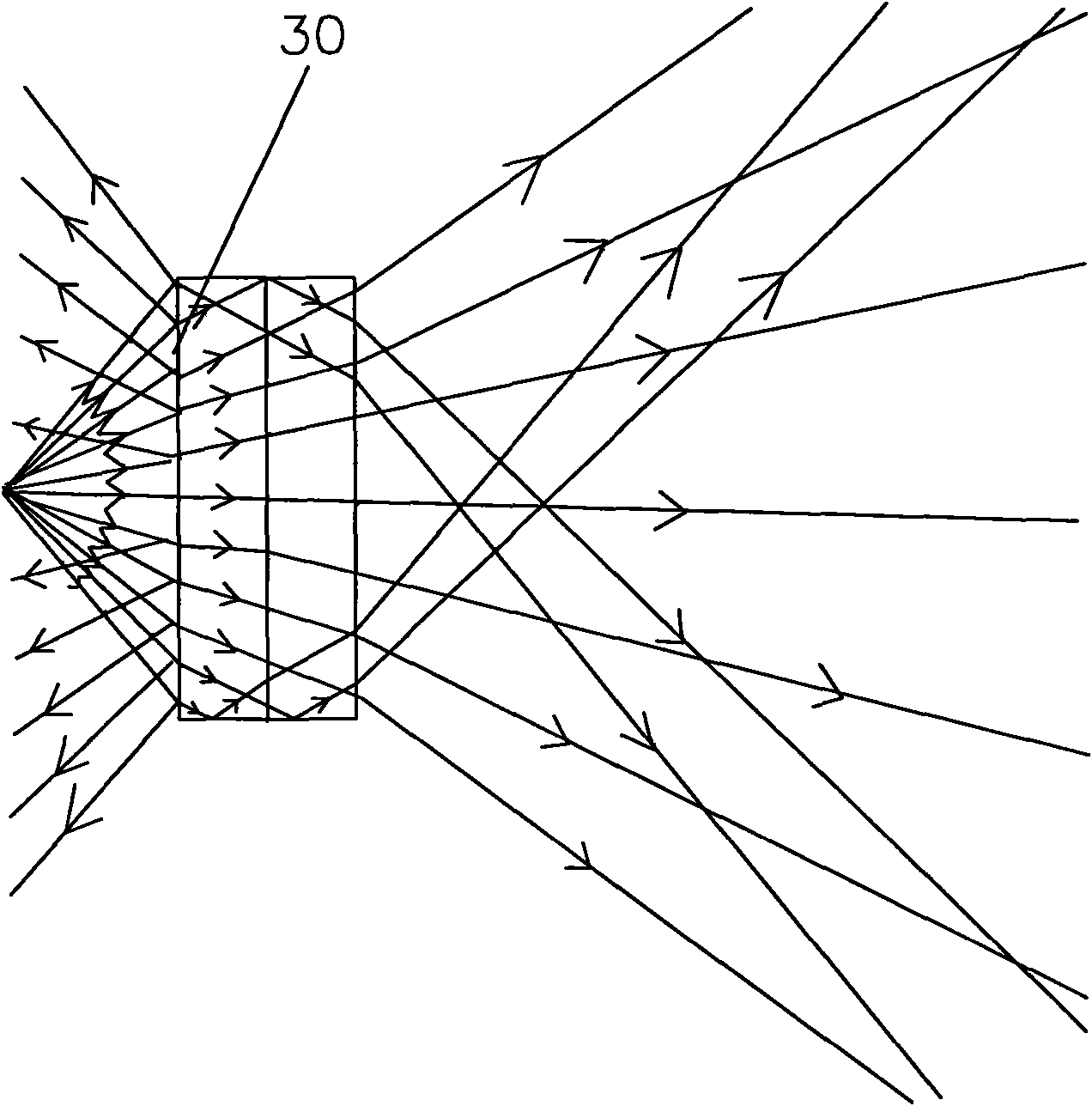

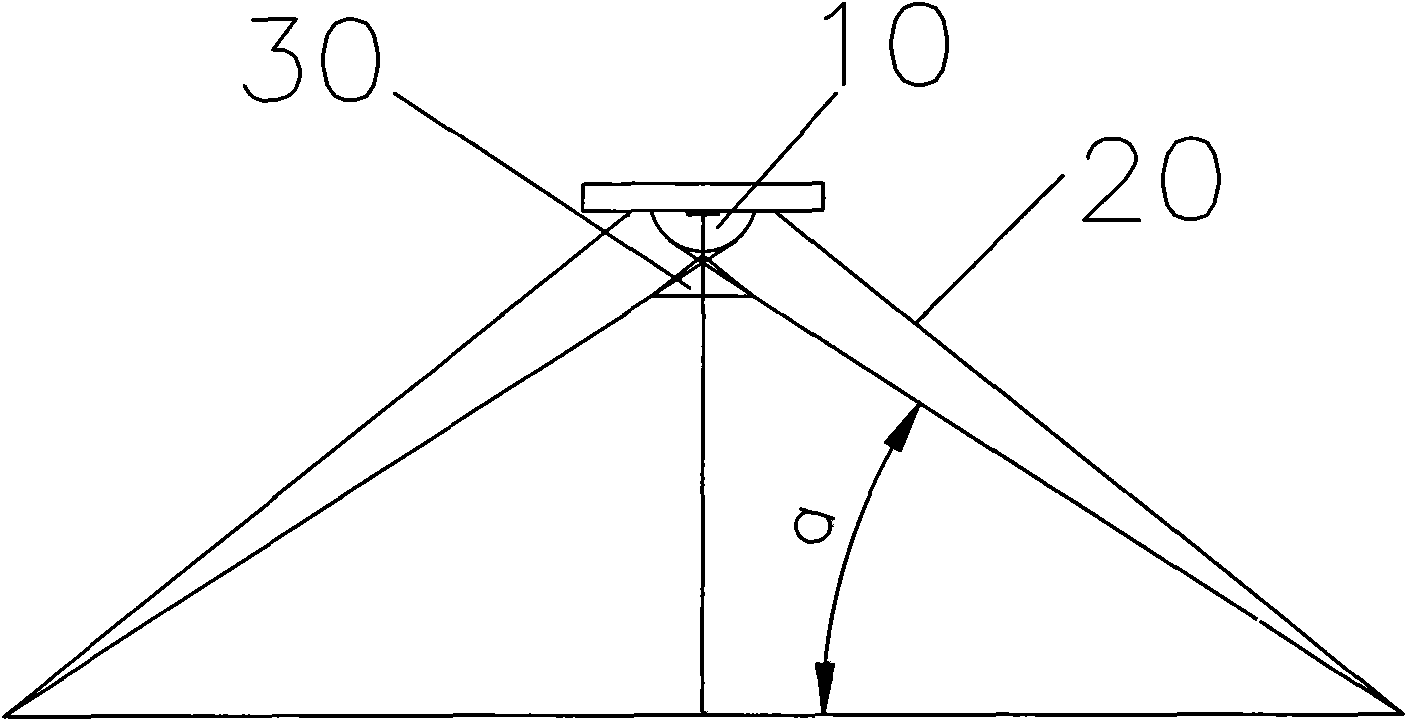

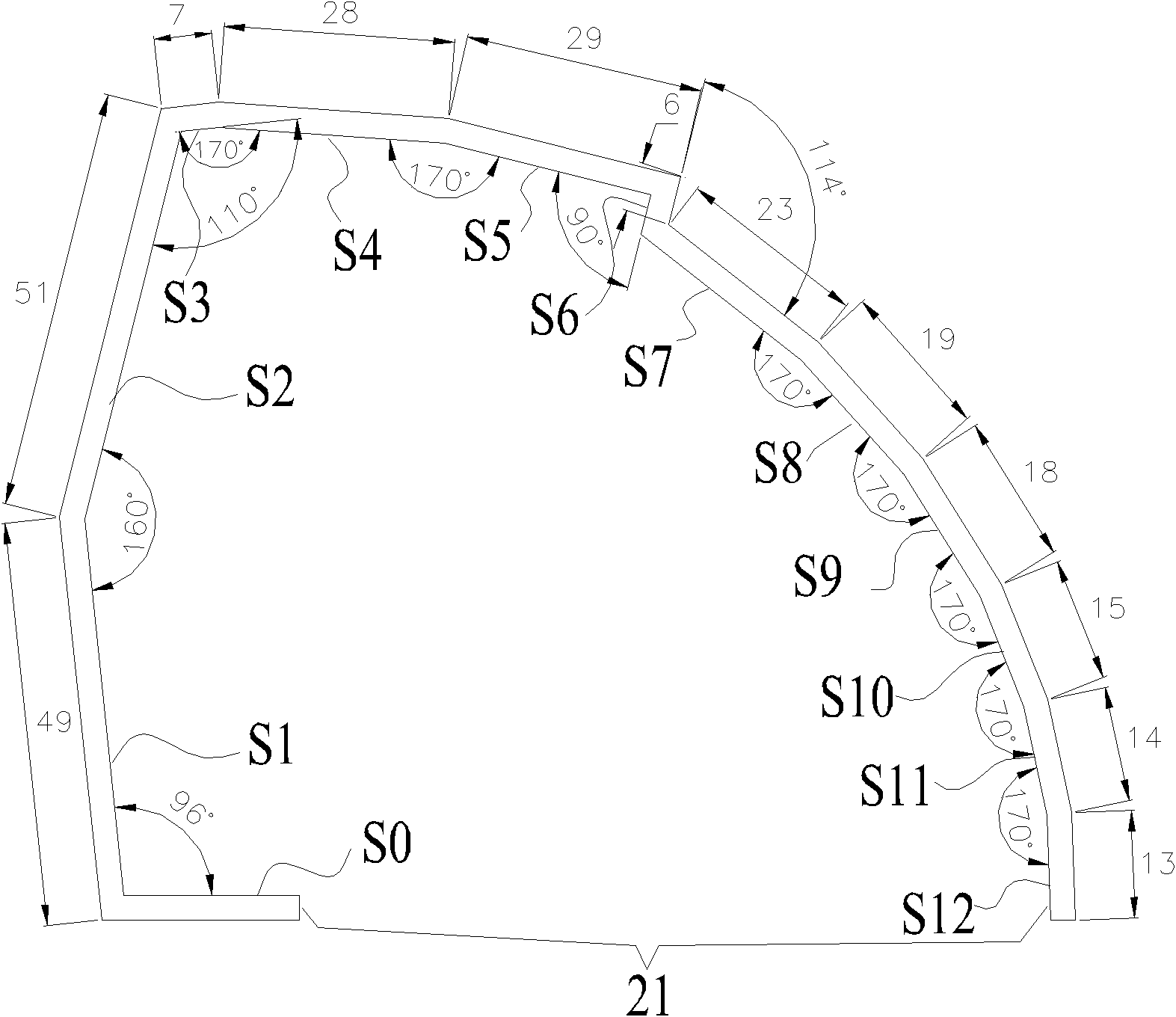

Matrix type vehicle lamp optical device

PendingCN112146049AImprove securityImprove comfortPlanar light sourcesVehicle headlampsLight spotEngineering

The invention relates to a matrix type vehicle lamp optical device which comprises an optical area of a high beam composed of 42 LEDs, a conical square rod and an imaging lens, the 42 LEDs are controlled to emit light independently, 42 rectangular light spots are generated in a near field through optical arrangement of the 42 LEDs and the conical square rod, and the imaging lens images the 42 rectangular light spots generated in the near field to the distance. The projection angle of the high beam is achieved. A high beam light is divided into 42 lighting areas, and light of each area is controlled by a single LED. In the driving process, the auxiliary camera, the radar and other devices are used for detecting the driving condition in front, turning off the corresponding LEDs and controlling the distance light of the area, the anti-dazzling purpose is achieved, the driving safety is improved, and the driving comfort is also improved.

Owner:海瑞奥(苏州)光电有限公司

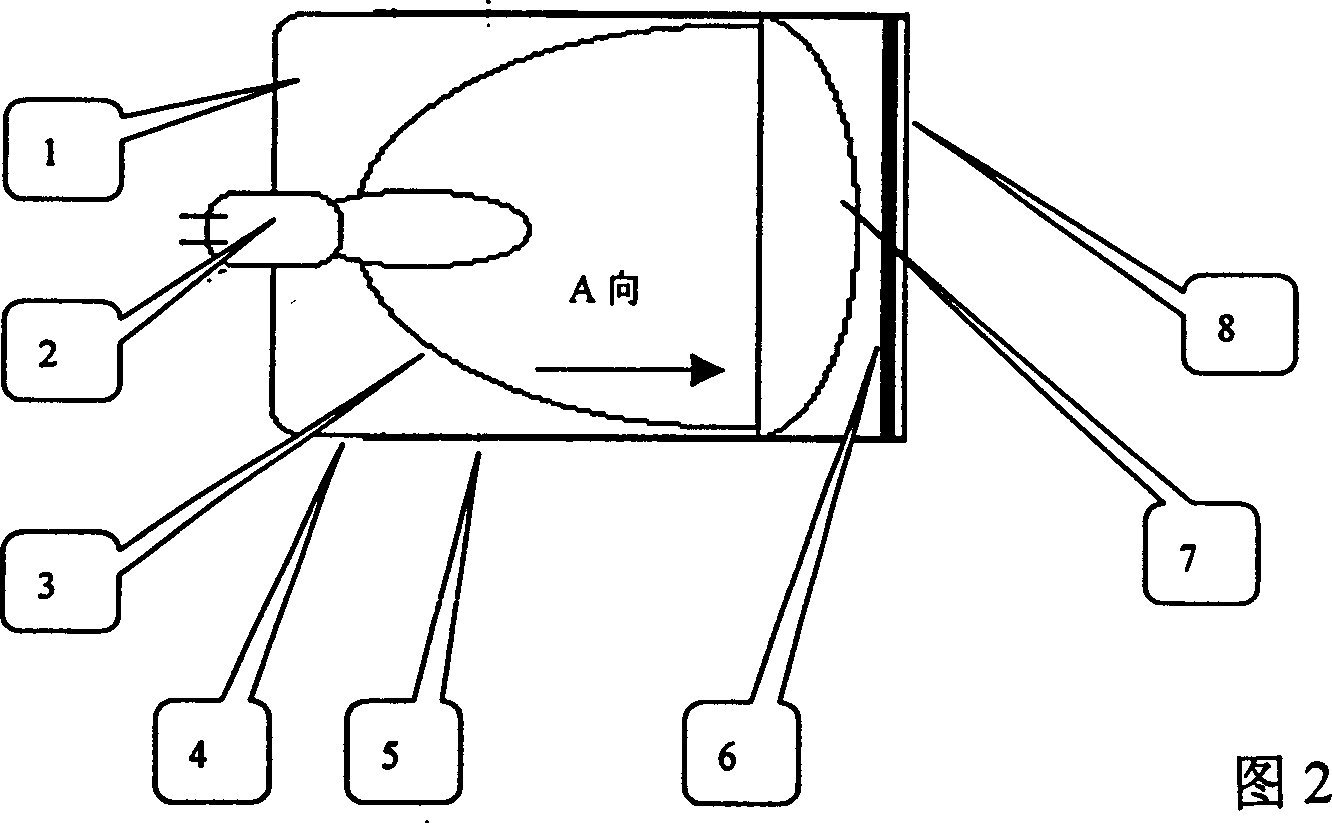

Automatic antiglare device for vehicle

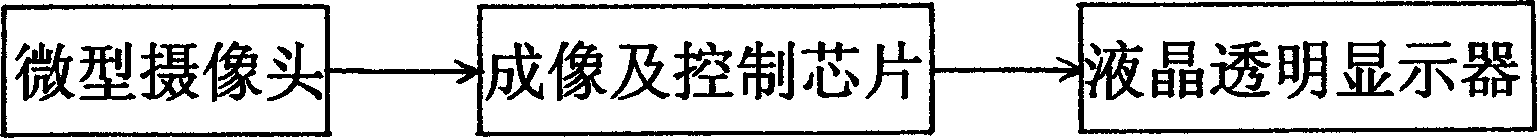

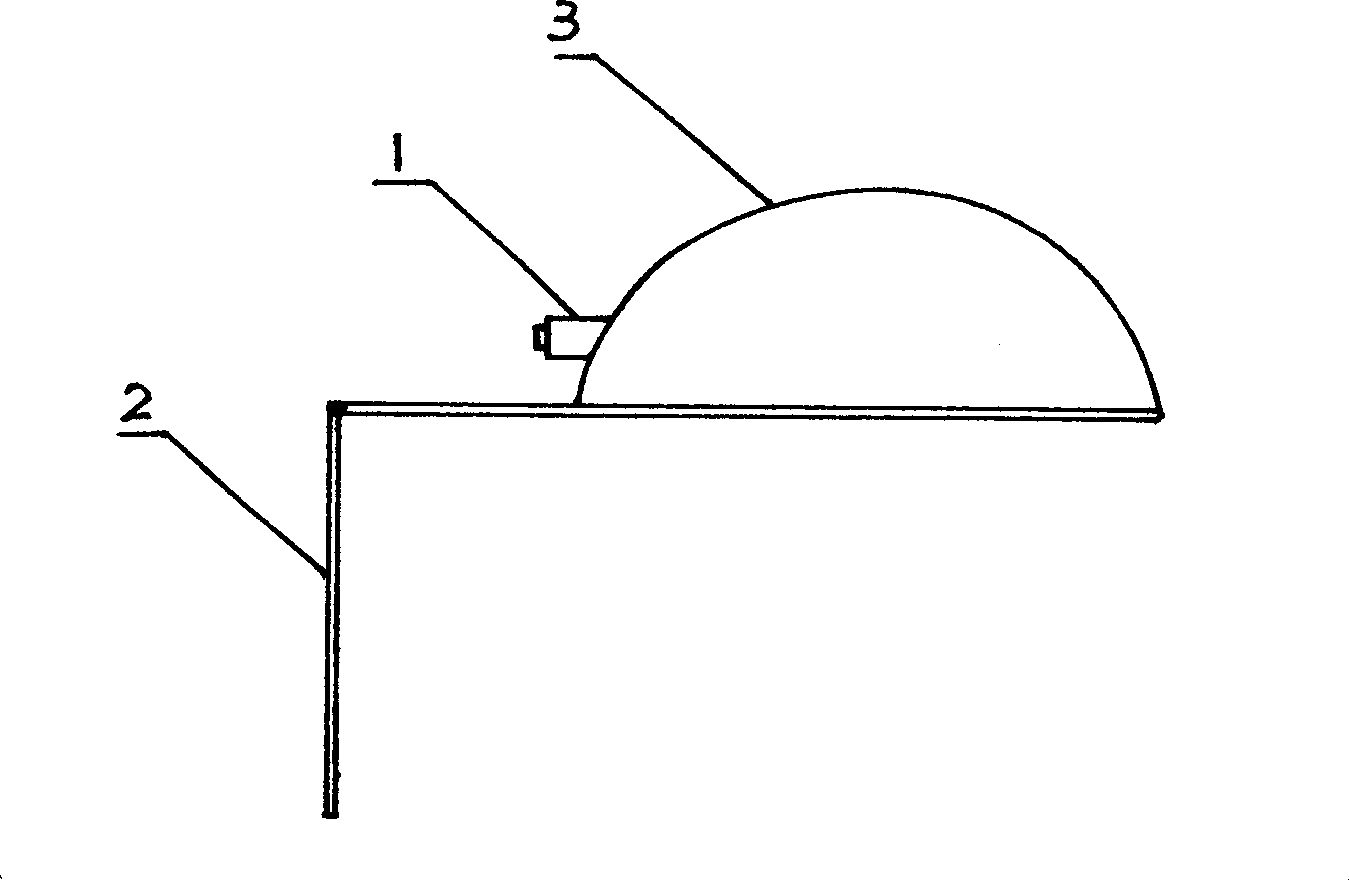

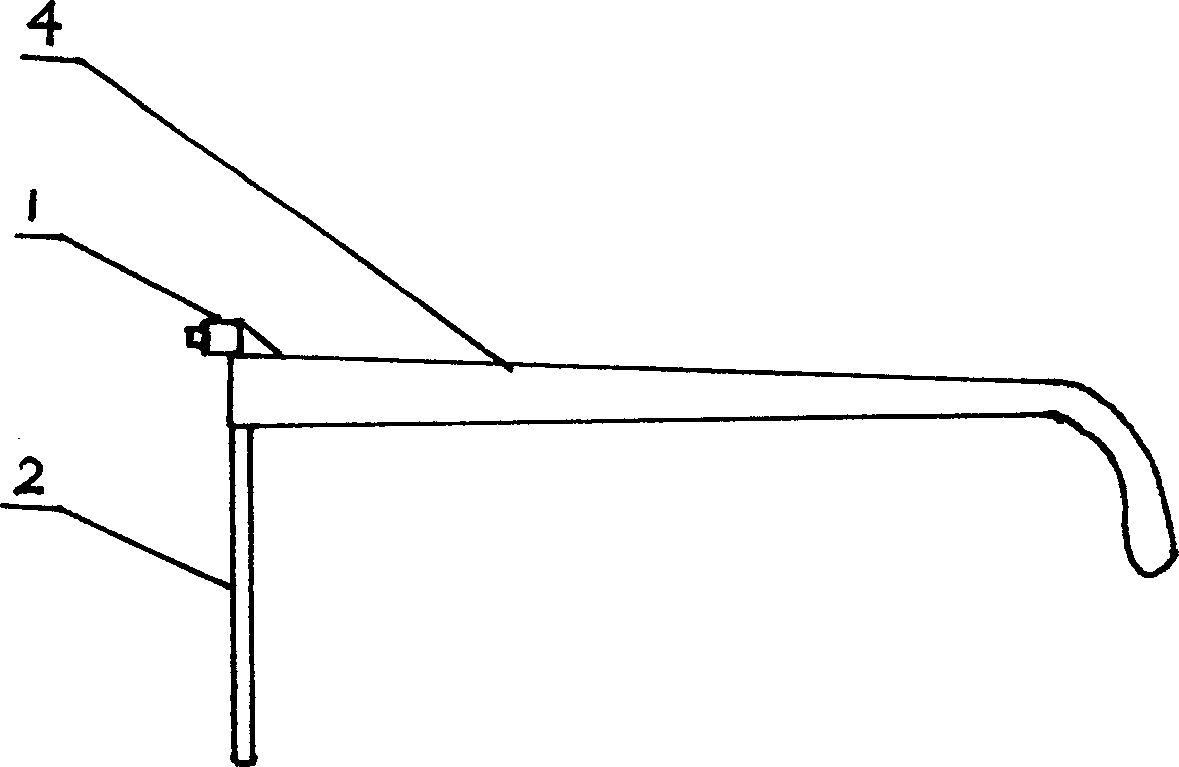

InactiveCN1384003ATo achieve the purpose of anti-glareEffective anti-glareAntiglare equipmentDriver/operatorLiquid-crystal display

The automatic antiglare device for vehicle consists of power source, miniature CCD camera, imaging and controlling chip and transparent liquid crystal display connected together. When the device is used, the CCD camera points forward and the transparent liquid crystal display is set before eyes of the driver. When two vehicles meet in opposite direction, the strong light from opposite vehicle is picked up and tracked by the CCD camera and the signal is processed in the imaging and controlling chip and two dynamic shadows are formed in the display to shade the strong light from the opposite vehicle or to avoid glare. After meeting of vehicles, the display is restored to be transparent. The present invention makes night meeting more safely.

Owner:林建明

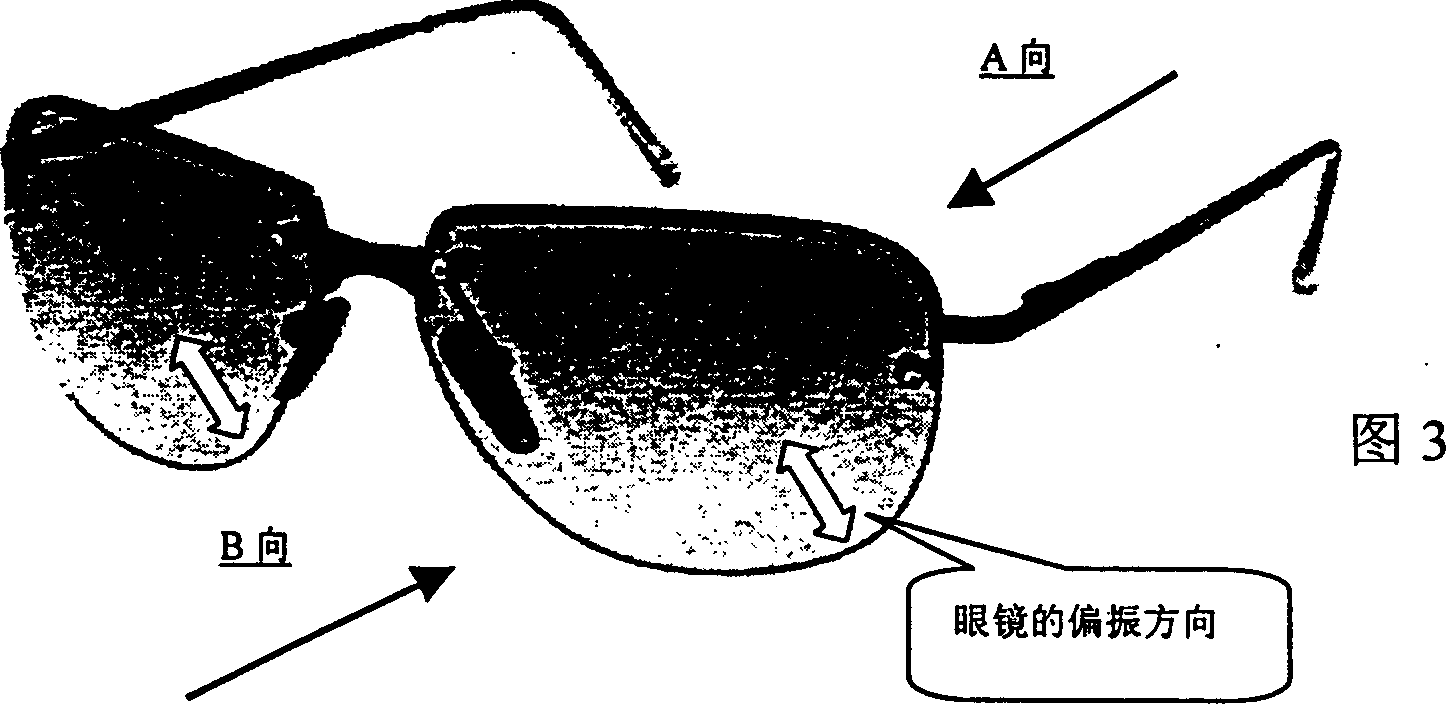

Anti-dazzle light used for vehicle and anti-dazzle glasses

InactiveCN1445476AReduce glareTo achieve the purpose of anti-glareSpectral modifiersOptical partsLight beamOptoelectronics

An anti-dazzle lamp of car is made up by adding a polarizer to ordinary bheadlight of car in such manner that there is a 45 deg of includes angle between the polarized light beam and horizontal lever. A pair of anti-dazzle glasses for car driver features two polarizers with a 45 deg of polarizing angle are used.

Owner:SHANGHAI JIAO TONG UNIV

LED anti-dazzle lamp

InactiveCN101818867AReduce lossTo achieve the purpose of anti-glarePoint-like light sourceElectric lightingEngineeringSurface reflection

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

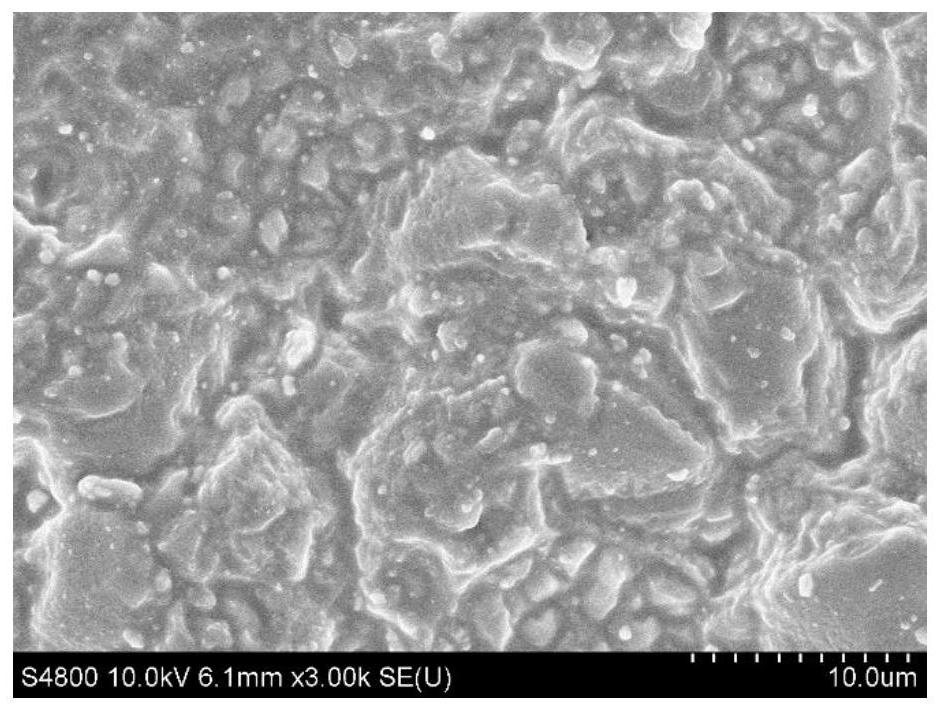

A kind of preparation method of glass surface treatment material

ActiveCN113512354BImprove wear resistanceImprove scratch resistanceElectrically-conductive paintsConductive polymerSilicon dioxide

The invention belongs to the technical field of glass coating materials, and specifically relates to a glass surface treatment material and a preparation method thereof. The treatment material includes organic silicon compounds, alcohol solvents, alcohol ether solvents, conductive polymer film-forming materials and deionized water. The present invention can form a layer of irregularities on the surface of the glass to cause light diffusion to achieve the purpose of anti-glare. The pass rate can reach more than 95.5%, and its adhesion is good. The conductive polymer film-forming material can eliminate static electricity, improve the mechanical properties of the glass surface, and improve the wear resistance, scratch resistance and radiation resistance of the glass. Anti-static, anti-glare. The preparation method of the invention is simple, easy to operate, low in cost, low in energy consumption, non-polluting and easy in industrialized production.

Owner:潍坊赛宝工业技术研究院有限公司

A kind of self-healing anti-glare waterborne polyurethane coating and preparation method thereof

ActiveCN106867388BGuaranteed transmission throughTo achieve the purpose of anti-glarePolyurea/polyurethane coatingsPolymer scienceCopolymer

The invention discloses anti-glare waterborne polyurethane paint with a self-repairing function and a preparation method thereof. The preparation method is characterized in that aliphatic polyether glycol subjected to dehydration treatment and diisocyanate are subjected to prepolymerization under the effect of organic tin catalyst; then, the aliphatic polyether glycol subjected to dehydration treatment is added to generate a segmented copolymer; primary chain extension is performed through dimethylolpropionic acid; neutralization is performed to form salt; deionized water and sodium sulfamate type chain extenders are subjected to emulsification and chain extension; sulfonic acid groups are introduced at a hard chain section; then, aliphatic diamine type or hydrazine chain extenders with higher reactivity is added, so that the rest isocyanate completely reacts; finally, the proper amount of auxiliary agents is mixed to obtain the waterborne polyurethane paint. The paint coating film has good diffusion performance and high transmissivity; the excellent anti-glare effect can be achieved without adding additional auxiliary agents or performing surface treatment; the coating film has the self repairing capability through a large number of reversible hydrogen bonds and sulfonic acid groups in polyurethane.

Owner:QINGYUAN YAKOO CHEM CO LTD

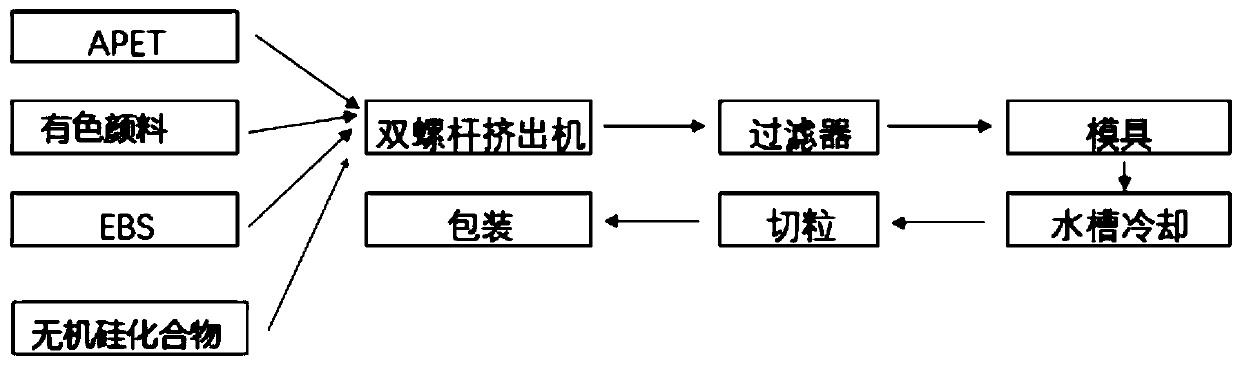

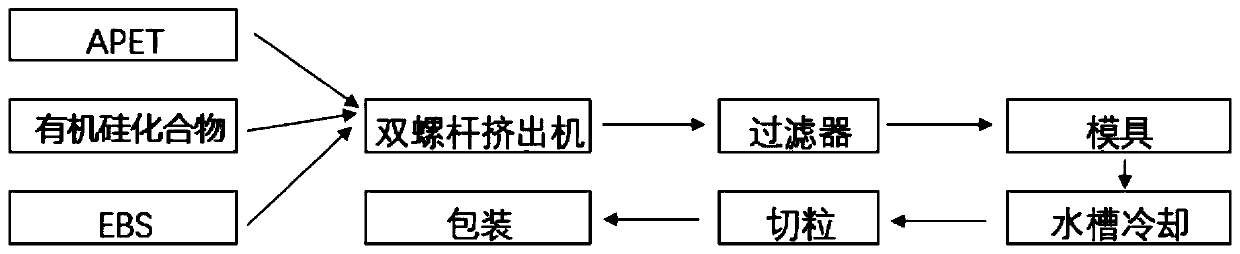

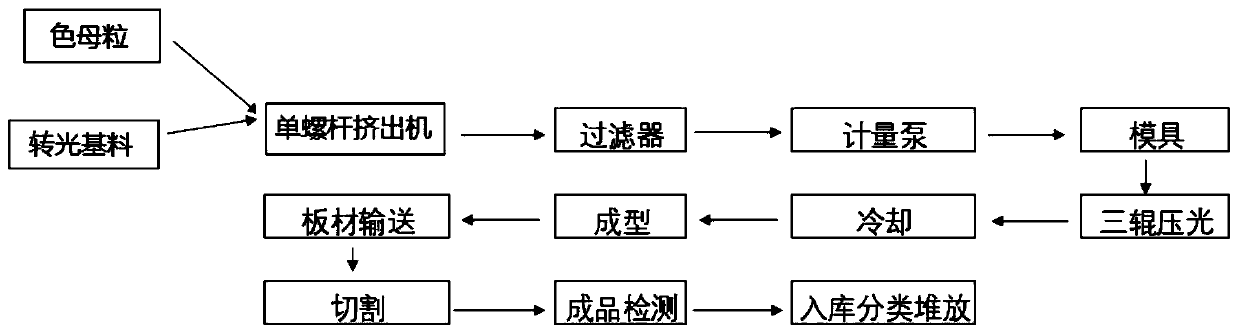

Colored light conversion plate and preparation method thereof

The invention relates to a colored light conversion plate. The colored light conversion plate is prepared by taking a polyester base material, ethylenebis(stearamide), a silicon compound and a coloredpigment as raw materials, performing mixing under stirring in a mixing kettle, performing extrusion by using an extruder, and finally performing molding treatment to obtain the colored light conversion plate. The invention has the beneficial effects that the colored light conversion plate provided by the invention is a high-transparency, high-strength, colored, green and environmentally-friendlylight conversion plate, and adopts a light energy illumination technology for converting dazzling light into another soft healthy matte light by adopting the light refraction and scattering optical principle.

Owner:陈友宝

LED anti-dazzle lamp

InactiveCN101818867BReduce lossTo achieve the purpose of anti-glarePoint-like light sourceElectric lightingEngineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

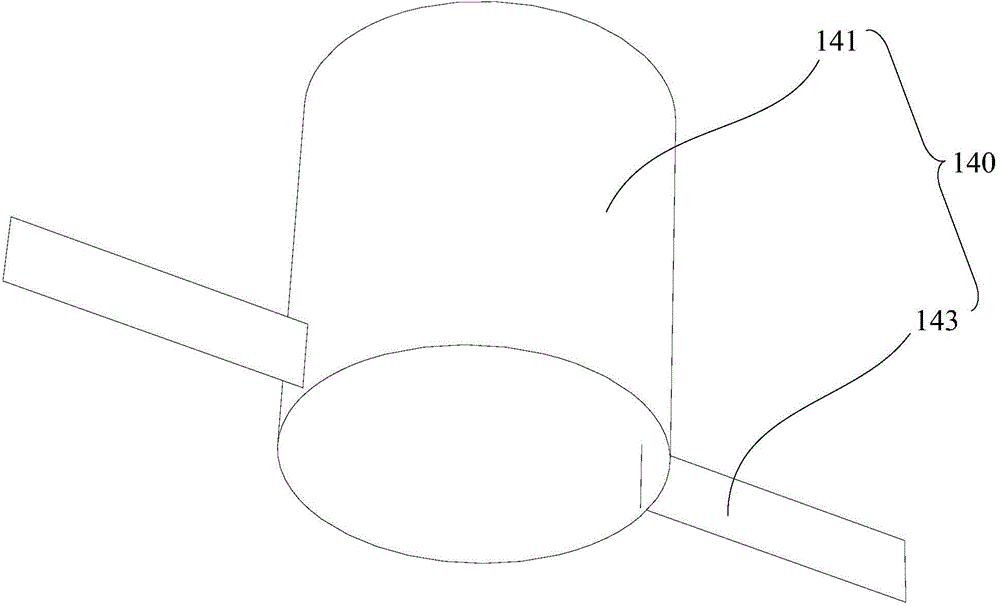

Metal halide down lamp

InactiveCN104654124AAvoid seeingTo achieve the purpose of anti-glareElongate light sourcesLight fasteningsMetal-halide lampLight reflection

A metal halide down lamp comprises a cylindrical lamp barrel provided with an inner cavity, a light reflection cover installed on the lamp barrel, a metal halide lamp installed in the light reflection lamp and an anti-dazzle grid, wherein one end of the lamp barrel is a light outlet, the light reflection cover comprises a reflection outlet, the reflection outlet corresponds to the light outlet, light emitted by the light reflection lamp is reflected by the light reflection cover and then is emitted out of the light outlet, the anti-dazzle grid is installed in the light outlet of the lamp barrel and comprises a cylindrical light shading barrel and two connecting cross beams, two ends of the light shading barrel are open, one open end corresponds to the metal halide lamp, and the other open end is flush with the peripheral edge of the light outlet. The two connecting cross beams are symmetrically arranged relative to the light shading barrel, and two ends of each connecting cross beam are respectively and fixedly connected with the outer wall of the light shading barrel and the lamp barrel. Under the condition that the depth of the light reflecton cover of the light outlet of the metal halide down lamp is not needed to be increased and light distribution is changed, and eyes are prevented from seeing the metal halide lamp so as to achieve the anti-dazzle purpose.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

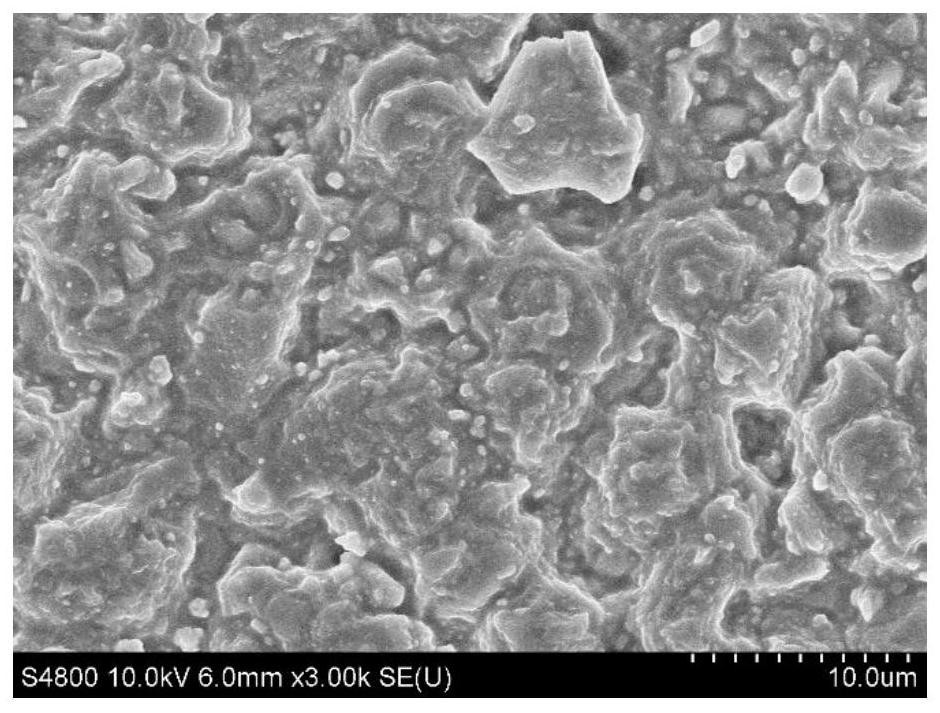

A kind of preparation method of anti-glare glass material

ActiveCN108529896BIncrease the nucleation rateIncrease granularityCoatingsOrganic filmHydration reaction

The invention discloses a method for preparing an anti-glare glass material, which belongs to the technical field of glass material preparation. In the present invention, the surface of the anti-glare glass material is covered with a layer of composite film, which is mainly composed of polyacrylate, titanium dioxide, and zinc oxide. First, the nano-titanium dioxide powder is dispersed in the complex stannous sulfate solution, and the doping composition is Aluminum nitrate nonahydrate, during the drying process, the concentration of aluminum ions increases, so it is necessary to modify the surface of nano-titanium dioxide particles to change from hydrophilic to lipophilic, through inorganic nanoparticles and organic polymers The refraction effect achieves the purpose of anti-glare. In the present invention, the siloxane bond formed between the glass and the organic film is hydrolyzed and the silanol forms a hydrogen bond with the hydroxyl group on the titanium dioxide surface, and then a dehydration reaction occurs through heating and drying to form a part of the covalent bond. , and bring unsaturated double bonds that can further participate in the reaction, so that the compatibility of the anti-glare glass material is improved, and the application prospect is broad.

Owner:江苏华玻光电技术有限公司

Anti-dazzle road sealing layer material and preparation method thereof

PendingCN112646494AReduce glossReduce road layer reflectivityBituminous coatingsPolyester coatingsMineralogyNiobium

The invention belongs to the technical field of road engineering, and discloses an anti-glare road sealing layer material which comprises the following raw materials in percentage by weight: 37%-52% of cationic emulsified asphalt, 35%-48% of tantalum-niobium tailings and 7%-15% of extinction resin. The extinction resin is adopted, so that the effect of reducing the glossiness of the asphalt pavement after raining can be achieved. A large number of research tests show that when the anti-dazzle road sealing layer material produced by the invention is applied to paving of an asphalt pavement, the reflectivity of the road layer is greatly reduced, and the anti-dazzle purpose is achieved, so that the safety of driving is improved.

Owner:NANJING FORESTRY UNIV

Composite silica gel mobile phone protection tempered film and production method thereof

PendingCN112810256AAvoidance of injuryLow refractive indexLamination ancillary operationsSynthetic resin layered productsChemistryRefractive index

The invention discloses a composite silica gel mobile phone protection tempered film, which comprises a glass substrate, a magnetic absorption layer is laid on the glass substrate, a shielding layer is bonded on the magnetic absorption layer, a protection layer is bonded on the shielding layer, a transparent film is laid on the surface of the protection layer, and an anti-refraction film is bonded on the transparent film. Because barium titanate ceramic is a dielectric material and can absorb electromagnetic waves, and then the nanoscale aluminum metal film can shield the electromagnetic waves, the electromagnetic waves can be shielded, and the situation that the electromagnetic waves injure the human body is avoided; as the refractive index of the silicon dioxide film is low, dazzling reflection is reduced through the interference effect between the film layers in the whole visible light range, so that the silicon dioxide film and the zinc oxide film can achieve the anti-dazzling purpose.

Owner:东莞市鑫科精密科技有限公司

Glass frosting liquid, frosted glass prepared from glass frosting liquid and preparation method of glass frosting liquid

The invention discloses a glass frosting liquid, frosted glass prepared from the glass frosting liquid and a preparation method of the glass frosting liquid. The glass frosting liquid comprises frosting powder and a solvent. The frosting powder comprises the following raw materials in mass percentage 1.0 to 5.0% of oxalic acid dihydrate, 2.0 to 8.0% of sulfamic acid, 0 to 2.0%of white granulated sugar, 0 to 3.0% of cane sugar, 11.0 to 14.0% of barium sulfate, 5.0 to 11.0% of barium fluoride, 0.02 to 0.5% of calcium fluoride, 0.1 to 2.5% of sodium fluoride, 0.05 to 4.0% of potassium fluoride dihydrate, 0 to 3.0% of potassium chloride, 1.5 to 6.0% of aluminum fluosilicate, 0.5 to 1.5% of sodium dodecyl sulfate, 0.1 to 9%of ammonium fluoride, 0.5 to 3.0%of magnesium fluosilicate and the balance of ammonium hydrogen fluoride, the sum of the mass percentage of the raw materials is 100%. According to the frosted glass prepared by the method of the invention, glare is effectively eliminated, and the anti-glare purpose is achieved.

Owner:XIANGSHI ENERGY SAVING GLASS KUNSHAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com