LED anti-dazzle lamp

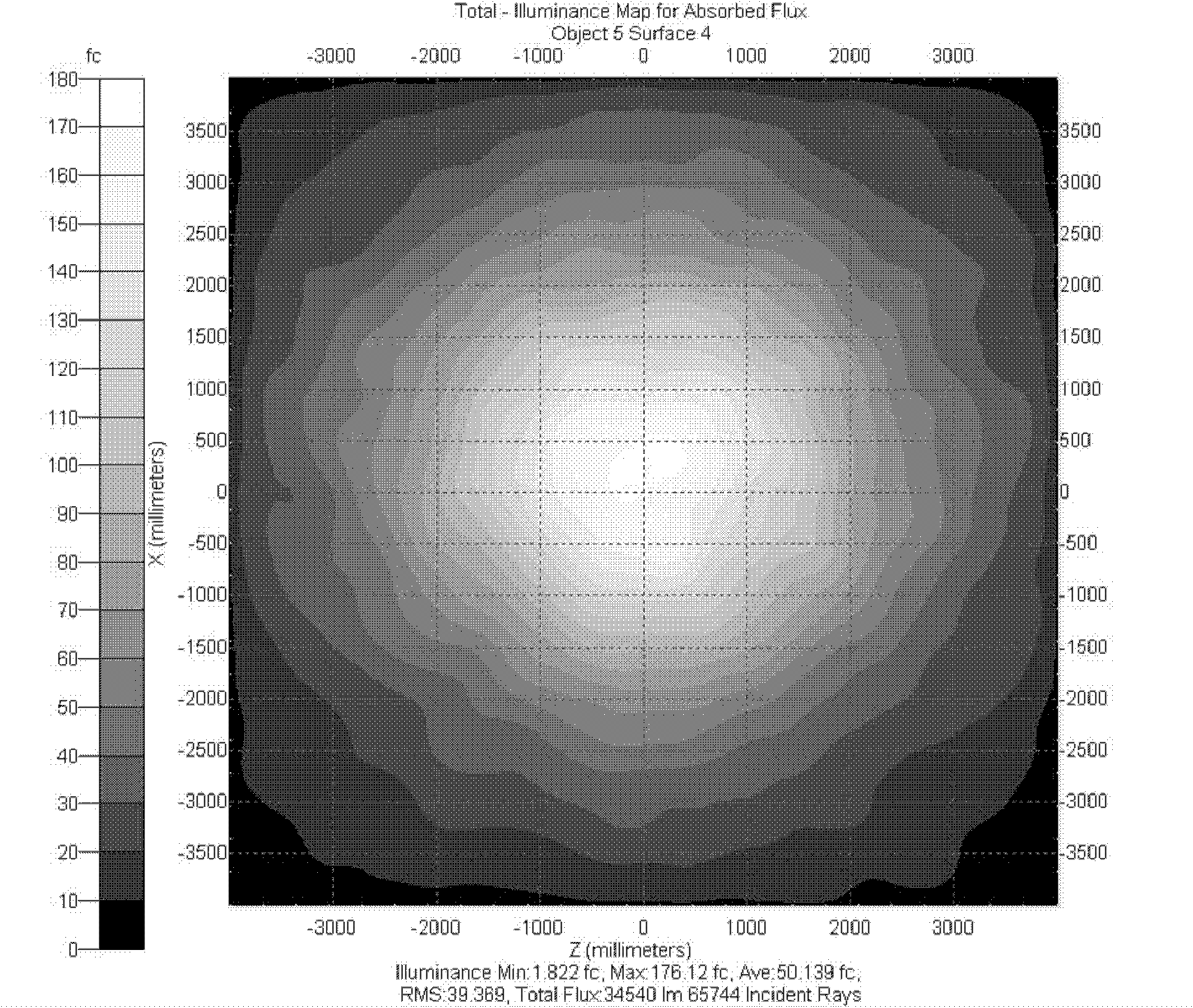

An LED anti-glare lamp and reflective plane technology, applied in the field of LED lamps, can solve the problems of high cost, large loss of light from transparent parts, complicated procedures, etc., and achieve the effects of low energy loss, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

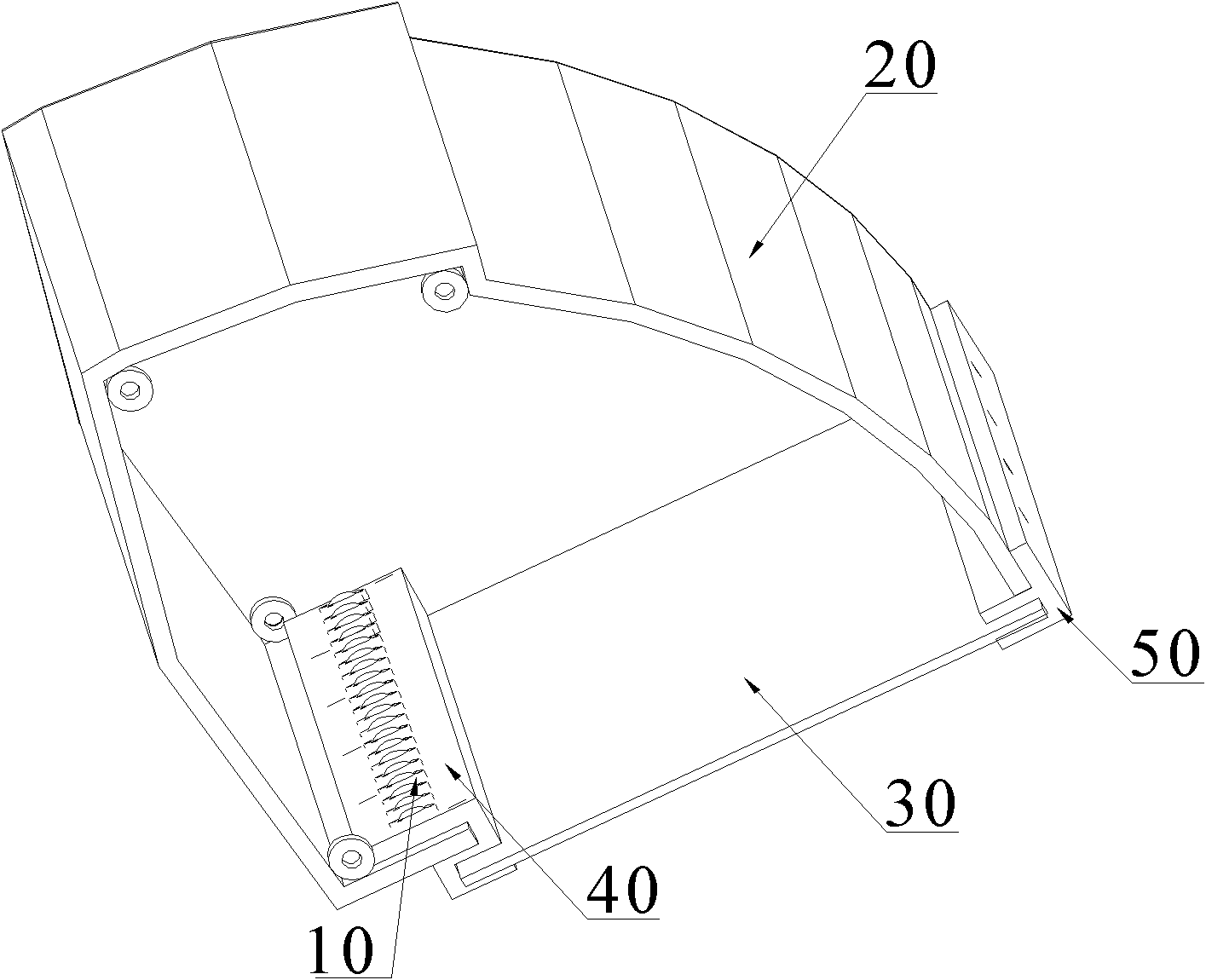

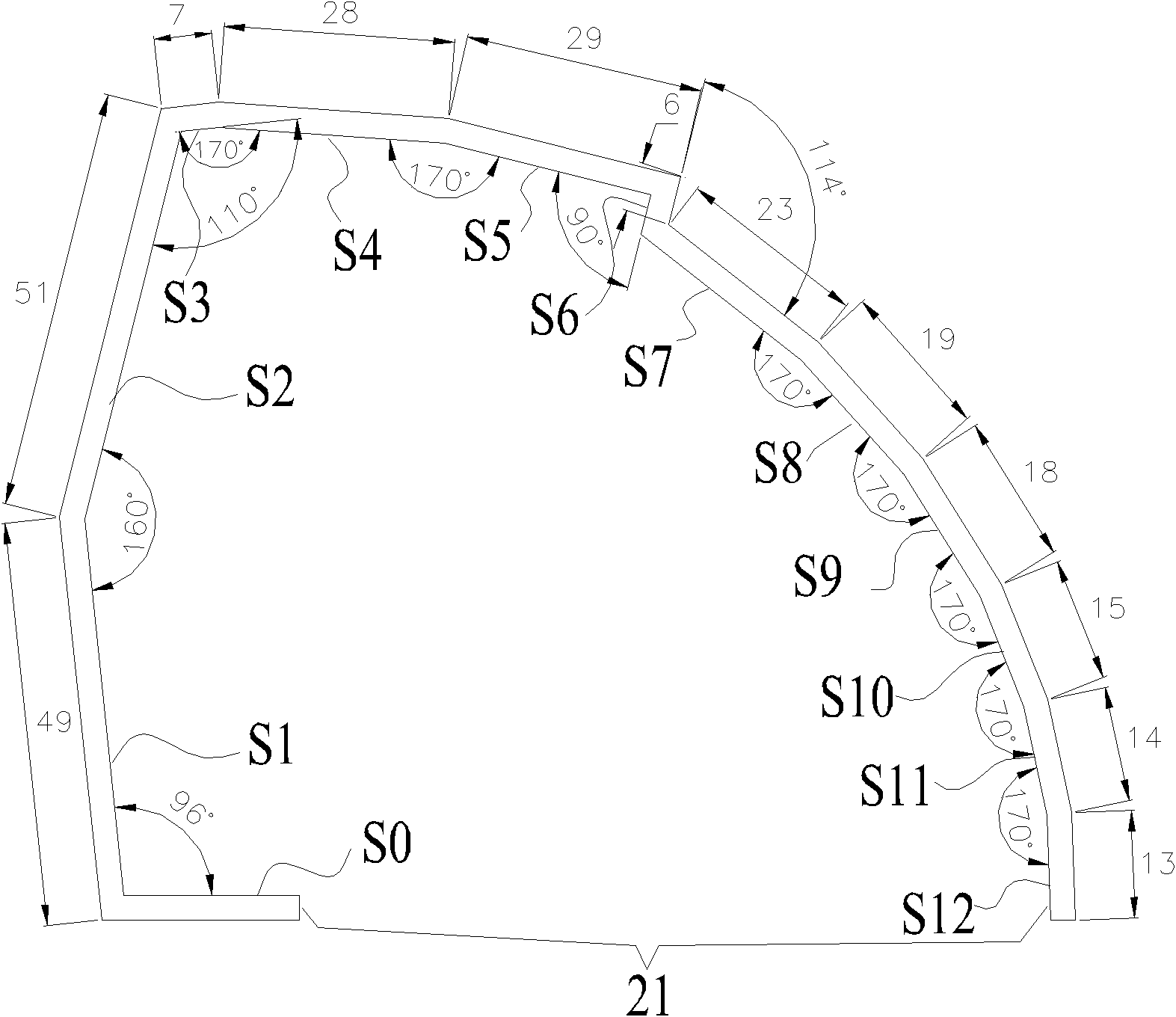

[0017] The present invention relates to an LED anti-glare lamp, which is used to reflect the light of LED 10 without directly entering human eyes, so as to play the role of anti-glare. The fixing seat 40 and the reflector 20 covering the fixing seat 40 and the LED 10 inside, the reflector 20 has a light-transmitting opening 21 so that the light emitted by the LED 10 is reflected and emitted from the light-transmitting opening 21 .

[0018] like figure 1 , figure 2 As shown, the inner surface of the reflector 20 for reflecting light has N reflective planes sequentially spliced clockwise / counterclockwise, and N is an integer greater than 1. In this embodiment, N is twelve, and then twelve reflective planes These are the first reflective plane S1 to the twelfth reflective plane S12 in sequence. Twelve reflective planes are connected in turn to form an enclosing space, and there is a distance between the first reflective plane S1 at the starting end and the twelfth reflective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com