Colored light conversion plate and preparation method thereof

A light-changing and colored technology, which is applied in the field of colored light-changing plates and its preparation, can solve the problems of poor brightness and transparency of colored light-changing plates, and achieve high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a colored light conversion plate. The colored light conversion plate is prepared from the following raw materials. The raw material includes a color masterbatch and a light conversion base material. The color masterbatch includes a polyester base material and ethylene bis-stearin acid amide, colored pigment and inorganic silicon compound; the ratio of the added amount of the polyester base material, ethylene bis stearic acid amide, blue pigment and inorganic silicon compound in the color masterbatch is 1:0.15:0.06:0.15 The light-changing base material includes polyester base material, ethylene bis-stearic acid amide and organosilicon compound, and the polyester base material, ethylene bis-stearic acid amide and organosilicon compound in the light-transferring base material The ratio of the added amount is 1:0.15:0.06; the polyester base material is PET polyester chips.

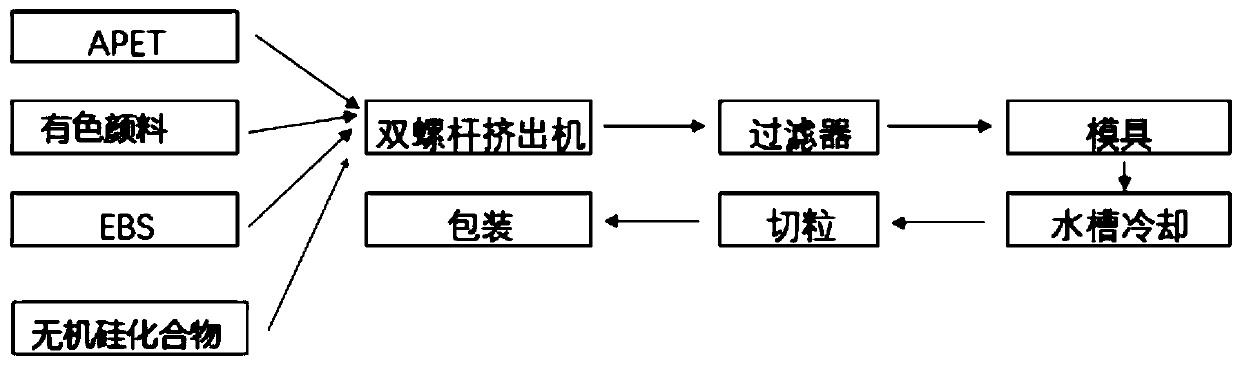

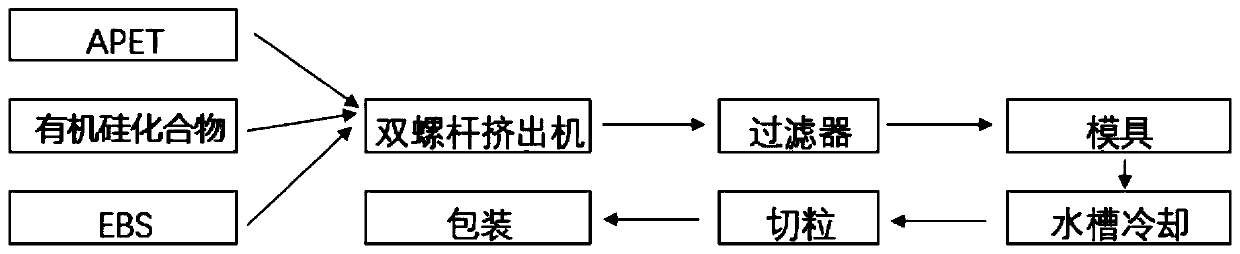

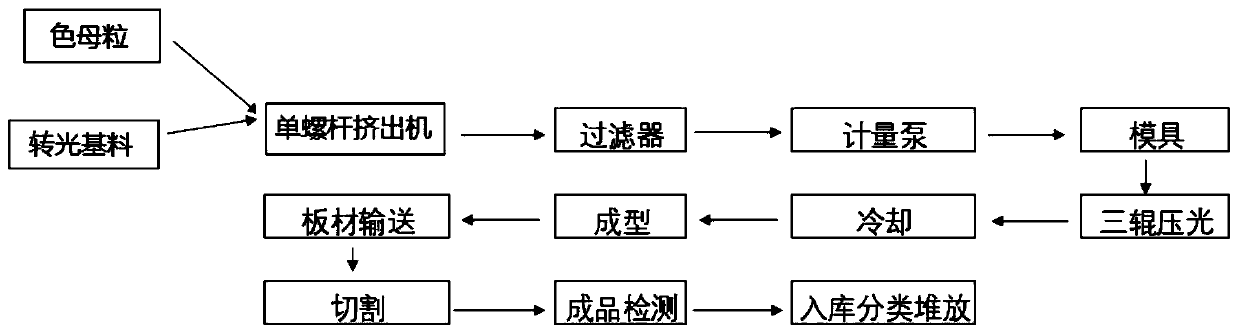

[0040] The preparation method comprises the following steps:

[0041] (1) ...

Embodiment 2

[0045] This embodiment provides a colored light conversion plate. The colored light conversion plate is prepared from the following raw materials. The raw material includes a color masterbatch and a light conversion base material. The color masterbatch includes a polyester base material and ethylene bis-stearin Acid amide, colored pigment and inorganic silicon compound; The ratio of the added amount of the polyester base material, ethylene bis stearic acid amide, pink pigment and inorganic silicon compound in the color masterbatch is 1:0.15:0.13:0.09; The light-changing base material includes polyester base material, ethylene bis-stearamide and organosilicon compound, and the addition of the polyester base material, ethylene bis-stearamide and organosilicon compound in the light-transfer base material The ratio of the amount is 1:0.13:0.1; the polyester base material is PETG polyester chip, the inorganic silicon compound is silicon dioxide, the organosilicon compound is polysil...

Embodiment 3

[0051] This embodiment provides a colored light conversion plate. The colored light conversion plate is prepared from the following raw materials. The raw material includes a color masterbatch and a light conversion base material. The color masterbatch includes a polyester base material and ethylene bis-stearin Acid amide, red pigment and inorganic silicon compound; The ratio of the added amount of the polyester base material, ethylene bis stearic acid amide, red pigment and inorganic silicon compound in the color masterbatch is 1:(0.03-0.15): (0.06-0.13): (0.05-0.15); the light-changing base material includes polyester base material, ethylene bis stearic acid amide and organosilicon compound, and the polyester base material, ethylene glycol in the light-changing base material The ratio of the addition of bis-stearic acid amide and organosilicon compound is 1:(0.03-0.15):(0.06-0.18); the particle diameter of described organosilicon compound is 25 μ m, and the particle diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com