A kind of preparation method of glass surface treatment material

A glass surface, deionized water technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of poor antistatic performance, poor anti-glare performance, good anti-glare performance, etc., to achieve improved mechanical properties, low cost, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

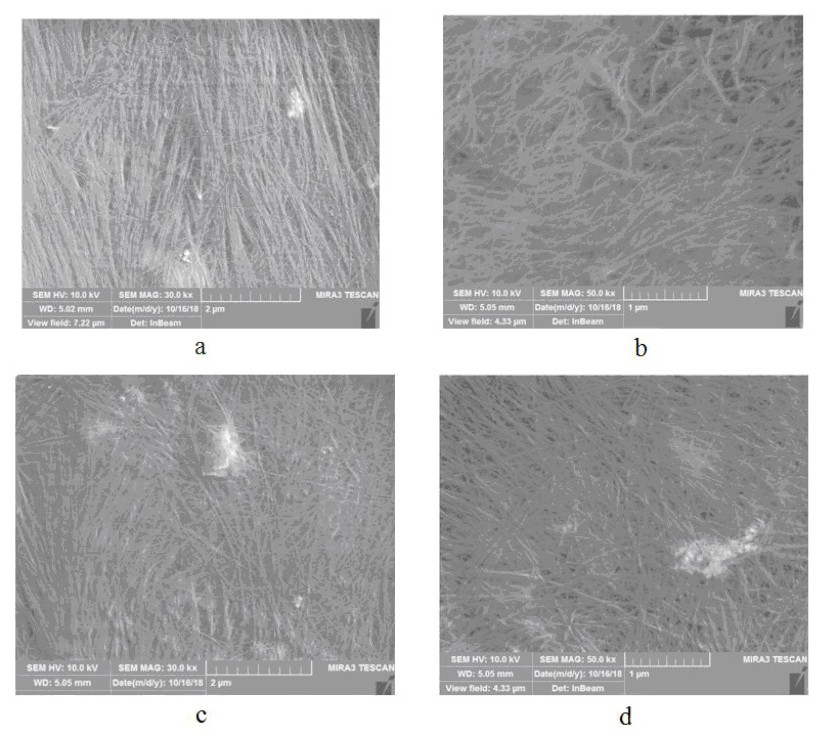

Image

Examples

Embodiment 1

[0026] A glass surface treatment material, comprising the following components by weight: 32 parts of ethanol, 14 parts of propylene glycol methyl ether, 1.5 parts of tetraethyl orthosilicate, poly(3,4-ethylenedioxythiophene)-polyphenyl 0.3 part of ethylene sulfonic acid, and the balance is deionized water.

[0027] Its preparation method is as follows:

[0028] (1) Add 32 parts of ethanol, 14 parts of propylene glycol methyl ether, 1.5 parts of ethyl orthosilicate and 0.5 parts of deionized water into the three-port reactor equipped with a stirring device, keep the temperature at about 30 ° C, start stirring, and keep The temperature is around 50°C.

[0029] (2) Turn on the low-temperature plasma device, pass in hydrogen gas, and control the flow rate of hydrogen at 20mL / min for 10 minutes, then introduce the atmosphere into the three-port reactor and react for 8 hours.

[0030] (3) After the reaction is over, let it stand still, and when the temperature of the solution dro...

Embodiment 2

[0033] A glass surface treatment material comprises the following components by weight: 10 parts of ethanol, 5 parts of propylene glycol methyl ether, 3.0 parts of methyltriethoxysilane, 1.0 part of polyaniline, and the balance is deionized water.

[0034] Its preparation method is as follows:

[0035] (1) Add 35 parts of ethanol, 15 parts of propylene glycol methyl ether, 1 part of methyltriethoxysilane and 0.5 parts of deionized water into the three-port reactor equipped with a stirring device, keep the temperature at about 40 ° C, and start stirring , keep the temperature at around 60°C.

[0036] (2) Turn on the low-temperature plasma device, pass in hydrogen, control the flow rate of hydrogen at 30mL / min, stabilize for 10 minutes, then introduce the atmosphere into the three-port reactor, and react for 8 hours.

[0037] (3) After the reaction is over, let it stand still, and when the temperature of the solution drops to room temperature, a comb nano-silica solution is obt...

Embodiment 3

[0040] A glass surface treatment material comprises the following components by weight: 25 parts of methanol, 20 parts of ethylene glycol ether, 5 parts of methyl orthosilicate, 0.8 part of polyaniline, and the balance is deionized water.

[0041] Its preparation method is as follows:

[0042] (1) Add 40 parts of methanol, 20 parts of ethylene glycol ethyl ether, 1.3 parts of methyl orthosilicate and 0.5 parts of deionized water into a three-port reactor equipped with a stirring device, keep the temperature at about 50°C, and start stirring. Keep the temperature around 40°C.

[0043] (2) Turn on the low-temperature plasma device, pass in hydrogen gas, and control the flow rate of hydrogen at 15mL / min for 10 minutes, then introduce the atmosphere into the three-port reactor and react for 8 hours.

[0044] (3) After the reaction is over, let it stand still, and when the temperature of the solution drops to room temperature, a comb nano-silica solution is obtained. Take a sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com