A kind of self-healing anti-glare waterborne polyurethane coating and preparation method thereof

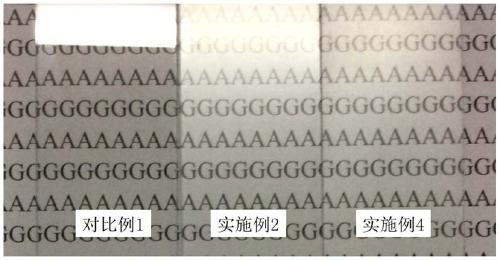

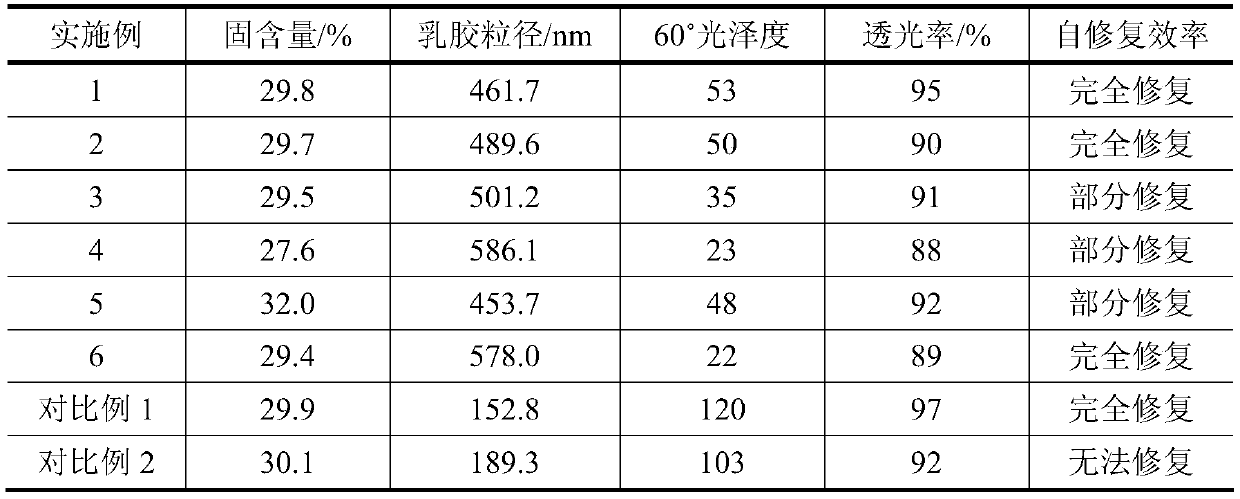

A water-based polyurethane, anti-glare technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor transparency and the lack of self-healing properties of coatings, and achieve the effect of self-repairing, simple and effective self-repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) After dehydrating 100g of polytetramethylene glycol (PTMG, 1000g / mol, Japan Mitsubishi Chemical Co., Ltd.), the temperature was lowered to 80°C; under the protection of nitrogen, 0.04g of dibutyltin dilaurate (DBTDL, American Aladdin Reagent) and 52g isophorone diisocyanate (IPDI, Bayer, Germany) were mixed homogeneously, and carried out prepolymerization reaction 1 hour;

[0045] (2) After dehydrating 19g of poly-1,4-butylene adipate diol (PBA, 1000g / mol, Asahikawa Chemical), lower the temperature to 80°C, add it to the product of step (1), and the reaction time is For 1 hour, the reaction temperature was 80°C. Samples were taken every 15 minutes to determine the end point of the reaction by n-butylamine titration. When the isocyanate value reached 4.5% (theoretical value was 5%), the temperature was cooled to 70°C;

[0046] (3) Add 7.3g dimethylolpropionic acid (DMPA, Perstorp, Sweden) to the product of step (2), the reaction time is 1 hour, and the reaction tempe...

Embodiment 2

[0053] (1) After dehydration treatment of 100g polypropylene glycol (PPG, 1000g / mol, American Dow), cool down to 70°C; under nitrogen protection, add 0.06g dibutyltin dilaurate (DBTDL, American Aladdin reagent) and 52g Isophorone diisocyanate (IPDI, Bayer, Germany) was mixed homogeneously, and carried out prepolymerization reaction for 2 hours;

[0054] (2) After dehydrating 19g of polycaprolactone diol (PCL, 1000g / mol, Sigma-Aldrich), cool down to 70°C and add it to the product of step (1). The reaction time is 1.5 hours and the reaction temperature is 70 ℃, take samples every 15 minutes and use n-butylamine titration method to judge the reaction end point, when the isocyanate value reaches 4.5% (theoretical value is 5%), cool the temperature to 70 ℃;

[0055] (3) Add 7.3g dimethylolpropionic acid (DMPA, Perstorp, Sweden) to the product of step (2), the reaction time is 2 hours, and the reaction temperature is 60°C, and every 15 minutes the sample is taken by n-butylamine tit...

Embodiment 3

[0062] (1) After dehydrating 81g of polypropylene glycol (PPG, 1000g / mol, American Dow), cool down to 70°C; under nitrogen protection, add 0.06g of dibutyltin dilaurate (DBTDL, American Aladdin reagent) and 57g Isophorone diisocyanate (IPDI, Bayer, Germany) was mixed homogeneously, and carried out prepolymerization reaction for 1 hour;

[0063] (2) After dehydration treatment of 21g poly-1,4-butylene adipate diol (PBA, 1000g / mol, Asahikawa Chemical), lower the temperature to 60°C, add to the product of step (1), and the reaction time is For 2 hours, the reaction temperature was 60°C. Samples were taken every 15 minutes to determine the end point of the reaction by n-butylamine titration. When the isocyanate value reached 7.7% (theoretical value was 8%), the temperature was cooled to 60°C;

[0064] (3) Add 6.2g dimethylol propionic acid (DMPA, Perstorp, Sweden) to the product of step (2), the reaction time is 2 hours, and the reaction temperature is 60°C, every 15 minutes the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com