Method for inserting generator rotor of gas-filling condensing steam turbine unit

A technology for generator rotors and steam turbine units, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of scratching stator safety accidents, affecting construction progress and maintenance quality, and reducing maintenance efficiency, and achieving good social benefits. And economic benefits, easy to grasp the essentials of operation, saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

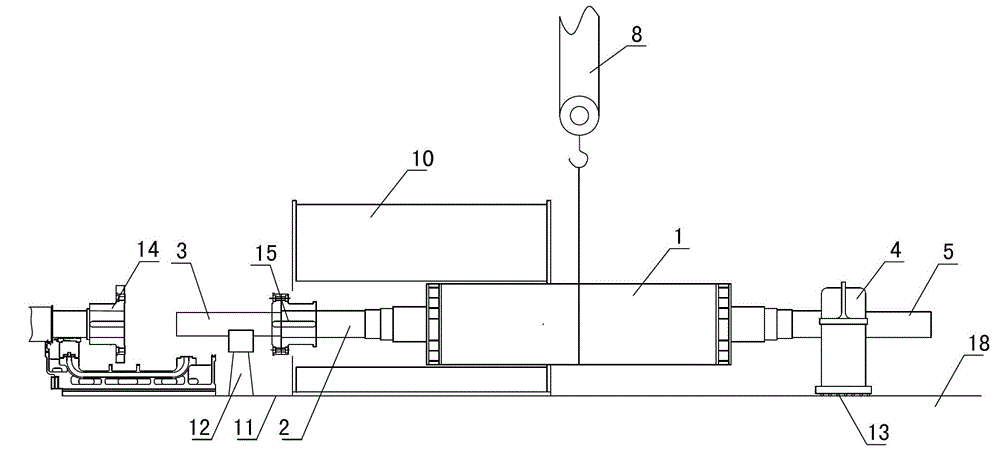

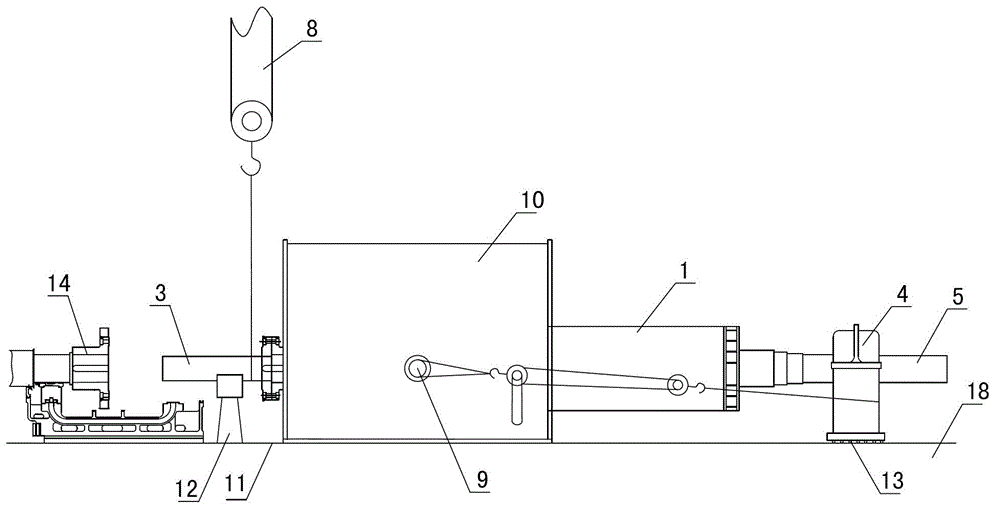

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0022] The present invention relates to a method for putting on the generator rotor of a gas-supplying condensing steam turbine unit, which is to change the position of the center of mass of the rotor 1 by arranging a connecting shaft at the steam end 2 of the generator rotor and connecting the counterweight to the exciter end 5 to change the position of the rotor 1 The rotor is more convenient to put on and install. The specific operation steps are as follows:

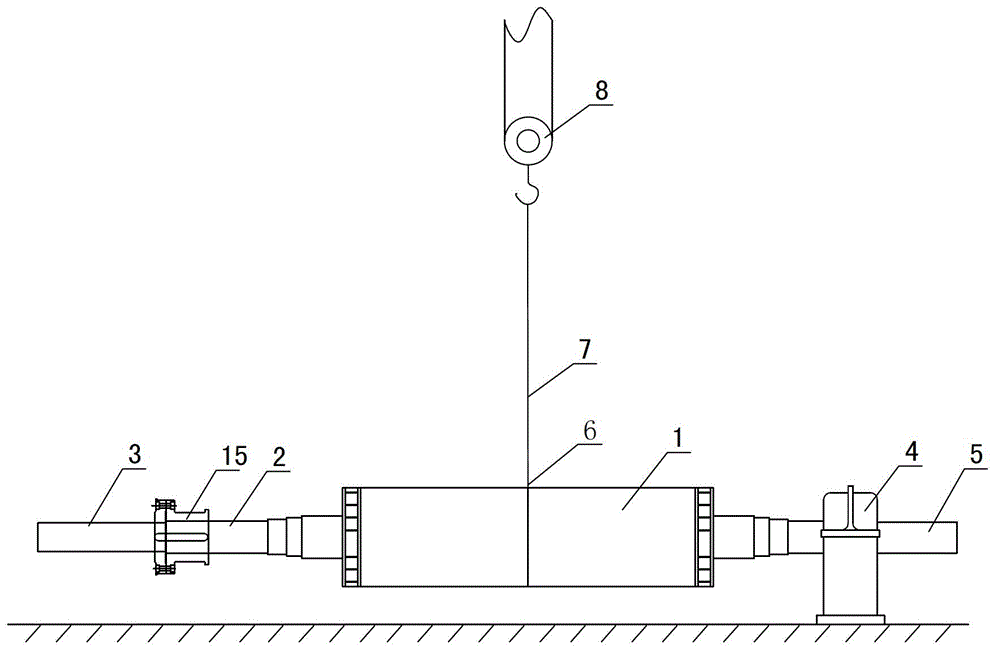

[0023] 1) see figure 1 , connect the connecting shaft 3 with the steam end coupling 15 of the rotor 1, hang the rear bearing seat 4 on the journal of the exciter end 5 as a counterweight, determine and mark the hoisting center 6 of the rotor 1, the exciter end 5 A soft pad should be provided between the journal and the rear bearing seat 4 of the generator to prevent the rear bearing seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com