Cam running-needle control mechanism of flat knitting machine

A control mechanism and cam technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problem of multi-knitting without minute needle knitting, secondary needle selection, increased wear between knitting needles, multi-needle wear and defective pieces and other problems to achieve the effect of reducing needle consumption, improving fabric quality and expanding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing of specification sheet and embodiment:

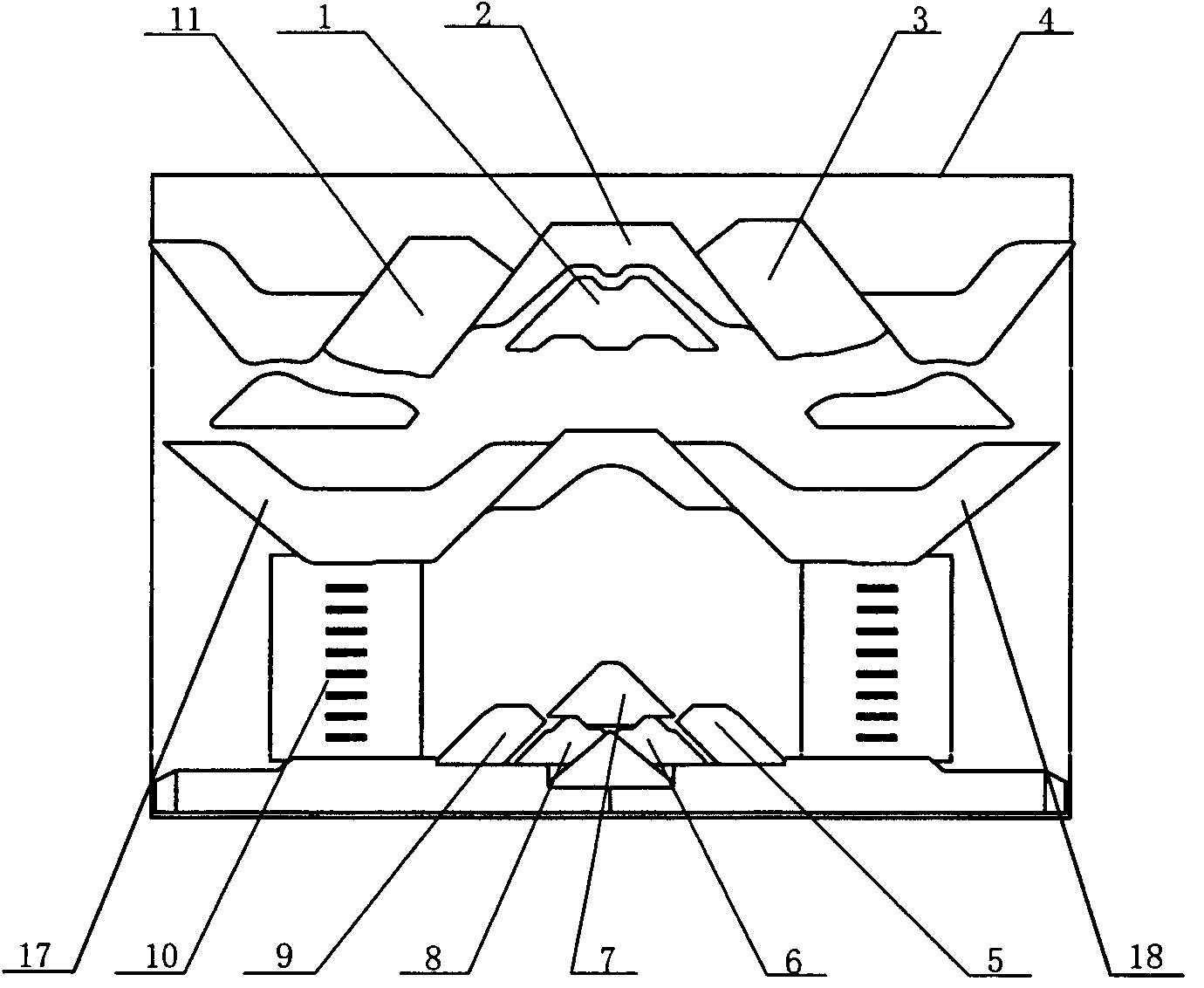

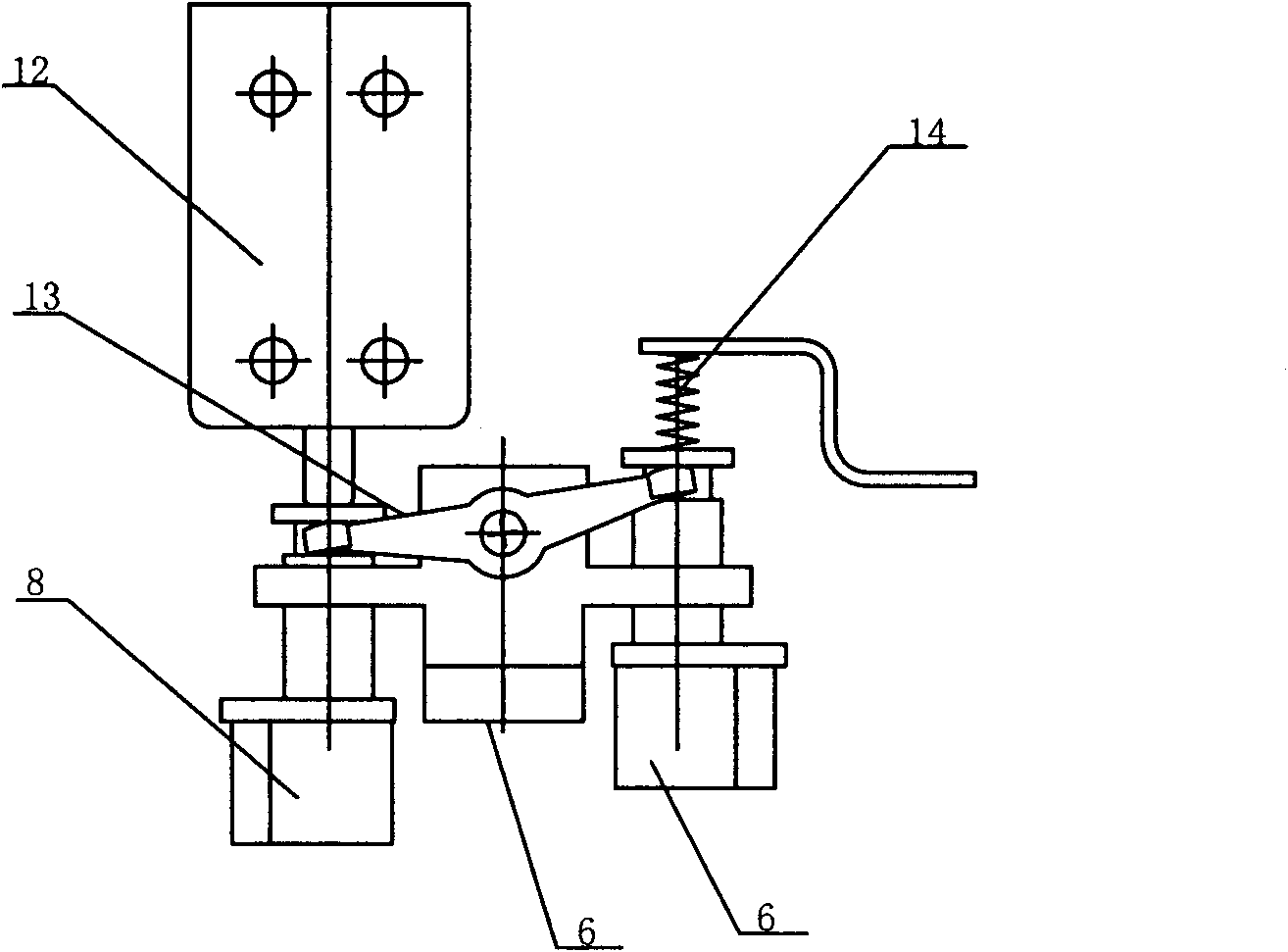

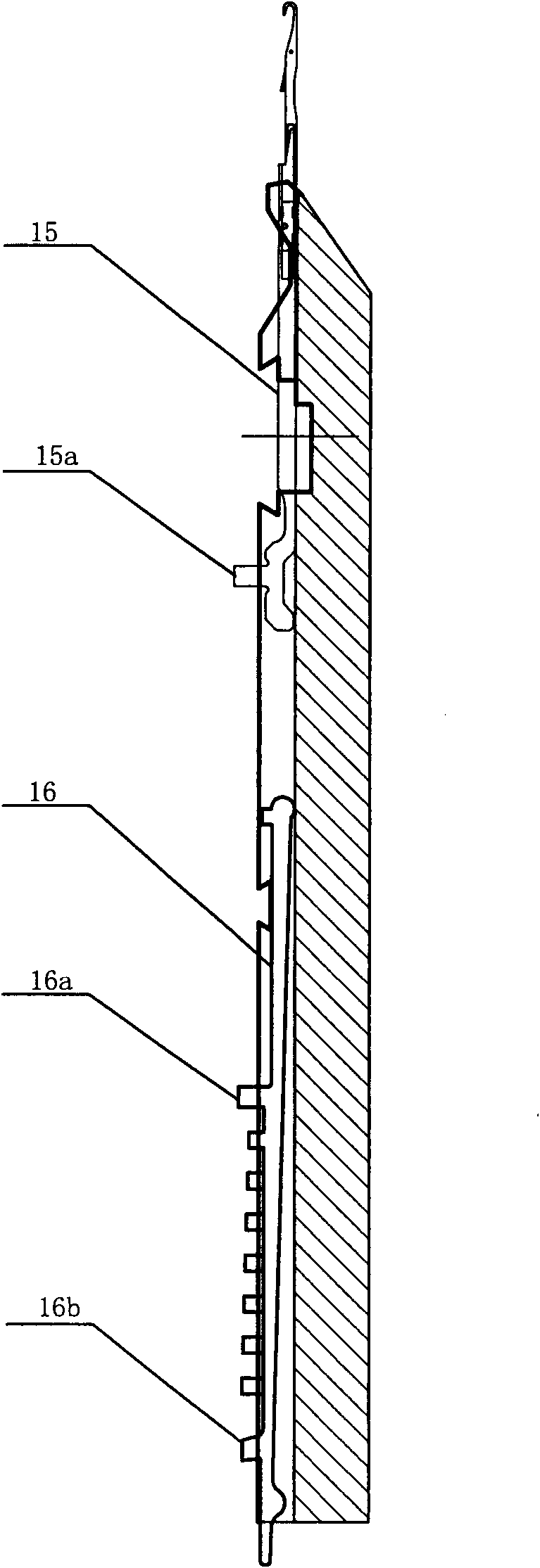

[0026] like Figure 1-7 As shown, the cam needle movement control mechanism of the flat knitting machine includes the cam bottom plate 4 of the flat knitting machine, which cooperates with the knitting needle control mechanism and the jacquard needle control mechanism arranged on the cam bottom plate 4 of the flat knitting machine. The cam bottom plate 4 of the flat knitting machine is also equipped with two A symmetrical needle selector 10, the top of the needle selector 10 is equipped with a left lower needle pressing cam 17 and a right lower needle pressing cam 18 respectively, and the knitting needle control mechanism includes a transfer cam 1 for the knitting needle 15 to move around, and The herringbone cam 2 fixedly connected to the cam bottom plate 4 of the flat knitting machine and the left knitting cam 11 and the right knittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com