Machine-vision based liquid level detection device and method

A technology of liquid level detection and machine vision, which is applied in the direction of measuring devices, engine lubrication, machine/engine, etc., can solve the problems that ultrasonic liquid level measuring instruments are difficult to achieve high precision, insufficient analog conversion precision, and low detection accuracy. Achieve the effect of low cost, easy installation and strong anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

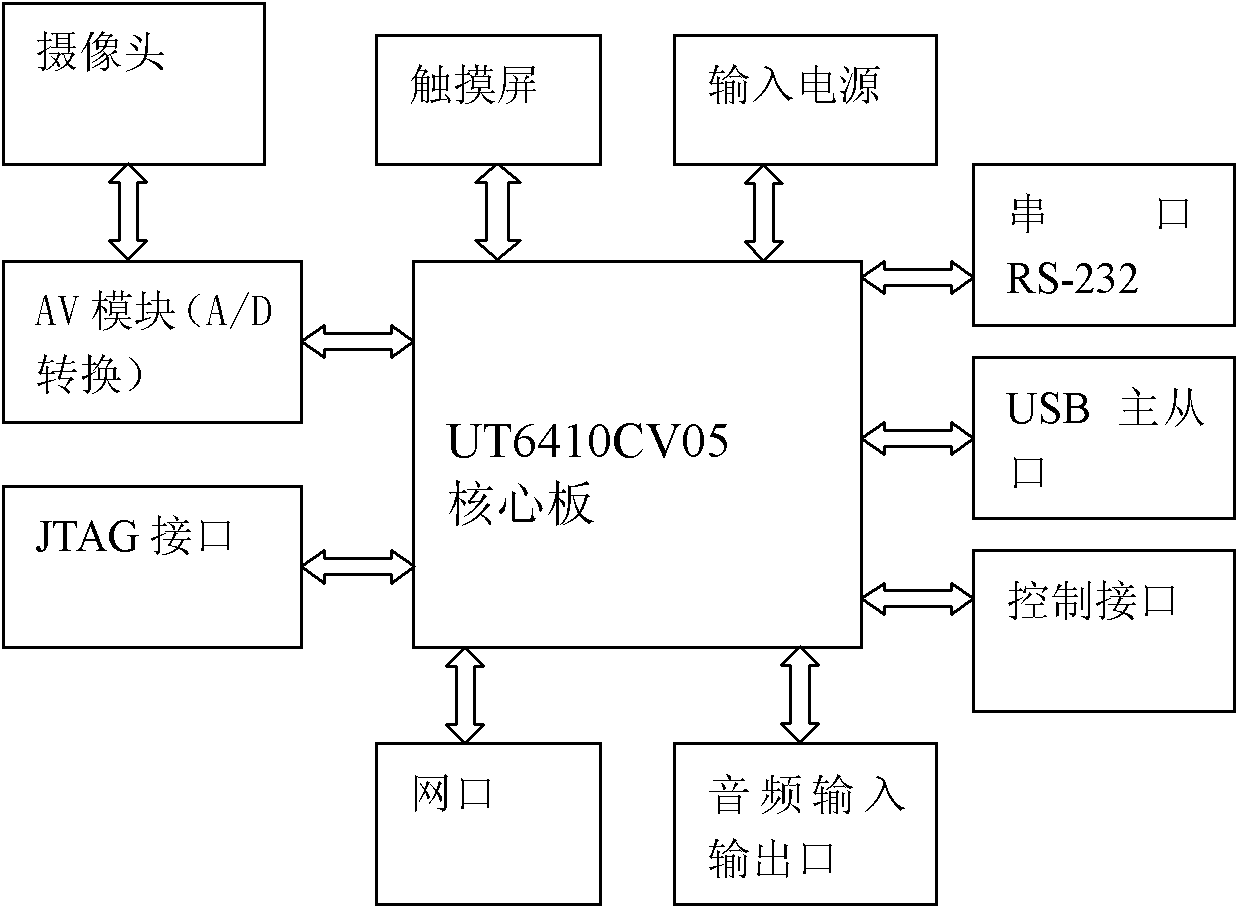

[0037] refer to figure 1 , the liquid level detection device based on machine vision is an embedded device, including the following parts: infrared camera or camera, embedded detection device, including liquid crystal display and touch screen, wired and wireless communication interface and control interface, etc. board, the object to be detected.

[0038] In this example, the embedded system is adopted, the Linux operating system is adopted, and ARM11 is the main chip to process the data collected in the system. The human-computer interaction of the embedded liquid level detection device adopts touch screen and color / black and white LCD display. Use the touch screen to set system parameters such as early warning liquid level and height. Use the liquid crystal display to display the liquid level height value and the liquid level change curve. The collected image information is transmitted to the system storage module by using the wired and wireless modules. The liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com