Nano hollow silica dioxide micro-sphere/polyurethane composite aqueous paint and preparation method thereof

A water-based coating, silica technology, applied in the direction of polyurea/polyurethane coatings, coatings, latex paints, etc., can solve the problems affecting the performance of water-based composite coatings, poor suspension stability and rheology, and many reaction steps. Maintain stable sedimentation phenomenon, no sedimentation phenomenon, improvement of hardness and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 1.5g of polyvinylpyrrolidone in 5g of hot water and add it to a 250mL four-neck flask equipped with a thermometer, condenser, stirrer, and nitrogen gas. Dissolve 0.39g of azobisisobutylamidine hydrochloride and 3g of Distilled styrene was added after ultrasonic dispersion, heated to 70°C after nitrogen gas for 60 minutes, and kept stirring for 24 hours to obtain PS emulsion, which was dialyzed through a dialysis bag for 12 hours before use. The above 5g PS emulsion and 40mL ethanol were stirred for 30min under nitrogen protection, and the temperature was raised to 50°C. Add 15mL of ammonia water into the flask, stir for 5-10min, then quickly add 2g of tetraethyl orthosilicate to react for 3-5h, centrifuge the prepared emulsion, wash with ethanol and deionized water for 3 times, and obtain the hollow SiO 2 Microspheres.

[0028] The prepared 2.5g hollow SiO with hydroxyl groups on the inner and outer surfaces 2 Microspheres, 1.0g of silane coupling agent KH-5...

Embodiment 2

[0032] Same as Example 1, but with isocyanate-terminated polyurethane prepolymer, nano-hollow SiO with amine groups 2 The ratio of microspheres, dibutyltin dilaurate and acetone from 100:1:1:100 was changed to 100:2:1:100.

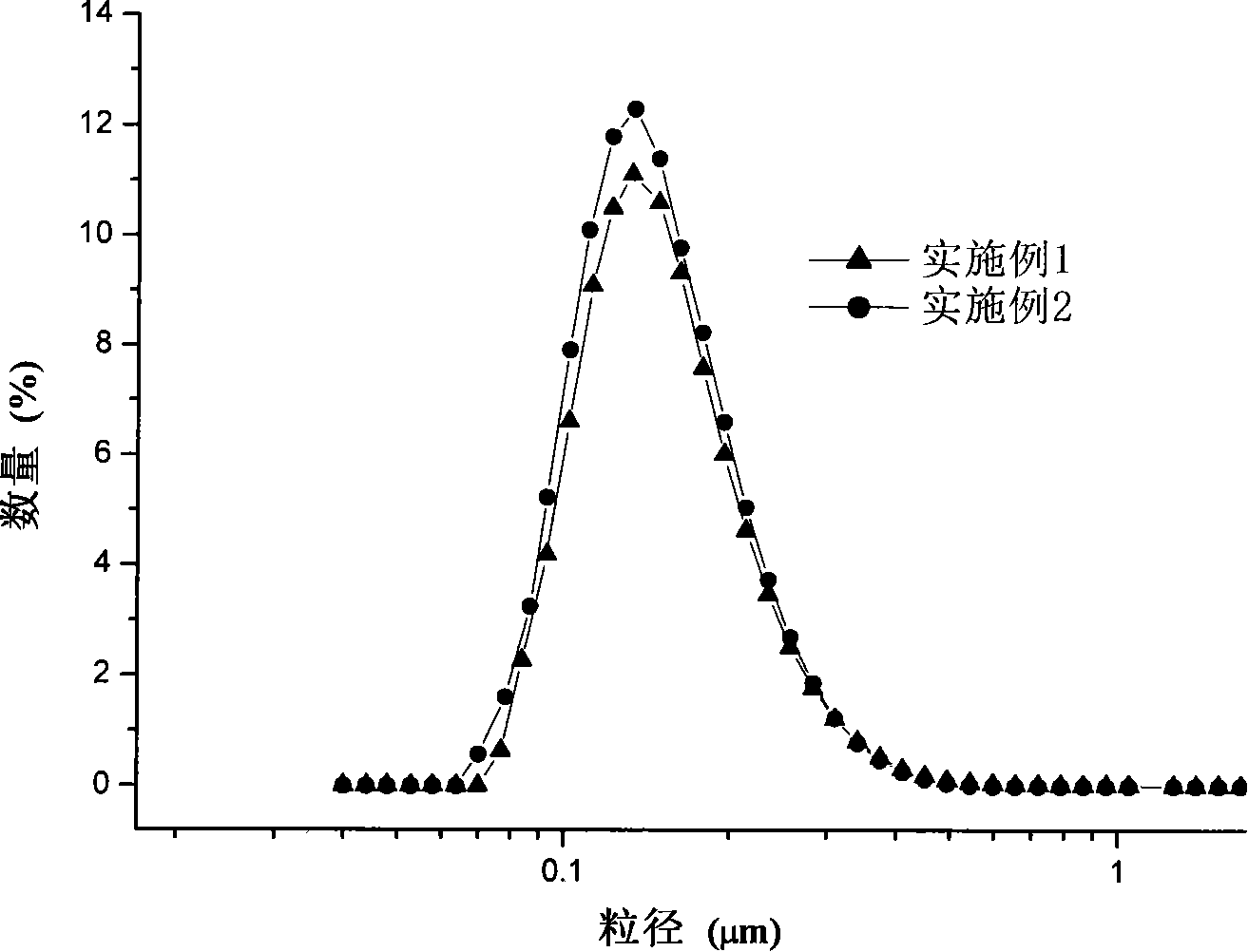

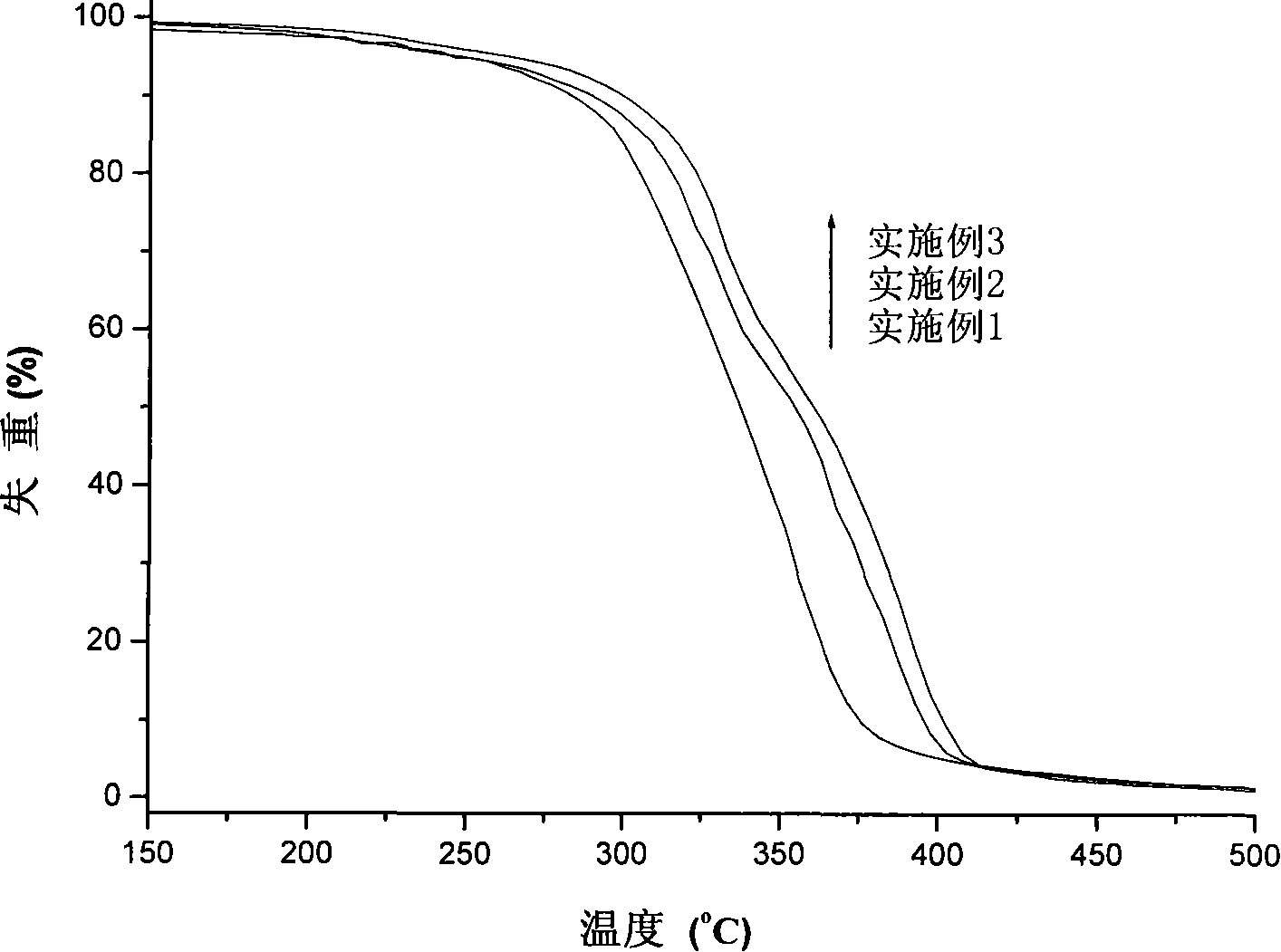

[0033] The coating film properties of nano hollow silica microspheres / polyurethane composite water-based coatings are shown in Table 1, and the particle size distribution is shown in figure 1 As shown, its thermal performance and UV-visible light transmittance are shown in image 3 and Figure 4 .

Embodiment 3

[0035] Same as Example 1, but with isocyanate-terminated polyurethane prepolymer, nano-hollow SiO with amine groups 2 The ratio of microspheres, dibutyltin dilaurate and acetone from 100:1:1:100 was changed to 100:3:1:100.

[0036] The film properties of nano hollow silica microspheres / polyurethane composite water-based coatings are shown in Table 1, and their thermal properties and UV-visible light transmittance are shown in Table 1, respectively. image 3 and Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com