Cloth winding device for garment making

A winding device and fabric technology, which is applied in the direction of winding strips, thin material processing, transportation and packaging, can solve the problems of difficulty in ensuring the flatness of the fabric, wrinkling of the fabric, and creases in the fabric, so as to improve the winding speed. quality, improve fabric quality, and ensure the effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

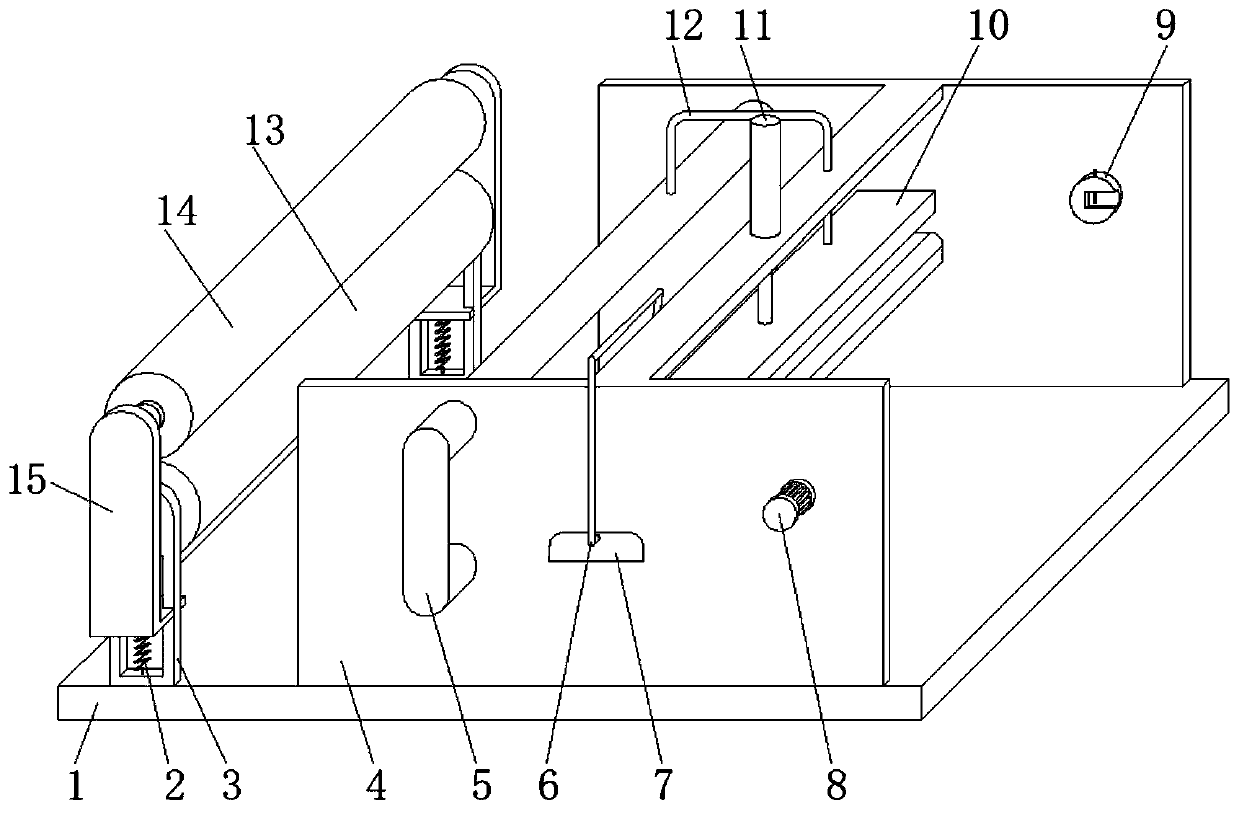

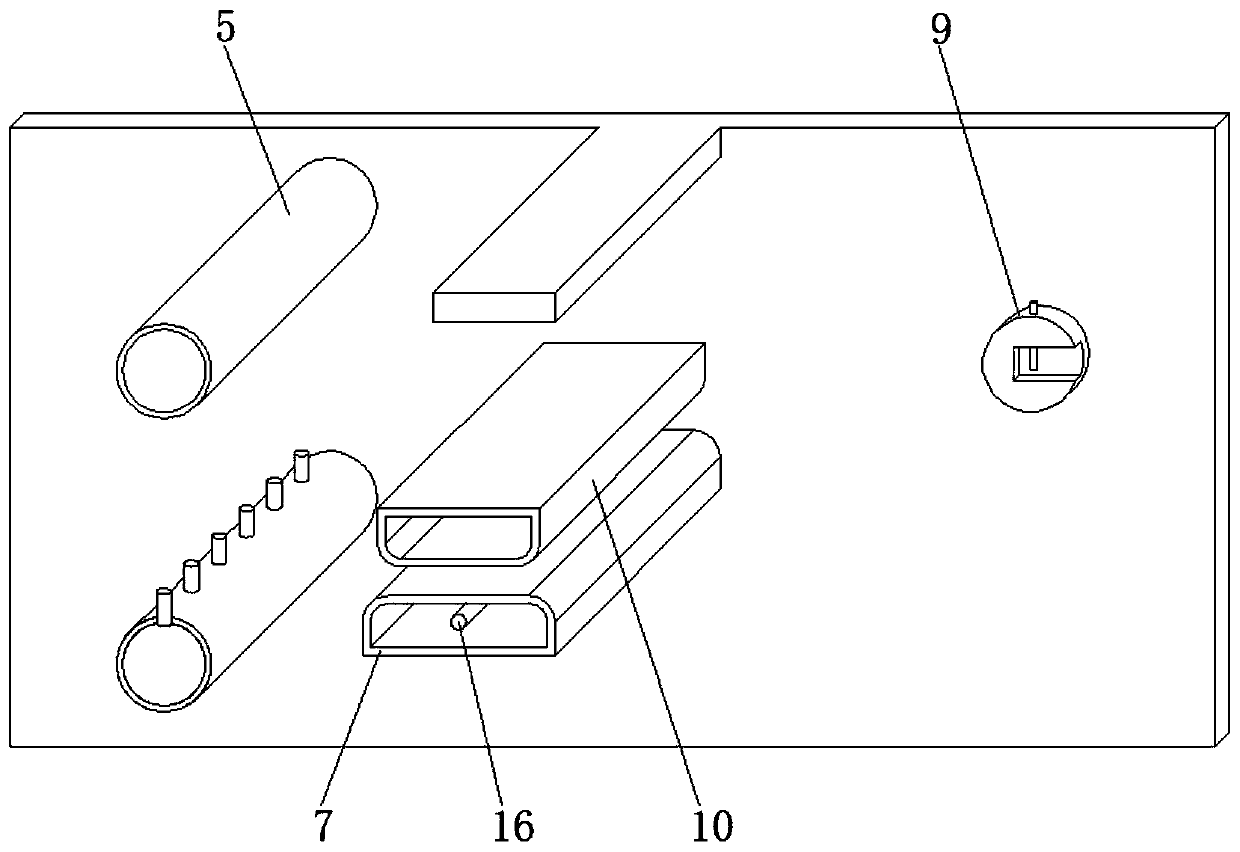

[0026] Reference Figure 1-2 , A cloth winding device for clothing processing, comprising a base 1, a fixing frame 3 and a mounting frame 4 are welded on both sides of the top outer wall of the base 1, and the fixing frame 3 is provided with a pressing mechanism, one of the fixing frame 3 A U-shaped tube installation hole is opened on the side outer wall, and the inner wall of the U-shaped tube installation hole is inserted with a U-shaped tube 5. For the air nozzle, the middle of the inner wall of the mounting frame 4 is fixed with the ironing box 7 by screws, and the top outer wall of the mounting frame 4 is fixed with a hydraulic cylinder 11 by screws. The bottom end of the piston rod of the hydraulic cylinder 11 is fixed with a pressure plate 10 by screws, and the pressure plate 10 is located directly above the ironing box 7.

[0027] In the present invention, both the outer wall of one side of the ironing box 7 and the top outer wall of the pressure plate 10 are provided wi...

Embodiment 2

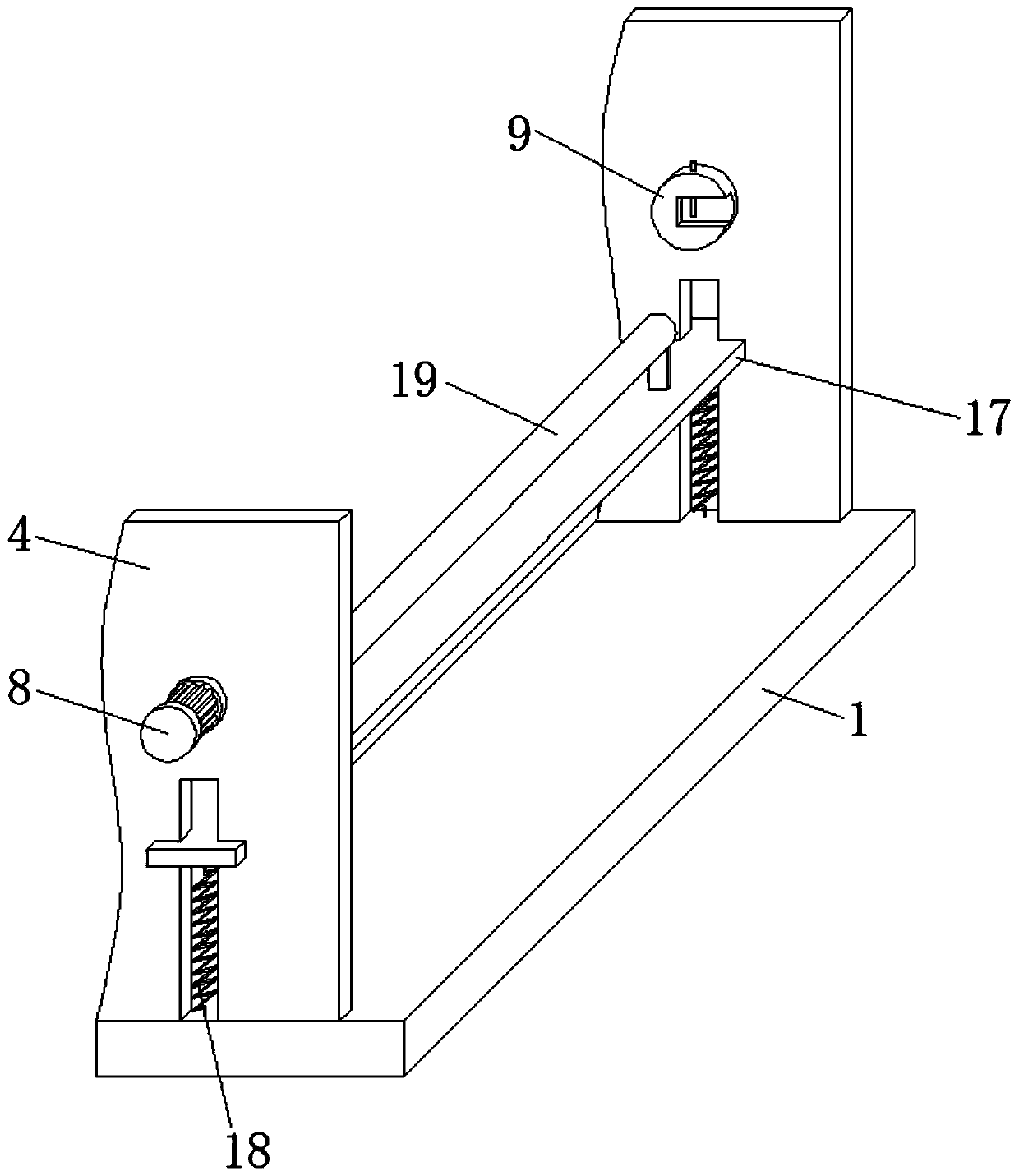

[0035] Reference image 3 , A cloth winding device for clothing processing. The inner walls of the mounting frame 4 are provided with sliding frame slide grooves, and the inner wall of the sliding frame slide groove is slidably connected with a sliding frame 17, the bottom outer wall of the sliding frame 17 and the top of the base 1 A support spring 18 is welded between the two sides. The inner wall of the sliding frame 17 is provided with squeeze roller mounting holes. The inner wall of the squeeze roller mounting hole is connected with a squeeze roller 19 through a bearing. The squeeze roller 19 is located on the connecting roller 9. Directly below.

[0036] Working principle: The support spring 18 exerts an upward pushing force on the sliding frame 17, which drives the squeeze roller 19 to attach to the wound fabric to ensure the flatness of the wound fabric.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com