Remote monitoring automatic thread stop system for textile tricot machine

A remote monitoring system and remote monitoring technology, which is applied in textiles, papermaking, knitting, etc., can solve the problems that the high-decibel noise in the textile workshop cannot be eliminated, and the work efficiency of the car operator is not high, so as to eliminate the impact of high-decibel noise and dust. The harm of personnel, the effect of increasing the capacity of stands, and preventing missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

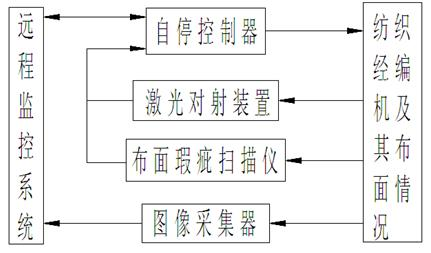

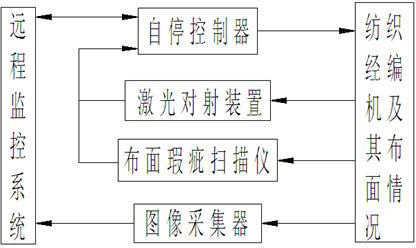

[0019] A remote monitoring and self-stopping system for textile warp knitting machines includes the following parts: (1) Image collector; (2) Remote monitoring system; (3) Scanner for cloth surface defects; (4) Laser shooting device; 5) Self-stop controller.

[0020] (1) Image collector: The image collector includes an optical lens, an image sensor, an image encoder, and a signal transmitter; the optical lens images the cloth surface to the image sensor, and the image sensor converts the image of the cloth surface into an image of an electrical signal, and the image The encoder converts the image of the electrical signal into an image signal of a certain format, and the signal transmitter transmits the image signal of a certain format to the remote monitoring syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com