Process for manufacturing saloon car clutch pressure plate casting

A production process and clutch technology, applied in the field of casting, can solve problems such as differences in product hardness, different quality states, and different temperature field states, and achieve the effects of improving process yield, reducing production costs, and optimizing product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The production technology of the clutch pressure plate casting of the present invention on the vertical molding production line comprises the following steps:

[0034] 1. Sand mixing modeling

[0035] The sand mixing process is completed in the sand processing system. The mixed molding sand is sent to the sand storage bucket above the molding machine through the belt conveyor, and then quantitatively injected into the compaction chamber of the molding machine for compaction by the molding machine. After the mold is lifted, the molding task is completed and rolled out, waiting for the molten iron to be poured.

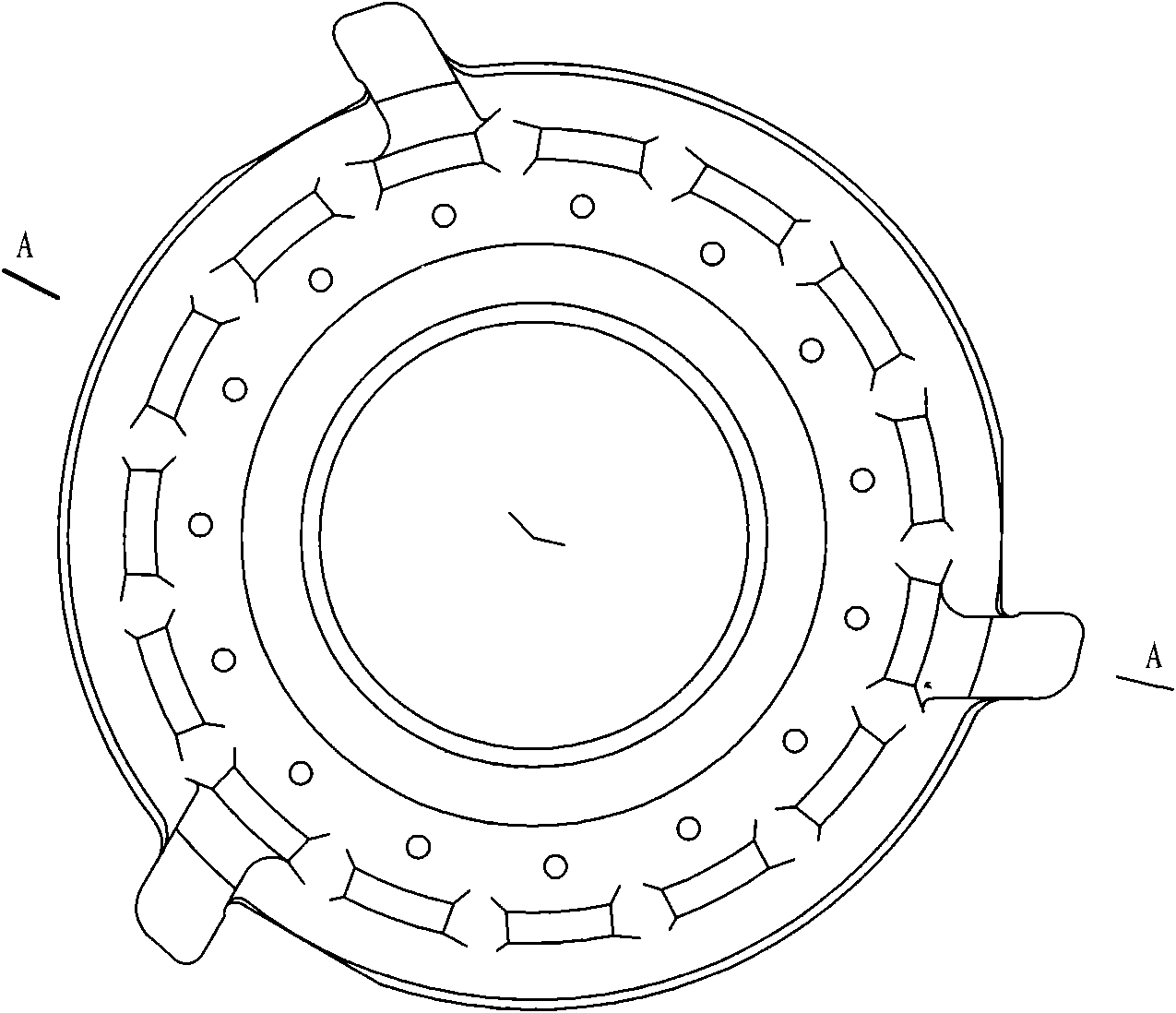

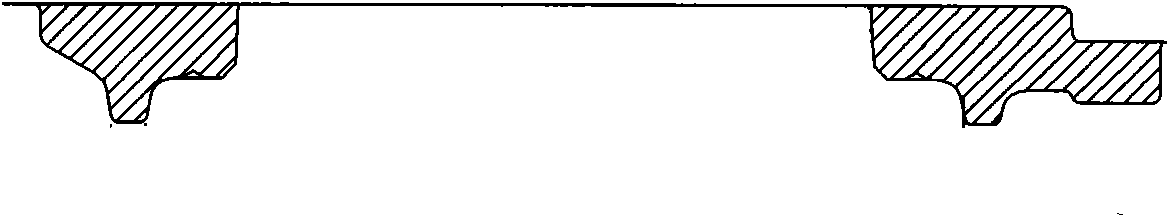

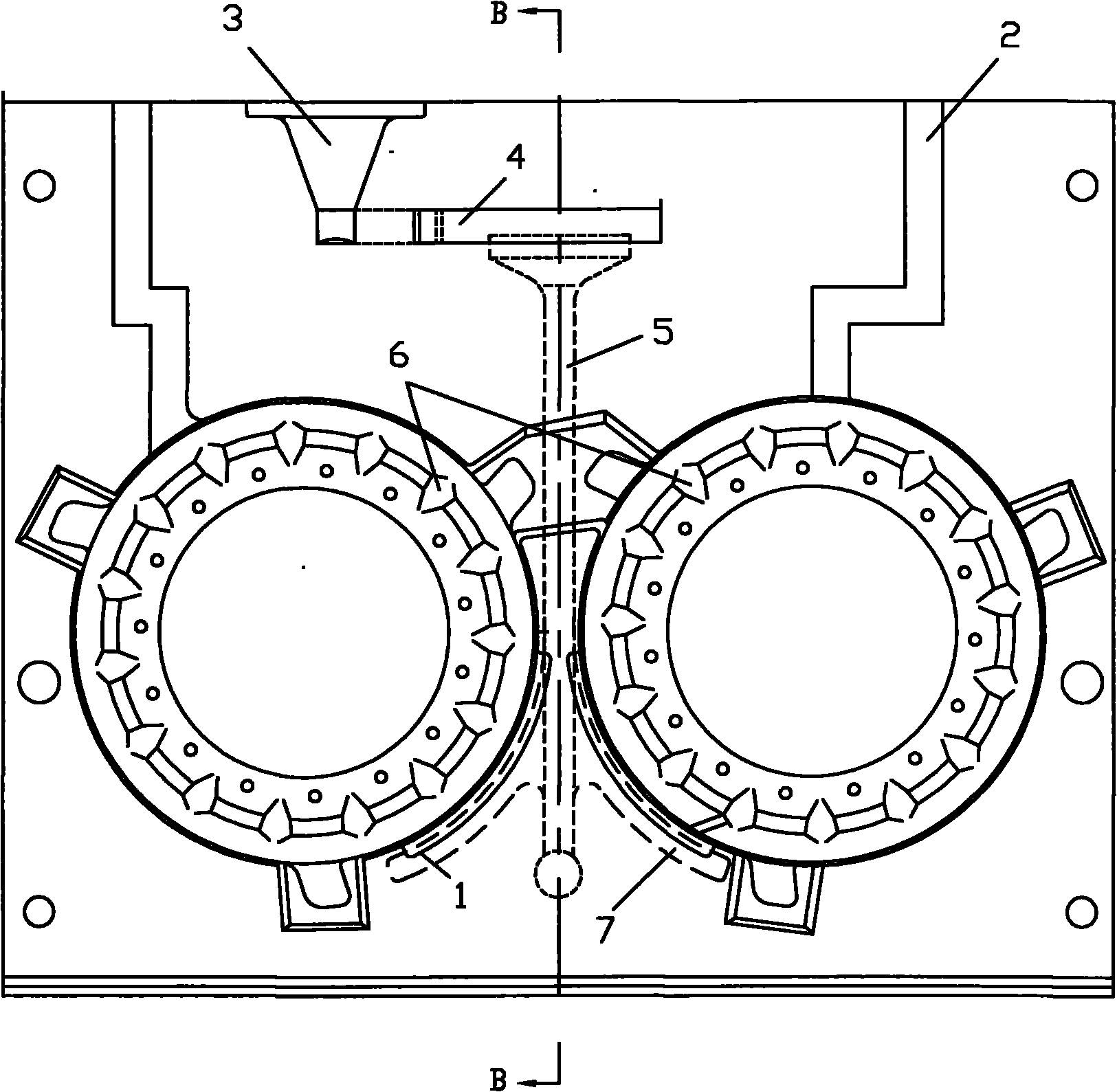

[0036] Among them, the two casting blanks are horizontally symmetrically arranged, and the inner runner 1 through which the molten iron enters the cavity and the air outlet piece 2 for exhaust are arranged symmetrically, so that the filling process of the two castings with molten iron is exactly the same, thus ensuring that the two castings have exactly the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com