Patents

Literature

30results about How to "Full metallurgical reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

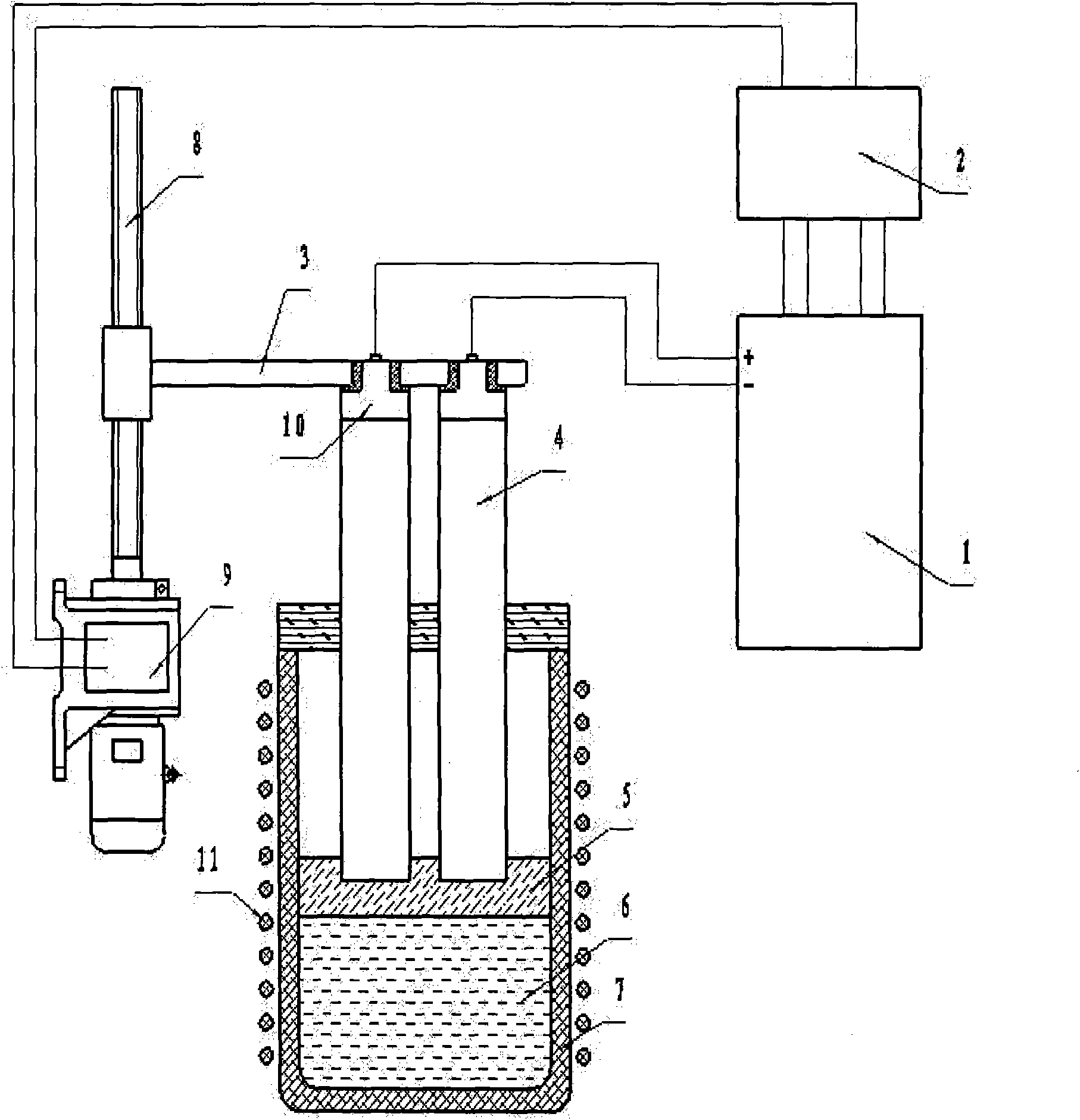

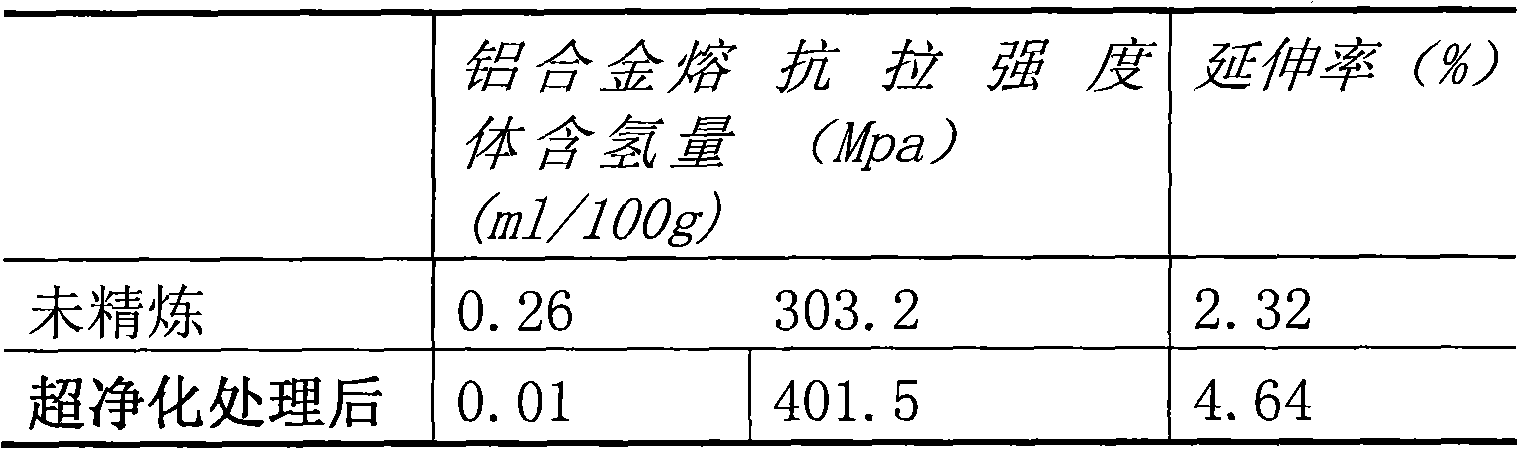

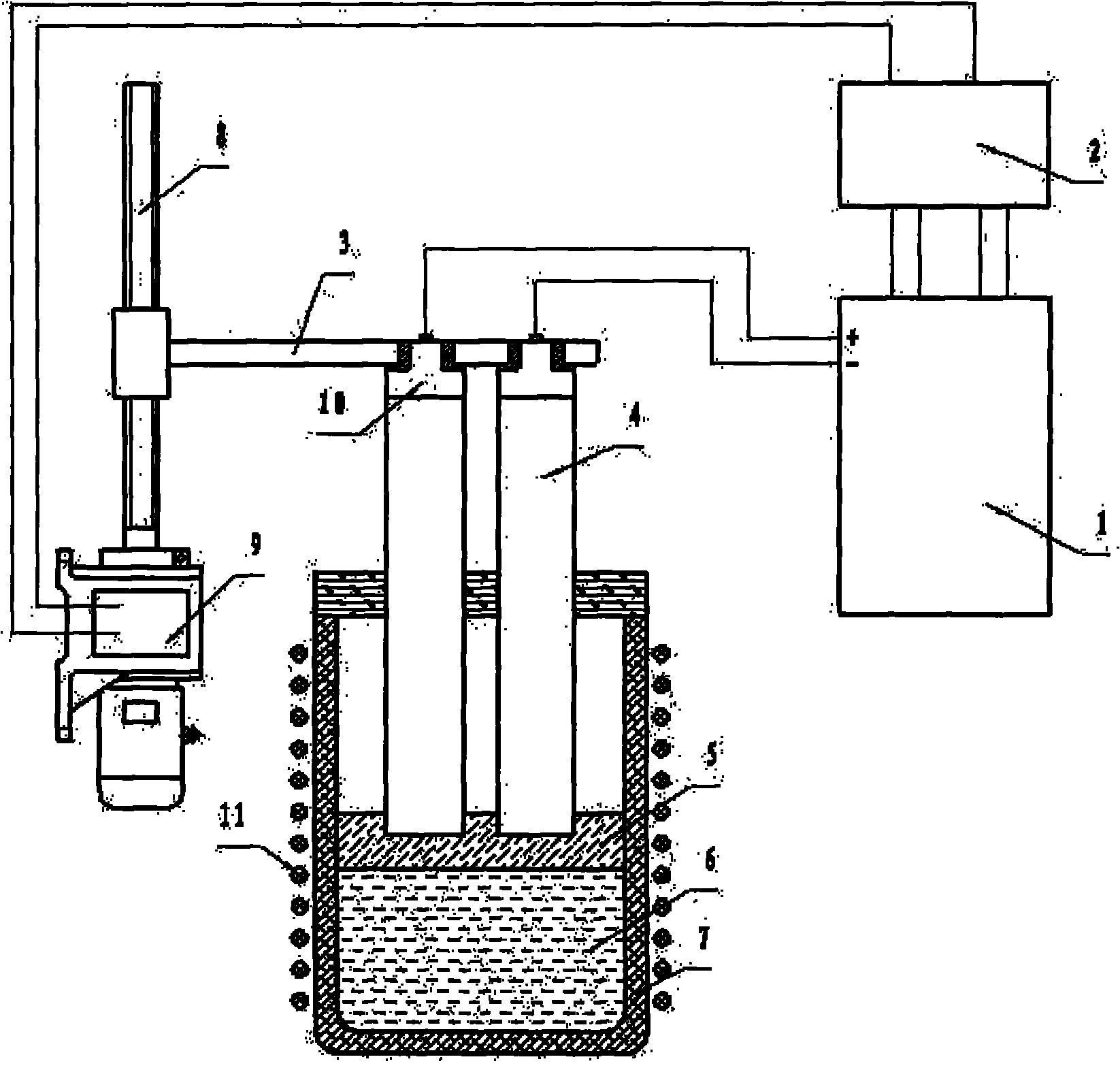

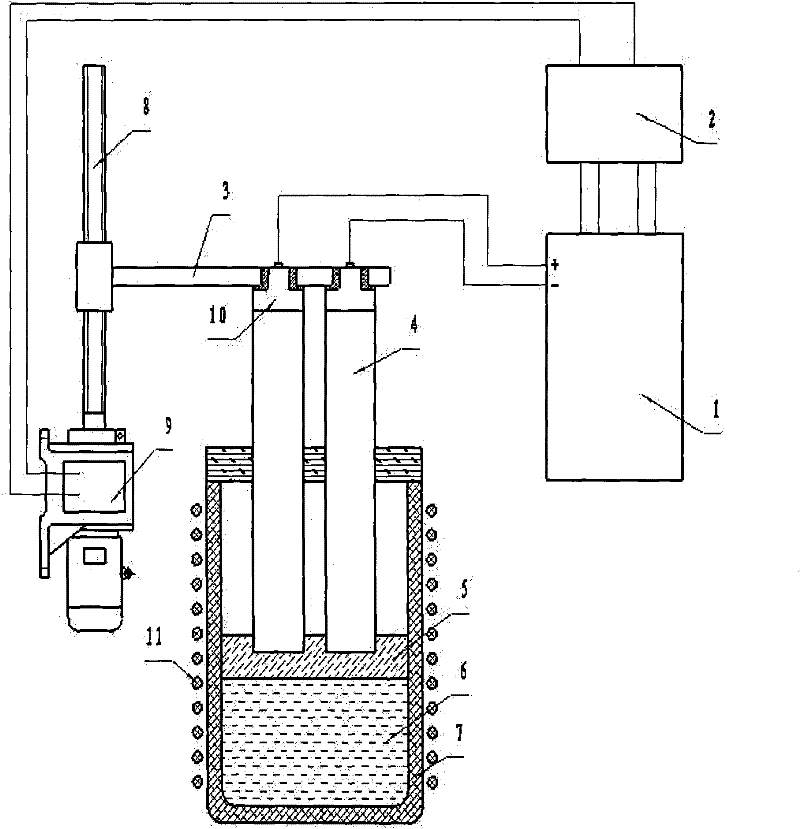

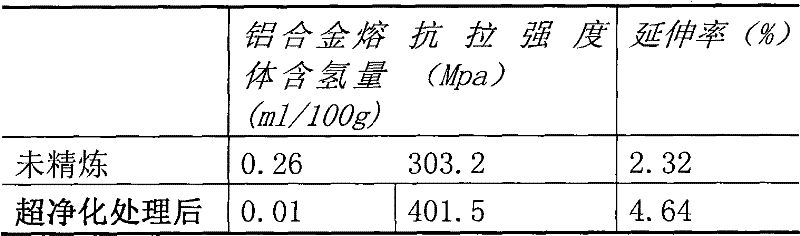

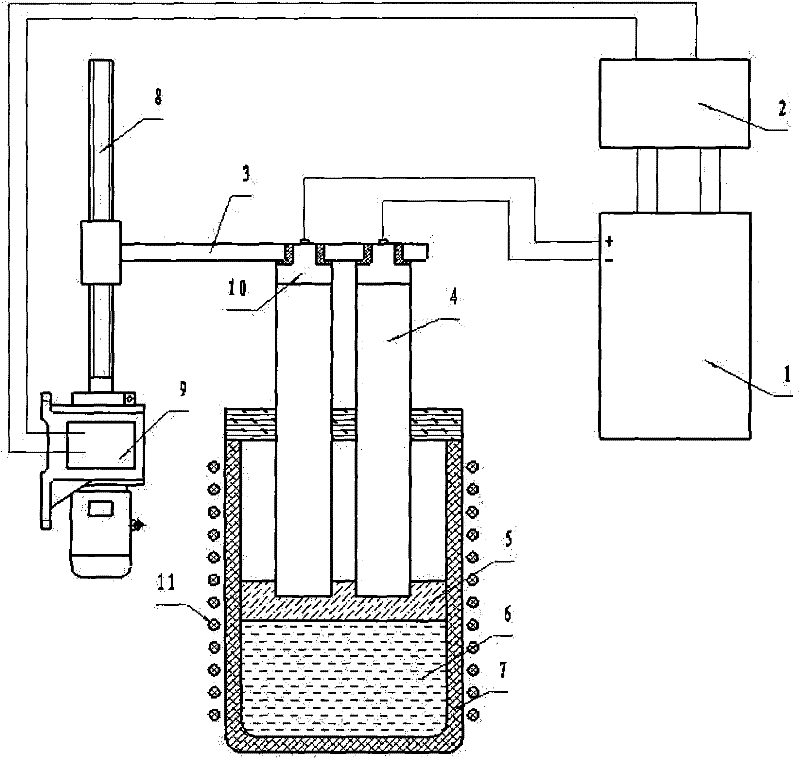

Aluminum alloy super-purification refining method

The invention discloses an aluminum alloy super-purification refining method, and aims to reduce the hydrogen content, oxide inclusion content and harmful alloy element content in the aluminum alloy. The method comprises the following steps of: arranging two aluminum alloy blanks to be melted on a lifting mechanism and connecting the two aluminum alloy blanks to the positive electrode and the negative electrode of a melting power supply respectively; arranging a non-metal crucible under the aluminum alloy blanks, placing the slag in the crucible and heating the slag to the working temperature of between 630 and 700 DEG C to change the slag into a liquid state; starting the lifting mechanism to drop the aluminum alloy blank and extend the lower end into the liquid-state slag, wherein the immersion depth is 10mm, and opening cooling water; preserving heat for a certain time and switching on the melting power supply after the slag in contact with the aluminum alloy blank is remelted, wherein the current is 250 to 280A and the voltage is 8 to 9V; automatically feeding by the lifting mechanism according to a voltage value and feeding downwards when the voltage value is more than 9V; stopping the feeding when the voltage value is less than 8V; when the feeding is stopped, increasing the voltage value along with the continuous melting of the aluminum alloy blank; automatically adjusting the feeding process by the lifting mechanism until all the aluminum alloy blanks are fed into the melting crucible by a feeding mechanism; ending the melting and closing the melting power supply when the feeding mechanism feeds the aluminum alloy blanks to the bottommost part and the voltage is more than 9V; and lifting the lifting mechanism, scratching the slag in the crucible out and casting an ingot with the refined aluminum alloy liquid or directly pouring a cast.

Owner:ZHONGBEI UNIV

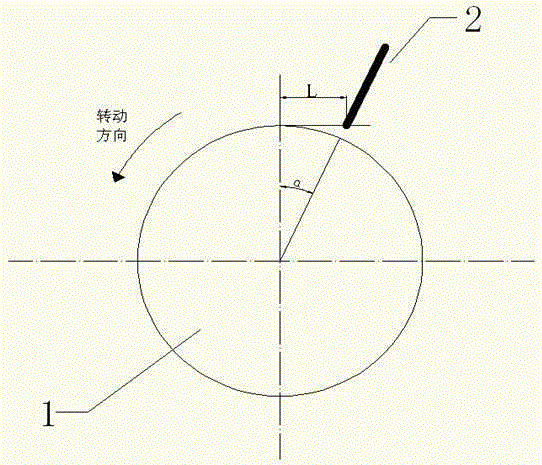

Surfacing welding method for abraded large roll shaft

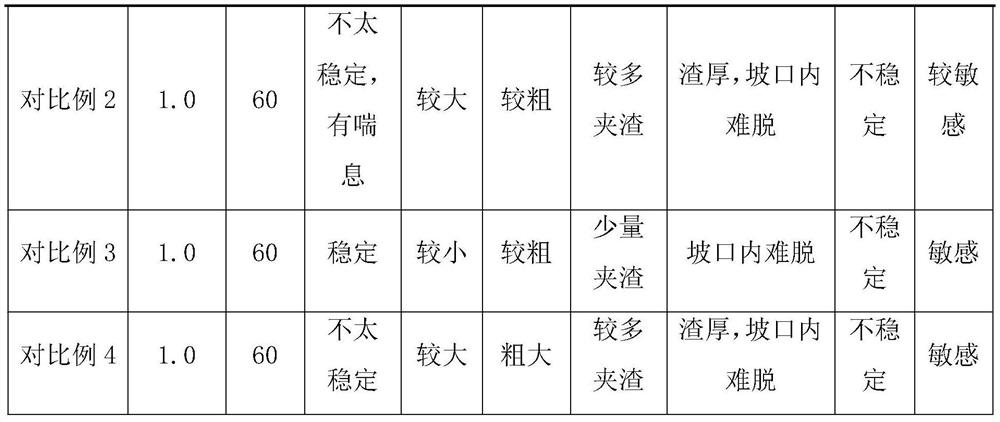

ActiveCN105382378AReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

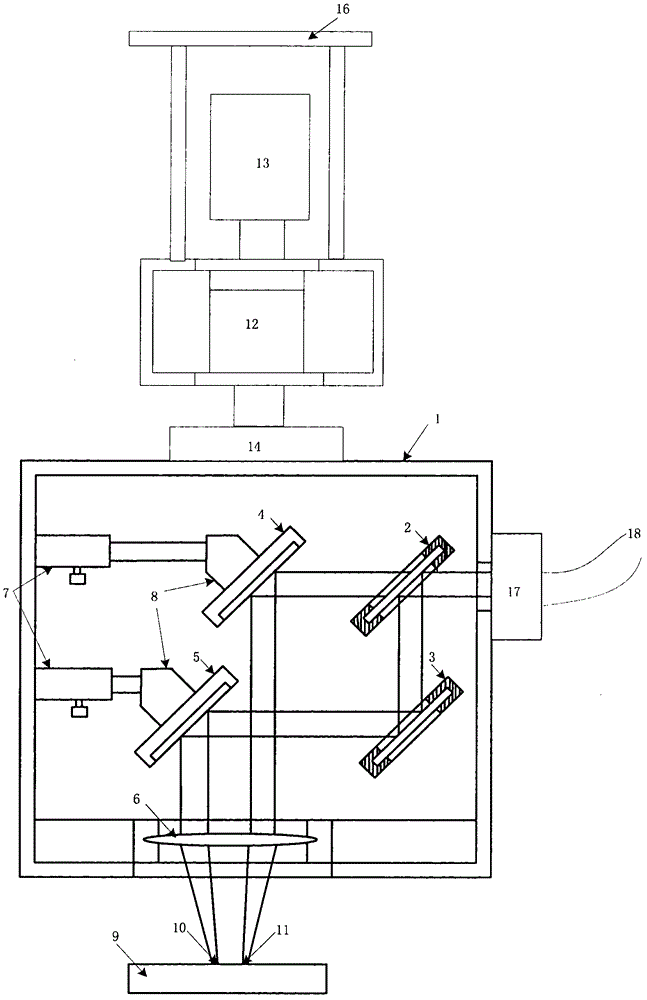

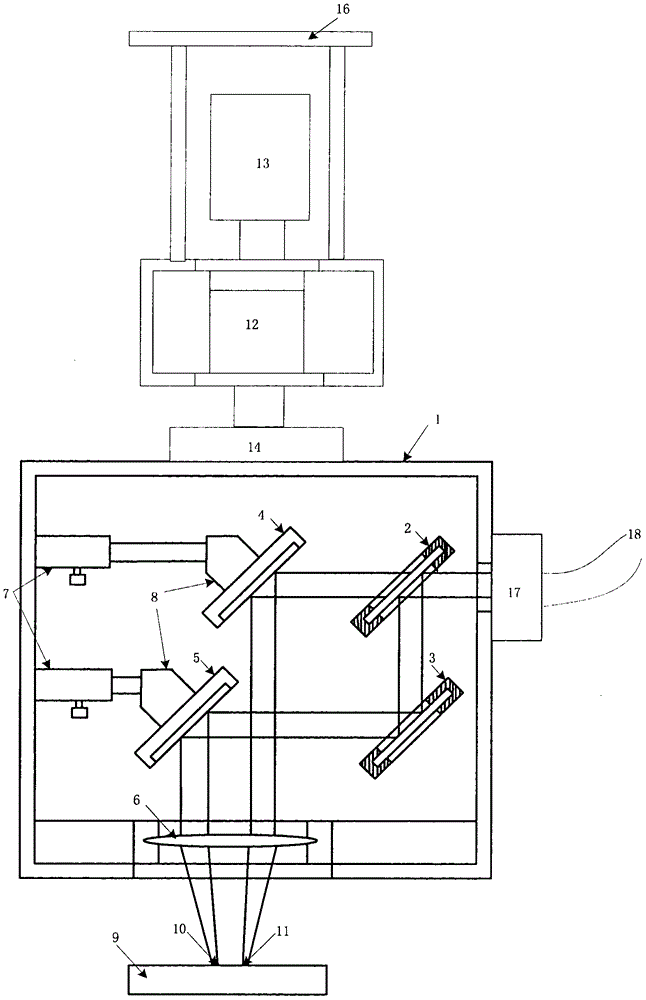

Beam splitting double-focus-point laser processing head

ActiveCN104801852ALower requirementMeets high energy density requirementsLaser beam welding apparatusLaser processingBeam splitting

The invention provides a beam splitting double-focus-point laser processing head, which comprises a light path cavity, a cavity connecting box, a servo motor and an external connecting flange, wherein the light path cavity is connected with an output shaft of the servo motor through a shaft coupler, a beam splitting mirror, a first reflecting mirror, a second reflecting mirror, a third reflecting mirror, a focusing mirror and two telescopic sleeves are arranged inside the light path cavity, the beam splitting mirror and the first reflecting mirror are respectively and fixedly arranged on the side wall of the light path cavity through a regulating mirror seat, the second reflecting mirror and the third reflecting mirror are respectively arranged on the telescopic ends of the two telescopic sleeves through a regulating mirror seat, and the fixing ends of the telescopic sleeves are arranged on the side wall of the light path cavity. The beam splitting double-focus-point laser processing head has the advantages that an incident laser beam is subjected to space beam splitting, the front focusing point and the back focusing point are realized, the relative space position between the double light beam focusing points is changed, the utilization efficiency of laser energy is improved, the laser welding plasma shielding effect can be effectively inhabited, the processing depth is improved, and the laser processing quality is improved.

Owner:WENZHOU UNIVERSITY

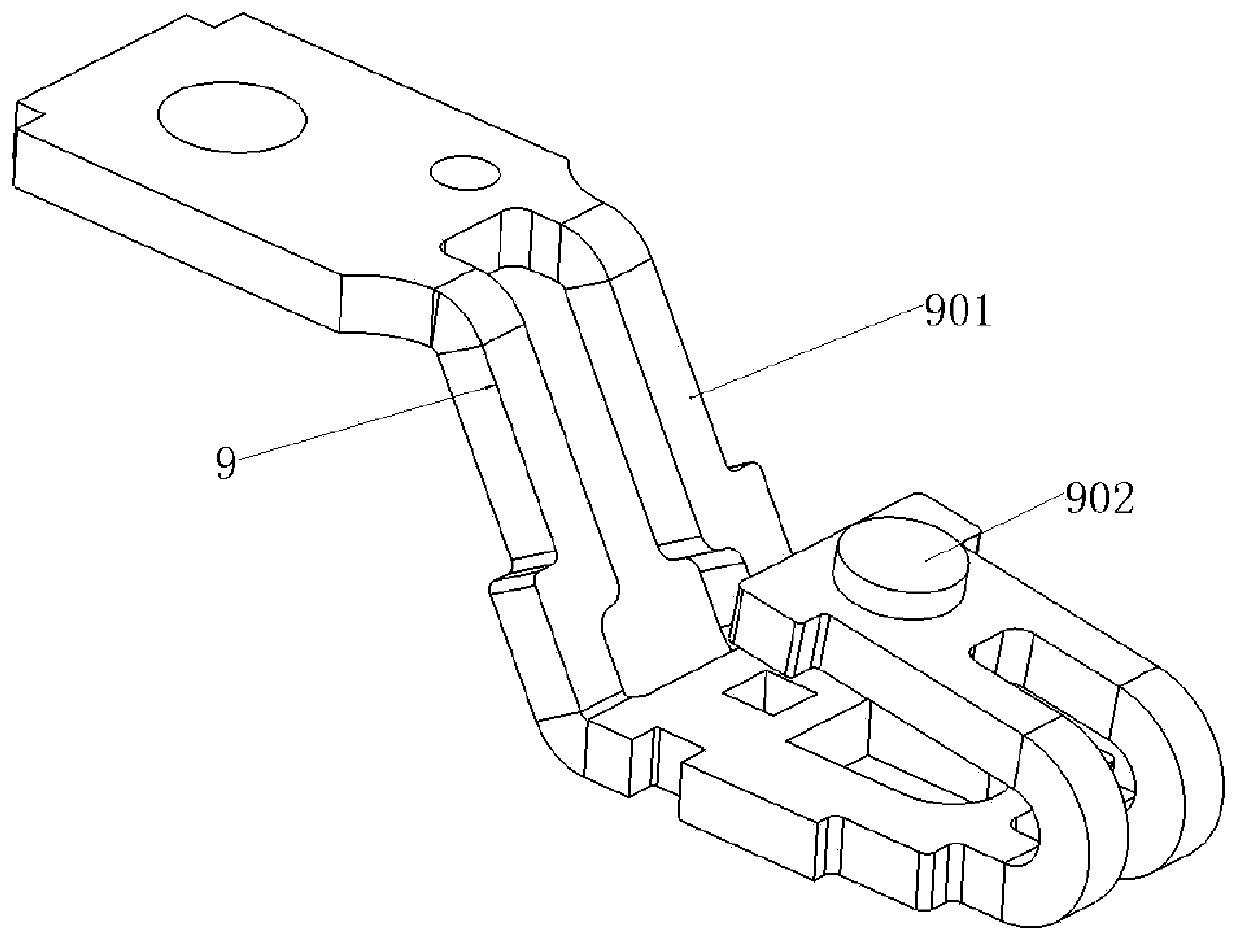

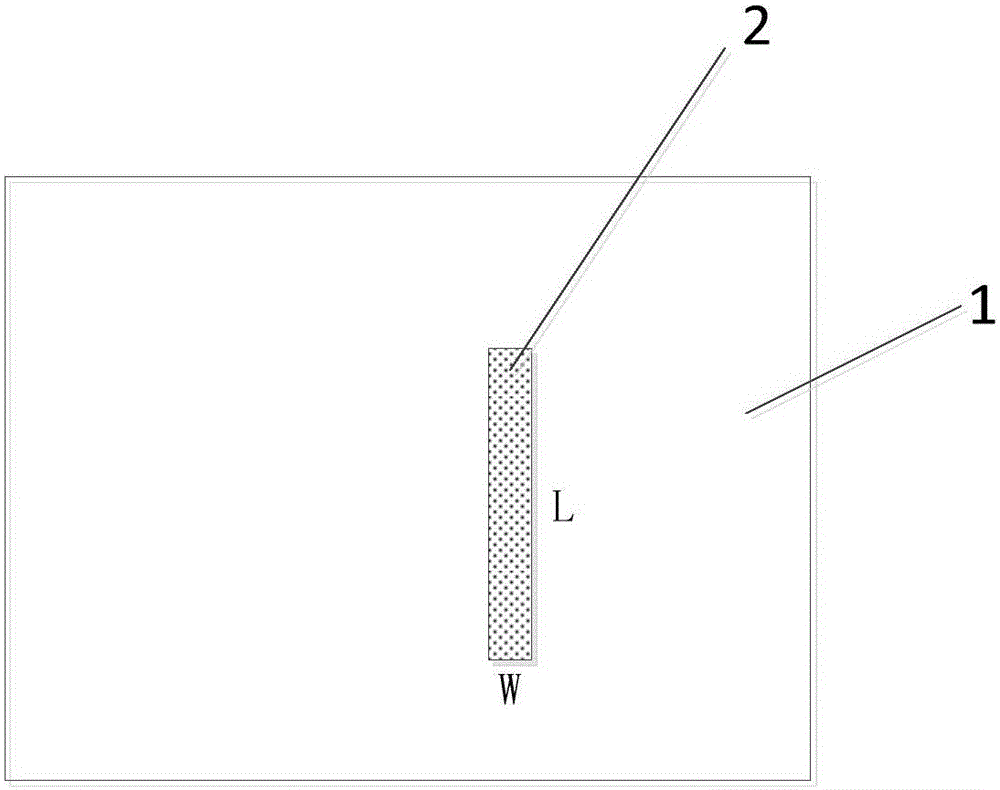

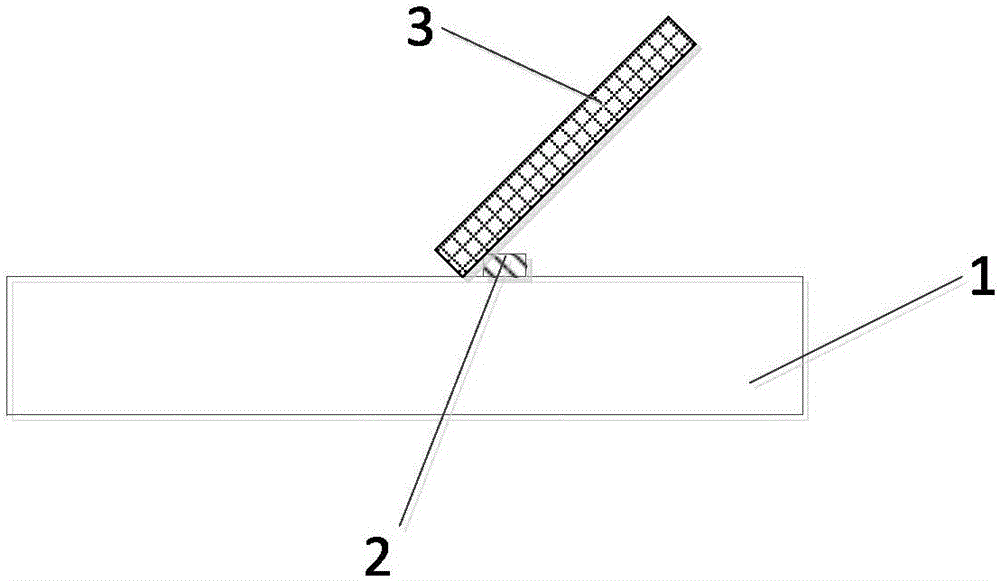

Ultrasound-assisted laser brazing method and device for dissimilar-metal assembly piece

ActiveCN107225327ARealize the welding effectHigh dimensional accuracyWelding/soldering/cutting articlesLaser beam welding apparatusUltrasonic assistedEngineering

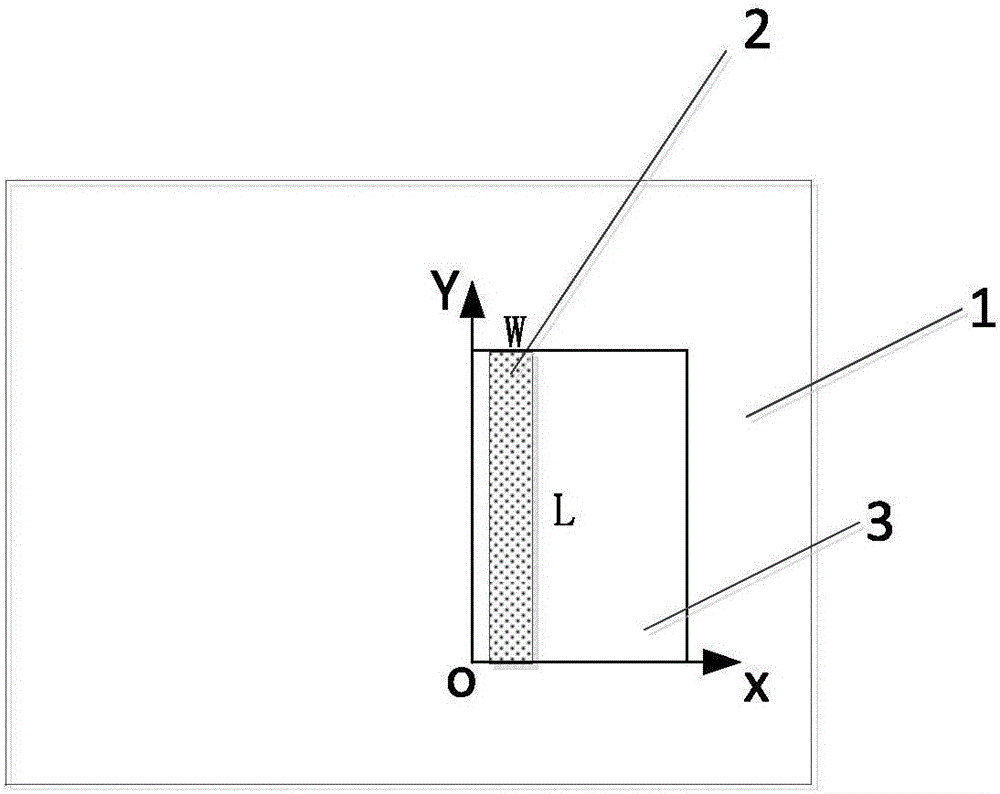

The invention provides an ultrasound-assisted laser brazing method for a dissimilar-metal assembly piece. The ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece comprises the steps that (1) a locating die is used for clamping a A-metal stand column; (2) the upper end of the A-metal stand column is heated to be soft; (3) the upper end, which is induction-heated and softened, of the A-metal stand column is inserted into a profiling hole of a B-metal base, and then a dissimilar-metal laser welded preassembly piece is obtained; (4) an ultrasonic vibration source connected with a locating die assembly is started, the laser is emitted out, under the auxiliary action of an ultrasonic vibration composite energy field, a laser-MIG composite welding head conducts melt-brazing along the outline of a connection face of the A-metal stand column and the B-metal base; and (5) the dissimilar-metal laser welded assembly piece is transfers to a conveyer belt and then falls into a material box. By the adoption of the ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece, the large-fusion-depth narrow-weld-joint welding effect can be achieved, and a welded connector better in metallurgical quality is obtained. The invention further provides an ultrasound-assisted laser brazing device for the dissimilar-metal assembly piece.

Owner:山东承坤信息科技有限公司

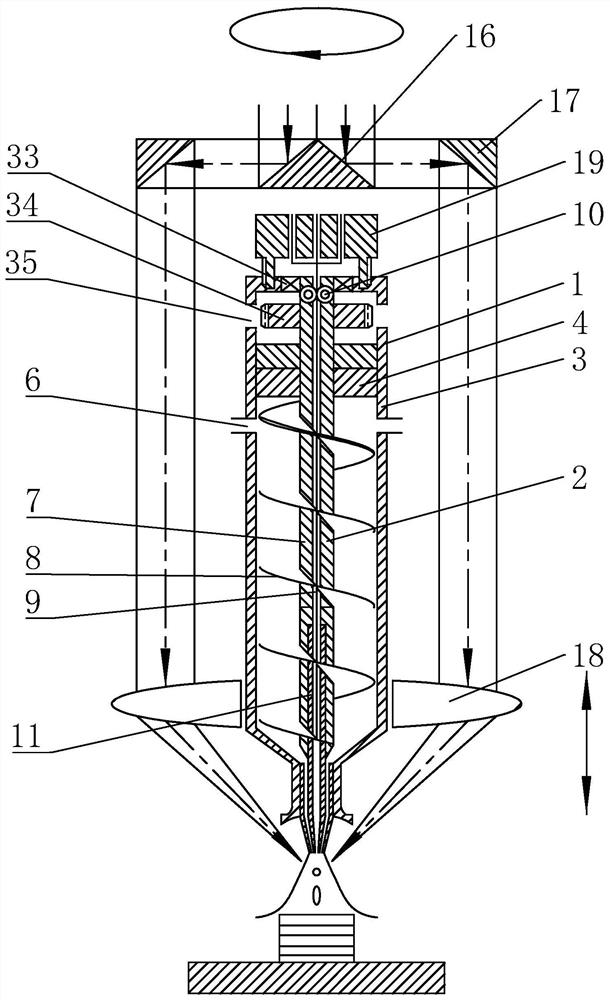

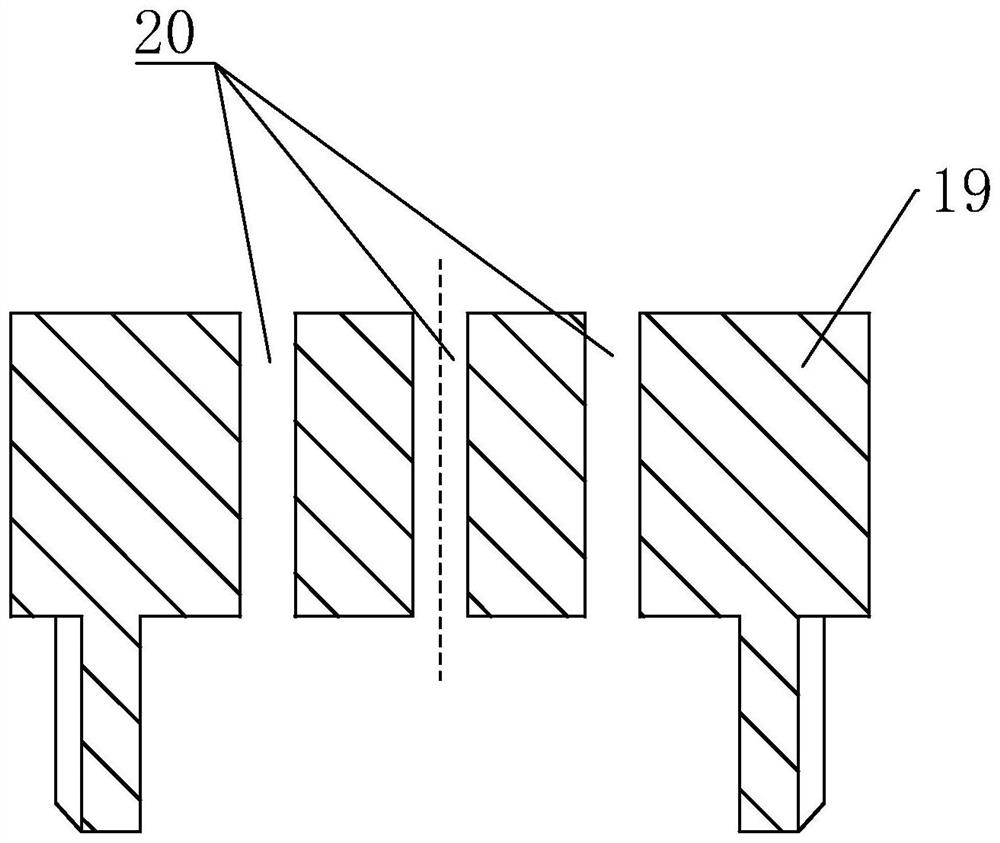

Wire-powder cooperation and laser-electric arc composite additive manufacturing device and method

ActiveCN113385821AEffective Online ProvisioningFull overflowLaser beam welding apparatusElectric arcBeam splitter

The invention discloses a wire-powder cooperation and laser-electric arc composite additive manufacturing device and method. The additive manufacturing device comprises a non-consumable electrode electric arc welding gun device for wire-powder coaxial heating feeding and a laser splitter set; the non-consumable electrode electric arc welding gun device for wire-powder coaxial heating feeding comprises an ultrasonic vibration gun body and a spiral stirring assembly, the ultrasonic vibration gun body comprises an amplitude-change pole and a transducer, the lower end of the amplitude-change pole is in a concave spherical curved surface shape, a powder feeding and air feeding combined channel is formed in the side portion of the amplitude-change pole, the spiral stirring assembly comprises a spiral stirring rod and a spiral blade, a main wire feeding and air feeding combined channel is arranged in the spiral stirring rod, and a hollow tungsten electrode is connected to the bottom of the spiral stirring rod; and the laser splitter set comprises a splitting reflector, a reflector set and a convex lens. The additive manufacturing device can achieve multi-mode additive manufacturing of field-force-heat combination and distribution, and has the advantages of being diversified in additive modes, high in additive efficiency, good in forming quality, high in material utilization rate, high in combinability and capable of adjusting alloy components flexibly.

Owner:温州竞合智造科技有限公司

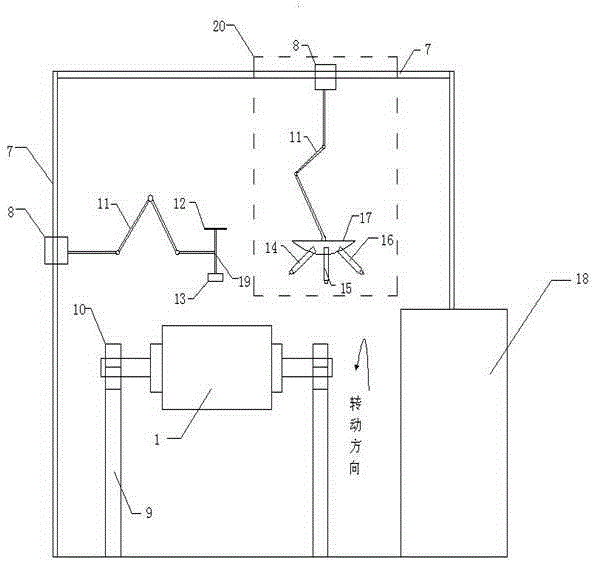

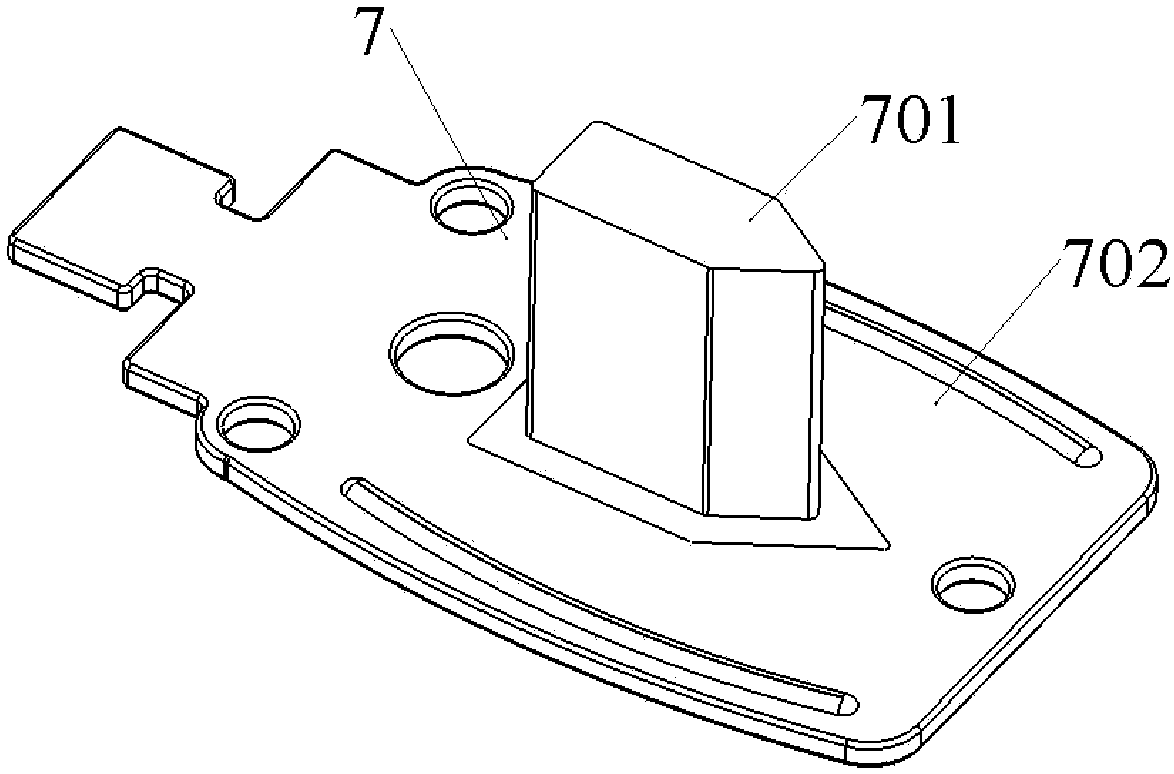

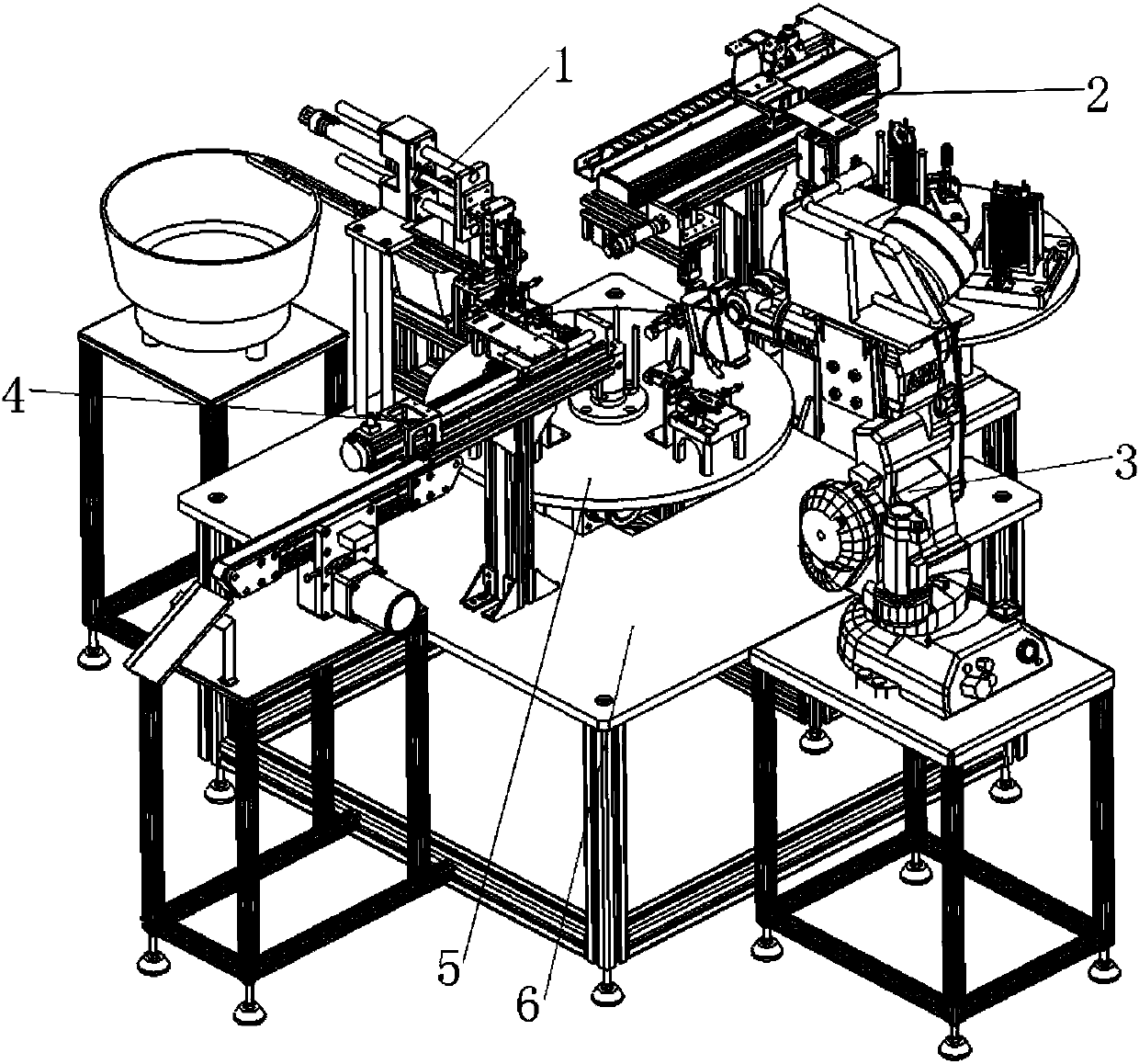

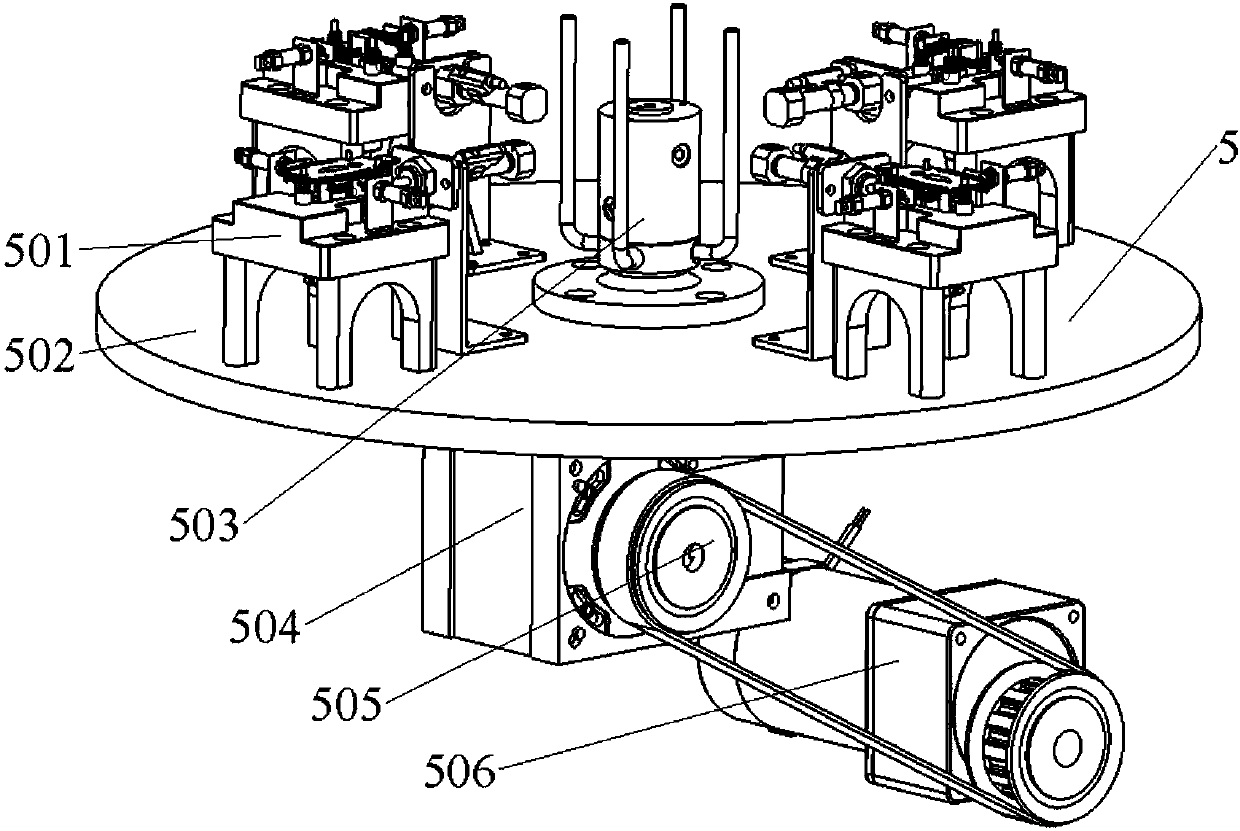

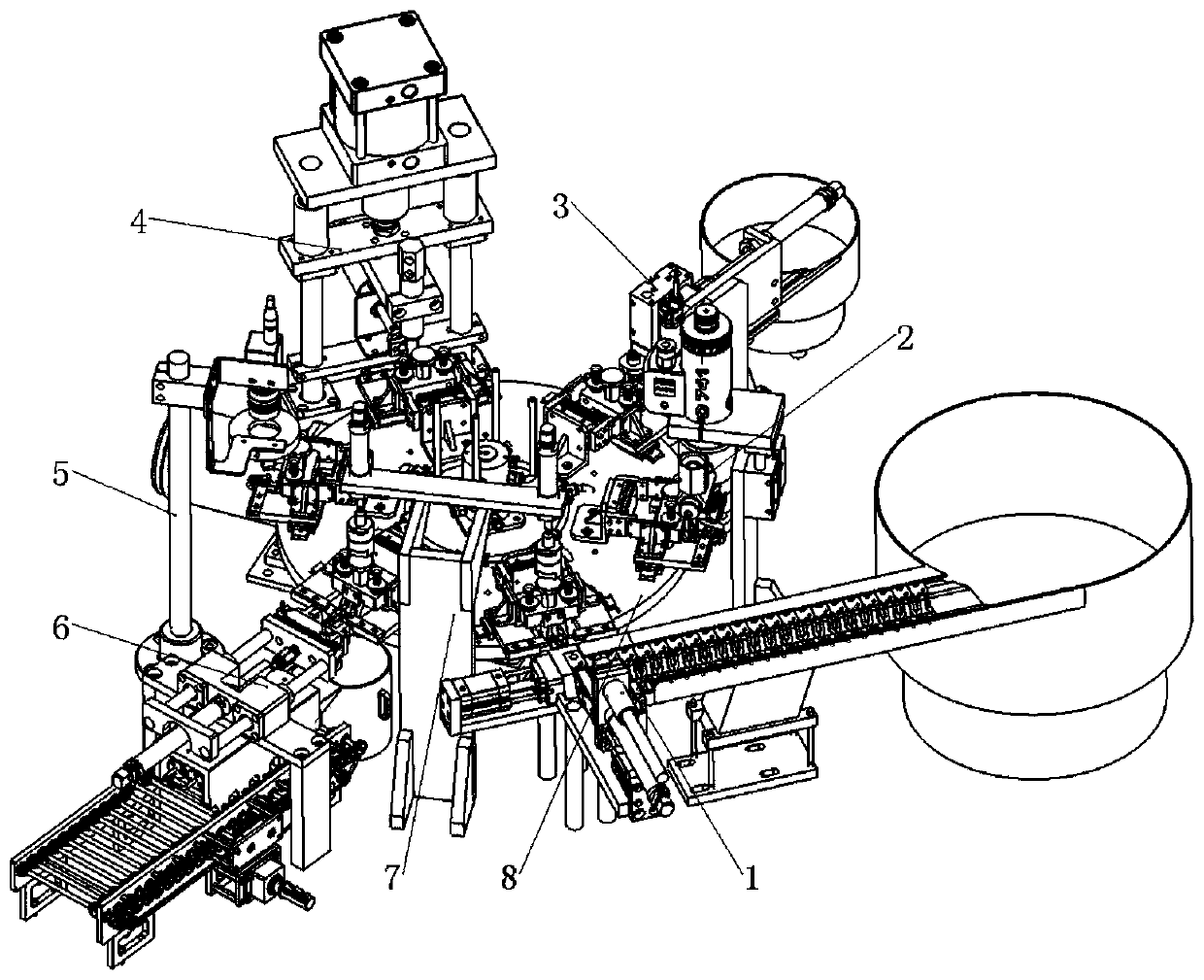

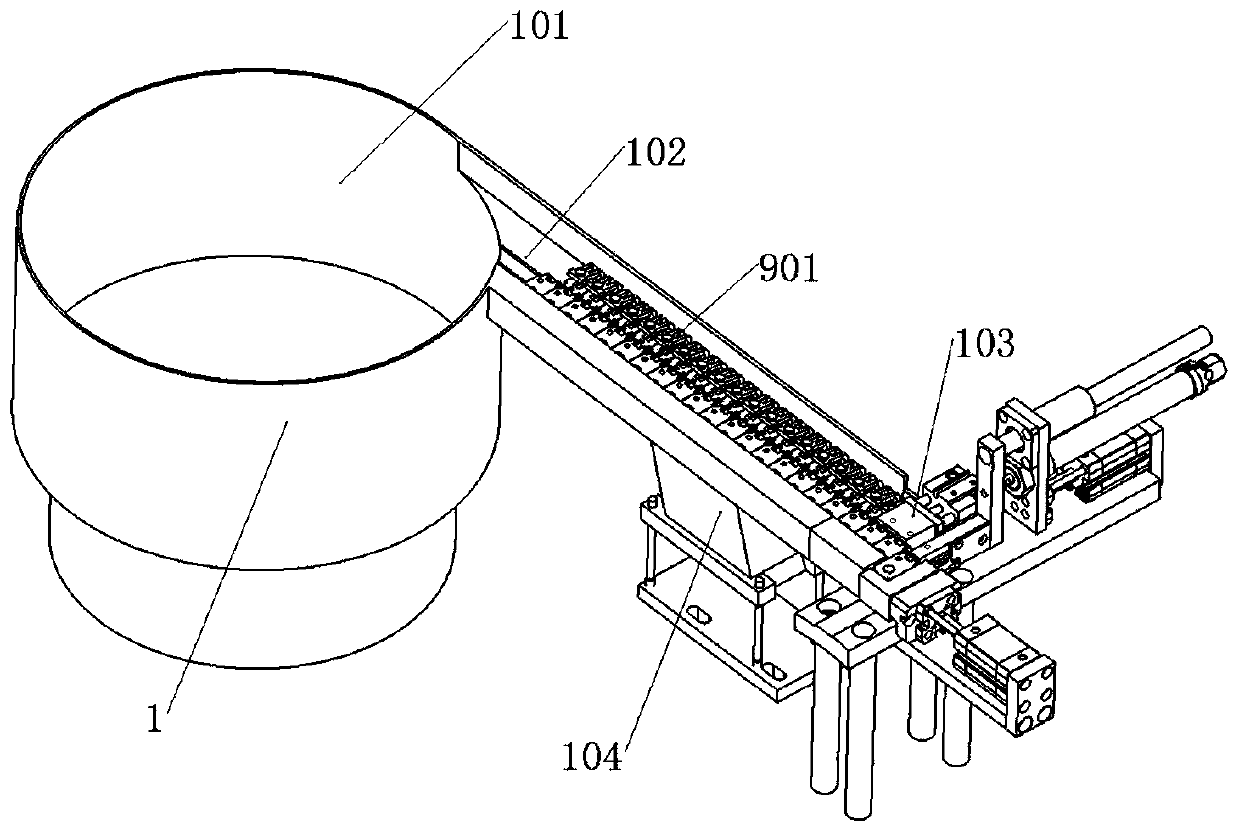

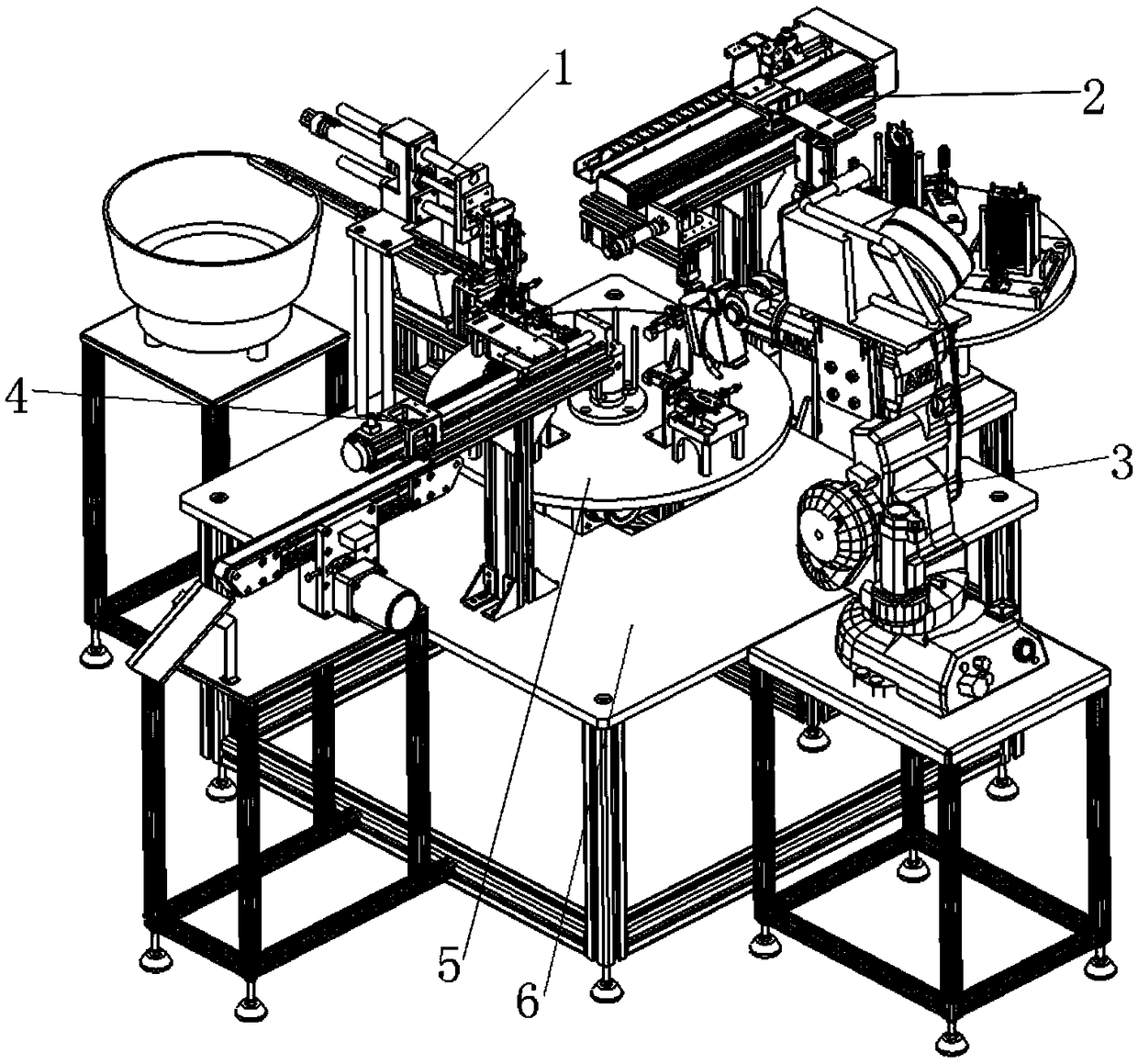

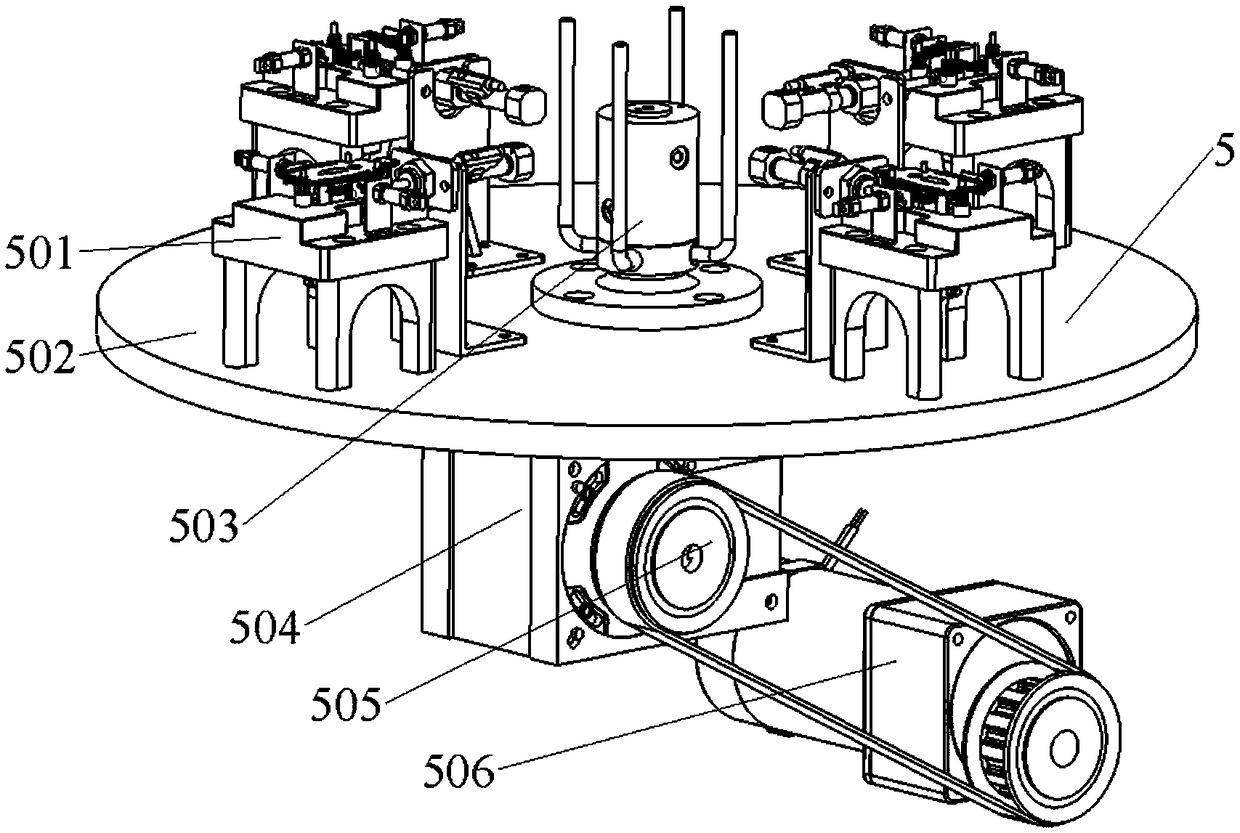

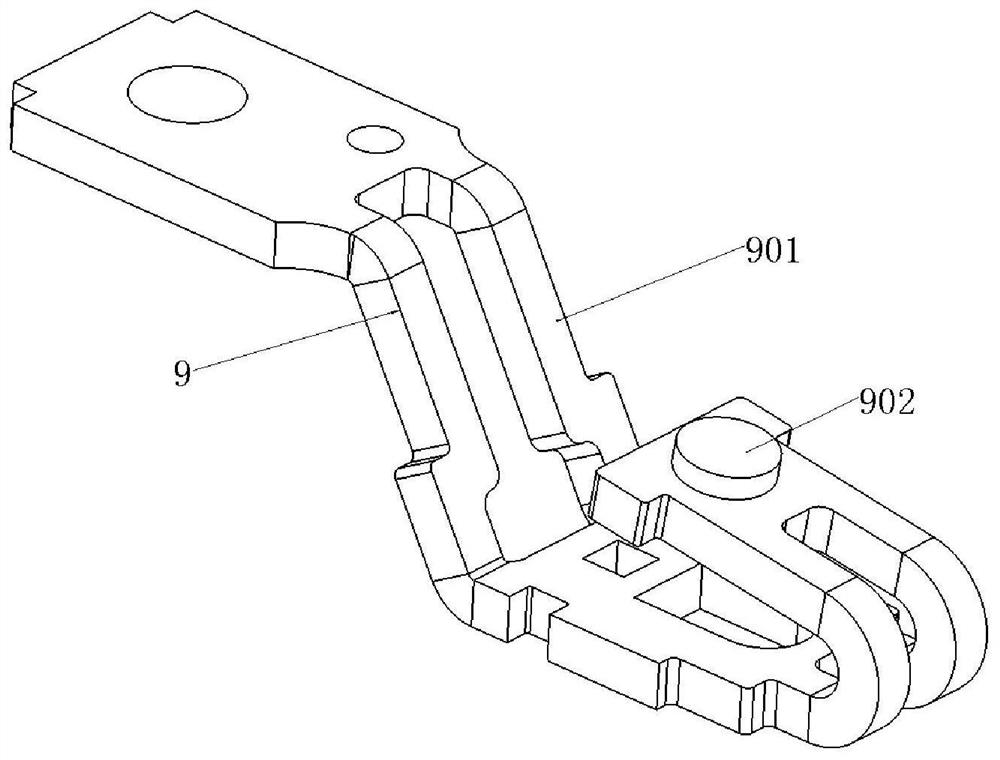

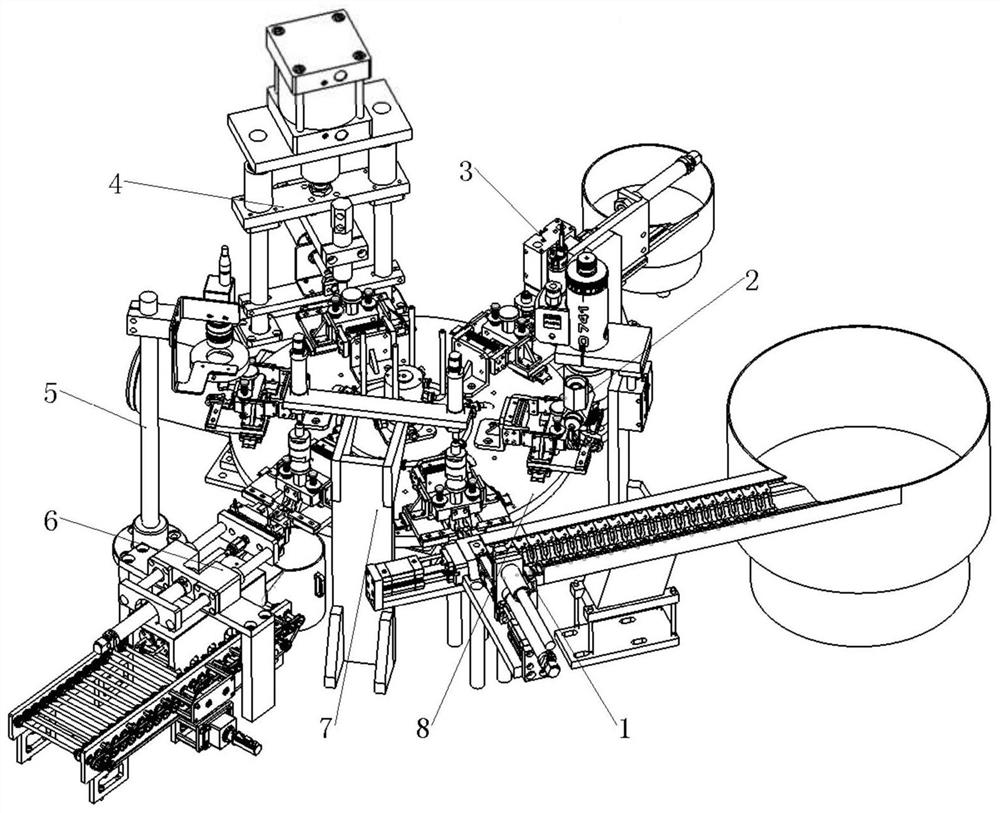

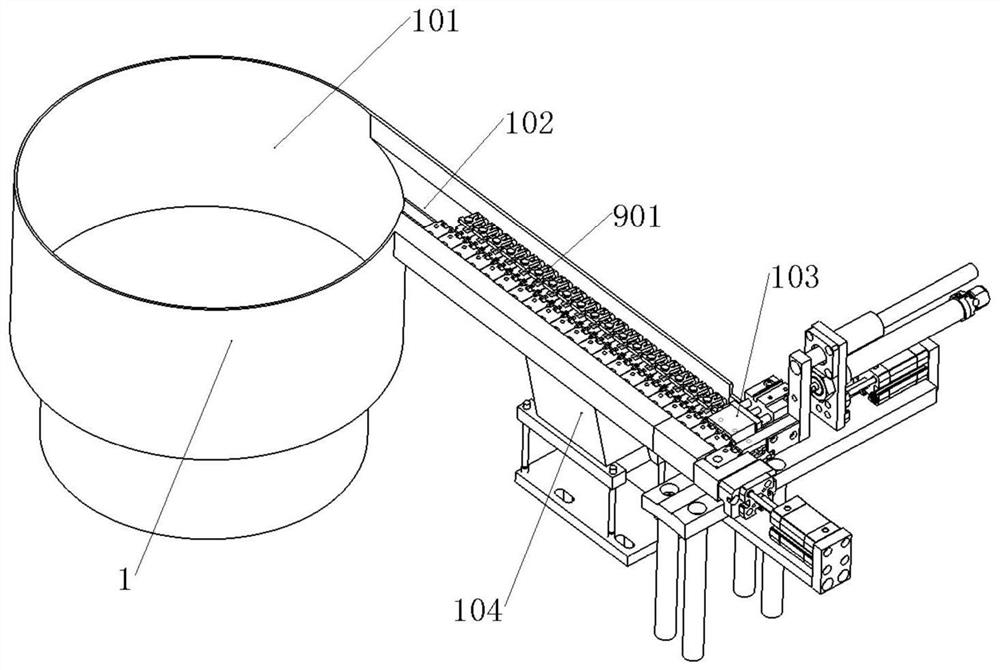

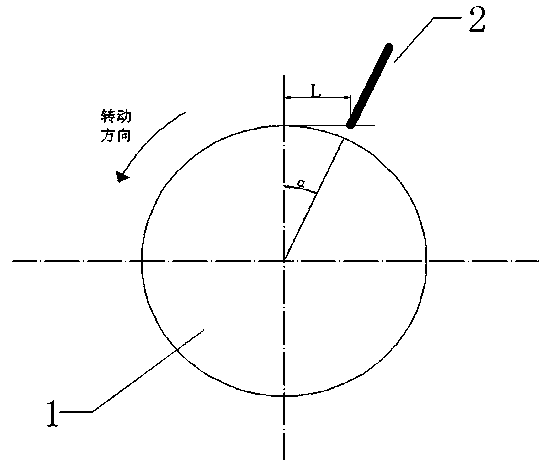

Electrical contact system ultrasonic-assisted high-frequency induction brazing device

ActiveCN110355437AImprove brazing rateImprove welding strengthMetal working apparatusSoldering auxillary devicesElectricityUltrasonic assisted

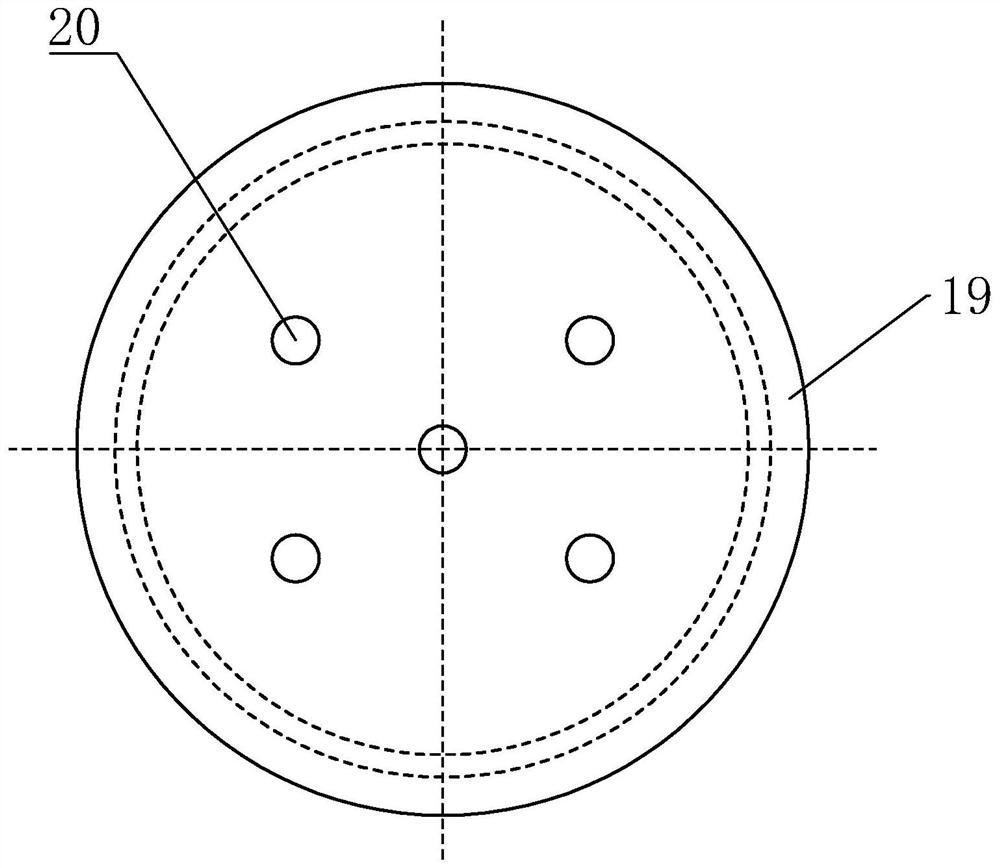

The invention provides an electrical contact system ultrasonic-assisted high-frequency induction brazing device. A body of the device adopts a six-index cam divider for driving, six assembling and machining stations are arranged on the periphery of a cam divider workbench in sequence, and a same positioning mould is arranged on each assembling and machining station. The electrical contact system ultrasonic-assisted high-frequency induction brazing device specifically comprises a contact bridge feeding assembly, a soldering paste dripping assembly, a contact feeding assembly, a high-frequency induction brazing assembly, a CCD industrial camera assembly, a discharging assembly, an electric chuck assembly 7 and a cam divider assembly. According to the device, through ingenious and reasonablestructural design, a high-frequency induction heat source and ultrasonic vibration double compound energy field is integrated in a compact space; through process procedure design, the welding positions are optimized before, during and after welding correspondingly; and the automation degree is high, and both the machining efficiency and the brazing quality are taken into consideration.

Owner:山东承坤信息科技有限公司

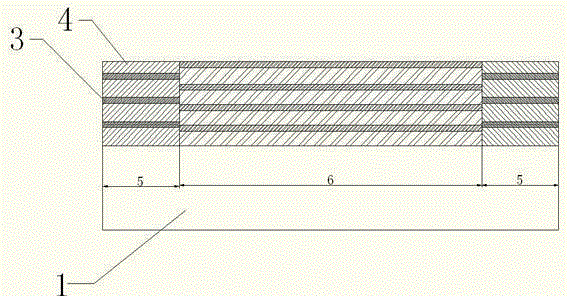

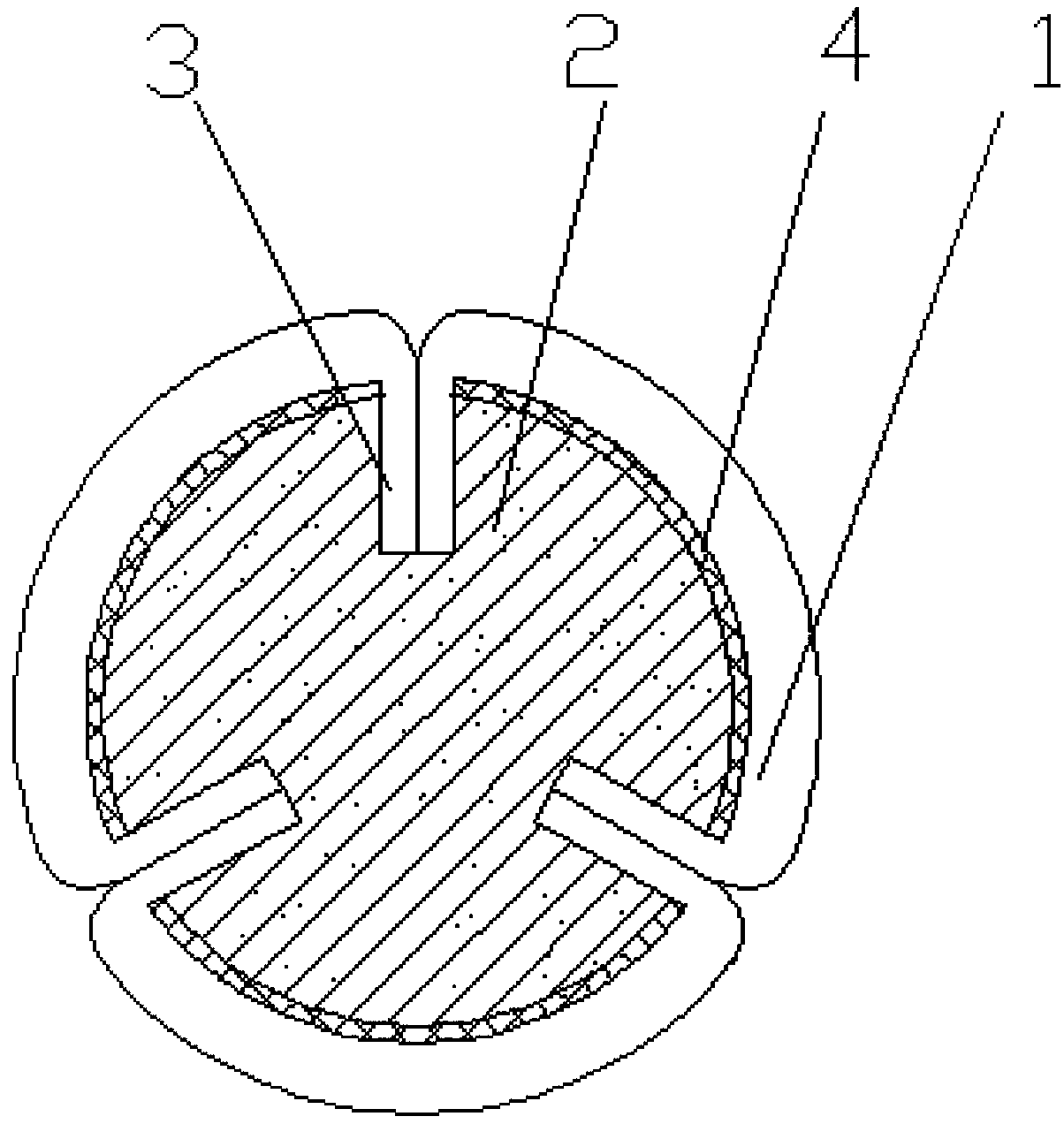

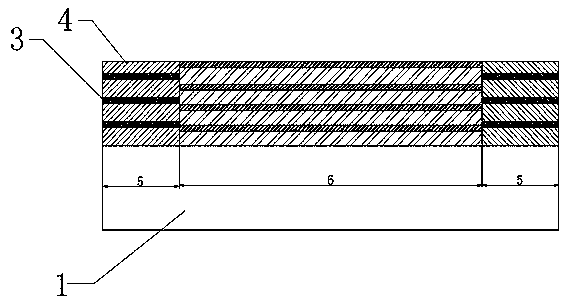

Marine side plate capable of resisting seawater corrosion and ocean environment corrosion

InactiveCN102554190AFull metallurgical reactionHigh bonding strengthHull shellsPhysical chemistryBronze

The invention discloses a marine side plate capable of resisting seawater corrosion and ocean environment corrosion, comprising a gray pig iron base body and a high-aluminum bronze based ceramic compound casting layer which is compounded on the outer surface of the gray pig iron base body and is capable of resisting the seawater corrosion. SiC ceramic in the compound layer on the surface of the corrosion-resisting marine side plate disclosed by the invention is uniformly distributed and the volume fraction is controllable; the compound casting layer is combined with the gray pig iron base body in a smelting manner and the casting layer is not cracked or damaged; and the corrosion resistance of the marine side plate disclosed by the invention is more than three times as much as that of a common antiseptic gray pig iron marine side plate which is coated by paint.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

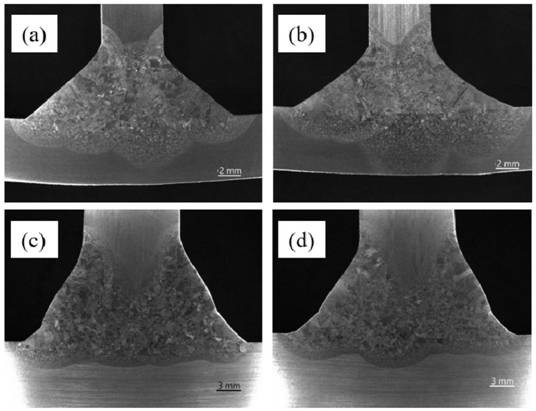

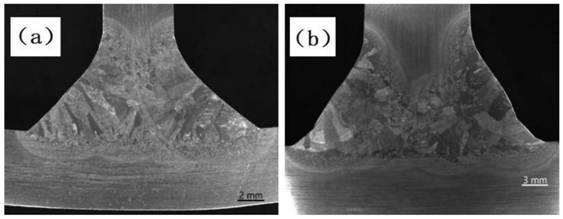

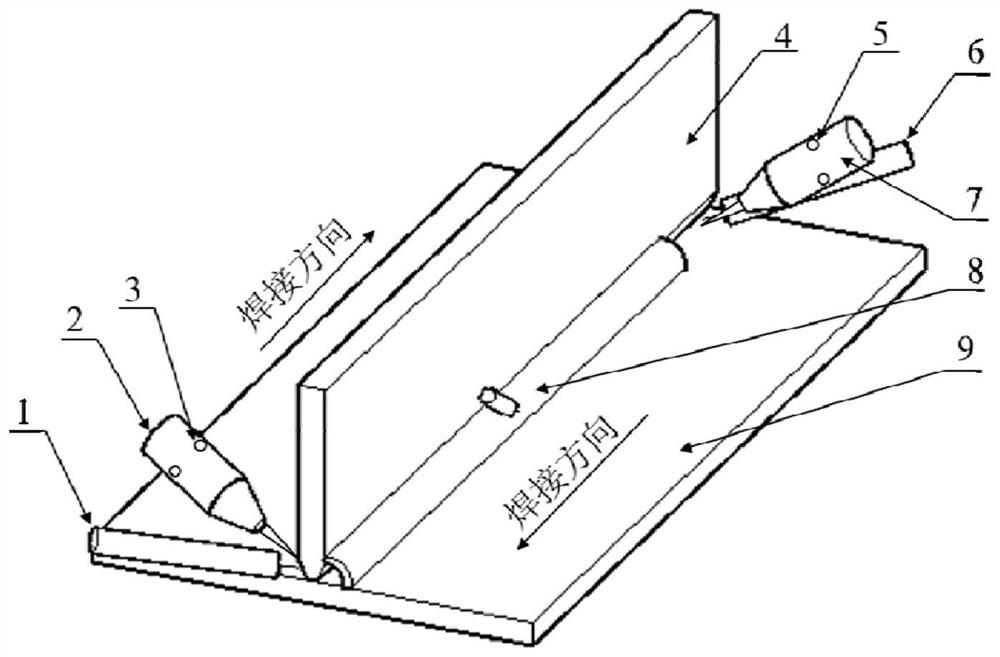

Welding method for heterogeneous titanium alloy T-shaped joint

ActiveCN113814535AImprove consistencyImprove welding strengthArc welding apparatusIncreasing energy efficiencyShielding gasStructural engineering

The invention discloses a welding method of a heterogeneous titanium alloy T-shaped joint, which comprises the following steps of: 1, processing a to-be-welded part of a rib plate into a K-shaped groove, and fixing the K-shaped groove on a welding tool clamp; 2, adopting coaxial powder feeding type laser cladding, wherein lasers act on the to-be-welded area on the two sides of the T-shaped connector correspondingly, an MIG welding gun swinging periodically is arranged on the rear side of a laser beam, and the included angle between the MIG welding gun and the rib plate and the included angle between the laser beam and the rib plate are adjusted to be located on the same plane; 3, setting welding process parameters; and 4, introducing shielding gas in advance, conducting double-face laser cladding composite electric arc welding of the T-shaped connector, conducting synchronous different-direction welding on welding heat sources on the two sides, wherein electric arcs swing periodically, single-pass welding forming of the workpiece is achieved, and the shielding gas is continuously introduced for cooling after welding. The laser cladding powder is used for regulating and controlling configuration, the internal consistency of the welding seam is enhanced, the welding seam strength is improved, and cracks are restrained through components of the welding wire before solidification of a molten pool.

Owner:JIANGSU UNIV OF SCI & TECH +1

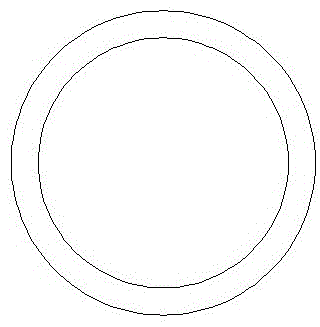

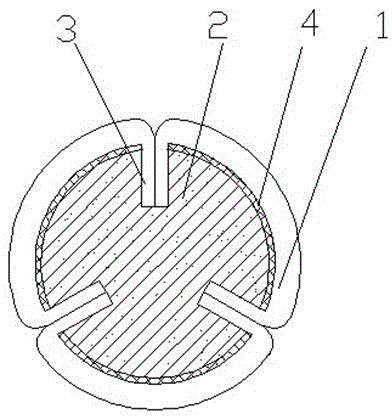

Flux-cored wire

InactiveCN104668805AEvenly distributedEvenly meltedWelding/cutting media/materialsSoldering mediaElectric arcEngineering

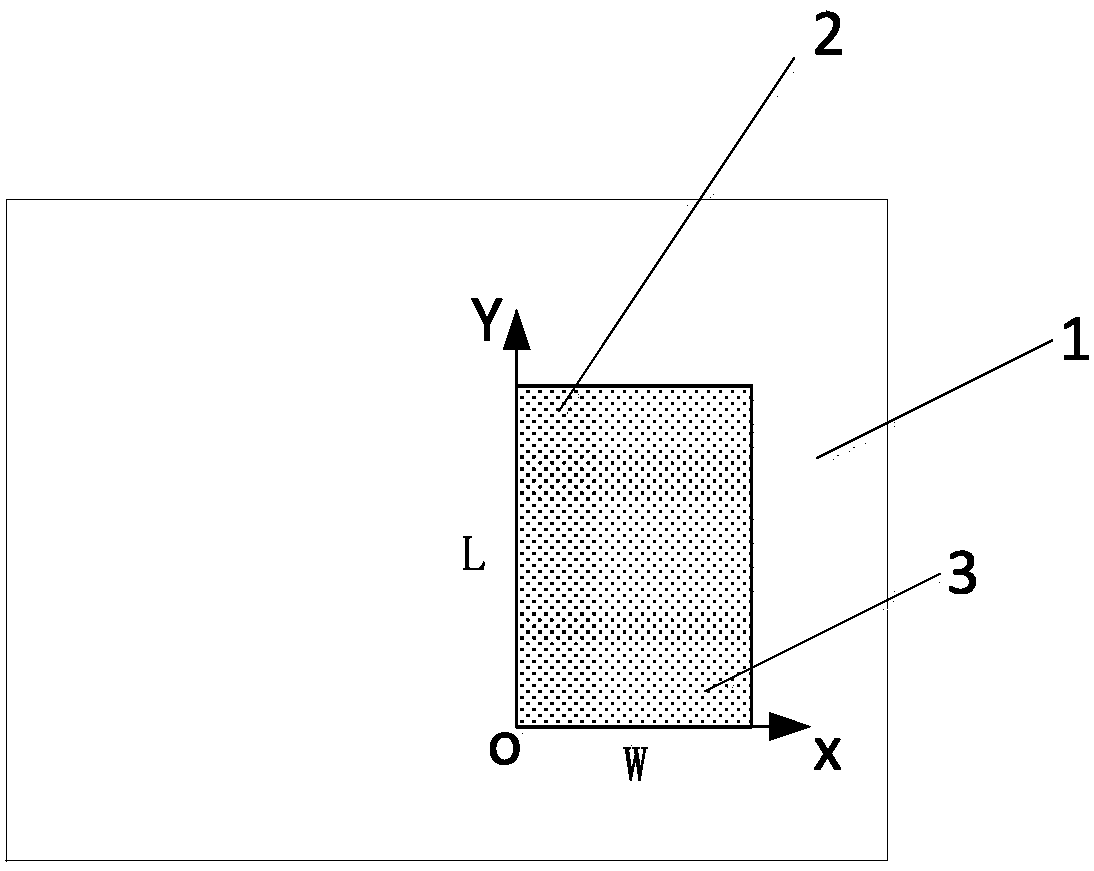

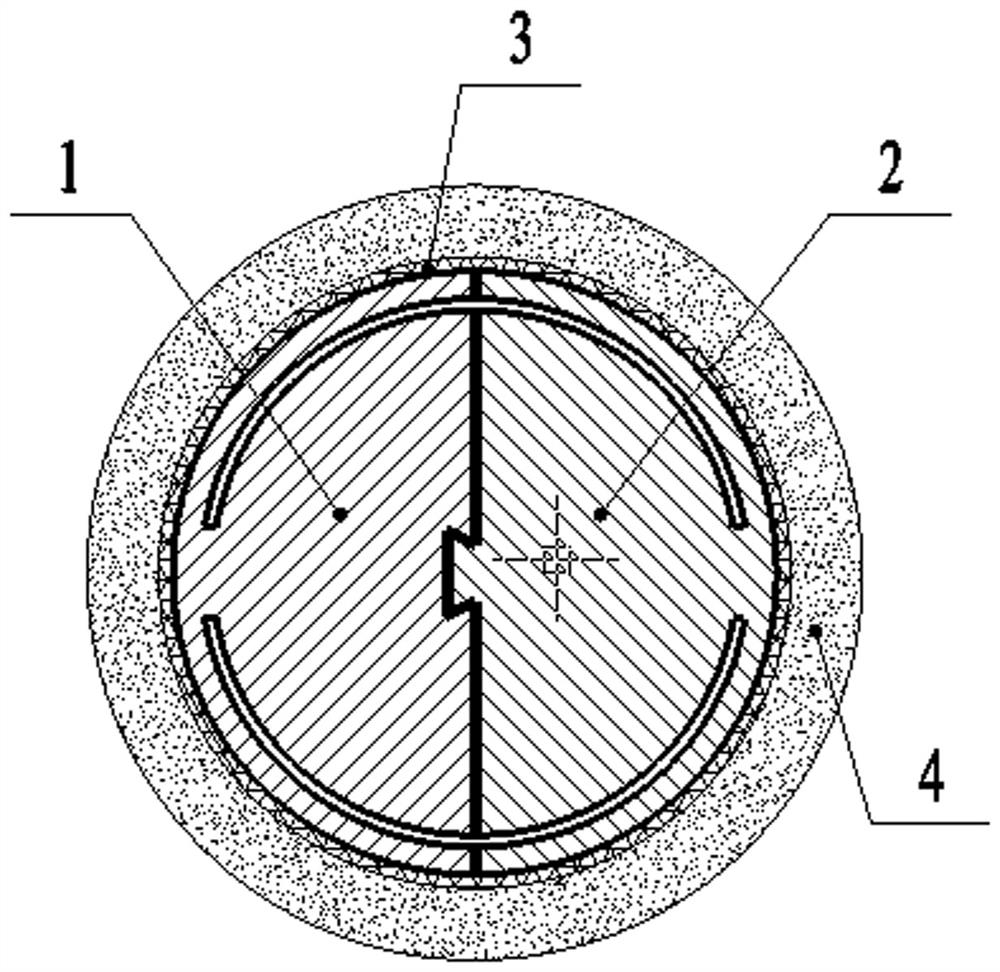

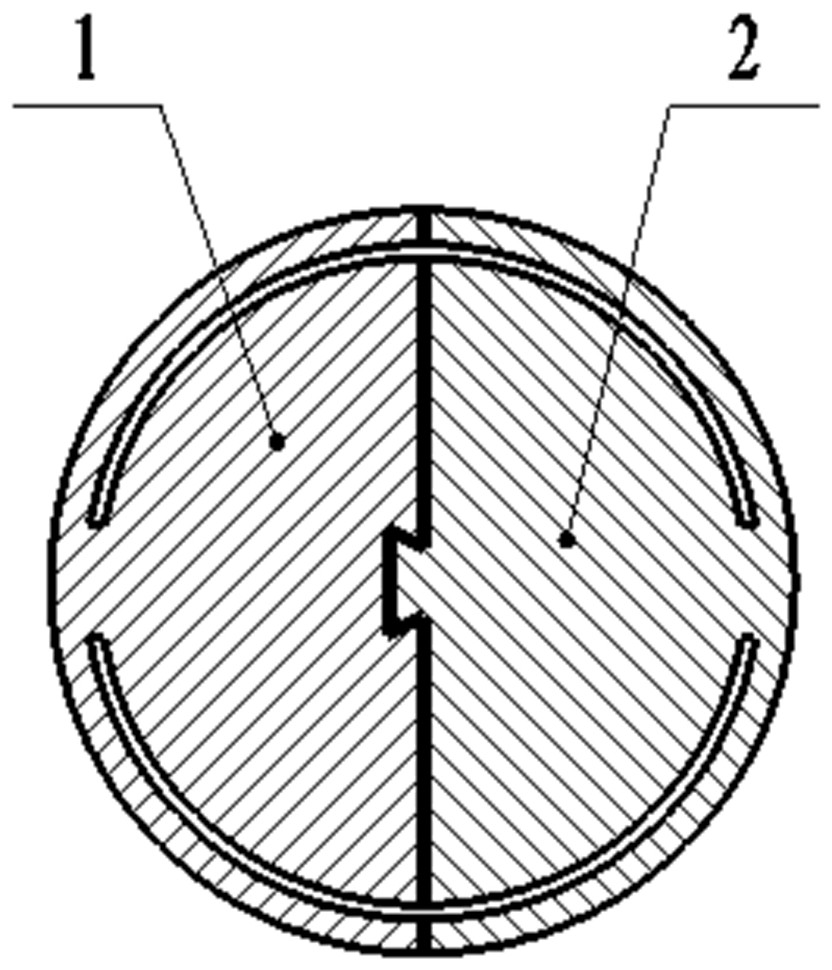

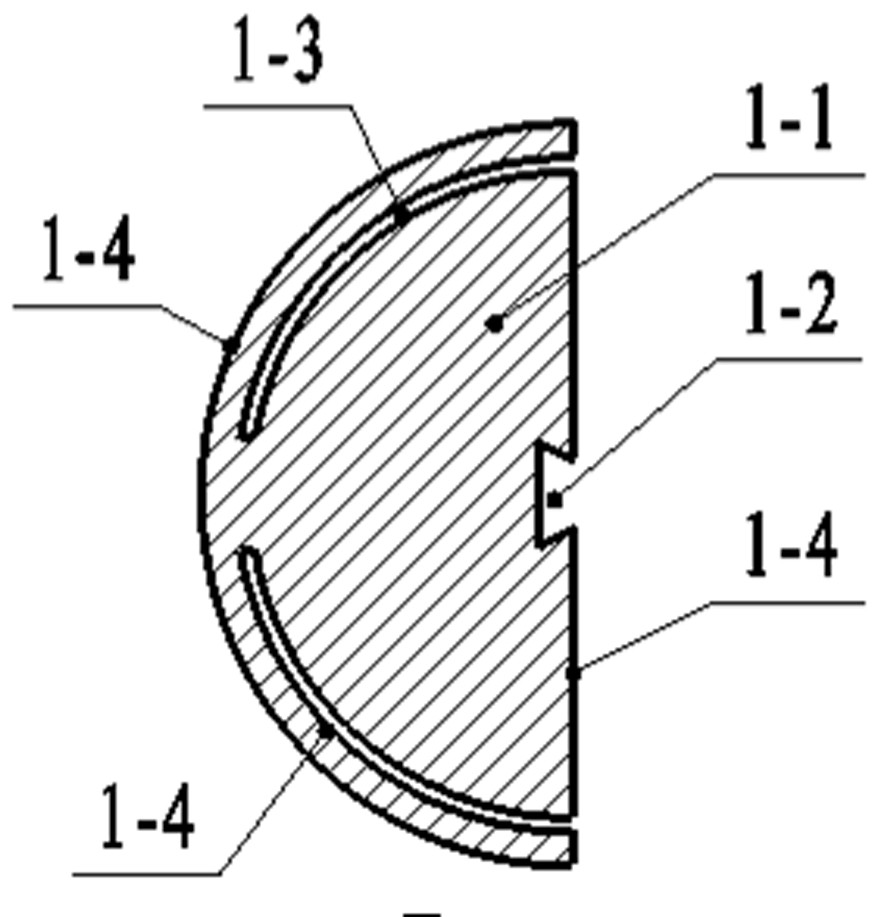

The invention relates to the field of welding material, in particular to a flux-cored wire. The flux-cored wire comprises sheet iron and core flux packaged by the sheet iron; the section formed by using the sheet iron to package the core flux is plum blossom-shaped, wherein the outer sheet iron is divided equally, two ends of each section of the equally divided sheet iron extend towards the center of the section to form petals of the plum blossom-shaped structure, and the petals contact closely to form the plum blossom shape. After using said structure, because the sheet iron is uniformly distributed on the whole section, the core of the flux-cored wire with the plum blossom-shaped section is conductive, the electric arc combustion is stable, the flux-cored wire melting is uniform, and the metallurgic reaction is complete.

Owner:何朋飞

Brazing filler metal and process for brazing molybdenum-rhenium alloy

InactiveCN106041365ASuitable melting temperatureGuaranteed high temperature performanceWelding/cutting media/materialsWelding/soldering/cutting articlesAlloy elementMicrometer

The invention discloses brazing filler metal and a process for brazing molybdenum-rhenium alloy. The brazing filler metal comprises, by weight, 7-15% of Mn, 3-6% of Co, 0-8% of Zr and the balance Cu. A method for preparing the brazing filler metal includes proportionally uniformly mixing the Cu, the Mn, the Co and the Zr with one another to obtain mixtures; preparing the brazing filler metal in the shape of a foil strap by the aid of a vacuum induction smelting furnace and a high-vacuum melt-spinning machine. The thickness of the brazing filler metal ranges from 20 micrometers to 50 micrometers. The brazing filler metal and the process have the advantages that the brazing temperature of the brazing filler metal ranges from 1020 DEG C to 1090 DEG C, the brazing filler metal has an appropriate melting temperature, the high-temperature performance of the brazing filler metal can be guaranteed, and the brazing filler metal can be uniformly molten; brazing filler metal foils are favorable for promoting diffusion and interface reaction of alloy elements in brazing connection procedures, the wetting and spreading capacity of the brazing filler metal on the surfaces of the molybdenum-rhenium alloy can be improved, crystalline grains can be refined, residual stress can be reduced, and the mechanical properties of connectors can be improved.

Owner:JIANGSU UNIV OF SCI & TECH

Aluminum alloy super-purification refining method

The invention discloses an aluminum alloy super-purification refining method, and aims to reduce the hydrogen content, oxide inclusion content and harmful alloy element content in the aluminum alloy. The method comprises the following steps of: arranging two aluminum alloy blanks to be melted on a lifting mechanism and connecting the two aluminum alloy blanks to the positive electrode and the negative electrode of a melting power supply respectively; arranging a non-metal crucible under the aluminum alloy blanks, placing the slag in the crucible and heating the slag to the working temperatureof between 630 and 700 DEG C to change the slag into a liquid state; starting the lifting mechanism to drop the aluminum alloy blank and extend the lower end into the liquid-state slag, wherein the immersion depth is 10mm, and opening cooling water; preserving heat for a certain time and switching on the melting power supply after the slag in contact with the aluminum alloy blank is remelted, wherein the current is 250 to 280A and the voltage is 8 to 9V; automatically feeding by the lifting mechanism according to a voltage value and feeding downwards when the voltage value is more than 9V; stopping the feeding when the voltage value is less than 8V; when the feeding is stopped, increasing the voltage value along with the continuous melting of the aluminum alloy blank; automatically adjusting the feeding process by the lifting mechanism until all the aluminum alloy blanks are fed into the melting crucible by a feeding mechanism; ending the melting and closing the melting power supply when the feeding mechanism feeds the aluminum alloy blanks to the bottommost part and the voltage is more than 9V; and lifting the lifting mechanism, scratching the slag in the crucible out and castingan ingot with the refined aluminum alloy liquid or directly pouring a cast.

Owner:ZHONGBEI UNIV

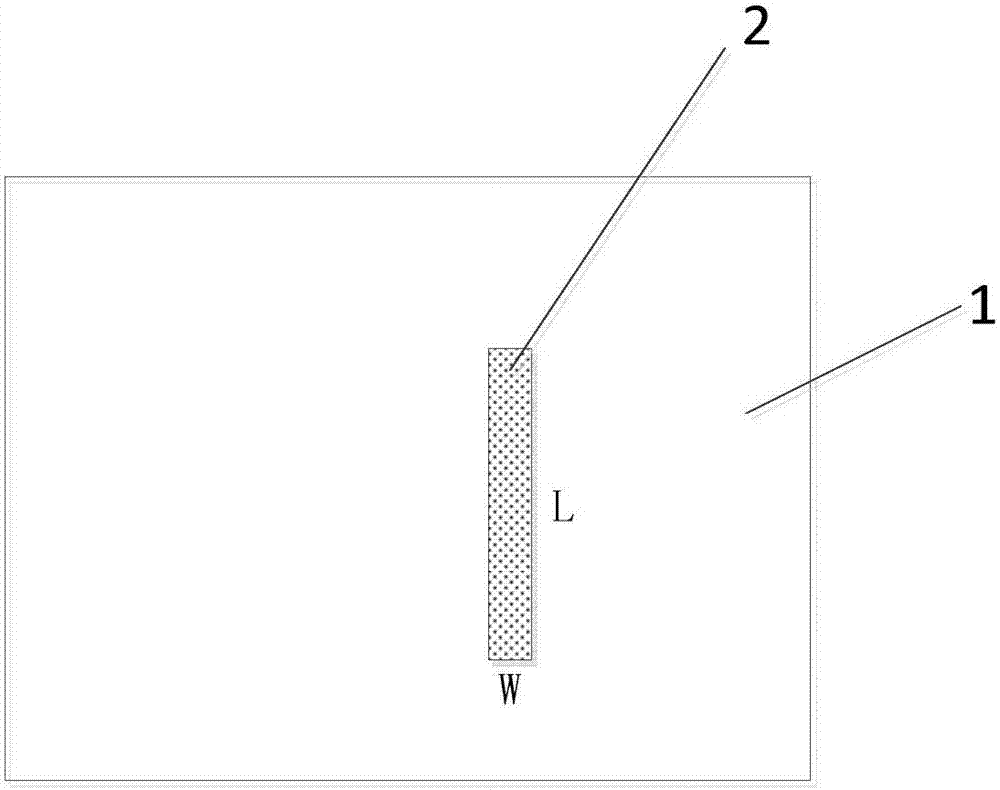

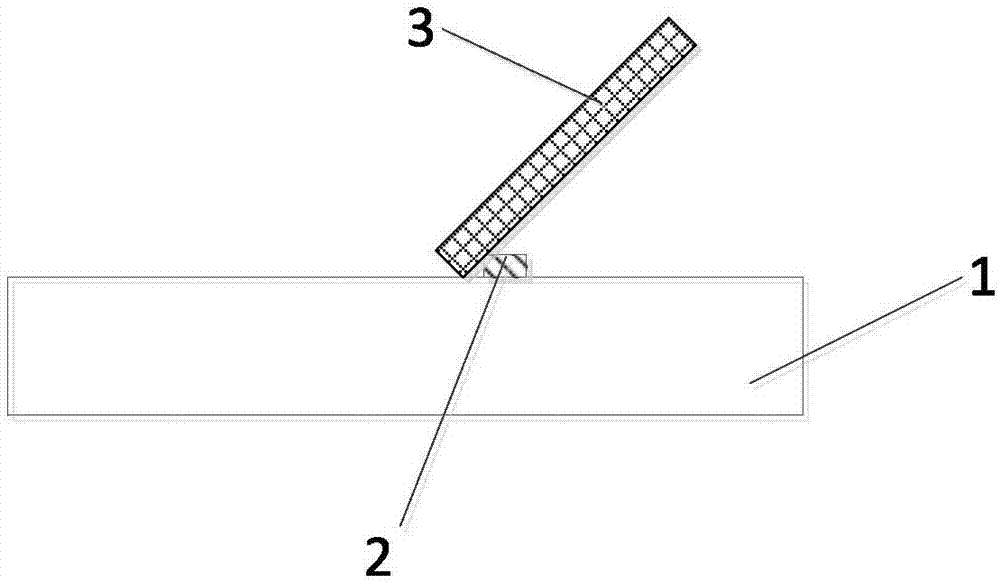

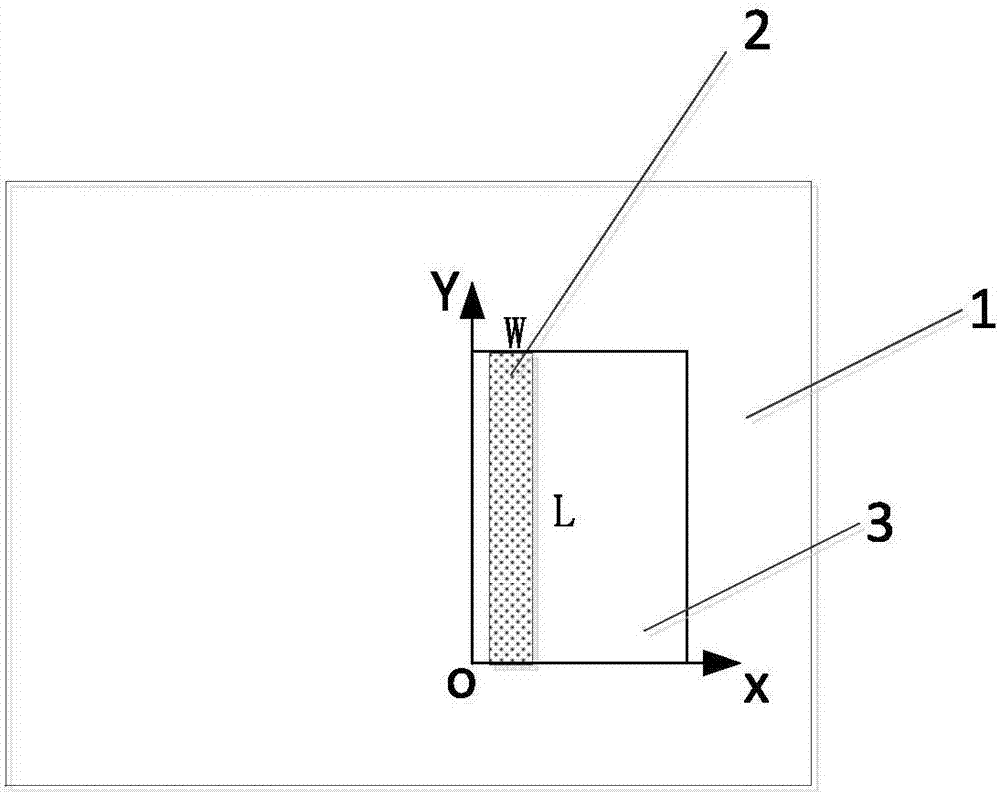

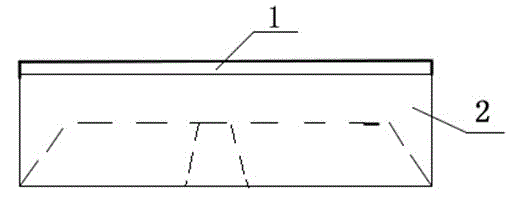

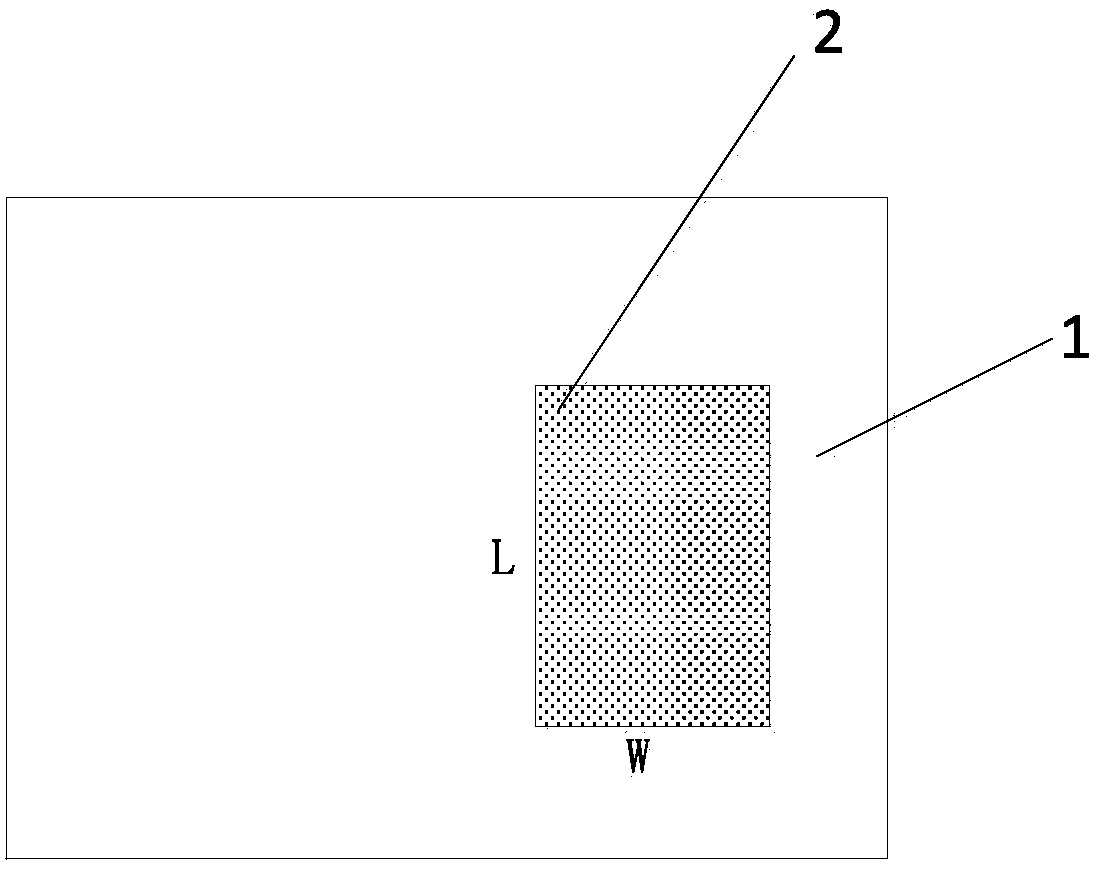

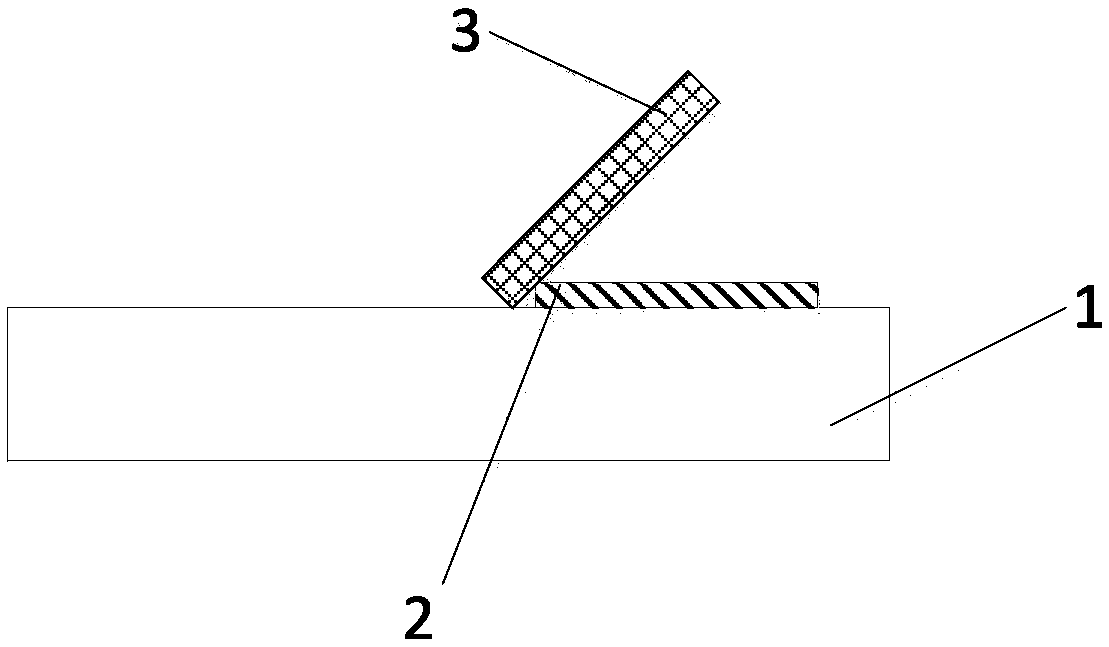

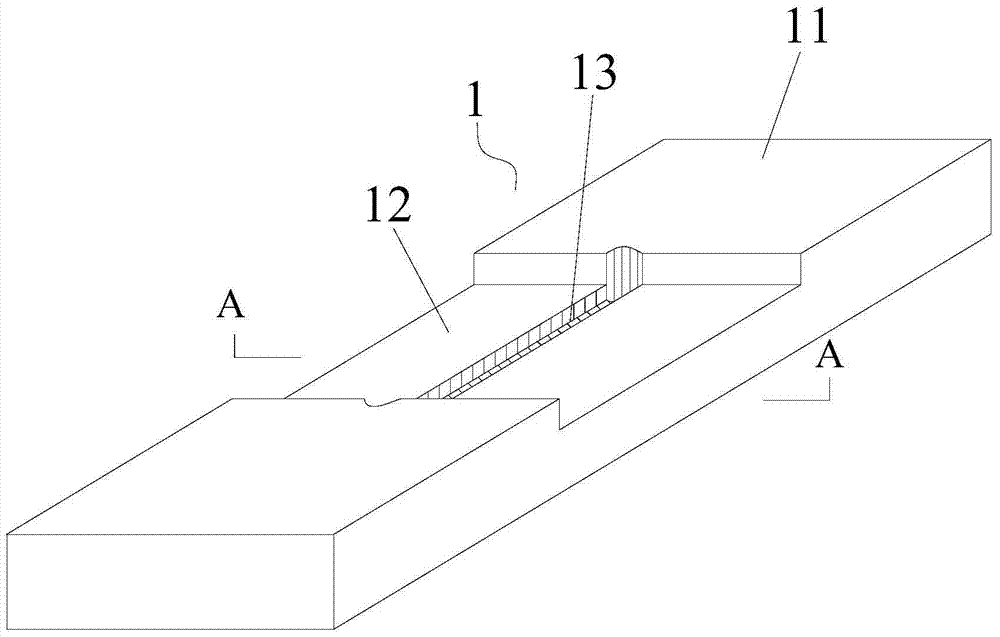

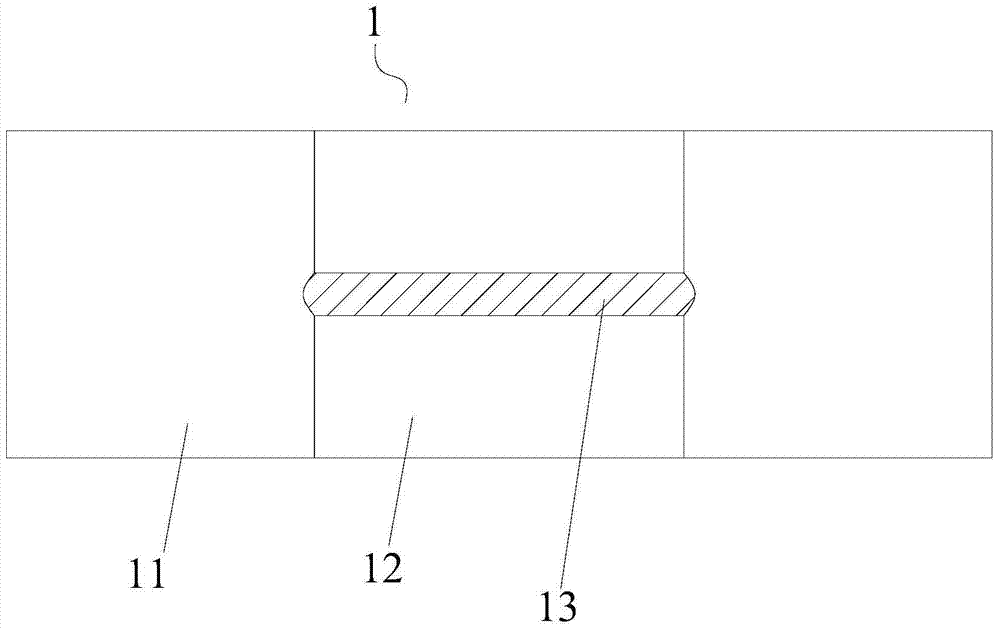

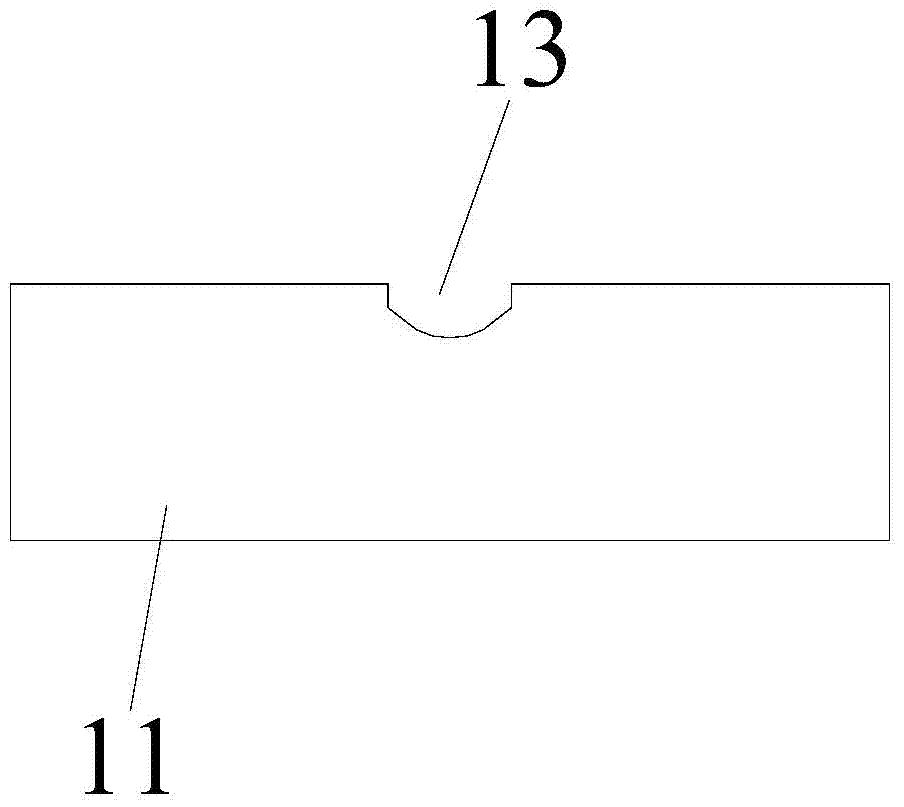

Extrusion forming laser welding brazing method

ActiveCN106077862ASpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMelting tankLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

Novel iron-aluminum thermal-spraying powder core wire material

InactiveCN102776461AReasonable formulation of ingredientsLow costMolten spray coatingVulcanizationThermal spraying

The invention discloses novel iron-aluminum thermal-spraying powder core wire material, which mainly comprises the following main components by weight: 40-70% of aluminum powder, 10-20% of magnesium powder, 30-35% of ferric oxide, 2-4% of potassium chloride and the balance of impurities such as Mn, Si, S and P, wherein the potassium chloride is used as oxidant of the magnesium powder; the magnesium powder is combusted so as to release heat quantity, so that the ferric oxide and the aluminum powder are in thermit reaction; a product obtained by the thermit reaction is in chemical reaction with residual aluminum powder again so as to form a Fe-Al intermetallic compound; and the content of the impurities such as S and P is controlled below 0.03%. The iron-aluminum thermal-spraying powder core wire material disclosed by the invention is characterized by reasonable component preparation and suitable cost; raw materials are subjected to metallurgical reaction completely in a coating layer preparation procedure; the prepared iron-aluminum intermetallic compound is high in content; so that, the coating layer has preferable performances such as high-temperature vulcanization resistance, oxidation, high-temperature corrosion resistance and the like. Therefore, the prepared parts are applied more widely.

Owner:KUSN QIAORUI METAL PRODS

Method and device for ultrasonic-assisted laser brazing of dissimilar metal assemblies

ActiveCN107225327BRealize the welding effectHigh dimensional accuracyWelding/soldering/cutting articlesLaser beam welding apparatusUltrasonic assistedUltrasonic vibration

The invention provides an ultrasound-assisted laser brazing method for a dissimilar-metal assembly piece. The ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece comprises the steps that (1) a locating die is used for clamping a A-metal stand column; (2) the upper end of the A-metal stand column is heated to be soft; (3) the upper end, which is induction-heated and softened, of the A-metal stand column is inserted into a profiling hole of a B-metal base, and then a dissimilar-metal laser welded preassembly piece is obtained; (4) an ultrasonic vibration source connected with a locating die assembly is started, the laser is emitted out, under the auxiliary action of an ultrasonic vibration composite energy field, a laser-MIG composite welding head conducts melt-brazing along the outline of a connection face of the A-metal stand column and the B-metal base; and (5) the dissimilar-metal laser welded assembly piece is transfers to a conveyer belt and then falls into a material box. By the adoption of the ultrasound-assisted laser brazing method for the dissimilar-metal assembly piece, the large-fusion-depth narrow-weld-joint welding effect can be achieved, and a welded connector better in metallurgical quality is obtained. The invention further provides an ultrasound-assisted laser brazing device for the dissimilar-metal assembly piece.

Owner:山东承坤信息科技有限公司

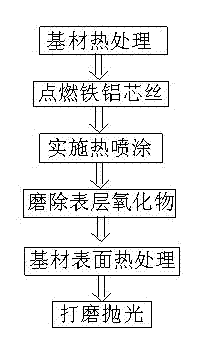

Novel manufacture method of iron-aluminum thermal spraying powder core wire

InactiveCN102776462AFull metallurgical reactionQuality improvementMolten spray coatingVulcanizationAluminum metal

The invention discloses a novel manufacture method of an iron-aluminum thermal spraying powder core wire. The manufacture method comprises the following steps of (a) mixing materials; (b) manufacturing U-shaped steel belts; (c) filling the materials; (d) sealing the U-shaped steel belts; and (e) drawing by using a wire-drawing die. The manufacture method is reasonable in procedure arrangement, convenient to implement and moderate in cost. A thermit reaction is performed on the core wire in the spraying process, so that the metallurgy reaction is full, the core wire is high in quality, iron-aluminum intermetallic compounds can be easily manufactured, a thermal spraying coating has performance of being good in high-temperature vulcanization resistance, high-temperature oxidization resistance and high-temperature corrosion resistance, and the core wire can be widely used.

Owner:KUSN QIAORUI METAL PRODS

Flux-cored welding wire

InactiveCN109746588AEvenly distributedEvenly meltedWelding/cutting media/materialsSoldering mediaElectricityCombustion

The invention relates to the field of welding materials, in particular to a flux-cored welding wire comprising a steel cover and a core flux wrapped by the steel cover. The section formed by wrappingthe core flux through the steel cover is shaped like a plum blossom, wherein the steel cover on the outer layer is equally divided, the two ends of each section of the equally-divided steel cover extend towards the center of the section to form a petal of the structure shaped like the plum blossom, and the petals make tight contact with one another to form the plum blossom shape. After the structure mentioned above is adopted, because the steel cover is evenly distributed on the whole fracture surface, a core part of the welding wire with the plum-blossom-shaped section can also conduct electricity; and therefore electric arc combustion is stable, welding wire fusion is uniform, and metallurgy reaction is sufficient.

Owner:丹阳市宏光机械有限公司

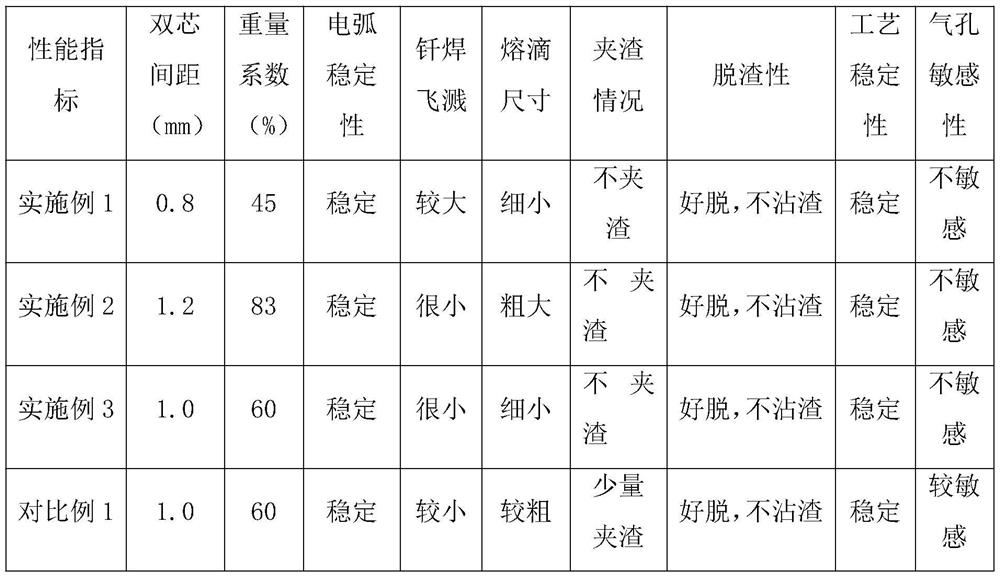

A Laser Arc Fused Wire Welding Process Avoiding Slag Inclusion

ActiveCN109926721BImprove tensile propertiesImprove bending performanceWelding/cutting media/materialsSoldering mediaSlag (welding)Active agent

Owner:HUBEI TRI RING FORGING

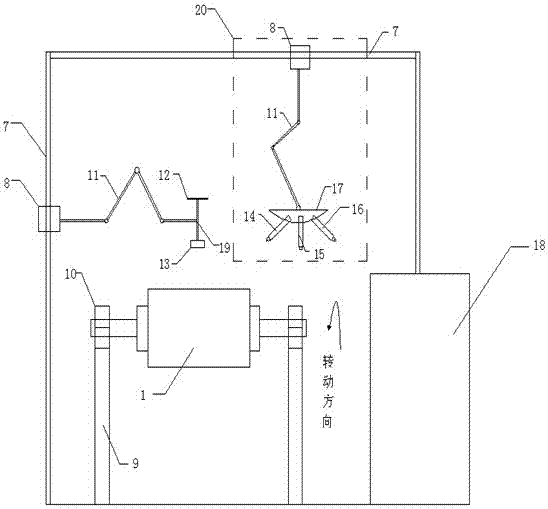

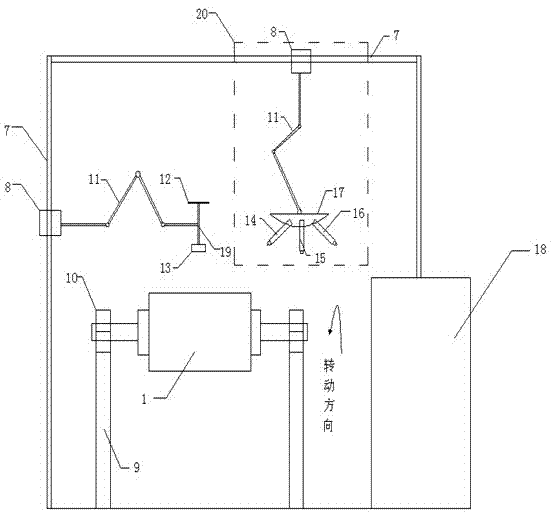

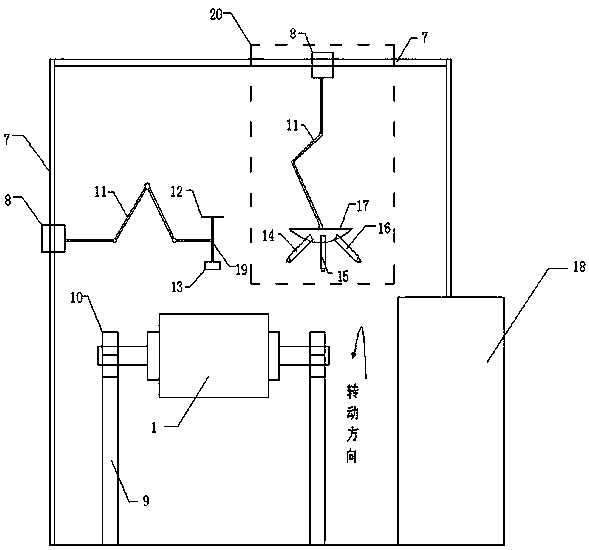

Automatic Control Method of Second Surfacing Welding after Large Roller Shaft Wears

ActiveCN105436664BLess prone to control errorsRealize automatic grinding processArc welding apparatusAutomatic controlGear wheel

The invention discloses an automatic double-overlaying control system and method for an abraded of a large roller shaft. A starting point and a terminal point of a welding point on the roller shaft are input into an input module and converted into digital signals which are transmitted to a programmable logic controller (PLC), a corresponding result is obtained through calculation by means of the PLC, and an executing signal is transmitted to a sliding module, an extending and retracting module, a polishing module, a gear module, an overlaying module, a flaw detection module and a heating module. By means of the control system and method, automatic overlaying of the abraded roller shaft is achieved, polishing, cleaning, welding, flaw detection and heating can be conducted on the abraded roller shaft automatically, and manpower resources are greatly saved; in addition, the accuracy and efficiency are high.

Owner:SHENZHEN RILAND IND

A laser melting and brazing method for extrusion molding

ActiveCN106077862BSpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMechanical propertyLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

A kind of aluminum steel hot-melt welding flux

ActiveCN106736038BRaw materials are easy to getLow costWelding/cutting media/materialsSoldering mediaSlagEconomic benefits

The invention discloses aluminum steel hot melting welding flux. The aluminum steel hot melting welding flux comprises aluminum powder, ferric oxide, alloy additives and a slag former. The aluminum steel hot melting welding flux is characterized in that the aluminum steel hot melting welding flux contains abrasive grits with the diameter being 2-3 mm and the length being 5-6 mm. Compared with existing hot melting welding flux, raw materials of the aluminum steel hot melting welding flux are easy to obtain, the cost is low, the formula is simple, and operation is convenient; the aluminum steel hot melting welding flux is adopted for welding, so that the welding quality is good, the ignition efficiency is high, the connection surface is smooth, the contact resistance is small, the extension strength is large, and the filling metal amount can be decreased. A metallurgy reaction is sufficient, and the probability of existence of defects such as pores and cracks is lowered. In addition, no external power source is needed during welding of the aluminum steel hot melting welding flux, the welding quality is stable and reliable, and the aluminum steel hot melting welding flux has the remarkable economic benefits when used for anode rod and steel claw welding.

Owner:XINJIANG JOINWORLD CO LTD

Automatic double-overlaying control method for abraded large roller shaft

ActiveCN105436664ALess prone to control errorsRealize automatic grinding processArc welding apparatusAutomatic controlProgrammable logic controller

The invention discloses an automatic double-overlaying control system and method for an abraded of a large roller shaft. A starting point and a terminal point of a welding point on the roller shaft are input into an input module and converted into digital signals which are transmitted to a programmable logic controller (PLC), a corresponding result is obtained through calculation by means of the PLC, and an executing signal is transmitted to a sliding module, an extending and retracting module, a polishing module, a gear module, an overlaying module, a flaw detection module and a heating module. By means of the control system and method, automatic overlaying of the abraded roller shaft is achieved, polishing, cleaning, welding, flaw detection and heating can be conducted on the abraded roller shaft automatically, and manpower resources are greatly saved; in addition, the accuracy and efficiency are high.

Owner:SHENZHEN RILAND IND

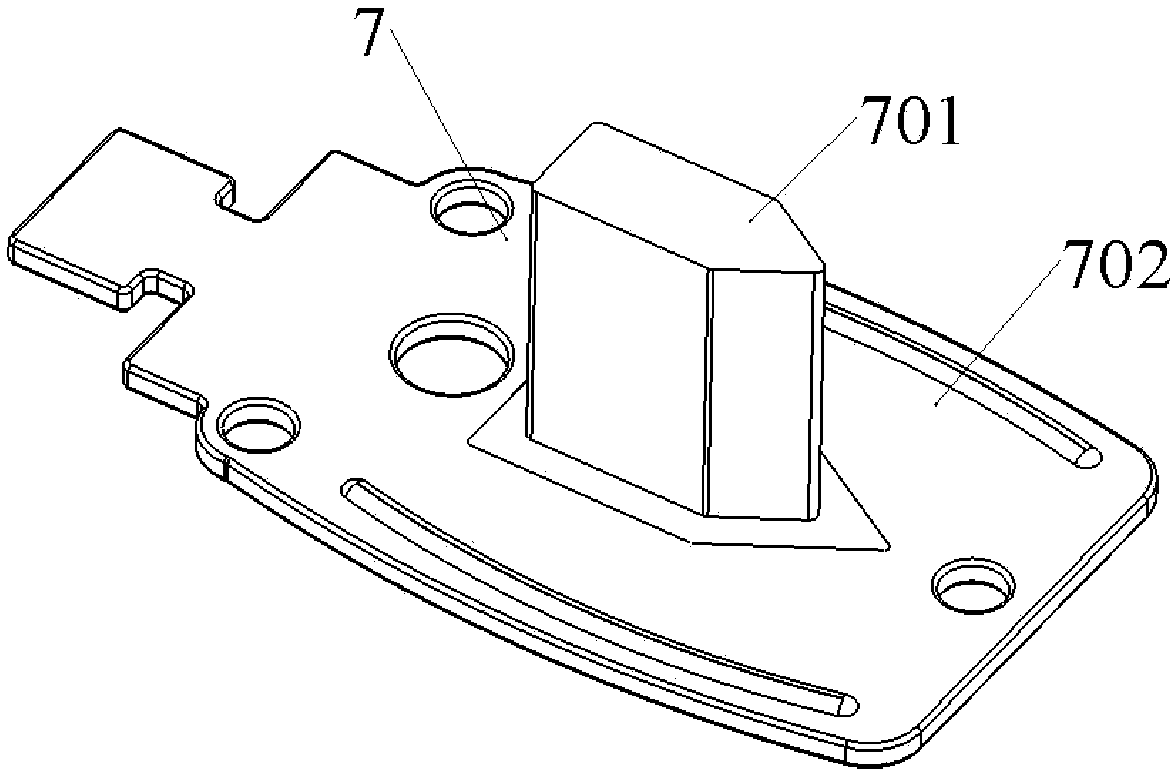

Ultrasonic-assisted high-frequency induction brazing device for electric contact system

ActiveCN110355437BImprove brazing rateImprove welding strengthMetal working apparatusSoldering auxillary devicesUltrasonic assistedUltrasonic vibration

The invention provides an electrical contact system ultrasonic-assisted high-frequency induction brazing device. A body of the device adopts a six-index cam divider for driving, six assembling and machining stations are arranged on the periphery of a cam divider workbench in sequence, and a same positioning mould is arranged on each assembling and machining station. The electrical contact system ultrasonic-assisted high-frequency induction brazing device specifically comprises a contact bridge feeding assembly, a soldering paste dripping assembly, a contact feeding assembly, a high-frequency induction brazing assembly, a CCD industrial camera assembly, a discharging assembly, an electric chuck assembly 7 and a cam divider assembly. According to the device, through ingenious and reasonablestructural design, a high-frequency induction heat source and ultrasonic vibration double compound energy field is integrated in a compact space; through process procedure design, the welding positions are optimized before, during and after welding correspondingly; and the automation degree is high, and both the machining efficiency and the brazing quality are taken into consideration.

Owner:山东承坤信息科技有限公司

A welding rod for brazing process

ActiveCN109926756BHigh arc stabilityModerate viscosityWelding/cutting media/materialsSoldering mediaAluminum fluorideSlag (welding)

Owner:HUBEI TRI RING FORGING

Laser-arc fuse wire welding process for avoiding slag inclusion

ActiveCN109926721AImprove tensile propertiesImprove bending performanceWelding/cutting media/materialsSoldering mediaActive agentSlag

The invention provides a laser-arc fuse wire welding process for avoiding slag inclusion. The laser-arc fuse wire welding process for avoiding slag inclusion comprises the following steps of S1, fixing a workpiece, and polishing a workpiece welding part; S2, spraying a cleaning agent for the welding part; S3, preheating before welding: preheating the workpiece before welding; S4, activating the welding surface: after stopping heating, quickly spraying an active agent; S5, after drying the welding part, adopting a welding rod for welding; and S6, cooling for shaping. The invention aims to research and develop the laser-arc fuse wire welding process for avoiding slag inclusion from the welding source in order to reduce slag inclusion of the die workpiece and reduce the difficulty and the necessity of a follow-up slag inclusion removal process.

Owner:HUBEI TRI RING FORGING

Marine side plate capable of resisting seawater corrosion and ocean environment corrosion

InactiveCN102554190BFull metallurgical reactionHigh bonding strengthHull shellsPhysical chemistryBronze

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

A laser-induced thermite welding method

Owner:呼和浩特市新城区创新创业服务中心

A combined stainless steel welding core coated electrode

ActiveCN111037147BReduce radial volume expansionReduce temperature riseWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceCopper plating

Owner:ZHENGZHOU UNIV

A beam-splitting double-focus point laser processing head

ActiveCN104801852BLower requirementMeets high energy density requirementsLaser beam welding apparatusLaser processingCoupling

The invention provides a beam splitting double-focus-point laser processing head, which comprises a light path cavity, a cavity connecting box, a servo motor and an external connecting flange, wherein the light path cavity is connected with an output shaft of the servo motor through a shaft coupler, a beam splitting mirror, a first reflecting mirror, a second reflecting mirror, a third reflecting mirror, a focusing mirror and two telescopic sleeves are arranged inside the light path cavity, the beam splitting mirror and the first reflecting mirror are respectively and fixedly arranged on the side wall of the light path cavity through a regulating mirror seat, the second reflecting mirror and the third reflecting mirror are respectively arranged on the telescopic ends of the two telescopic sleeves through a regulating mirror seat, and the fixing ends of the telescopic sleeves are arranged on the side wall of the light path cavity. The beam splitting double-focus-point laser processing head has the advantages that an incident laser beam is subjected to space beam splitting, the front focusing point and the back focusing point are realized, the relative space position between the double light beam focusing points is changed, the utilization efficiency of laser energy is improved, the laser welding plasma shielding effect can be effectively inhabited, the processing depth is improved, and the laser processing quality is improved.

Owner:WENZHOU UNIV

Overlay welding method after large roller shaft wear

ActiveCN105382378BReduce defectsImprove forming qualityArc welding apparatusWelding/cutting media/materialsFatigue damageSlag

The invention discloses a surfacing welding method for an abraded large roll shaft. The surfacing welding method is characterized by comprising the following steps that 1, preweld material analysis is carried out, preweld cleaning is carried out on the roll shaft, and preweld preparation is carried out; 2, after preweld preparation is finished, preweld preheating is carried out; 3, after preweld preheating is finished, automatic submerged arc welding is adopted for surfacing welding; 4, after surfacing welding is finished, welding slag is broken down, and postweld heat treatment is carried out; and 5, after heat treatment is finished, finally machining is carried out according to requirements. After the surfacing welding method is adopted, surfacing welding layer defects at the surfacing welding position are few, and the forming quality of a welding channel is good; the hardness of the surfacing welding position is distributed in a ladder manner from low to high from inside to outside, and the hardness of the outermost layer even ranges from 55 HRC to 60 HRC; the impact toughness and strength of the surfacing welding position are equal to those of the roll shaft and even exceed those of a base material by 1-2 times; the capacity for resisting spalling fatigue damage is high, the surfacing welding effect is remarkable, and the welding quality requirement can be completely met; and the whole surfacing welding process is easy to master and control, and good economical efficiency is achieved.

Owner:JIANGSU JINHANG MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com