Aluminum alloy super-purification refining method

A technology of aluminum alloy and blank, applied in the field of ultra-purification and refining of aluminum alloy, can solve the problems of high labor intensity, great influence of degassing effect, serious environmental pollution, etc., and achieve the effect of small environmental pollution, high melting speed and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

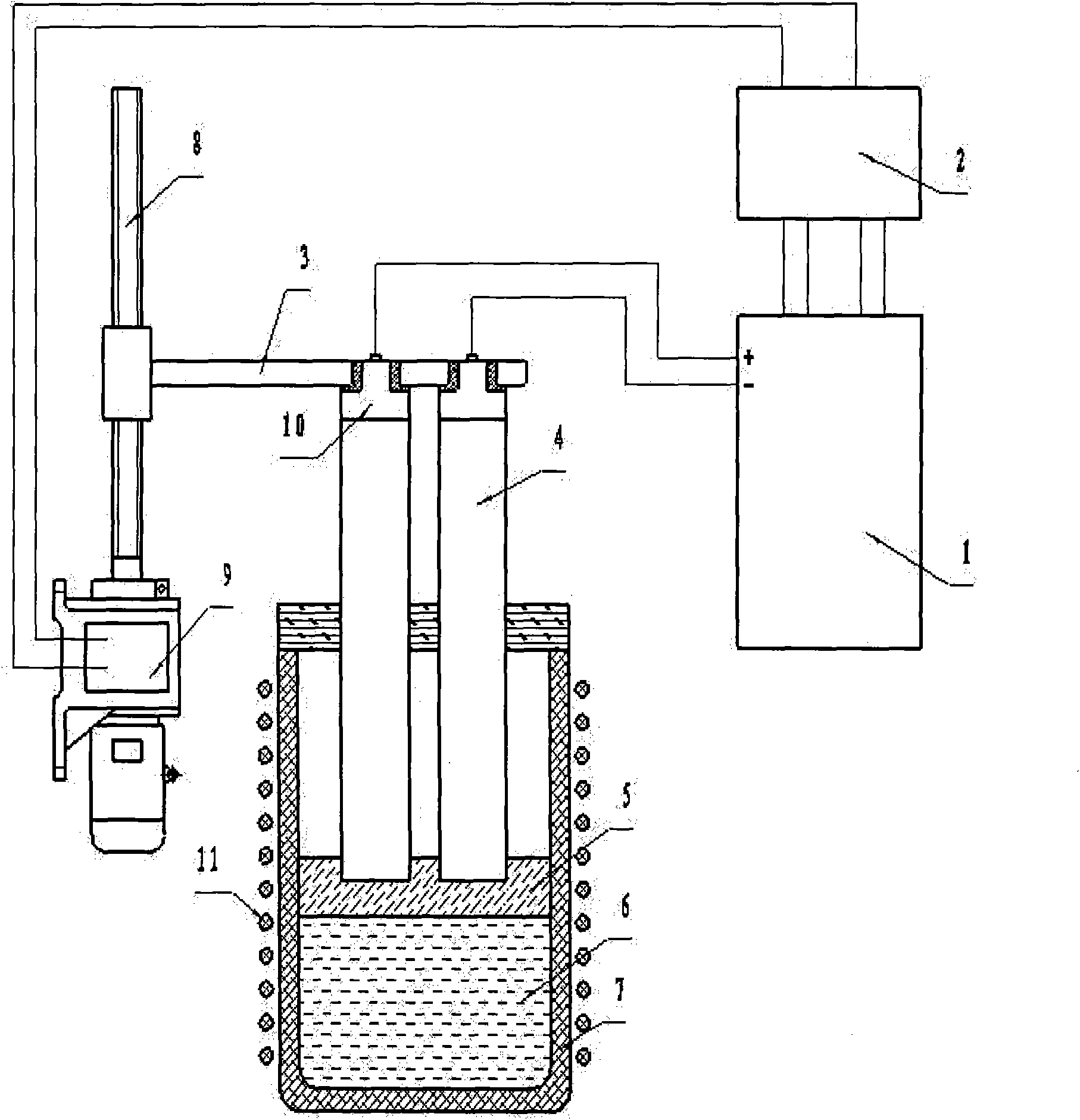

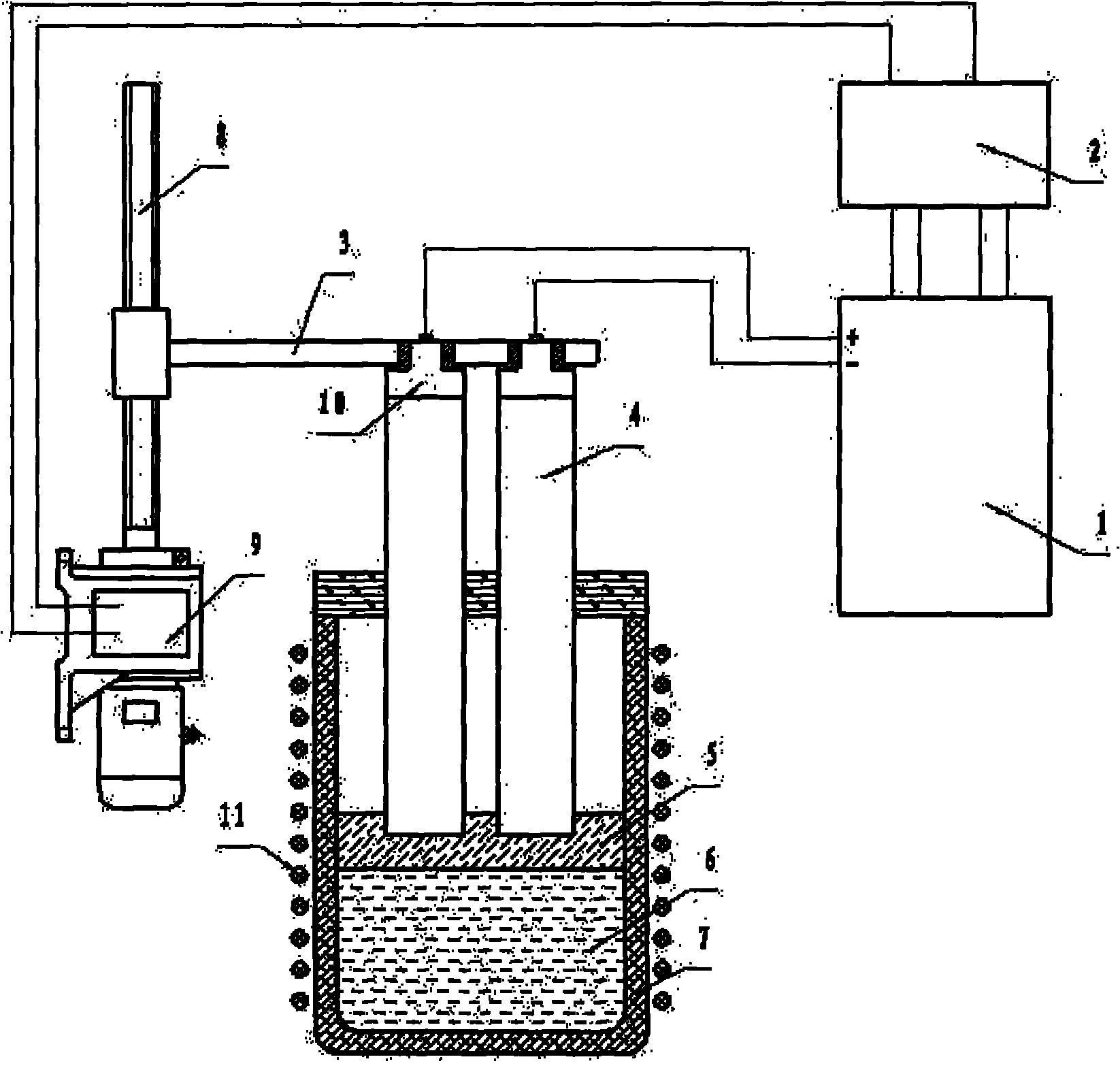

[0017] Install the aluminum alloy blank 4 to be melted on the water-cooled electrode 10, the water-cooled electrode 10 is connected to the positive and negative electrodes of the melting power supply 1, put the molten slag 5 in the non-metallic crucible 7, and heat the crucible 7 to The working temperature is 670°C, so that the slag is in a liquid state; for the ZLSi7Cu2Mg aluminum alloy material, the melting current is 250A, the voltage is 8.5V, and the slag is 45% KCl+45% MgCl 2 +10%Na 3 AlF 6 .

[0018] The controller 2 sends a start signal to the speed regulating motor 9, and the speed regulating motor 9 rotates to drive the lead screw 8 to move the support 3 downward, so that the lower end of the aluminum alloy blank extends into the liquid slag, and the immersion depth is 10 mm. Keep warm for a certain period of time, and after the molten slag in contact with the aluminum alloy blank is re-melted, turn on the melting power supply 1; the controller automatically feeds t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com