Patents

Literature

90results about How to "Reduce slag content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

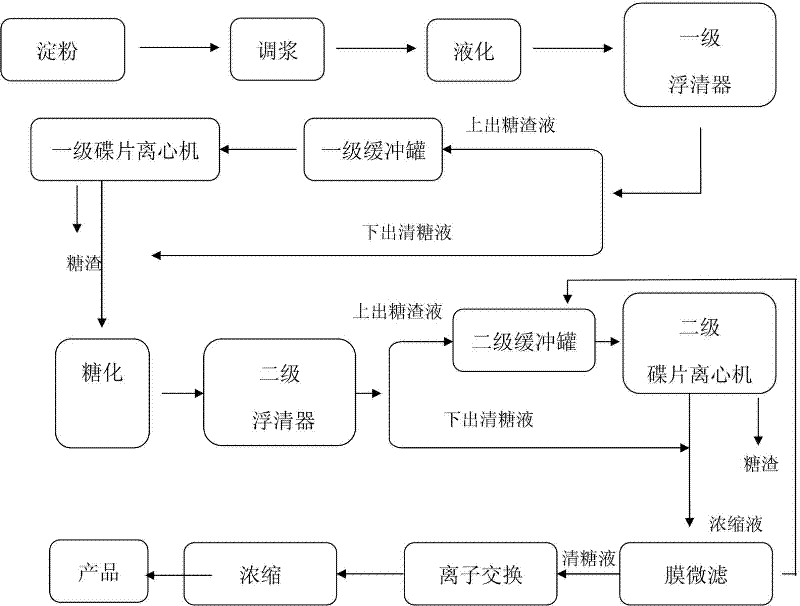

Process for producing starch sugar

ActiveCN102337316AQuality improvementImprove function and effectAnimal feeding stuffAccessory food factorsActivated carbonChaptalization

The invention discloses a process for producing starch sugar. The process comprises the following steps of: pulp-conditioning edible starch; liquefying; passing liquefied starch through a primary floating clarifier, guiding an upper floating sugar dreg liquid into a primary buffer tank, and then entering a primary disc-type centrifuge to be centrifugated and separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the primary disc-type centrifuge and a clear sugar liquid flowing out of the primary floating clarifier and flowing into a saccharifying tank to be saccharified into a saccharified liquid; passing the saccharified liquid through a secondary floating clarifier, guiding an upper floating sugar dreg liquid into a secondary buffer tank, and then enteringa secondary disc-type centrifuge to be separated so as to extract sugar dregs; combining a clear sugar liquid flowing out of the secondary disc-type centrifuge and a clear sugar liquid flowing out ofthe secondary floating scum clearing device and filtering by passing through a membrane micro-filtration system; and flowing a micro-filtered concentrated liquid containing dregs back to the secondary buffer tank, entering a micro-filtered clear sugar liquid into an ion exchange system to be decolorized and desalted, and then finally concentrating into a product. According to the process for producing the starch sugar disclosed by the invention, filter aids and activated carbon are not required in the clarification and the filtration processes, and high-purity sugar liquid can be obtained through the efficient operation of solid-liquid separation equipment; and meanwhile, sugar dregs without the filter aids and the activated carbon are extracted and can be used as a feedstuff raw materialfor animals, thereby changing waste into valuable, and no discharge of filtered solid wastes during the whole process exists.

Owner:双桥(厦门)有限公司

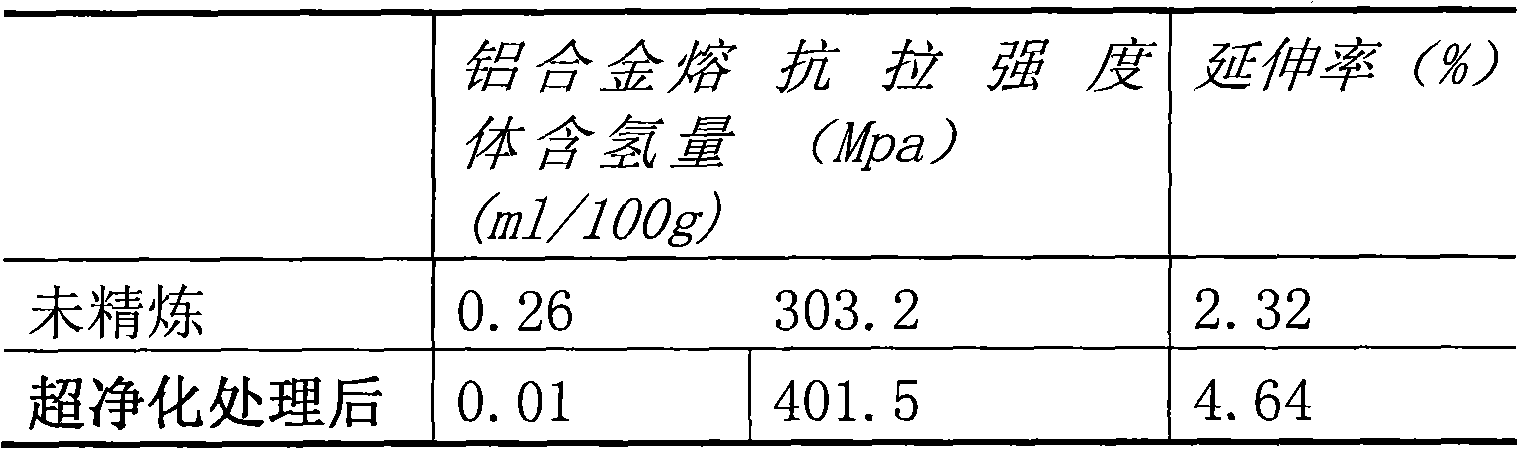

Aluminum alloy for high power radiator and purification method of melt of aluminum alloy

ActiveCN104233020AMeet quality requirementsImprove degassing effectPurification methodsHydrogen content

The invention relates to an aluminum alloy for a high power radiator. The aluminum alloy is characterized by being prepared from the following chemical components in percentage by weight: 0.50-0.55% of Mg, 0.40-0.45% of Si, less than 0.19% of Fe, less than or equal to 0.05% of Ti, less than or equal to 0.02% of Cr, less than or equal to 0.02% of Mn, less than or equal to 0.02% of Zn, less than or equal to 0.02% of Cu, less than or equal to 0.02% of a single content of other impurity elements, less than or equal to 0.15% of total content of other impurity elements and the balance of Al. According to a purification method of the melt of the aluminum alloy for the high power radiator, the hydrogen content in the aluminum alloy melt is reduced to below 0.07ml / 100g and the dregginess of the melt is reduced to below 0.01% by virtue of process control of aluminum alloy smelting, refining, degassing, deslagging and the like, so that the processing quality requirement on the aluminum alloy for the high power radiator is satisfied.

Owner:ALNAN ALUMINIUM CO LTD

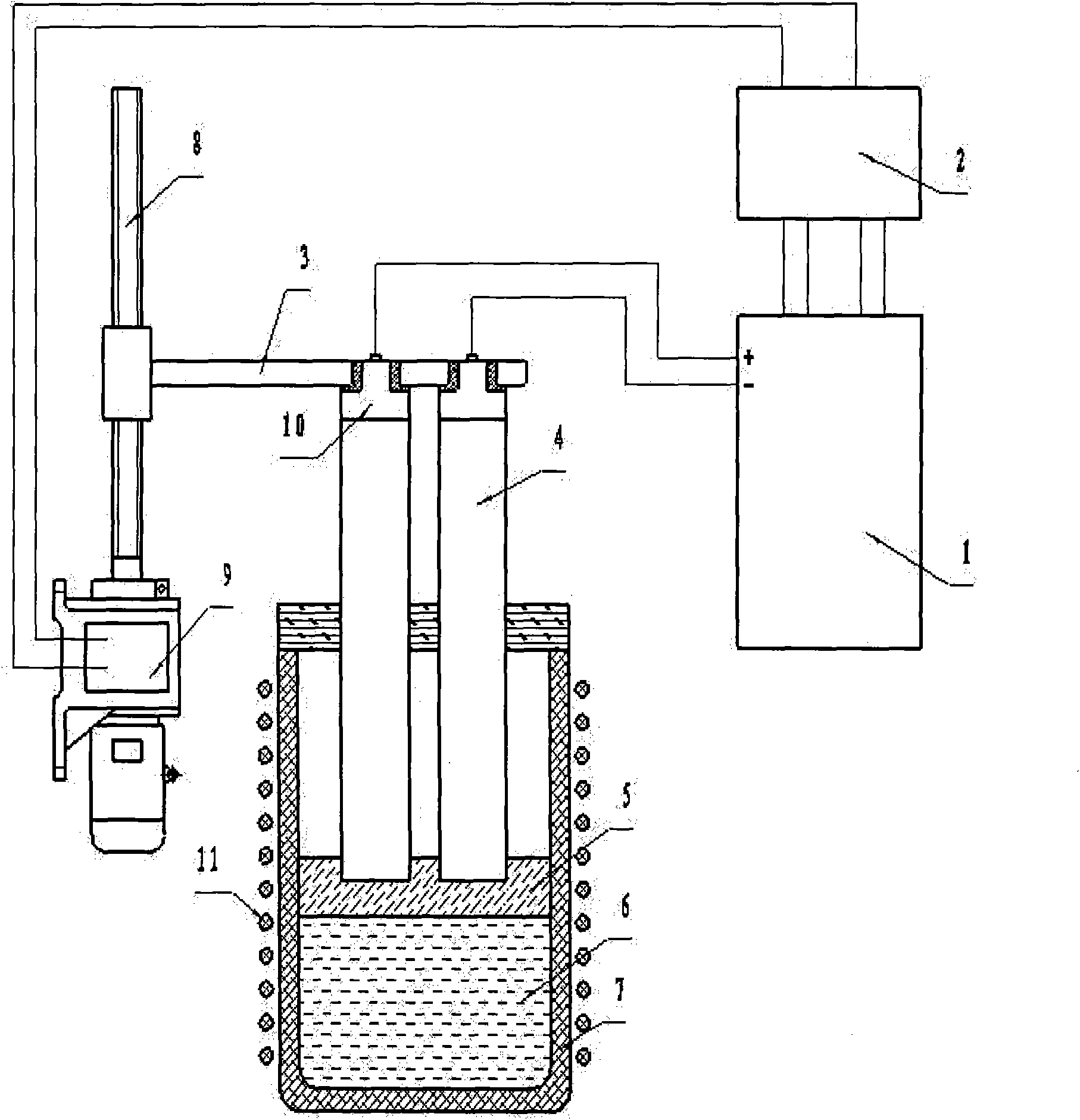

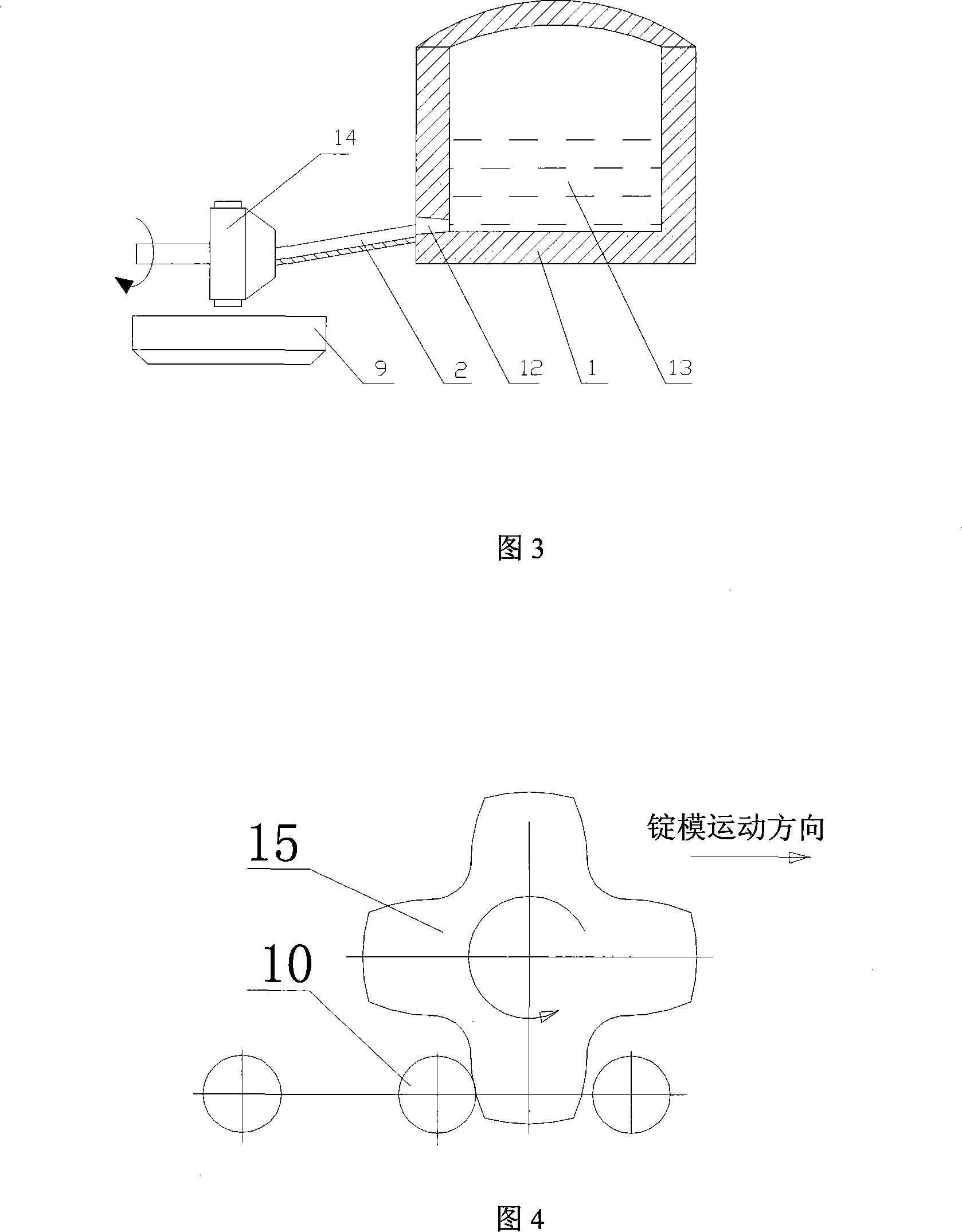

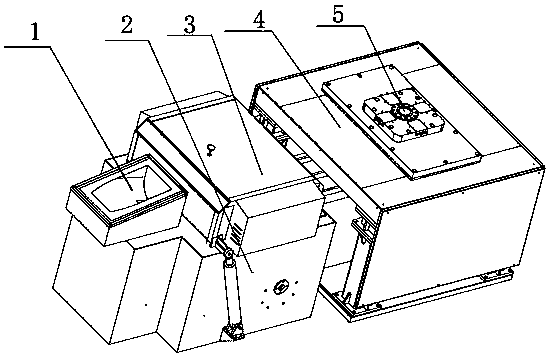

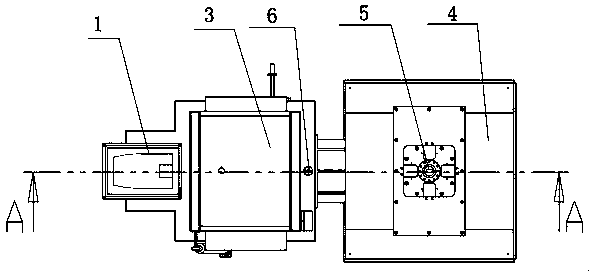

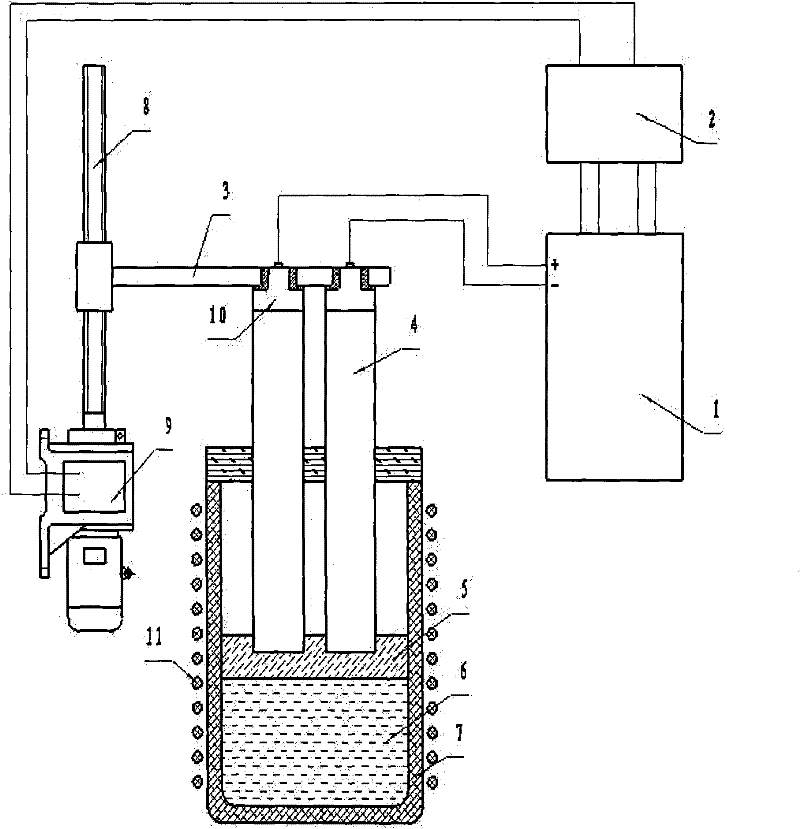

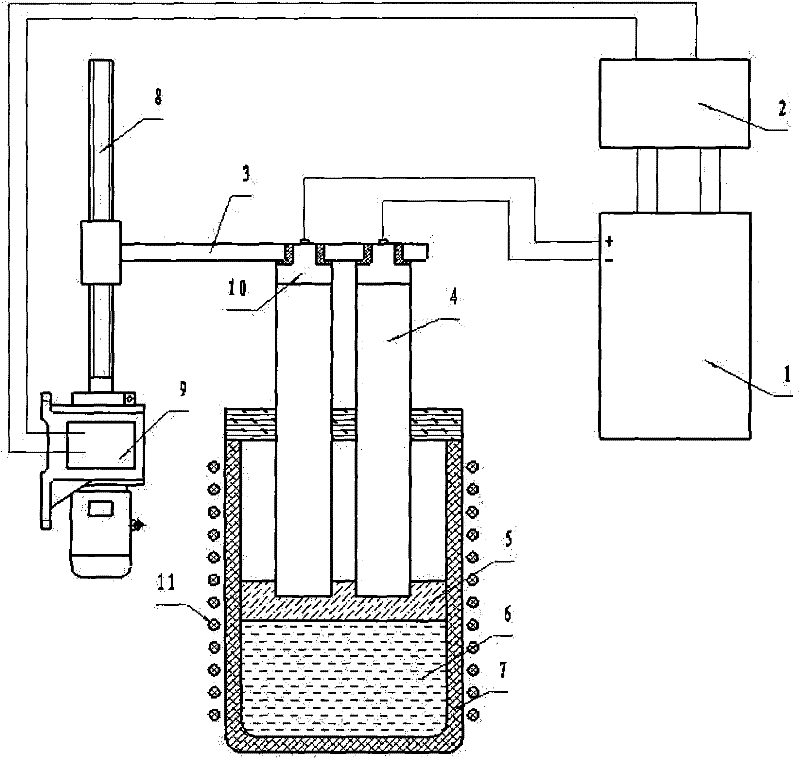

Aluminum alloy super-purification refining method

The invention discloses an aluminum alloy super-purification refining method, and aims to reduce the hydrogen content, oxide inclusion content and harmful alloy element content in the aluminum alloy. The method comprises the following steps of: arranging two aluminum alloy blanks to be melted on a lifting mechanism and connecting the two aluminum alloy blanks to the positive electrode and the negative electrode of a melting power supply respectively; arranging a non-metal crucible under the aluminum alloy blanks, placing the slag in the crucible and heating the slag to the working temperature of between 630 and 700 DEG C to change the slag into a liquid state; starting the lifting mechanism to drop the aluminum alloy blank and extend the lower end into the liquid-state slag, wherein the immersion depth is 10mm, and opening cooling water; preserving heat for a certain time and switching on the melting power supply after the slag in contact with the aluminum alloy blank is remelted, wherein the current is 250 to 280A and the voltage is 8 to 9V; automatically feeding by the lifting mechanism according to a voltage value and feeding downwards when the voltage value is more than 9V; stopping the feeding when the voltage value is less than 8V; when the feeding is stopped, increasing the voltage value along with the continuous melting of the aluminum alloy blank; automatically adjusting the feeding process by the lifting mechanism until all the aluminum alloy blanks are fed into the melting crucible by a feeding mechanism; ending the melting and closing the melting power supply when the feeding mechanism feeds the aluminum alloy blanks to the bottommost part and the voltage is more than 9V; and lifting the lifting mechanism, scratching the slag in the crucible out and casting an ingot with the refined aluminum alloy liquid or directly pouring a cast.

Owner:ZHONGBEI UNIV

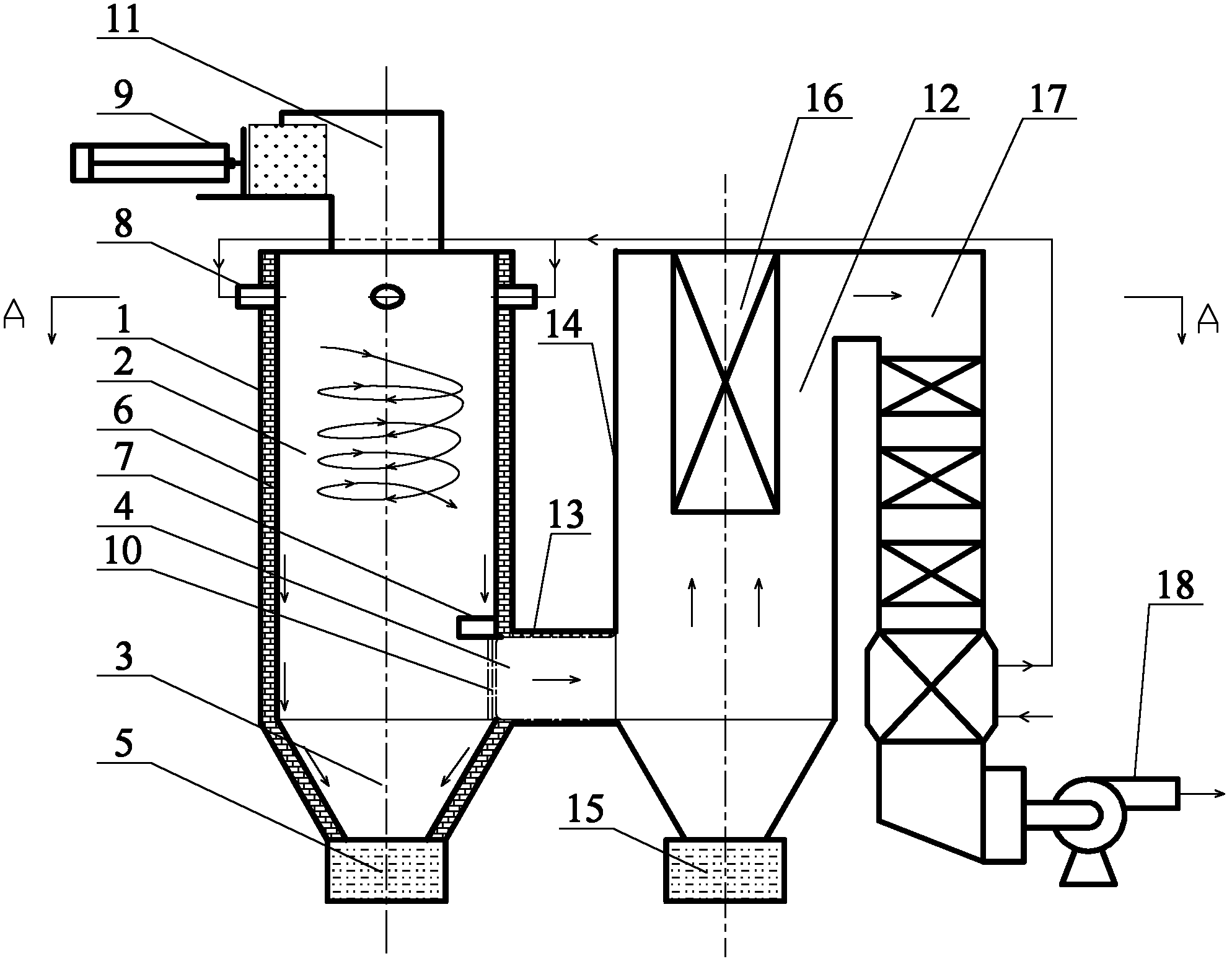

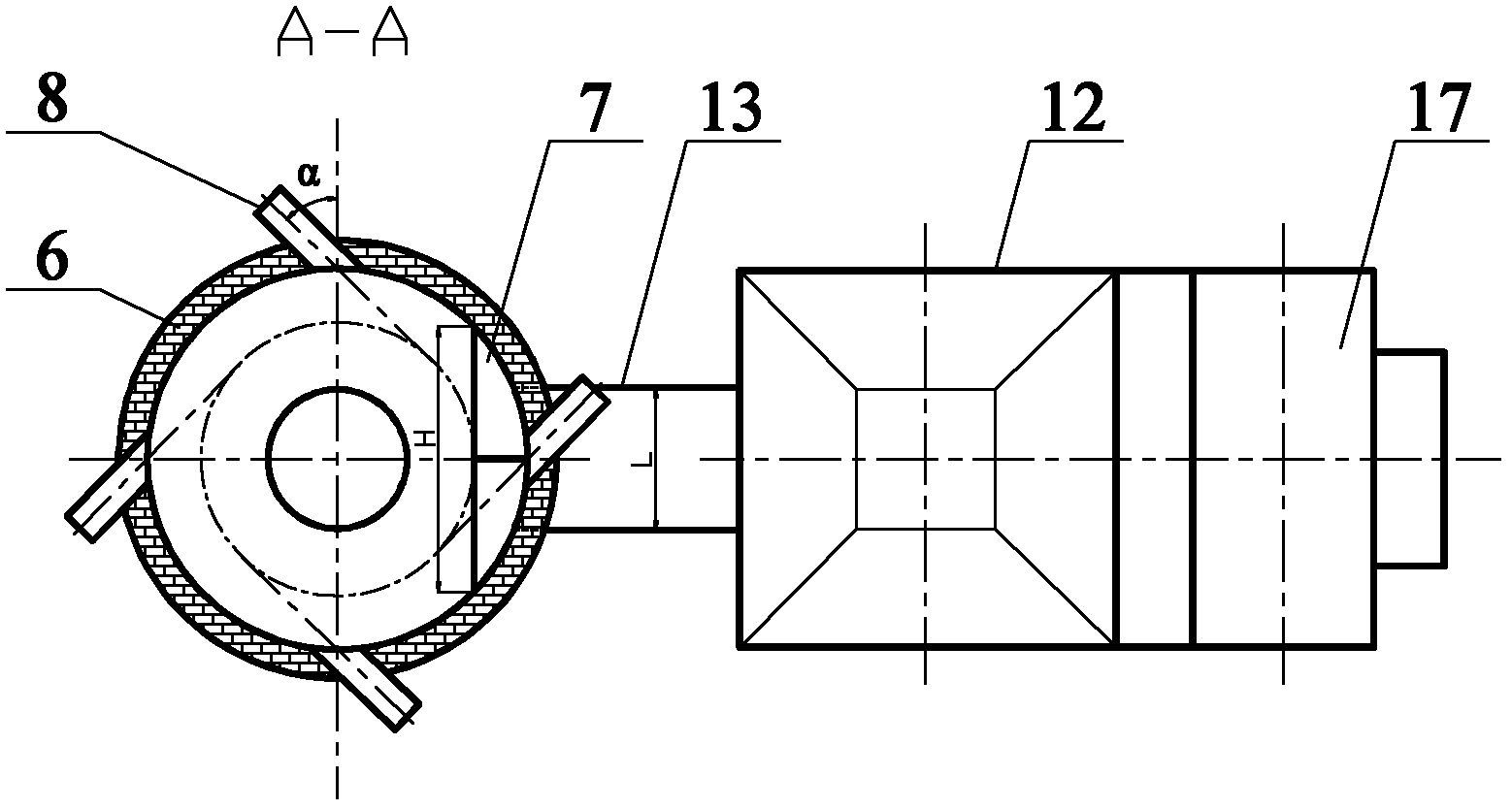

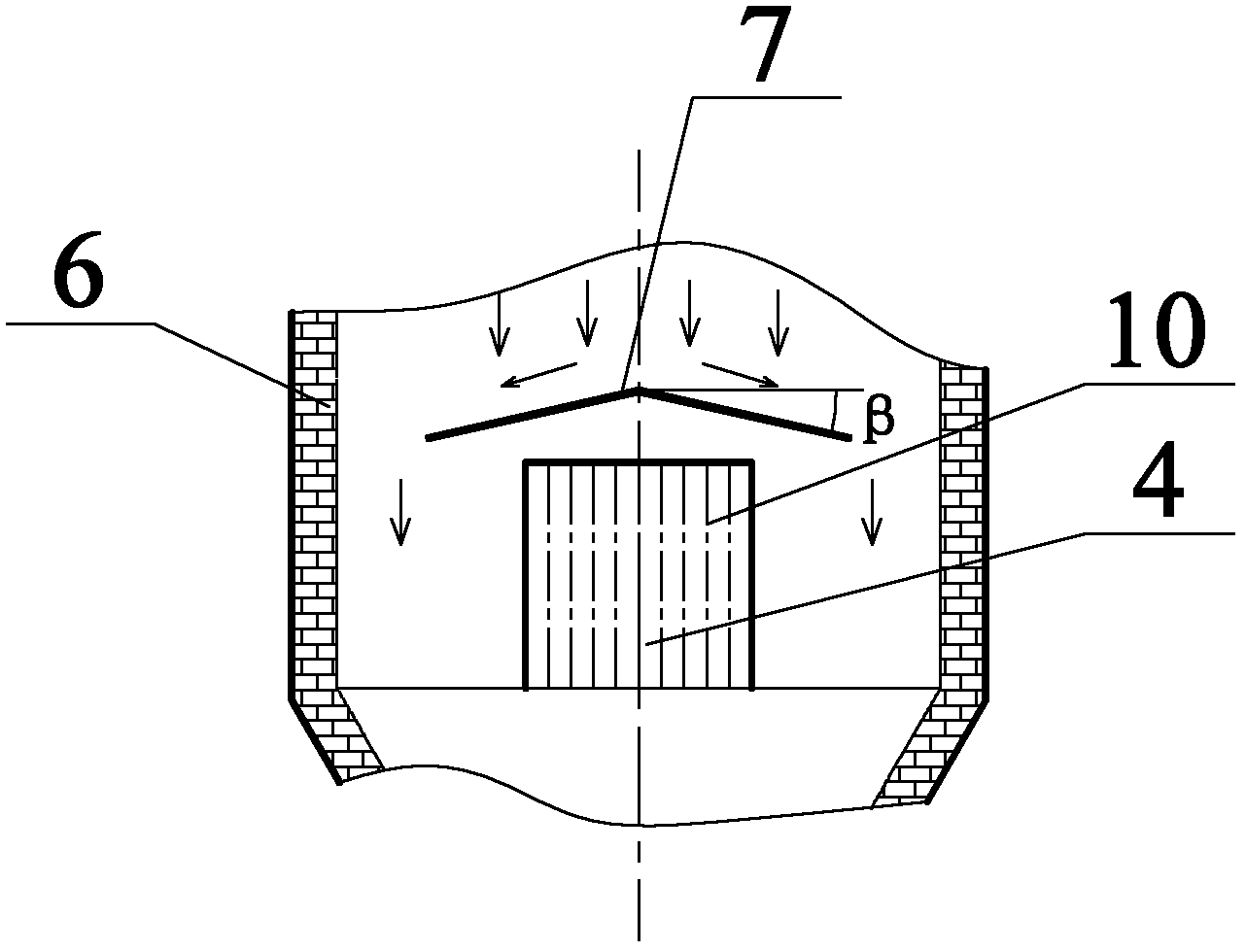

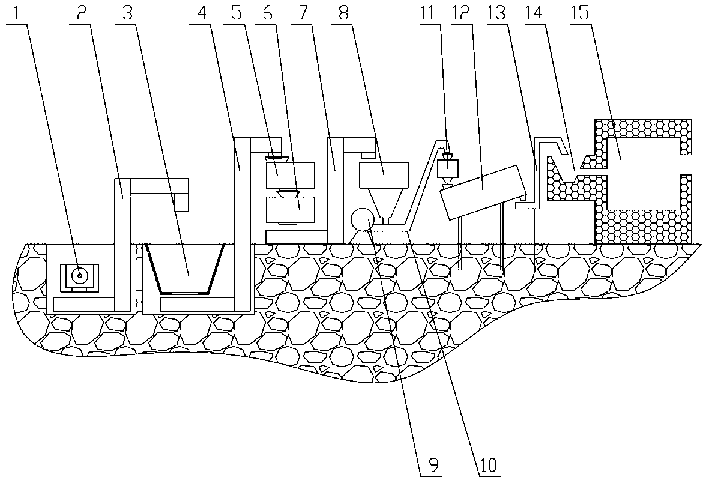

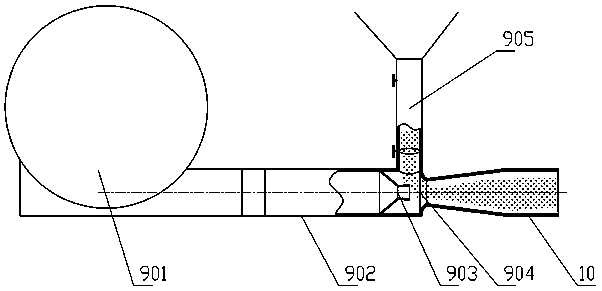

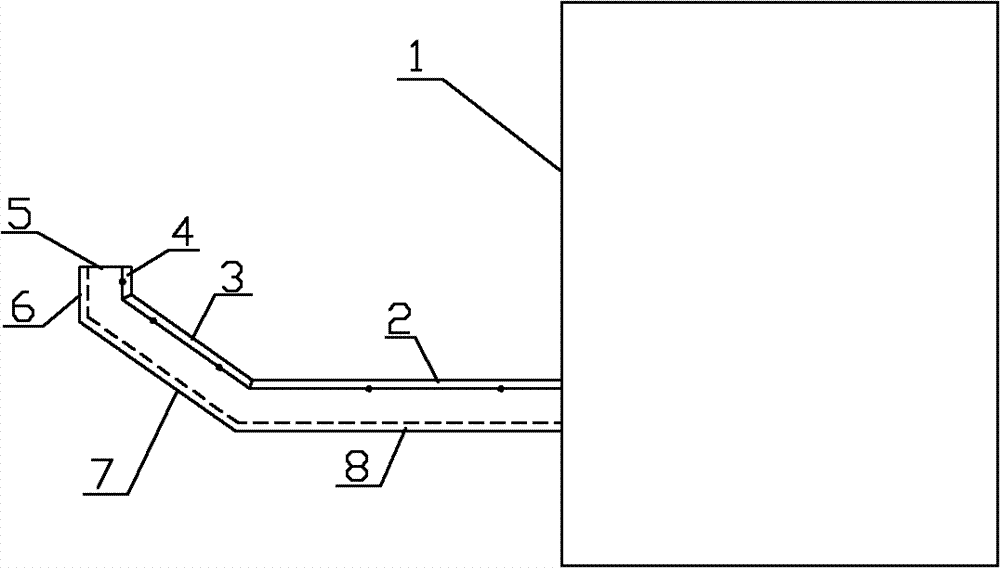

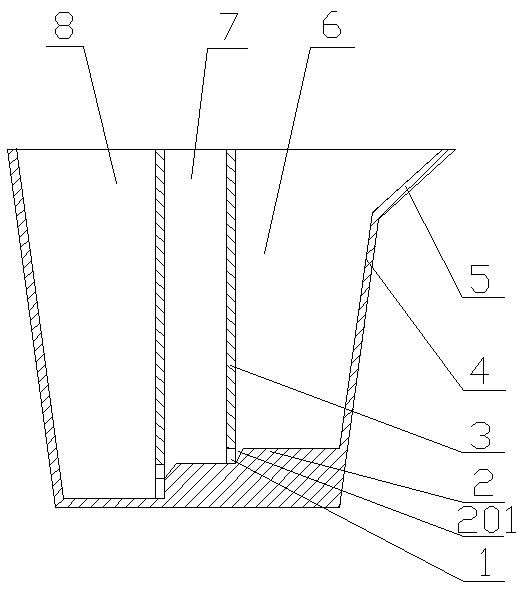

Liquid slag trapping biomass combustion device and method

InactiveCN102425787AReduce slag contentEasy to reuseIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyFlueEaves

The invention relates to a liquid slag tapping biomass combustion device and a method, which belongs to the combustion technical field of the biomass. The device comprises a biomass combustion furnace, a surplus heat boiler and a flue on the tail part of the surplus heat boiler. A secondary draught port is horizontally and obliquely arranged on the upper part of a combustion part of the biomass combustion furnace, a smoke outlet on the bottom part of the combustion chamber is provided with a row of screen pipes, and the top part of each screen pipe is provided with slag trapping eaves to effectively screen the slag. The method comprises the following steps that: air is sent into the combustion chamber through the secondary draught port in a cyclone way after being preheated to 150 to 400 DEG C, the temperature of the combustion chamber is rapidly increased to 1300 DEG C, biomass slag is molten, so the slag tapping is realized, heat exchange is adequately conducted between smoke and an inner heated surface of a surplus heat boiler hearth, the temperature of the smoke is decreased to 500 DEG C to enter the tail flue, and the exhausted smoke is pumped by a draught fan after the temperature is decreased to 120 to 150 DEG C. The device has a simple and reasonable structure, the biomass combustion slag tapping can be adequately realized through the method, the smoke is clean, and the problems such as dust accumulation, coking, corrosion and the like inside the boiler caused by the low melting point of the biomass dust can be solved.

Owner:沈阳汇丰生物能源发展有限公司 +1

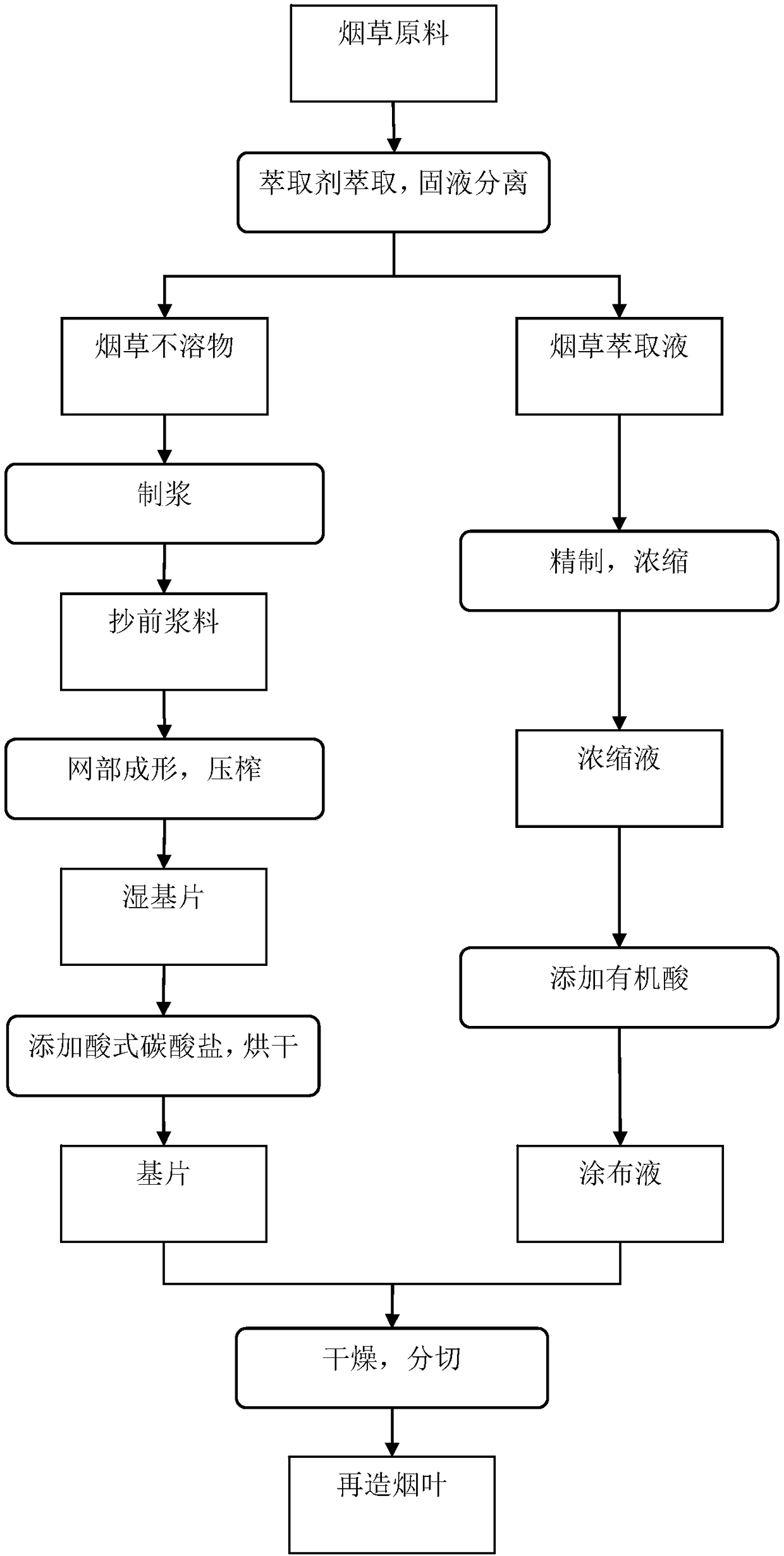

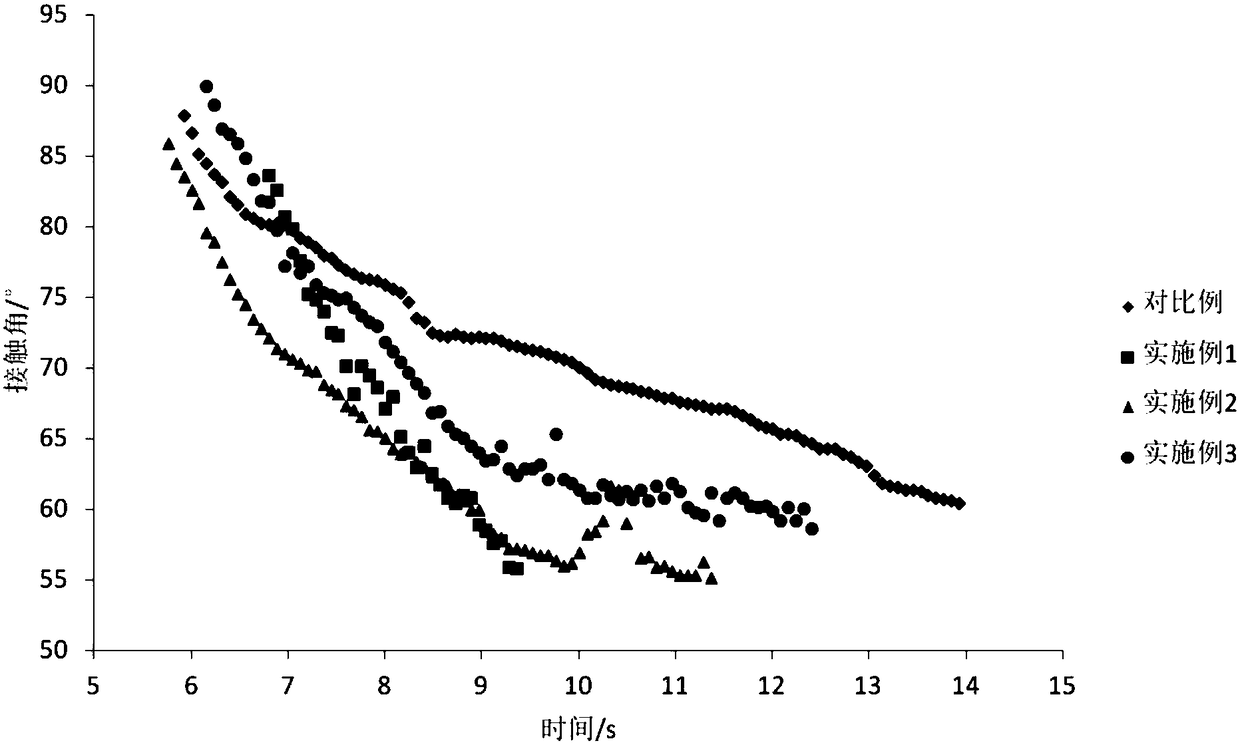

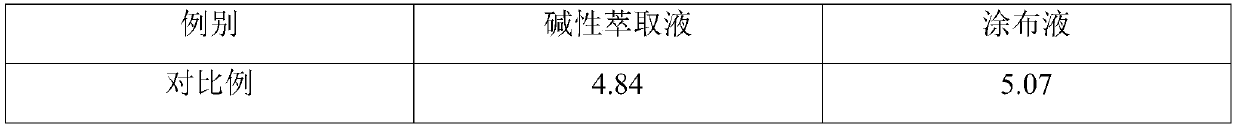

Paper-making reconstituted tobacco preparation method and method for improving coating liquid absorbability of paper-making reconstituted tobacco substrate

The invention provides a paper-making reconstituted tobacco preparation method and a method for improving coating liquid absorbability of a paper-making reconstituted tobacco substrate. The paper-making reconstituted tobacco preparation method includes steps: 1) after extracting with an extracting agent, performing solid-liquid separation to obtain tobacco insoluble matters and tobacco extract liquid; 2) subjecting the tobacco insoluble matters to pulping, and performing net forming and pressing to obtain a wet substrate; 3) subjecting the wet substrate to drying, coating of bicarbonate and drying to obtain a substrate; 4) subjecting the tobacco extract liquid to refining concentration to obtain coating liquid; or adding organic acid after refining concentration to obtain the coating liquid; 5) coating the substrate with the coating liquid, and drying and slitting to obtain reconstituted tobacco. Liquid absorbability of the substrate is improved by thermal decomposition action of bicarbonate; preferably, coating liquid absorbability of the paper-making reconstituted tobacco substrate is improved by improving substrate infiltration performance of the coating liquid through reductionof residue content of the coating liquid.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Aluminum foil for electric cable and production method

InactiveCN101383200AReduce burning lossReduce segregationNon-insulated conductorsInsulated cablesMagnesiumMaterials science

The invention discloses a cable aluminum foil and a production method thereof. The cable aluminum foil comprises components of the following weight percent: 0.79 to 0.83 percent of Si, 0.22 to 0.26 percent of Fe, at most 0.1 percent of Cu, at most 0.2 percent of Mn, at most 0.05 percent of Mg, at most 0.05 percent of Cr, at most 0.1 percent of Zn, at most 0.08 percent of Ti, at most 0.05 percent of single impurity content, at most 0.15 percent of the total content of impurities and Al as the rest, wherein the content summation of the Fe and the Si in weight percent is less than 1.1 percent. The production method comprises the production technical processes: burdening, melting, component analysis, feeding dilution, powder injection refining, N2 refining, on-line refining outside a furnace, casting, casting plate type detection, blank winding, cold rolling, vertical cutting and splitting, finished product annealing, detection, packing, storage and leaving a factory. The cable aluminum foil has good mechanical property, the tensile strength is from 90 to 105MPa, the extension rate is greater than 25 percent, the production requirement has larger development potential, and the enterprise benefit and the social benefit can be obviously increased.

Owner:河南省银湖铝业有限责任公司

Reconstituted tobacco coating liquid and preparation method thereof

ActiveCN110810894AHigh boiling pointLow boiling pointTobacco preparationOrganic acidBiochemical engineering

The invention provides reconstituted tobacco coating liquid and a preparation method of the reconstituted tobacco coating liquid. The preparation method comprises the following steps: extracting a tobacco raw material with water, and carrying out solid-liquid separation to obtain tobacco extracting liquid; adding strong base into the tobacco extracting solution, thus obtaining an alkaline extracting solution; centrifugally purifying the alkaline extracting solution to obtain a refined extracting solution; concentrating the refined extracting solution under reduced pressure to obtain a tobaccoconcentrated solution; and adding tobacco essence and organic acid into the tobacco concentrated solution to obtain the tobacco coating liquid. According to the technical scheme, the operation is simple, the cost is low, and large-scale production can be easily realized.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

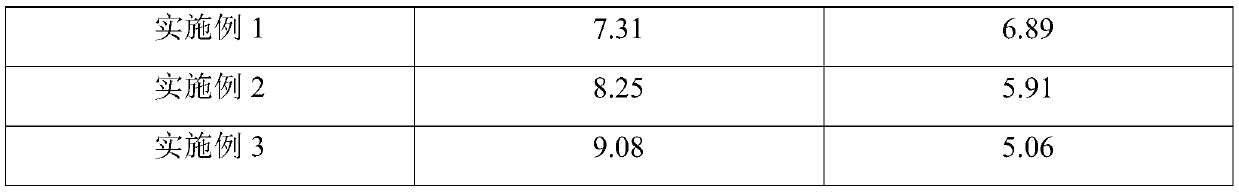

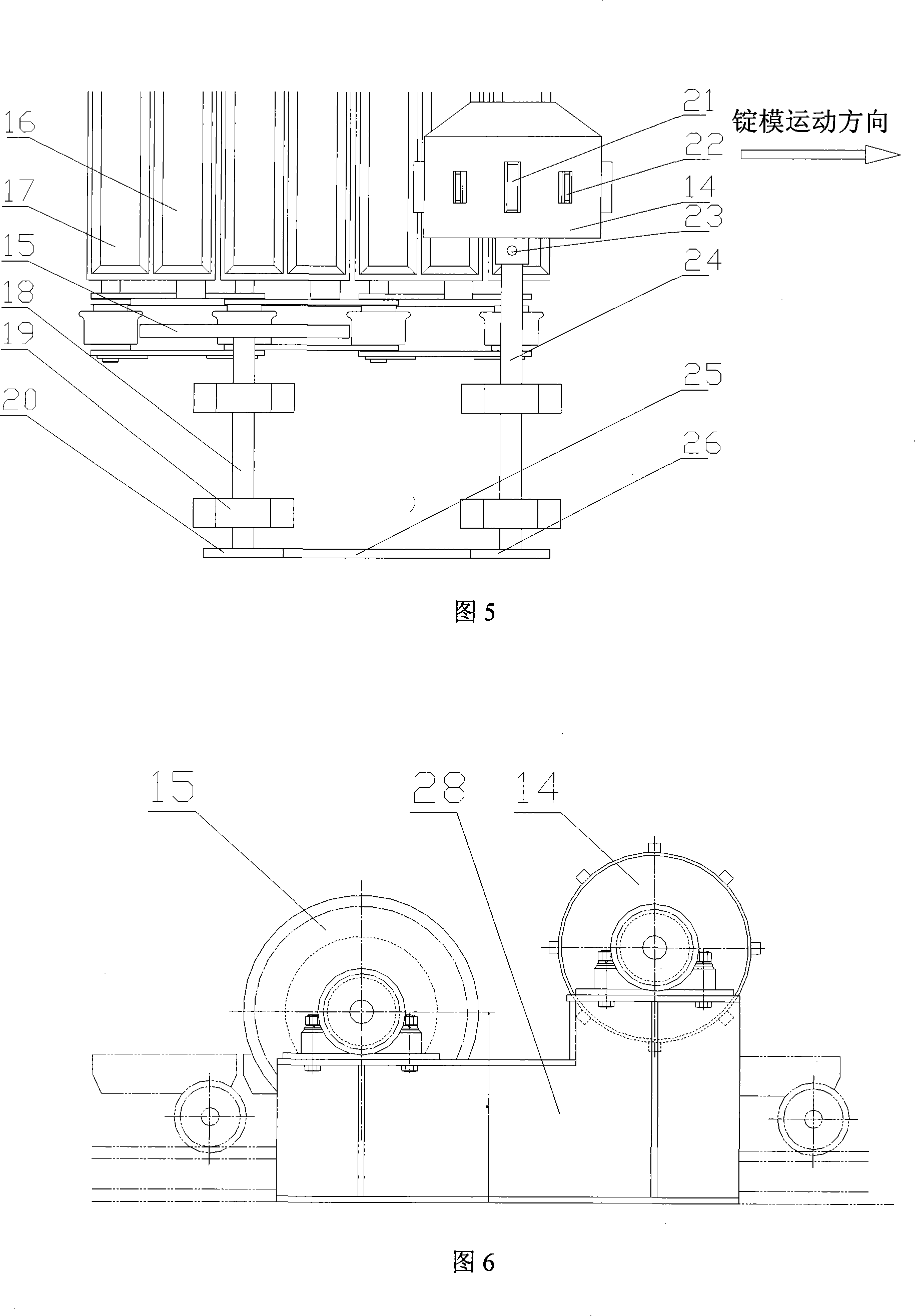

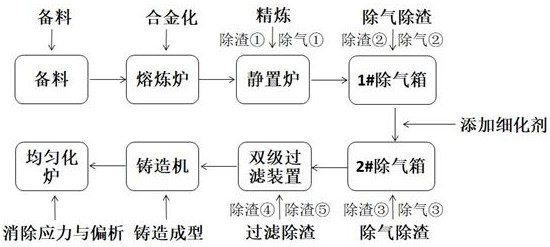

Preparation method of Al-Zn-Mg large-sized flat cast ingot

The invention relates to a preparation method of an Al-Zn-Mg large-sized flat cast ingot. The preparation method includes the following steps that preparing is conducted; smelting is conducted; heat preservation is conducted; degassing and filtering are conducted; on-line grain refinement is conducted; casting is conducted, specifically, a lower casting pipe is used for casting, a distribution bagis installed at the bottom of the lower casting pipe, and an aluminum melt can flow in a semi-closed cavity formed by a crystallizer and a dummy bar head in the crystallizer; and homogenization treatment is conducted. The preparation method of the Al-Zn-Mg large-sized flat cast ingot can effectively solve the problems of uneven composition and prone cracking of the large-sized flat cast ingot.

Owner:广西南南铝加工有限公司

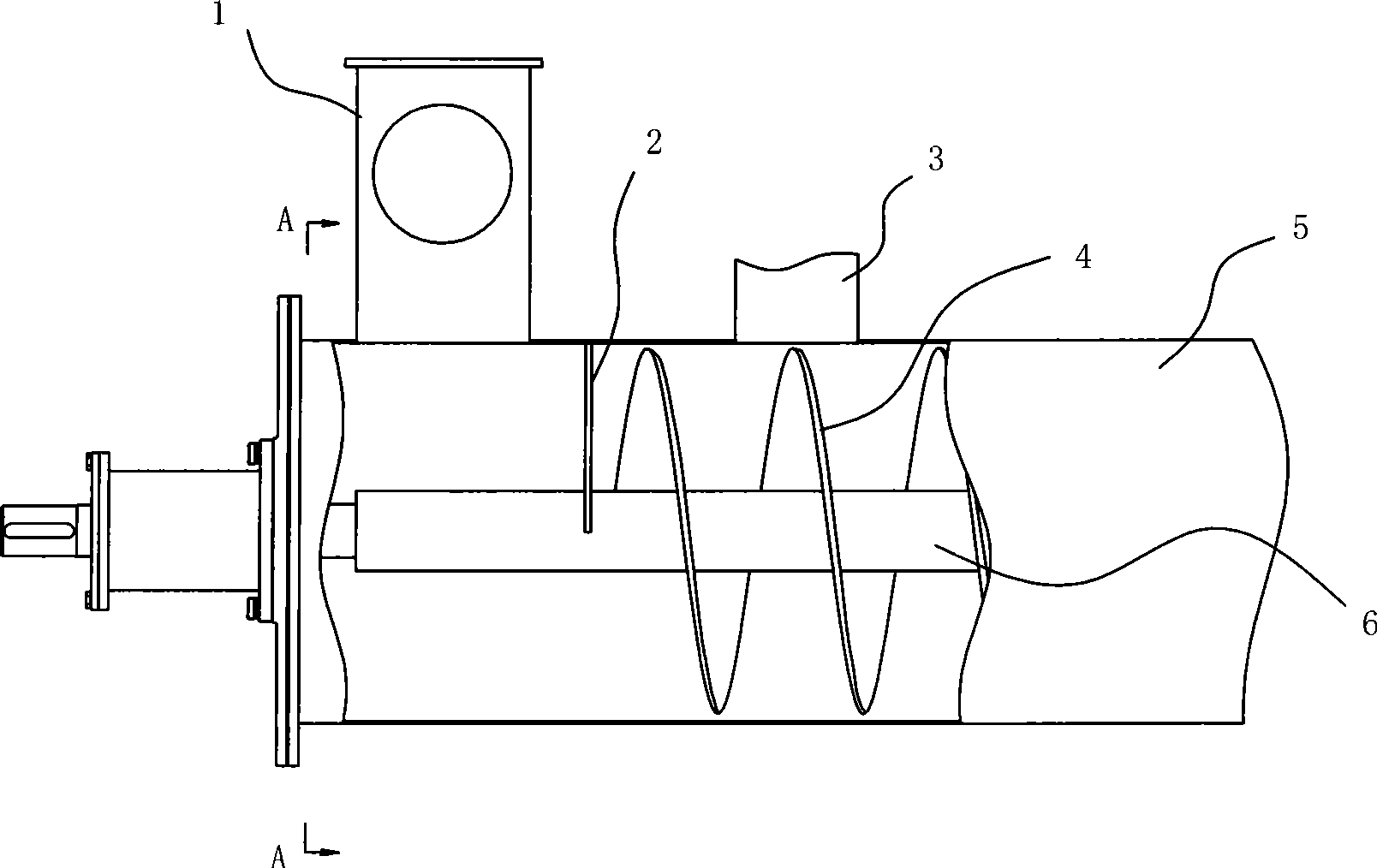

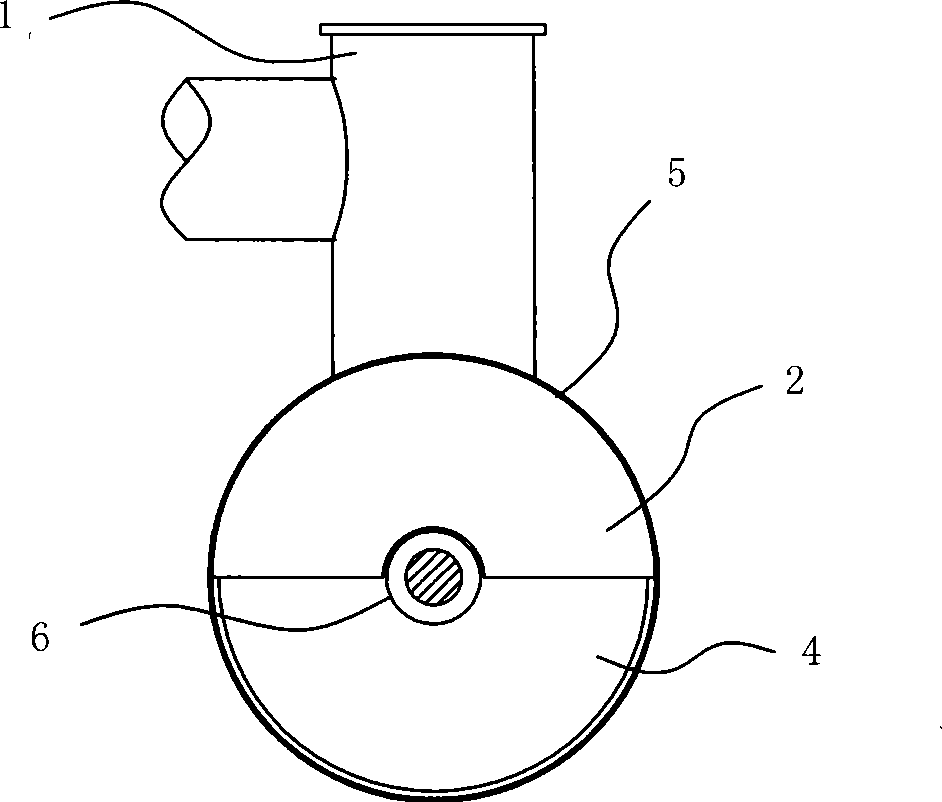

Draining device of extracting tube

The invention provides horizontal pipeline extraction equipment for extracting solid materials by utilization of a solvent, and in particular relates to a technical proposal of a draining device for a reverse-flow extraction pipe. The proposal comprises the extraction pipe and a screw propeller which is arranged inside the extraction pipe and consists of a propulsion shaft and a spiral blade which is fixed on the propulsion shaft, wherein a feeding pipe is arranged on one end of the extraction pipe. The proposal is characterized in that a drain pipe is arranged on the upper top of the extraction pipe between the side end of the extraction pipe and the feeding pipe; a retaining plate is fixed between the upper drain pipe of an inner cavity of the extraction pipe and the feeding pipe and positioned on the end part of the spiral blade, and is a semicircular sector; and the upper edge of the retaining plate is closely connected with the inner cavity of the extraction pipe.

Owner:JINING SINOBEST BIOLOGICAL MACHINERY

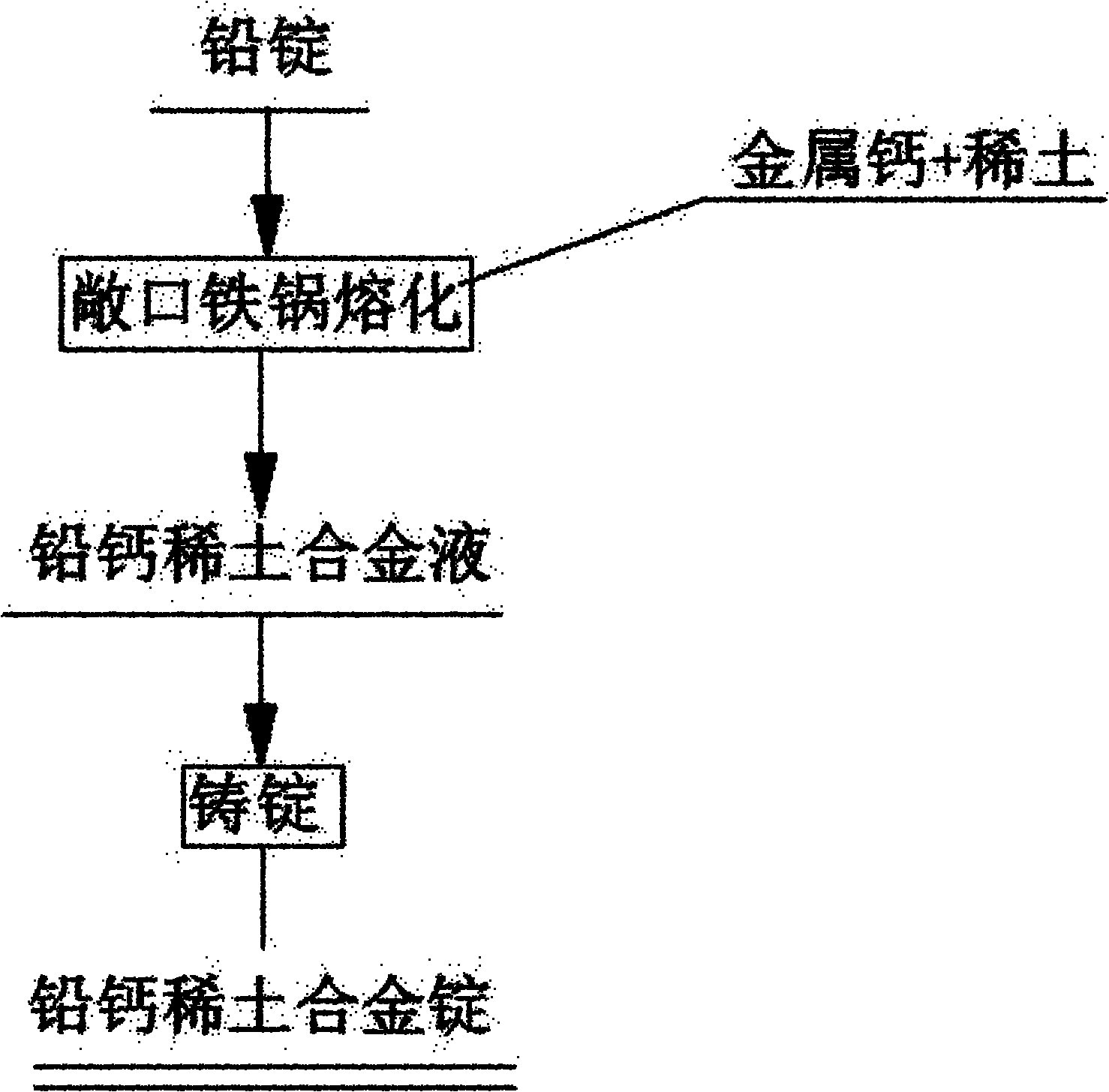

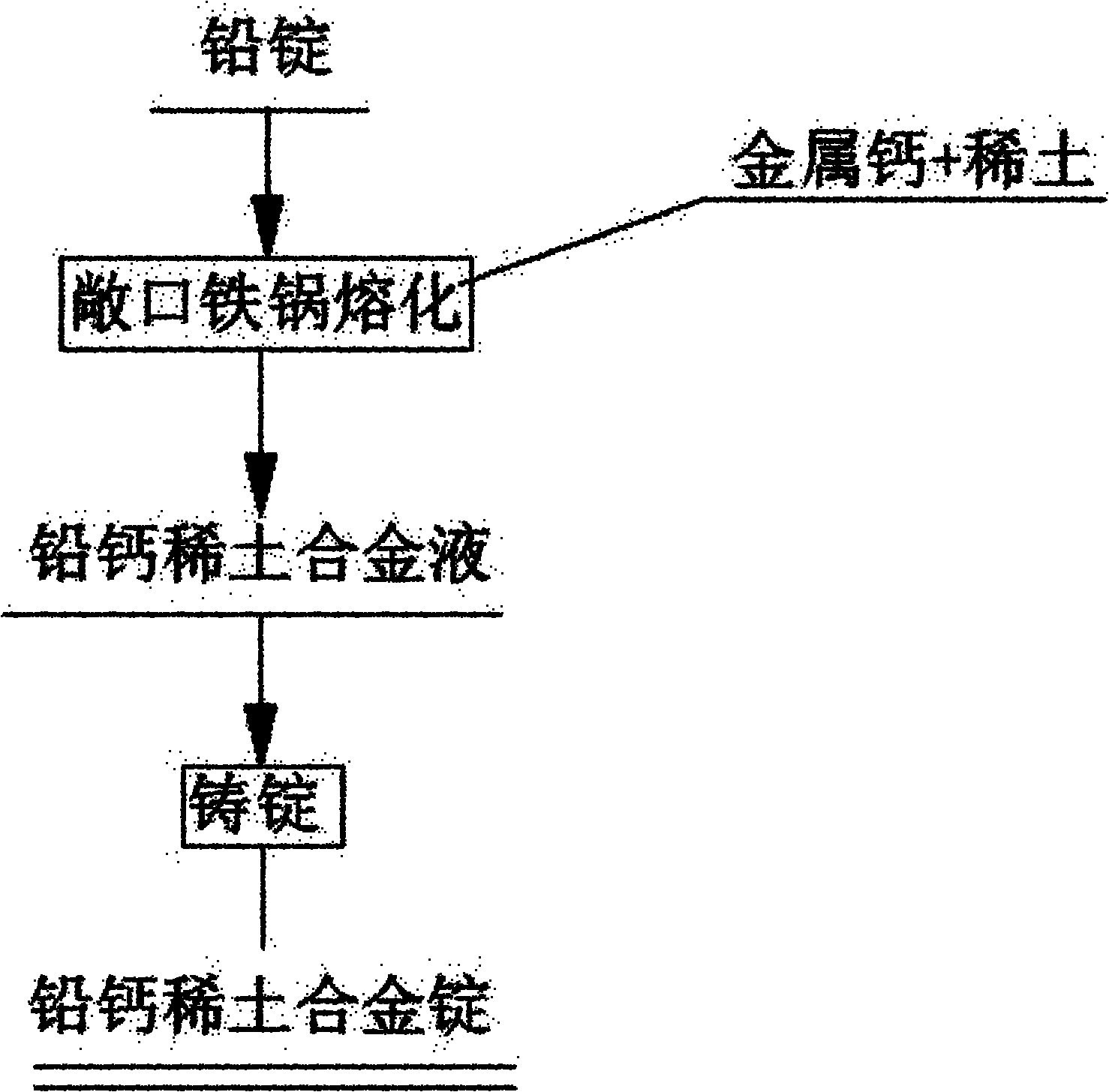

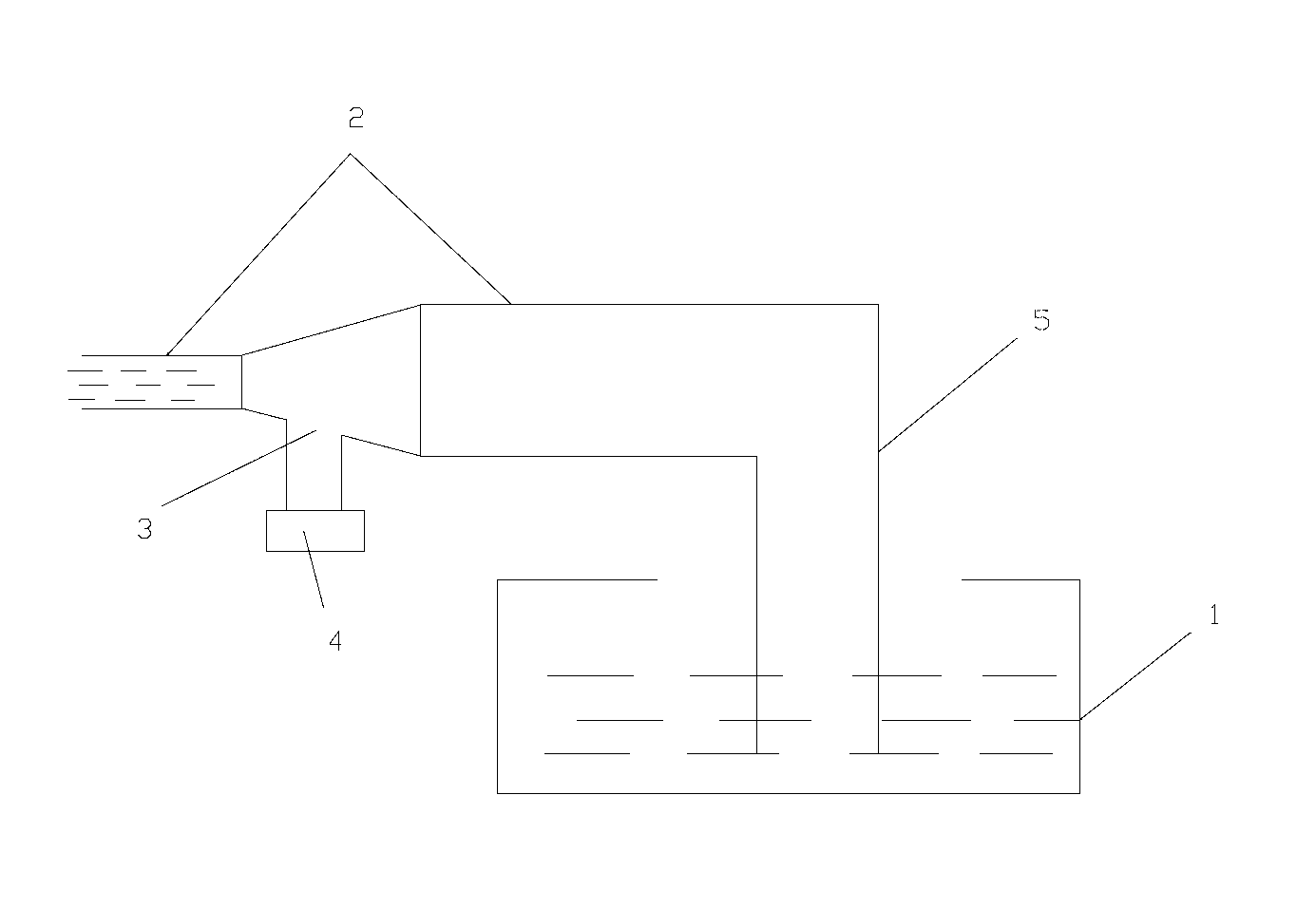

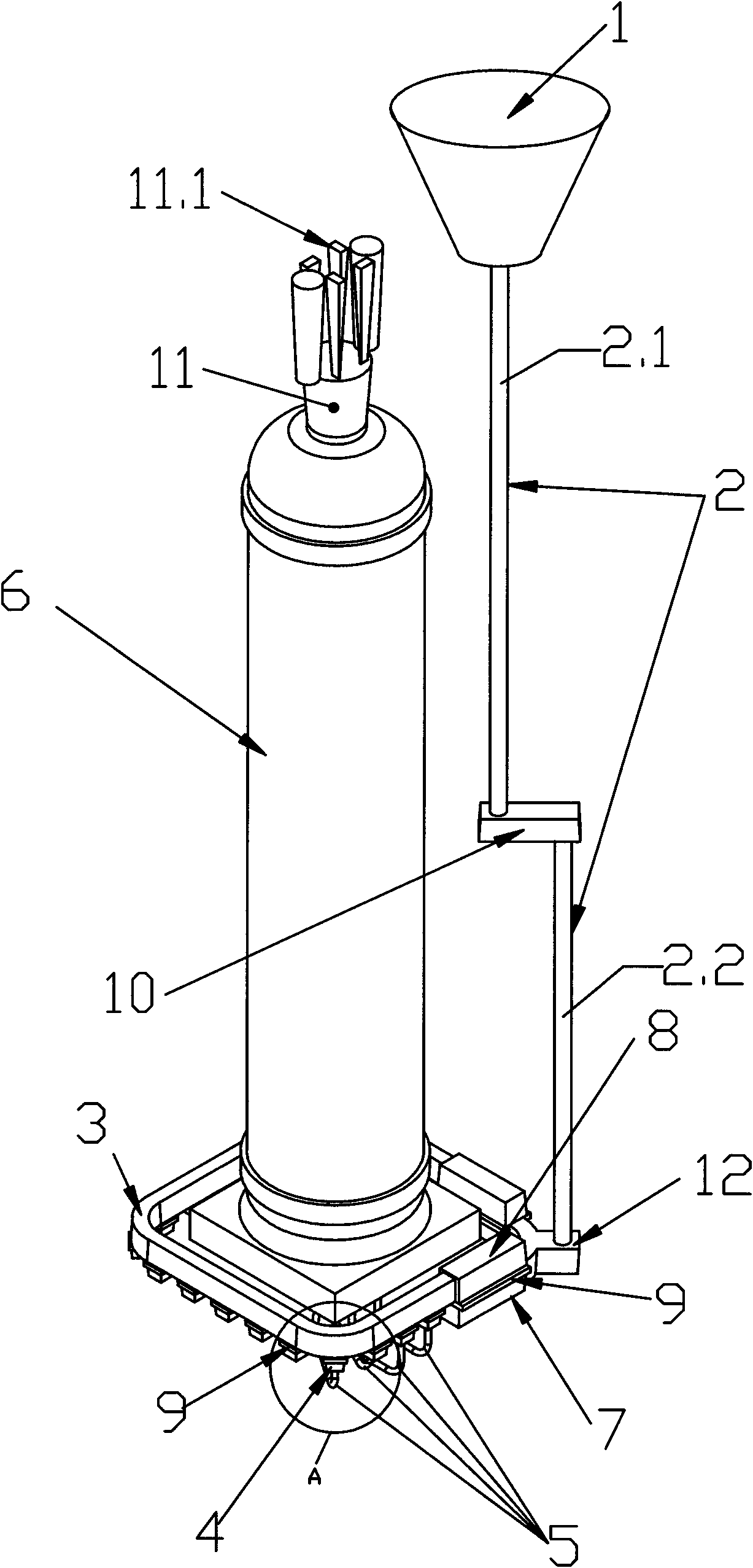

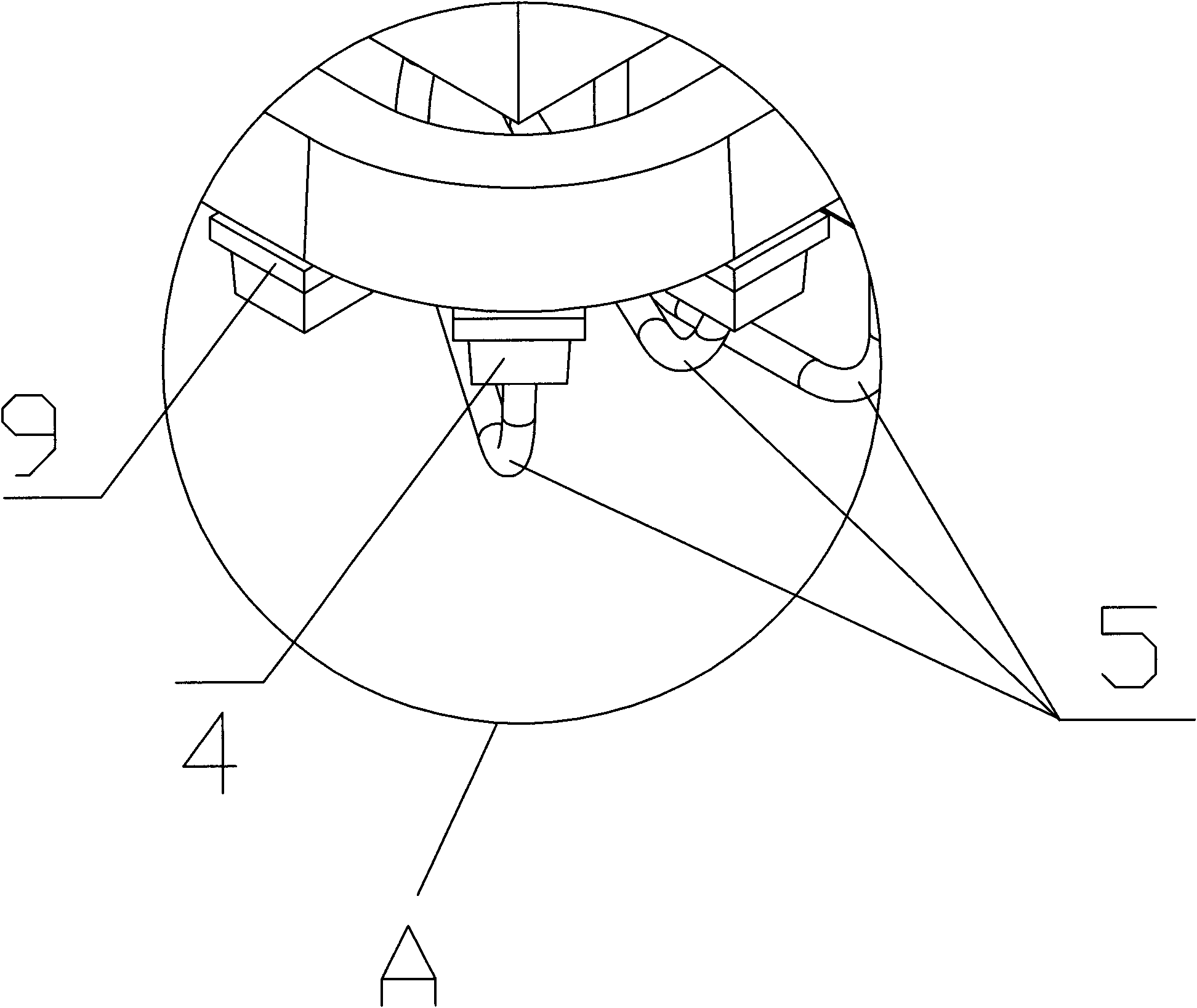

Direct production method for lead calcium rare earth alloy

The invention discloses a direct production method for a lead calcium rare earth alloy. The method is characterized by comprising the following steps of: A, putting lead ingots into an open iron pot, and heating to smelt the lead ingots into liquid lead; B, putting the needed metal calcium and rare earth into an iron bell jar; C, arranging the bell jar in the step B on an end part of a stirrer shaft, stirring the liquid lead and rapidly mixing the calcium and rare earth in the bell jar so as to prepare lead calcium rare earth alloy liquid in the liquid lead; and D, casting the lead calcium rare earth alloy liquid produced in the step C into ingots so as to prepare the lead calcium rare earth alloy ingot products, wherein the needed metal calcium and rare earth in the steps B and C are rapidly thrown into the whirlpool of the stirred liquid lead so as to prepare lead calcium rare earth alloy liquid. The method is mainly used for directly producing the lead calcium rare earth alloy.

Owner:ZHUZHOU SMELTER GRP

Lime slaking device

The invention discloses a lime slaking device, which comprises a pool type slaking tank or revolving drum slaker, and a steam pipe for introducing steam into the pool type slaking tank or the revolving drum slaker, wherein an opening for conveying lime into the steam pipe is formed in one side of the steam pipe. The lime slaking device disclosed by the invention has the remarkable characteristics that the lime is pre-slaked by the steam, wherein the slaking temperature always keeps at above 100 DEG C; the lime is high in activity and high in reaction speed and can be finally slaked after entering the pool type slaking tank or the revolving drum slaker; the produced lime milk is fin in granules, low in residue content, excellent in dispersibility and simple in technological process; and meanwhile, the lime slaking device is formed by simple modification on the basis of original equipment and is simple and convenient to operate, low in investment and easy to implement.

Owner:宜兴天力化工纳米科技有限公司

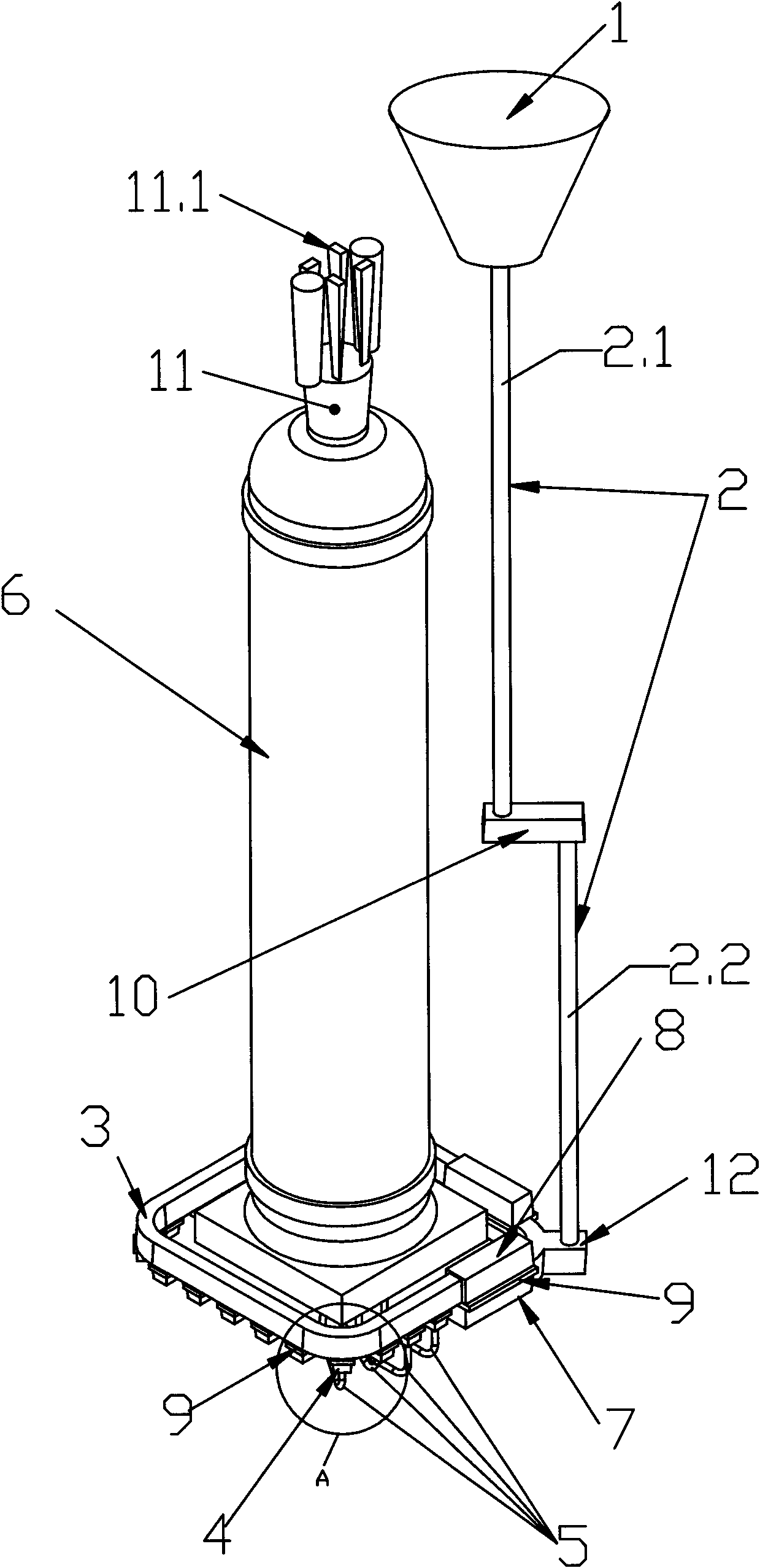

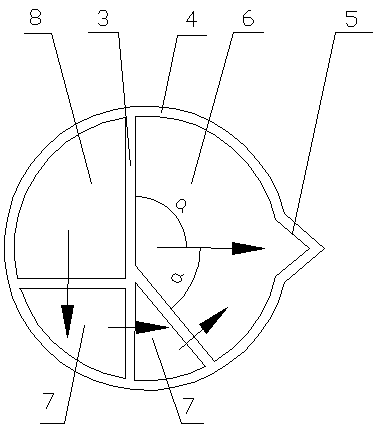

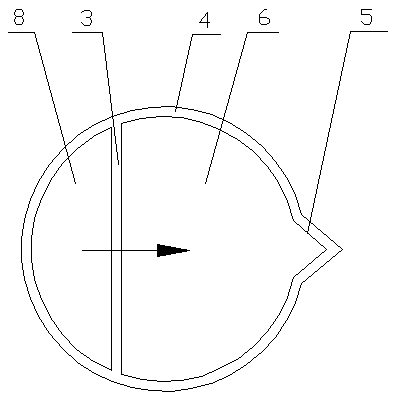

Gating system for stamping cylinder

The invention discloses a gating system for a stamping cylinder. The gating system comprises a pouring basin (1), a sprue (2), an upper cross gate (3), a lower cross gate (4), inner pouring heads (5), and a sand mold (6) which are connected sequentially along the flowing direction of molten iron; the sand mold (6) consists of a sand mould and a cavity; the sprue (2) is divided into at least two buffer sprues; and a first buffer cross gate (10) is arranged between adjacent buffer sprues. The molten iron can be poured stably, secondary oxidation caused by splashing is avoided, the molten iron scummings can be filtered, and the influence of sand removal on a casting is avoided. The gating system belongs to the technical field of casting processing.

Owner:RIYUE HEAVY IND

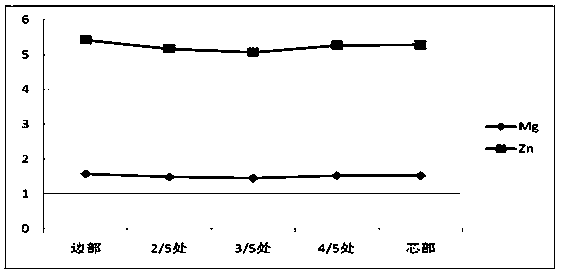

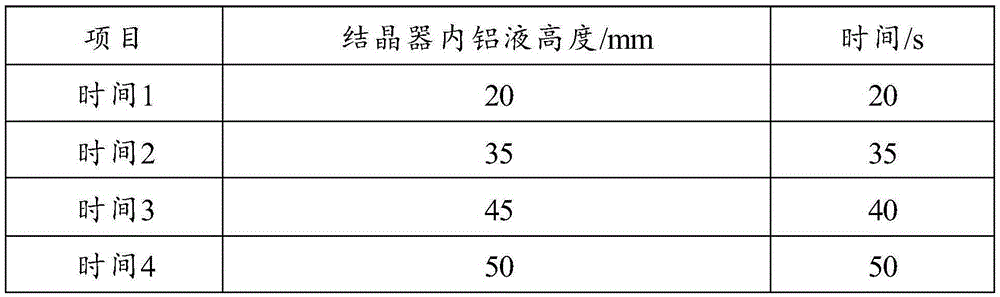

Preparing technology of 7050 aluminum alloy cast ingot

The application provides a preparing technology of an aluminum alloy cast ingot. The preparing technology comprises the following steps: after mixing materials according to the components of the 7050 aluminum alloy cast ingot, melting the materials, and guiding molten aluminum obtained into a holding furnace to carry out continuous refining; then, adding the molten aluminum obtained into Al-3Ti-0.2C wires to carry out online thinning; then, carrying out online degassing on the molten aluminum obtained by SNIF degassing equipment; then, carrying out two-stage filtering on the molten aluminum obtained; and finally, casting the molten aluminum obtained, and controlling the height of the molten aluminum in a crystallizer in the casting process so as to control a bottoming technology. The application improves the metallurgical quality of a 7050 alloy slab ingot and reduces the production cost of 7050 alloy through improving the casting tool of the 7050 aluminum alloy cast ingot and optimizing a casting technology.

Owner:SOUTHWEST ALUMINUM GRP

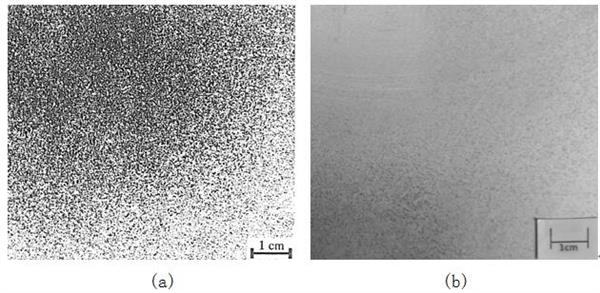

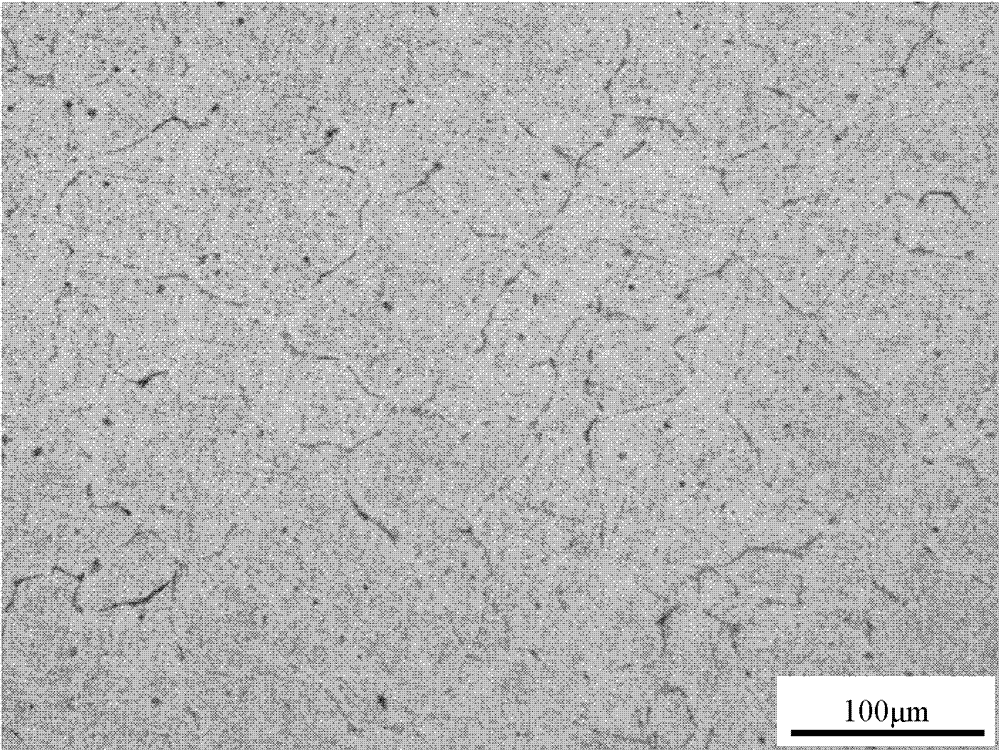

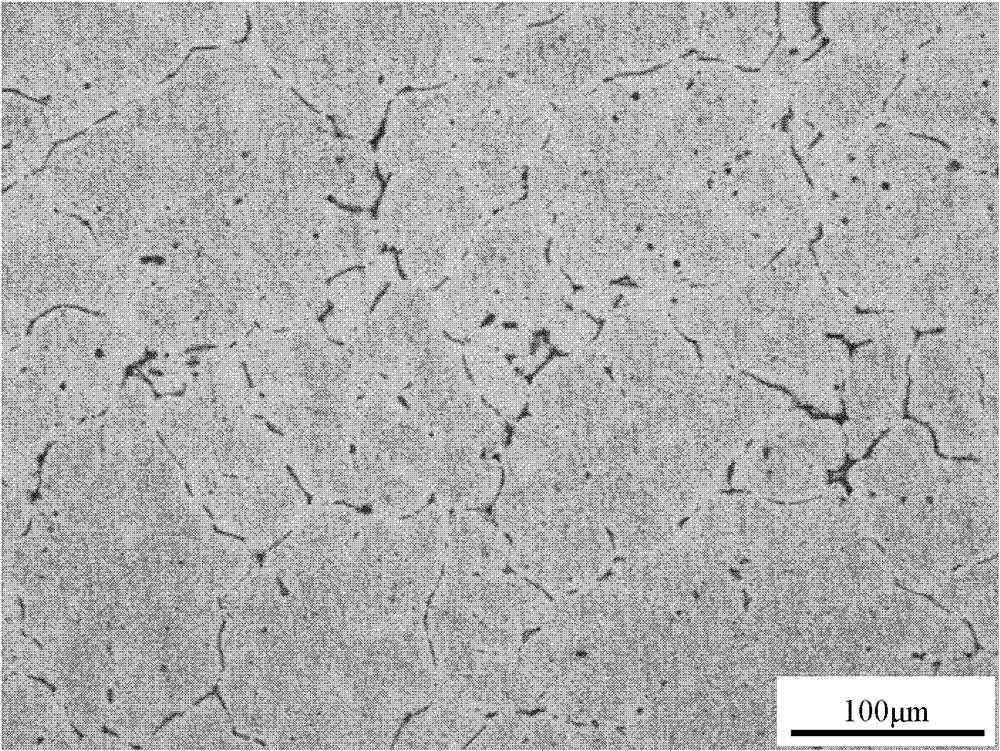

Preparation method of high-quality aluminum-titanium-boron alloy rods

The invention provides a preparation method of high-quality aluminum-titanium-boron alloy rods and belongs to preparation of refiners. The method is characterized by producing aluminum-titanium-boronalloys through cooperation of a frequency-variable induction electric furnace and a medium-frequency induction electric furnace, refining aluminum liquid before charging, adding a mixture of villiaumite and a diffusion agent, taking the mixture as a nucleating agent of TiAl3 and TiB2 mass points in the alloying process, wherein the TiAl3 and TiB2 mass points formed after completing alloying are fine and are more uniformly distributed; the formation of rod shape of the TiAl3 mass points and the aggregation of the TiB2 mass points are eliminated; the diffusion agent is added into the villiaumitemixture, so that the aggregation of the TiAl3 and TiB2 mass points is effectively controlled; the alloying process is equipped with mechanical stirring, so that the enlargement of the TiAl3 and TiB2mass points is effectively prevented; the separation and purification effect of villiaumite slag and alloys can be improved; through check analysis, the TiAl3 and TiB2 mass points in the produced products are fine, are uniform and dispersive in distribution and are extremely low in slag content; the problems that the TiAl3 mass points in the continuously cast and rolled aluminum-titanium-boron alloy rods in the current market are thick and big, the TiB2 mass points are aggregated, the content of the slag in the alloys is high, and the aluminum-titanium-boron alloy rods are poor in refining capacity in the aluminum alloys are effectively solved.

Owner:河北晶宝新金属有限公司

Preparation method of fusion casting aluminum bar for section aluminum

InactiveCN107723495AStrong weather resistanceImprove performanceAnodisationProcess efficiency improvementWeather resistanceSlag

The invention discloses a preparation method of a fusion casting aluminum bar for section aluminum. The preparation method comprises the steps of weighing of a raw material for preparing the aluminumbar, smelting of the raw material of the aluminum bar, refining, fusion casting, extrusion, mechanical pretreatment, degreasing, alkaline washing, water washing, oxidization, surface treatment, the coloring process, the spraying process, the curing process and coating of an anticorrosive coating with the thickness being 20-50 microns on the outer surface of the aluminum bar. The aluminum bar prepared through the method is high in weather resistance, and the performance of the aluminum bar is improved. Moreover, the aluminum bar is energy-saving, environment-friendly and good in anticorrosion effect, the good oxidation resistance of the aluminum bar can be guaranteed. The slag content of the aluminum bar is low. A refining machine is used for spraying a refining agent to an alloy aluminum solution to conduct slag removal treatment, and slag removal treatment is further conducted through a ceramic filter plate. Slag inclusions in the alloy aluminum solution are effectively removed. The slag content of the aluminum bar is greatly reduced.

Owner:奋安铝业股份有限公司

Aluminium alloy for household appliance handle and purification method of melt of aluminium alloy

ActiveCN104233019AIncrease extrusion speedImprove surface qualityRare-earth elementPurification methods

The invention relates to an aluminium alloy for a household appliance handle and a purification method of melt of the aluminium alloy. The aluminium alloy is characterized by comprising the following chemical components in percentage by weight: 1.0%-1.12% of Mg, 0.16%-0.22% of Si, 0.1%-0.5% of La+Ce, less than 0.25% of Fe, no more than 0.02% of Cr, no more than 0.02% of Mn, no more than 0.03% of Zn, no more than 0.02% of Cu, no more than 0.02% of each of other impurity elements, and the balance of Al, wherein the total content of the other impurity elements is not more than 0.15%. By adding rare earth elements La and Ce, the aluminium alloy for the household appliance handle is capable of improving the surface quality of an aluminium alloy section and improving the extrusion speed of the aluminium alloy. The household appliance handle produced by adopting the aluminium alloy for the household appliance handle disclosed by the invention has the advantages of being smooth in surface, strong in metal feel, environment-friendly and durable, collision-resistant, corrosion-resistant, high in strength, good in mechanical property and the like.

Owner:ALNAN ALUMINIUM CO LTD

5182-H36 aluminum alloy sheet material for luggage compartment door plate of new energy passenger car and preparation method of 5182-H36 aluminum alloy sheet material

The invention discloses a 5182-H36 aluminum alloy sheet material for a luggage compartment door plate of a new energy passenger car. The 5182-H36 aluminum alloy sheet material comprises the followingcomponents in percentage by mass: 0.05 to 0.10 percent of Si, 0.10 to 0.20 percent of Fe, 0.01 to 0.10 percent of Cu, 0.4 to 0.8 percent of Mn, 4.6 to 5.2 percent of Mg, 0.07 to 0.12 percent of Cr, 0.01 to 0.20 percent of Zn, 0.01 to 0.05 percent of Ti and the balance of Al. A preparation process comprises the following steps: smelting, filtering a melt, casting, carrying out saw cutting on a milling surface, heating a casting ingot, carrying out hot rolling, carrying out cold rolling and carrying out stabilized annealing. The 5182-H36 aluminum alloy sheet material for the luggage compartmentdoor plate of the new energy passenger car, prepared by a preparation method, has good properties including low density, corrosion resistance, high strength, good bending performance and the like, andcan meet requirements of the luggage compartment door plate of the new energy passenger car on light weight and high comprehensive performance of production materials.

Owner:CHINALCO RUIMIN +1

Casting device of zinc straight line ingot molding machine with duplex-mold

ActiveCN101185967ASimple equipment structureReduce the impactMolten metal conveying equipmentsSlagSprocket

The invention relates to a casting device of a double linkage-die zinc beeline ingot-casting machine. A zinc discharging hole is cut at the bottom of a zinc smelter. Zinc liquid is collected through a downward suspension launder and a zinc liquid distributing disk of a turntable style casting device without contact. The zinc smelter is in sealed state. The turntable style casting device drives the distributing disk on which zinc liquid casting distribution nozzles are equally arranged in a radial direction to revolve through a chain-wheel transmission device, so as to realize the synchronous operation of casting operation and ingot mold running. The invention changes liquid-collecting from a zinc liquid surface of the traditional scoop ration casting mechanism and also displaces a motor and a transmission system of the prior scoop ration casting mechanism. Therefore, the equipment structure is simplified and the equipment failure becomes less, with high reliability, reduced maintenance cost. The zinc liquid is collected in sealed state so as to reduce slag rate and enhance the product quality.

Owner:ZHUZHOU SMELTER GRP

High-performance automobile die casting aluminum alloy material and preparation method thereof

The invention discloses a high-performance automobile die casting aluminum alloy material and a preparation method thereof. The high-performance automobile die casting aluminum alloy material comprises the following components of, by mass, 8%-9% of Si, 0.5%-0.8% of Fe, Cu 3.2%-3.8% of Cu, 0.15%-0.40% of Mn, less than or equal to 0.3% of Mg, less than or equal to 1.5% of Zn, 0.008%-0.02% of Sr, less than or equal to 0.05% of other single impurity element, less than or equal to 0.15% of impurity element total amount, and 84.2%-88.1% of Al. The preparation method of the high-performance automobile die casting aluminum alloy material comprises the following steps of material preparation, smelting, alloying, cooling and component adjustment, refining, standing and modification. According to thehigh-performance automobile die casting aluminum alloy material and the preparation method thereof, the composition proportion of the aluminum alloy material is optimized, so that die casting production is facilitated, sufficient strength is achieved so as to meet load requirements of an automobile die casting, and wide applicability is achieved.

Owner:南通众福新材料科技有限公司

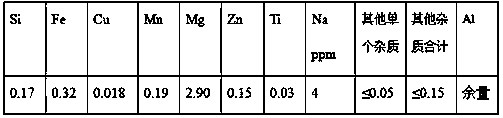

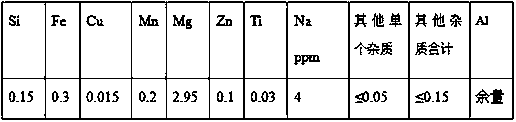

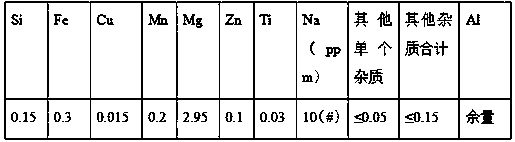

Preparation method of aluminum alloy for aerosol bottle cap

ActiveCN108642344AOvercoming technical deficienciesSolve problems such as slag inclusionSlagImpurity

The invention provides a preparation method of an aluminum alloy for an aerosol bottle cap. The method comprises the steps of S1, preparing a cast ingot through alloy components based on the mixing ratio; S2, milling the cast ingot; S3, uniformly thermally processing the cast ingot; S4, performing hot rolling on the cast iron to obtain a blank; S5, performing cold rolling to the blank which is subjected to hot rolling until the intermediate annealing thickness is reached; S6, washing the surface with weak alkali; S7, completely recrystallizing and annealing the middle; S8, performing pass rolling on a finished product; S9, stably chemically processing the finished product; and S10, stretching and bending and correcting back roll. According to the method, the Na content is effectively decreased based on the component mixing ratio and the technical method; the range of Na element which easily causes Na embrittlement in a high-magnesium alloy is avoided, and thus the problem of Na embrittlement is solved; and meanwhile, the component fluctuation is well controlled, and the problem that the magnesium element easily results to slag inclusion is solved; and meanwhile, the problem of liquid leaking caused by impurities adhering to the surface can be solved by a special weak alkali washing technology in the middle process; and the produced aluminum alloy for the aerosol bottle cap is high in stability in batch.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

Aluminium scrap online furnace returning device and process

PendingCN109161693ARealize zero systemReduce slag contentRotary drum furnacesCharge manipulationSlagContinuous operation

Owner:CITIC DICASTAL

Novel process for preparing soybean milk

InactiveCN102177972AShorten pulping timeImprove water retentionMilk substitutesFood sciencePetalSoybean meal

The invention relates to a novel process for preparing soybean milk. The process comprises a raw material supply stage at which a soybean raw material is provided, and a user side pulverization and pulping stage, wherein the raw material supply stage comprises the steps of crushing whole soybeans into a plurality of soybean petals and curing the soybean petals; and the user side pulverization and pulping stage comprises the steps of mixing the soybean petals and water, pulverizing and pulping. By the novel preparation process, the soybean petals are cured in the raw material supply stage, so that a step of boiling the soybean milk is not required in the user side pulverization and pulping stage, namely when people want to prepare the soybean milk, the cured soybean petals provided in the raw material supply stage are directly mixed with water for pulverization and pulping, so that the pulping time of a user side is greatly shortened.

Owner:JOYOUNG CO LTD

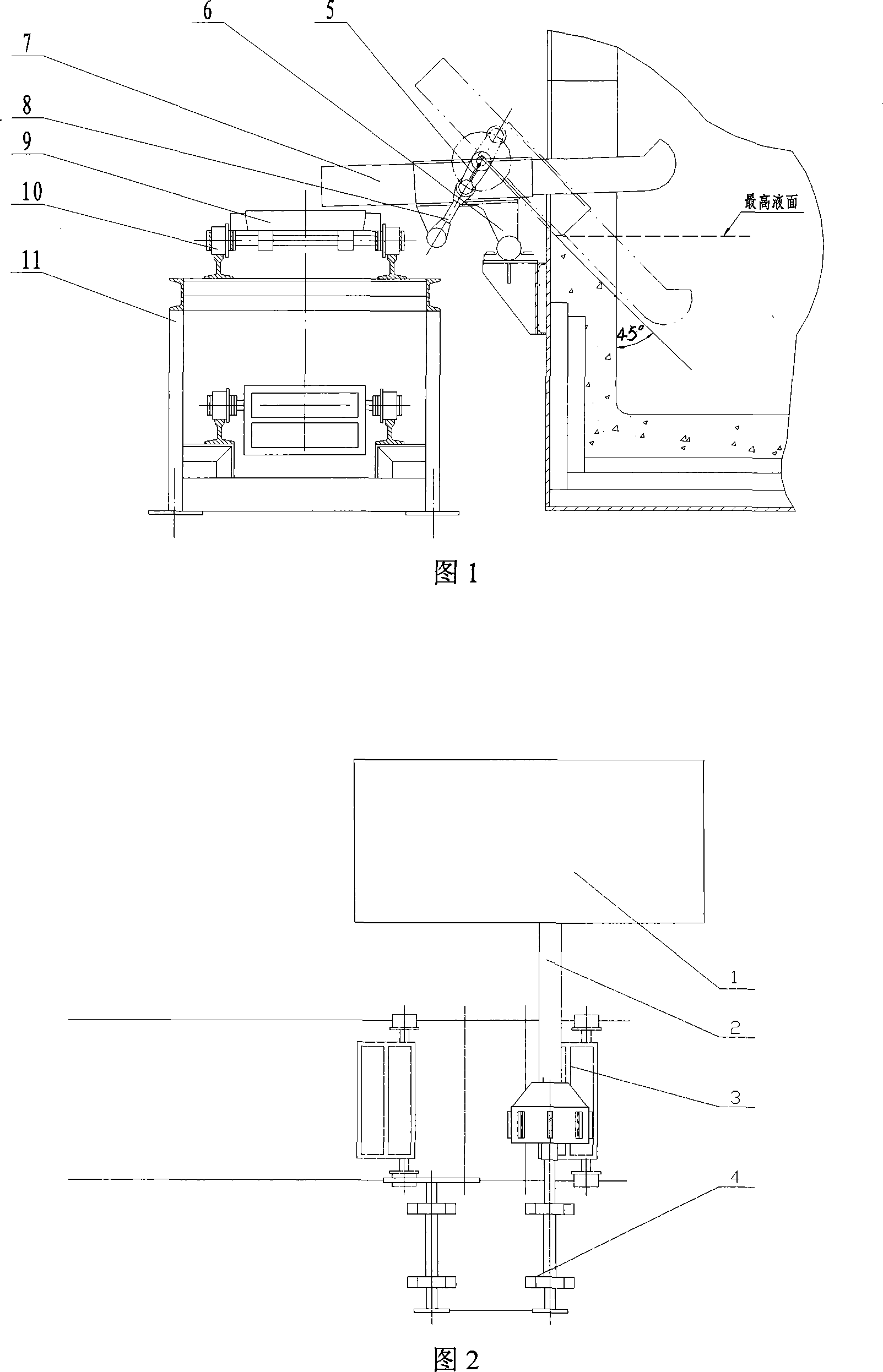

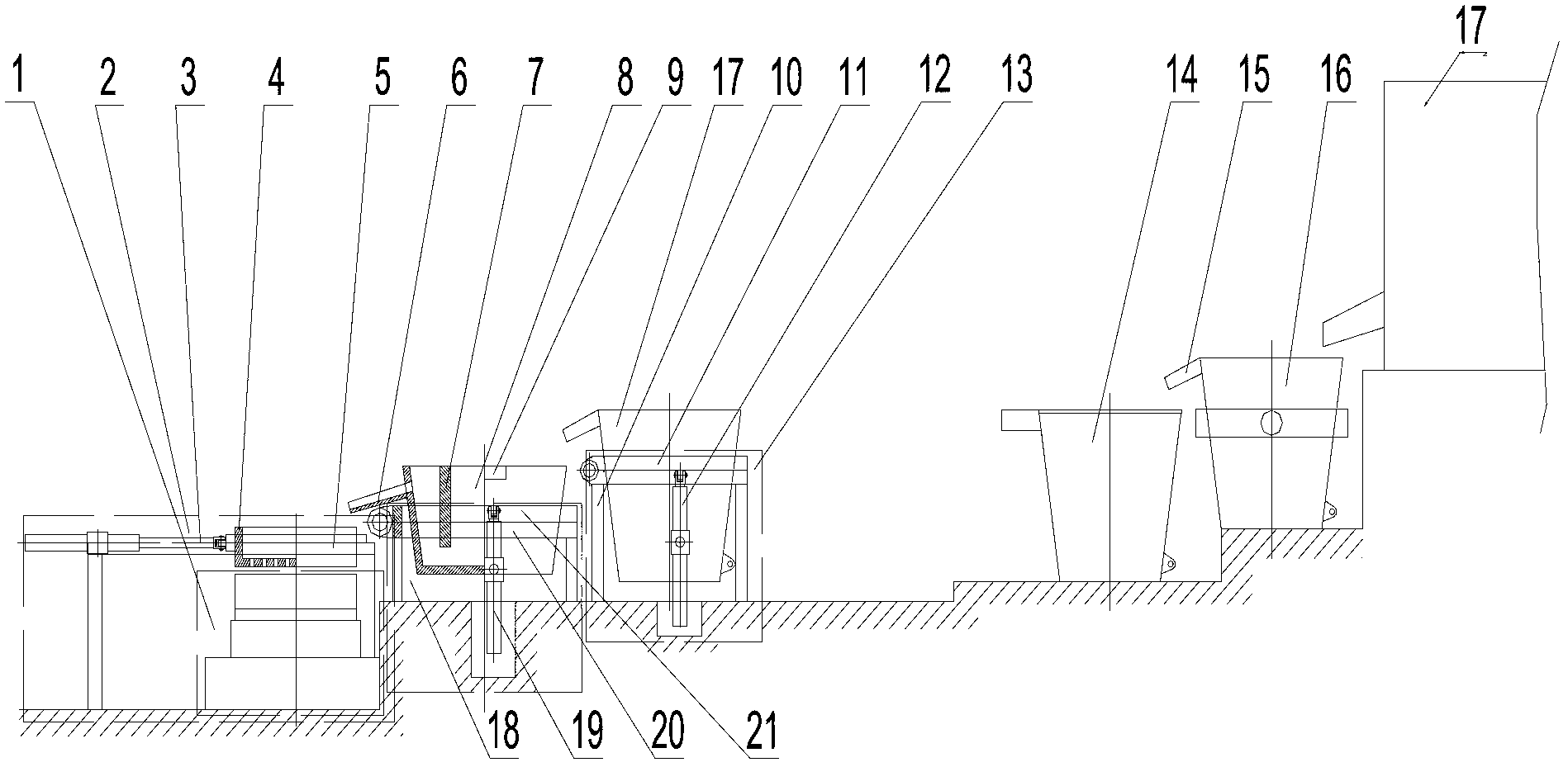

Ferroalloy casting modeling device and ferroalloy casting modeling process in front of furnace

InactiveCN103170609AEasy to separateHigh recovery rateMolten metal conveying equipmentsHydraulic cylinderCast iron

Provided are a ferroalloy casting modeling device and a ferroalloy casting modeling process in front of a furnace. The ferroalloy casting modeling device is composed of a ladle, a slag ladle, a ladle tip-over device, a slag and iron separating device, a casting tundish device and a cast iron car. The slag and iron separating device is composed of a slag and iron separating ladle and a tip-over device. A slag overflow port is arranged in the upper portion of the slag and iron separating ladle, a tap hole which is lower than the slag overflow port is arranged in the front portion of the slag and iron separating ladle, and a slag blocking wall is arranged inside the slag and iron separating ladle. The casting tundish device is composed of a casting tundish and a hydraulic cylinder. When the ferroalloy casting modeling device is used for conducting ferroalloy casting, firstly, the ladle and the slag ladle are used for conducting one-time slag removing to tap-off ferroalloy, secondly, the ladle is hoisted on the tip-over device, and the slag and iron separating device, the casting tundish device and a pig casting machine are used for carrying out secondary slag removing and casting modeling. According to the ferroalloy casting modeling process, through two times of slag removing, the effect of slag and iron separating is greatly improved, and not only is iron losing avoided, but also the slag content in the ferroalloy is lowered. Manual drossing is of no need, and labor power and cost are saved. Meanwhile, the granular size of the ferroalloy can be formed at one time according to the demands of users, and secondary processing and crushing are of no need.

Owner:LIAONING HENGDA HEAVY IND +1

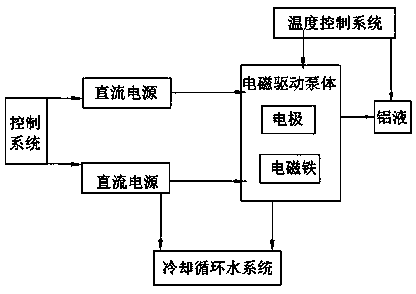

Electromagnetically-driven low-pressure casting forming system

The invention discloses an electrically-driven low-pressure casting forming system. The electrically-driven low-pressure casting forming system comprises a heat preserving furnace, a magnetic field system, an electric field system, a temperature control system, a cooling circulating water system and a control system, wherein the electric field system and the magnetic field system define an electrically-driven pump body, and are controlled by the control system; molten aluminum is stored in the heat preserving furnace; a charge hole is formed in the upper part of the heat preserving furnace; aradiation type heating device is arranged on the top of the heat preserving furnace; an opening is formed in the lower part of the heat preserving furnace, and the opening is connected to a bottom chute of the electrically-driven pump body; and an opening is formed in the top of the bottom chute, and the opening is in sealing connection with a riser tube. The electrically-driven low-pressure casting forming system drives molten aluminum forming by replacing compressed air with electromagnetic drive force, is stable in transmission in a casting process, does not generate turbulent flow and gasair entrainment, and is low in gas and slag content in molten aluminum; through the magnetic field effect, the molten aluminum improves structure performance of a casting, and does not need to repeatedly add gas for pressurization; and the molten aluminum in the heat preserving furnace is in a sealing state, oxidation and gas suction tendency is low, mechanical performance of the casting is improved, the production process is stable, and product consistency is good.

Owner:天津海特智能装备有限公司

Aluminum alloy super-purification refining method

The invention discloses an aluminum alloy super-purification refining method, and aims to reduce the hydrogen content, oxide inclusion content and harmful alloy element content in the aluminum alloy. The method comprises the following steps of: arranging two aluminum alloy blanks to be melted on a lifting mechanism and connecting the two aluminum alloy blanks to the positive electrode and the negative electrode of a melting power supply respectively; arranging a non-metal crucible under the aluminum alloy blanks, placing the slag in the crucible and heating the slag to the working temperatureof between 630 and 700 DEG C to change the slag into a liquid state; starting the lifting mechanism to drop the aluminum alloy blank and extend the lower end into the liquid-state slag, wherein the immersion depth is 10mm, and opening cooling water; preserving heat for a certain time and switching on the melting power supply after the slag in contact with the aluminum alloy blank is remelted, wherein the current is 250 to 280A and the voltage is 8 to 9V; automatically feeding by the lifting mechanism according to a voltage value and feeding downwards when the voltage value is more than 9V; stopping the feeding when the voltage value is less than 8V; when the feeding is stopped, increasing the voltage value along with the continuous melting of the aluminum alloy blank; automatically adjusting the feeding process by the lifting mechanism until all the aluminum alloy blanks are fed into the melting crucible by a feeding mechanism; ending the melting and closing the melting power supply when the feeding mechanism feeds the aluminum alloy blanks to the bottommost part and the voltage is more than 9V; and lifting the lifting mechanism, scratching the slag in the crucible out and castingan ingot with the refined aluminum alloy liquid or directly pouring a cast.

Owner:ZHONGBEI UNIV

Large-scale 2-series aluminum alloy ingot for civil aircraft and preparation method thereof

The invention discloses a large-scale 2-series aluminum alloy ingot for a civil aircraft and a preparation method thereof, and belongs to the field of preparation of 2-series aluminum alloys for civilaircrafts. The aluminum alloy ingot is prepared from the materials in percentage by mass: less than 0.05% of Si, less than 0.06% of Fe, 3.7% to 4.1% of Cu, 1.2% to 1.4% of Mg, less than 0.4% to 0.8%of Mn, less than 0.02% of Cr, 0.02% to 0.06% of Ti, 0.08% to 0.12% of Zr, less than 0.15% of other impurity elements, and the balance of Al. According to the large-scale 2-series aluminum alloy ingotfor the civil aircraft and the preparation method thereof, a three-stage degassing and five-stage slag removal melt purification technology, a refiner precise addition and efficient utilization technology and a casting temperature precise control technology are adopted, a series of technical problems such as melt purification, crystal grain coarsening, composition segregation and casting crackingare solved, the quality indicators of the large-scale 2-series ingot are comprehensively improved, the large-scale and high-quality 2-series aluminum alloy ingot which meets the requirements for the production and installation of a long stringer under wings of the civil aircraft is produced, and the domestic blank is filled.

Owner:SHANDONG NANSHAN ALUMINUM +2

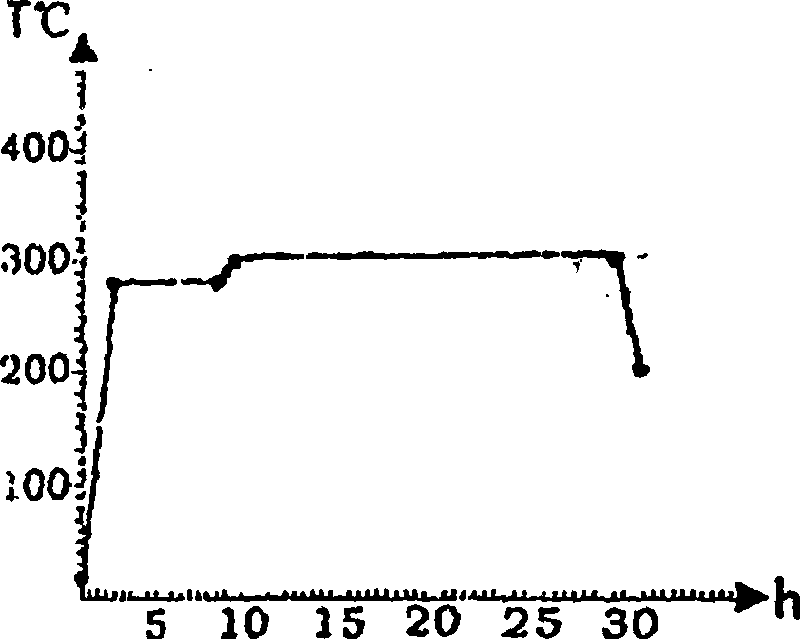

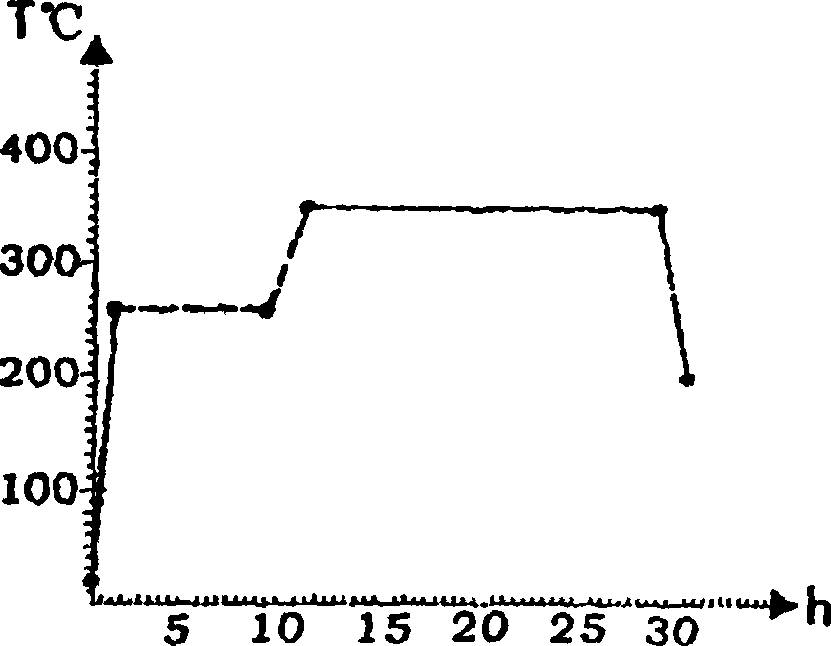

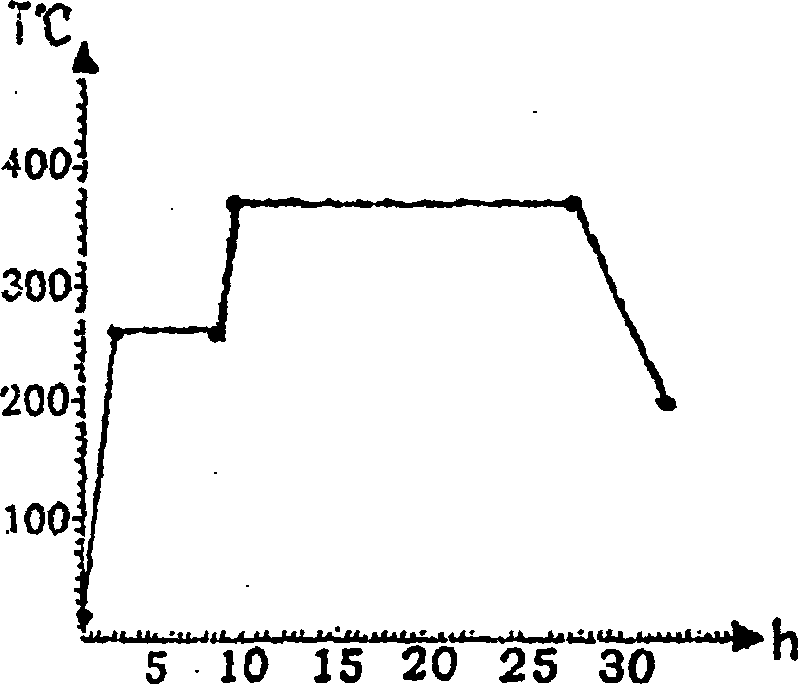

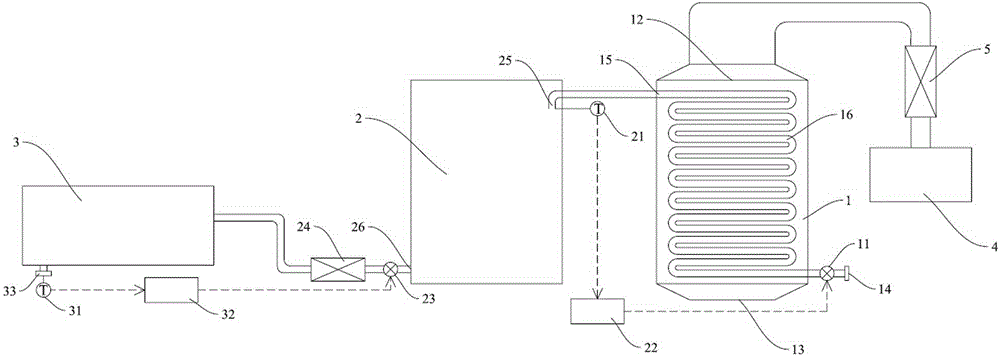

Digestion system utilizing waste heat and temperature control method thereof

ActiveCN104990419AGuaranteed stabilityHigh activityIncreasing energy efficiencyControl devices for furnacesTemperature controlProportion integration differentiation

The invention discloses a digestion system utilizing waste heat and a temperature control method thereof. The digestion system comprises a heat exchanger, a hot water storage tank, a digestion slot, a first temperature control solenoid valve, a first temperature sensor and a first PID (proportion integration differentiation) controller, wherein the heat exchanger is used for heating cold water by utilizing waste heat; the hot water storage tank is connected with a hot water outlet of the heat exchanger, and is used for storing heat-exchanged hot water; the digestion slot is connected with the outlet of the hot water storage tank and used for receiving hot water and digesting lime; the first temperature control solenoid valve is connected at a cold water inlet of the heat exchanger; the first temperature sensor is used for sensing a temperature signal at a hot water inlet of the hot water storage tank; and the first PID controller is connected with the first temperature control solenoid valve and the first temperature controller, and used for receiving a temperature signal of the first temperature sensor and regulating flow opening of the first temperature control solenoid valve to regulate water amount of cold water which enters the heat exchanger. The digestion system is used for recycling tail gas waste heat and keeping the stability of the hot water storage tank and a digestion temperature by virtue of intelligent regulation to guarantee that the waste heat is utilized to the greatest extent, and the digestion quality is improved.

Owner:吉安市五峰材料股份有限公司 +1

Microalloy smelting process for aluminum-magnesium-silicon aluminum alloy

The invention discloses a microalloy smelting process for an aluminum-magnesium-silicon aluminum alloy, and belongs to the field of aluminum product processing. Electrolytic aluminum liquid and industrial silicon are prepared into a AlSi12 liquid intermediate alloy in an intermediate frequency furnace, the liquid intermediate alloy is utilized to scour a magnesium ingot in a special runner, and the mixed aluminum liquid is diluted in a smelting furnace to form an aluminum-magnesium-silicon aluminum alloy melt with good alloying effect. The process can replace a silicon addition method for adding industrial silicon, rapid dissolution silicon or an aluminum-silicon intermediate alloy and a magnesium addition method for stirring or pressing the magnesium ingot into the smelting furnace, which are commonly used at present, is favorable for full dissolution, diffusion and absorption of Mg and Si elements, and facilitates formation and uniform distribution of a Mg2Si strengthening phase so as to improve the quality and processability of extrusion ingot products.

Owner:SHANDONG INNOVATION METAL TECH

Multi-cavity slag stop mechanism for metal liquid and method for recovering villaumite from aluminum electrolysis bath

The invention relates to the field of casting and metal electrolytic smelting, in particular to a multi-cavity slag stop mechanism for metal liquid and a method for recovering villaumite from an aluminum electrolysis bath. The mechanism comprises a separation wall arranged in a metal liquid container cavity; the separation wall divides the metal liquid conducting part in the metal liquid containercavity as a flowing-in cavity and the metal liquid flowing-out part as a flowing-out cavity; a communicating hole is formed in the bottom of the separation wall; a flowing mouth for enabling metal liquid to flow out from the flowing-out cavity is arranged on the cavity wall of the metal liquid container cavity corresponding to the flowing-out cavity; and an included angle between the part, corresponding to the flowing-out cavity, of the separation wall and the flowing-out direction of the metal liquid from the flowing mouth is larger than 45 degrees. In the electrolytic aluminum production process, aluminum liquid is sucked from the electrolysis bath through a vacuum negative-pressure hoisting bag with the multi-cavity slag stop mechanism; and then, the stop collecting effect of the multi-cavity slag stop mechanism on slag is used for conveniently collecting the sucked electrolyte and slag to feed in the electrolysis bath again, so that the investment cost of electrolytic aluminum additives is greatly saved.

Owner:王会智

Slag conglomeration agent for treating magnesium and magnesium alloy

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com