Digestion system utilizing waste heat and temperature control method thereof

A digestion system and waste heat technology, applied in waste heat treatment, furnace control devices, lighting and heating equipment, etc., can solve the problems of unfavorable energy conservation and environmental protection, low digestion temperature, long digestion time, etc., to achieve energy conservation and environmental protection, energy conservation and Cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

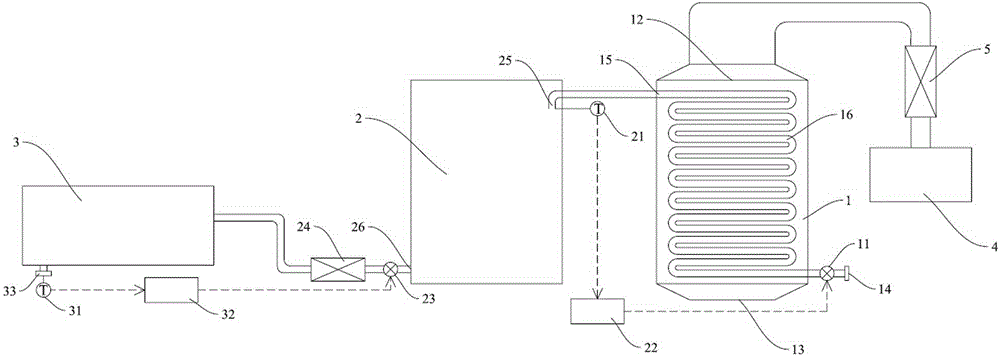

[0027] Please refer to figure 1 , which shows a digestion system utilizing waste heat. The digestion system is used for digesting lime and is applied in the technical field of calcium carbonate production. The digestion system includes a heat exchanger 1, a hot water storage tank 2, a digestion tank 3, a A temperature control solenoid valve 11, a second temperature control solenoid valve 23, a first temperature sensor 21, a second temperature sensor 31, a first PID controller 22 and a second PID controller 32; wherein,

[0028] The heat exchanger 1 is connected to a device 41 that generates residual exhaust gas, and is used to heat cold water with waste heat to exchange hot and cold water;

[0029] The hot water reservoir 2 is connected to the hot water outlet 15 of the heat exchanger 1 for storing hot water after heat exchange;

[0030] The digesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com