Electromagnetically-driven low-pressure casting forming system

An electromagnetic-driven, low-pressure casting technology, applied in the field of low-pressure casting, can solve problems such as aluminum burning and slag, failure to meet requirements, and waste loss, etc., achieve low oxidation and air absorption tendency, stable production process, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

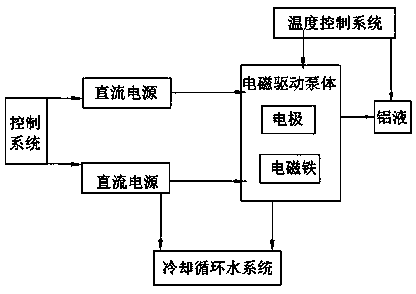

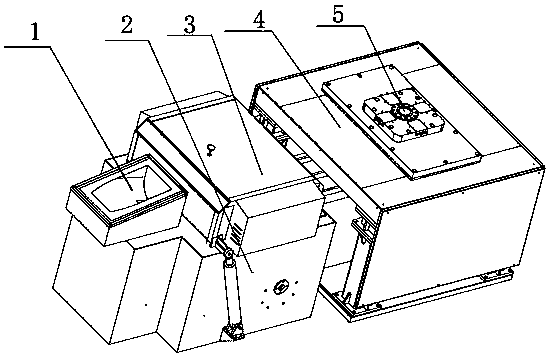

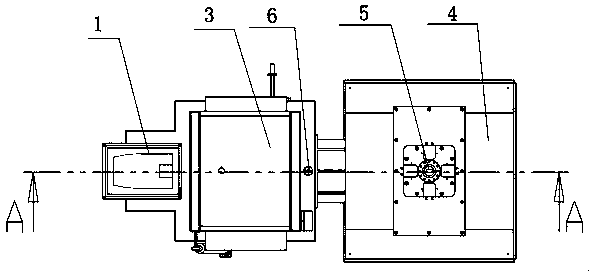

[0025] An electromagnetically driven low-pressure casting molding system, comprising a holding furnace 2, a magnetic field system 4.2, an electric field system 4.1, a temperature control system, a cooling circulating water system and a control system, the electric field system 4.1 and the magnetic field system 4.2 constitute an electromagnetically driven pump body 4, and Controlled by the control system, the aluminum liquid is stored in the holding furnace 2, the upper side of the holding furnace 2 is provided with a feed inlet 1, the top of the holding furnace 2 is provided with a radiant heating device 3, and the lower part of the holding furnace 2 is provided with an opening, which is connected with the electromagnetically driven pump body The bottom chute 7 of 4 is connected to each other, the top of the bottom chute 7 is provided with an opening, and the opening is sealed and connected with the liquid riser 5, and the uniform electric field of the electric field system 4.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com