Preparing technology of 7050 aluminum alloy cast ingot

An aluminum alloy ingot and preparation process technology, applied in the field of aluminum alloy, can solve the problems of cracking of the ingot, increasing the casting process, and inability to completely remove impurities in the melt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] This application adjusts the preparation process of 7050 aluminum alloy ingots, so that the aluminum alloy ingots can significantly reduce metallurgical defects such as looseness and coarse compounds in the ingots, and the product quality can meet aerospace requirements, while the yield rate and flaw detection pass rate are greatly improved , the production cost is significantly reduced.

[0041] In the process of preparing the aluminum alloy ingot, the applicant first batches ingredients according to the ingredients in the 7050 aluminum alloy, and then melts the ingredients after batching, and the melting temperature is ≤800°C.

[0042] The applicant then puts the melted molten aluminum to a standstill, and the standstill process is specifically: introducing the molten aluminum into a resting furnace, and adopting the air-permeable bricks in the furnace for continuous refining, and the refining process is: the refining temperature is preferably 720 ~760°C, the refining...

Embodiment 1

[0050] Ingredients: The following raw materials are mixed according to weight percentage: Si=0.06wt%, Fe=0.11wt%, Cu=2.1wt%, Mn=0.01wt%, Mg=2.4wt%, Cr=0.01wt%, Zn=6.5wt% %, Ti=0.03wt%, Zr=0.12wt%, the rest Al99.95 aluminum ingot;

[0051] Melting: Put the above raw materials into a melting furnace and melt them at a melting temperature of 700°C to obtain liquid aluminum;

[0052] Static continuous refining process: the obtained molten aluminum is introduced into a static furnace, and continuously refined by using ventilated bricks in the furnace. The refining temperature is 740°C, the gas pressure is 0.55Mpa, and the gas flow rate is 450L / h×4;

[0053] On-line refinement process: add 6kg / t Al-3Ti-0.2C wire to the refined aluminum liquid, and the adding temperature is 745℃;

[0054] Filtration process: double-stage filtration is performed on the on-line refined aluminum liquid at the first stage of 40ppi and the second stage of 60ppi;

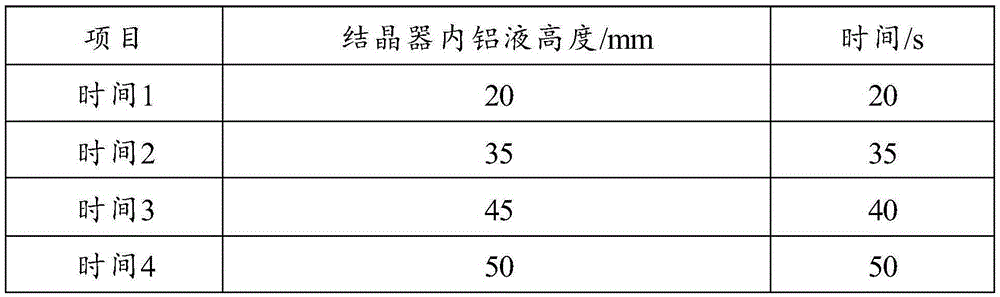

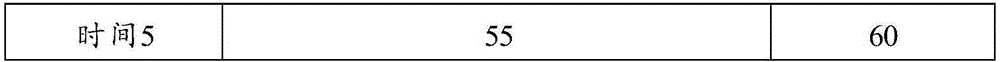

[0055] Casting process: cast the filter...

Embodiment 2

[0061] Ingredients: The following raw materials are mixed according to weight percentage: Si=0.10wt%, Fe=0.12wt%, Cu=2.0wt%, Mn=0.05wt%, Mg=1.9wt%, Cr=0.04wt%, Zn=5.7wt% %, Ti=0.05wt%, Zr=0.09wt%, the rest Al99.95 aluminum ingot;

[0062] Melting: Put the above raw materials into a melting furnace and melt them at a melting temperature of 750°C to obtain liquid aluminum;

[0063] Static continuous refining process: the obtained molten aluminum is introduced into a static furnace, and continuously refined by using breathable bricks in the furnace. The refining temperature is 720°C, the gas pressure is 0.40Mpa, and the gas flow rate is 400L / h×4;

[0064] On-line refinement process: add 5kg / t Al-3Ti-0.2C wire to the refined aluminum liquid, and the adding temperature is 745℃;

[0065] Filtration process: double-stage filtration of the on-line refined aluminum liquid in the first stage of 30ppi and the second stage of 50ppi;

[0066] Casting process: cast the filtered aluminum l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com