Preparation method of Al-Zn-Mg large-sized flat cast ingot

A slab and large-size technology, which is applied in the field of Al-Zn-Mg large-size slab preparation, can solve the problems of uneven composition and easy cracking of large-size slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

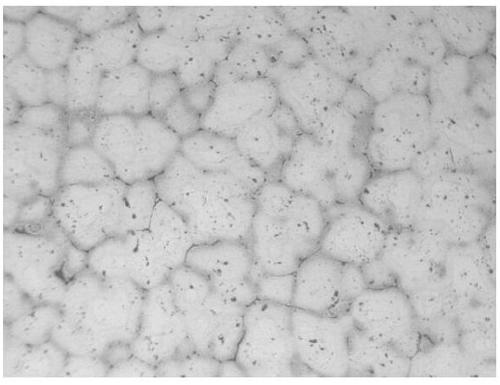

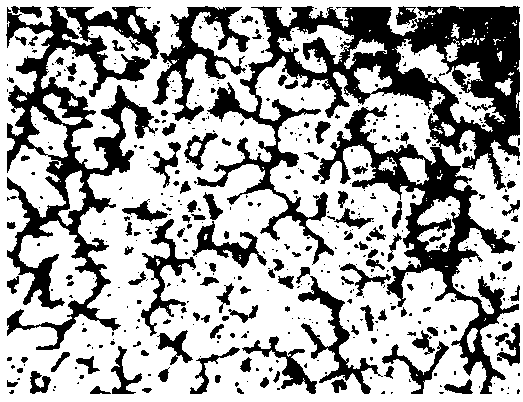

[0026] The production process steps of large-size aluminum alloy slabs with a casting size of 650mm×2670mm×6000mm are as follows:

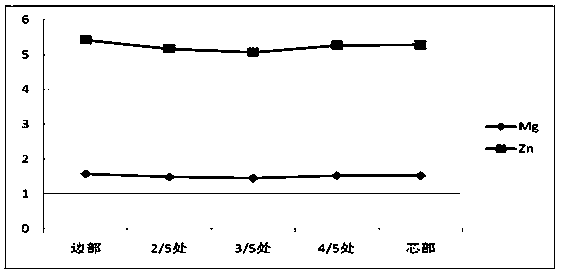

[0027] S1. Ingredients: According to the composition: Si<0.25%, Fe<0.40%, Cu<0.25%, Mn<0.10%, Mg=1.0~1.8%, Cr<0.05%, Zn=5.3~6.0%, Zr=0.11~ 0.18%, the balance is Al and unavoidable impurity elements for batching, respectively weighing aluminum ingots, pure magnesium ingots, pure zinc ingots, aluminum-titanium master alloys, and aluminum-zirconium master alloys for remelting as raw materials;

[0028] S2. Melting: Put the weighed raw materials into a dry smelting furnace for smelting. Melting temperature: 760℃, smelting time: 5~8h. During the smelting process, turn on the electromagnetic stirrer to fully stir, sample and analyze the chemical composition to see if it meets the requirements. Composition control requirements, if necessary, make composition adjustments, and transfer to the holding furnace when the composition is qualified.

[0029] S3. Insula...

Embodiment 2

[0039] The production process steps of large-size aluminum alloy slabs with a casting size of 550mm×2520mm×6000mm are as follows:

[0040] S1. Ingredients: According to the composition: Si<0.25%, Fe<0.40%, Cu<0.25%, Mn<0.10%, Mg=1.0~1.8%, Cr<0.05%, Zn=5.3~6.0%, Zr=0.11~ 0.18%, the balance is Al and unavoidable impurity elements for batching. The implementation of this case adopts the method of adding all the first-level return materials, without adding remelted aluminum ingots, and adding a small amount of master alloy according to the composition adjustment;

[0041] S2. Melting: Put the weighed raw materials into a dry smelting furnace for smelting. Melting temperature: 755℃, smelting time: 6~8h. During the smelting process, turn on the electromagnetic stirrer to fully stir, sample and analyze the chemical composition to see if it meets the requirements. Composition control requirements, if necessary, make composition adjustments, and transfer to the holding furnace when the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com