Preparation method of aluminum alloy for aerosol bottle cap

An aluminum alloy and aerosol technology, which is applied in the field of preparation of aluminum alloy for aerosol bottle caps, can solve problems such as slag inclusion of magnesium elements, and achieve the effects of reduced slag content, excellent overall performance, and high weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

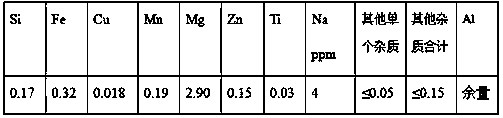

[0088] Chemical Composition of Materials (WT%): Table 7

[0089]

[0090] (1) Calculate and prepare the materials according to the above ingredients, put them into the melting furnace for melting, the melting temperature is 730-750°C, and after refining (using Na-free covering agent + composite material KCl+GaCl+MgCl 2 , KCl, GaCl, MgCl 2The mass ratio is 1:1:1. , Na element is controlled below 5ppm, the gas uses Ar, SNIF rotary degassing device. After removing slag, stirring, analyzing and adjusting the composition, it enters the static furnace, the static temperature is 645°C, degasses, removes slag (using a ceramic tube filter), and then enters the casting machine after adding an appropriate amount of Al-5Ti-1B wire into the molten aluminum. Cast into ingots, the casting temperature is 587°C. The casting speed is 40mm / min. The surface of the ingot is milled. Single rotor degassing. The grain refiner adopts AlTiC refiner.

[0091] (2) Soak the ingot, the holding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com