Patents

Literature

35results about How to "Consumable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

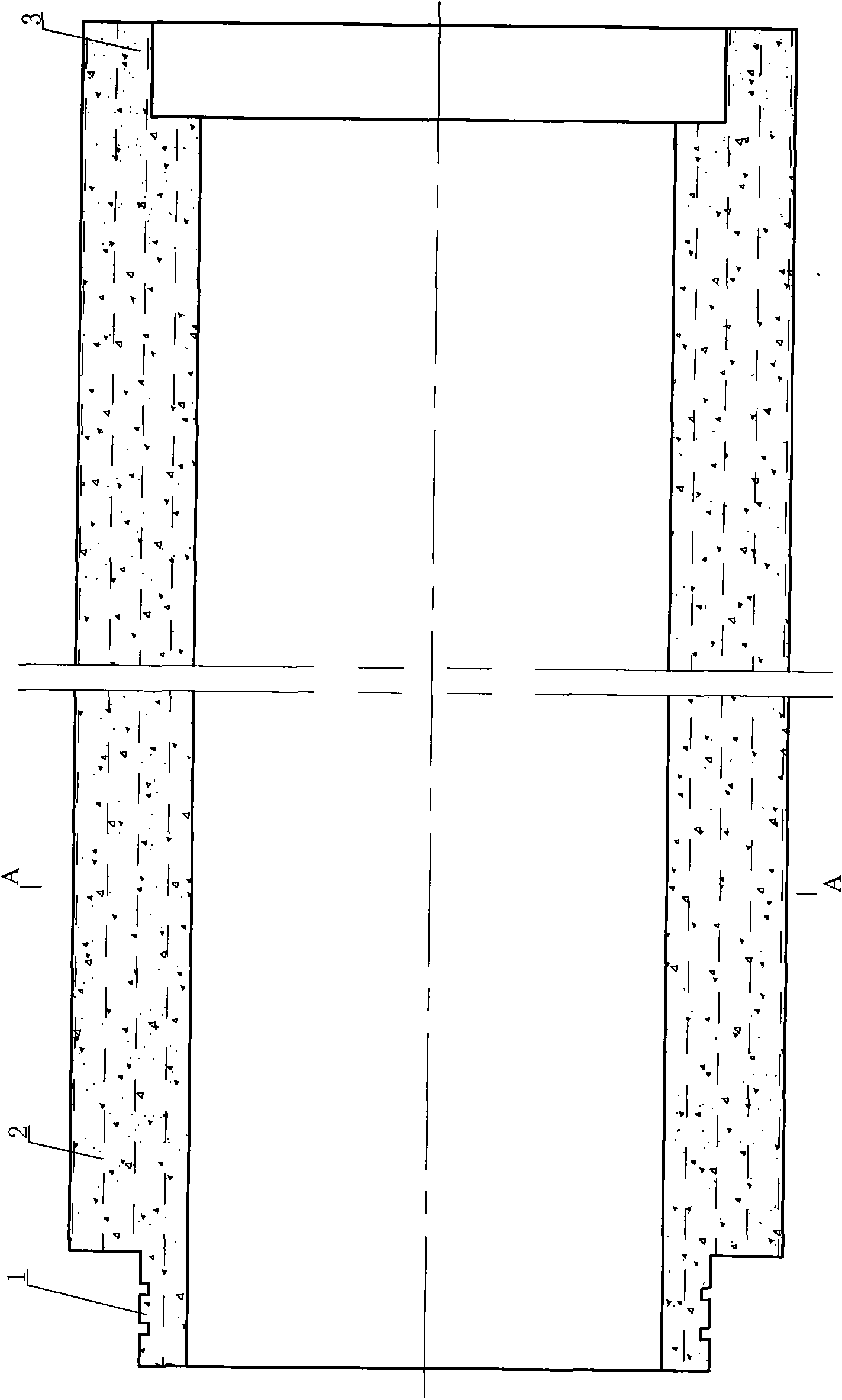

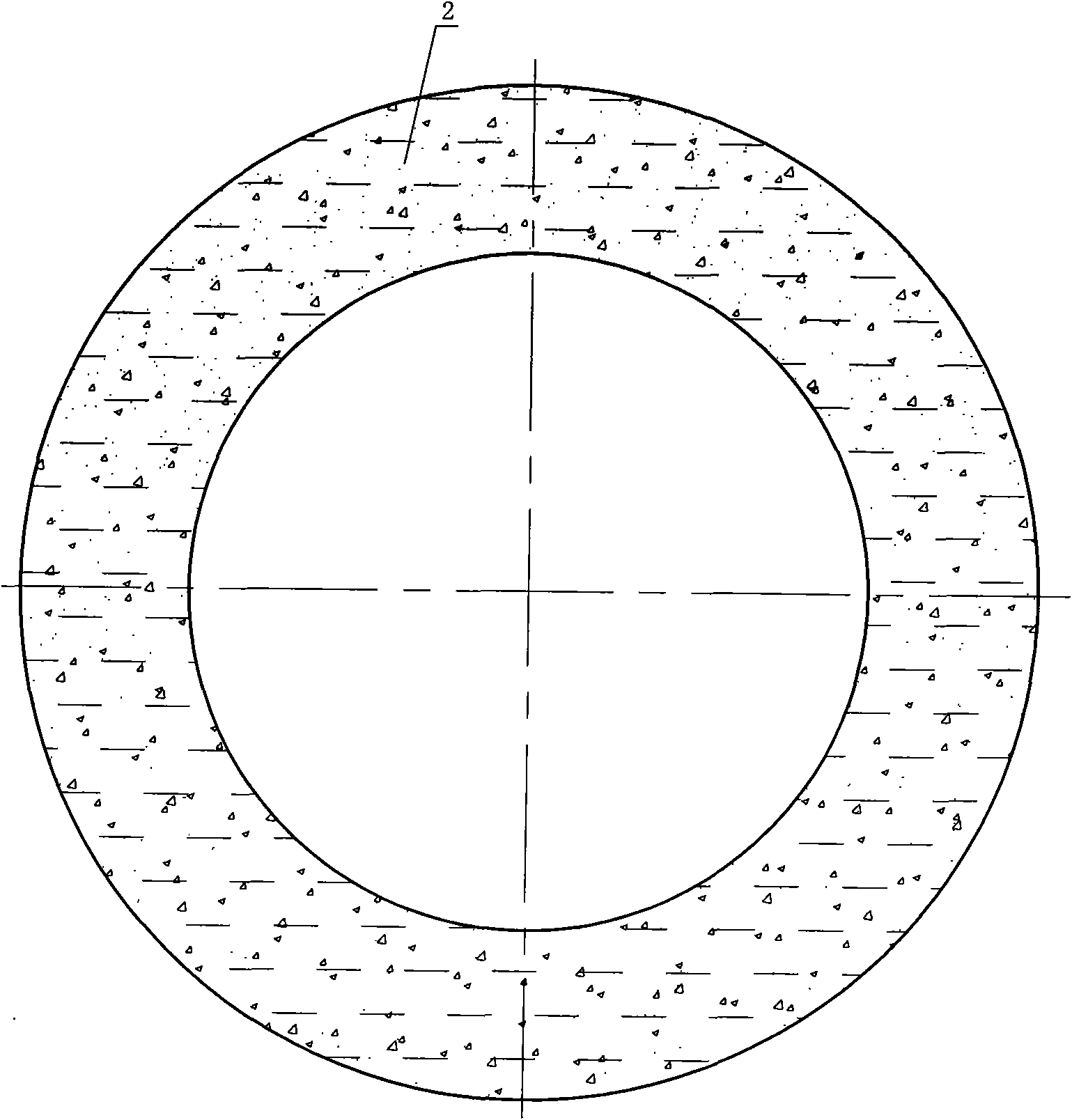

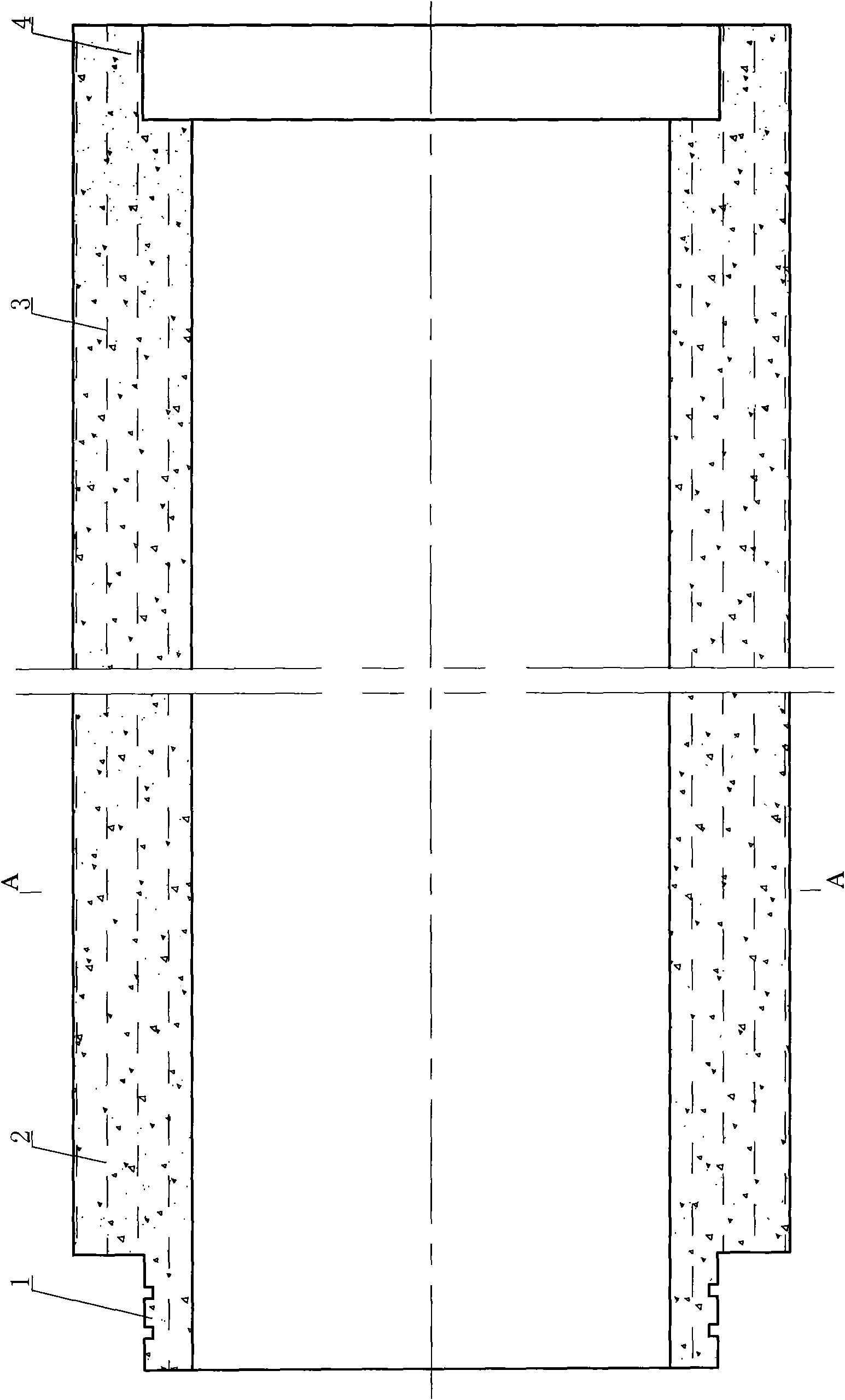

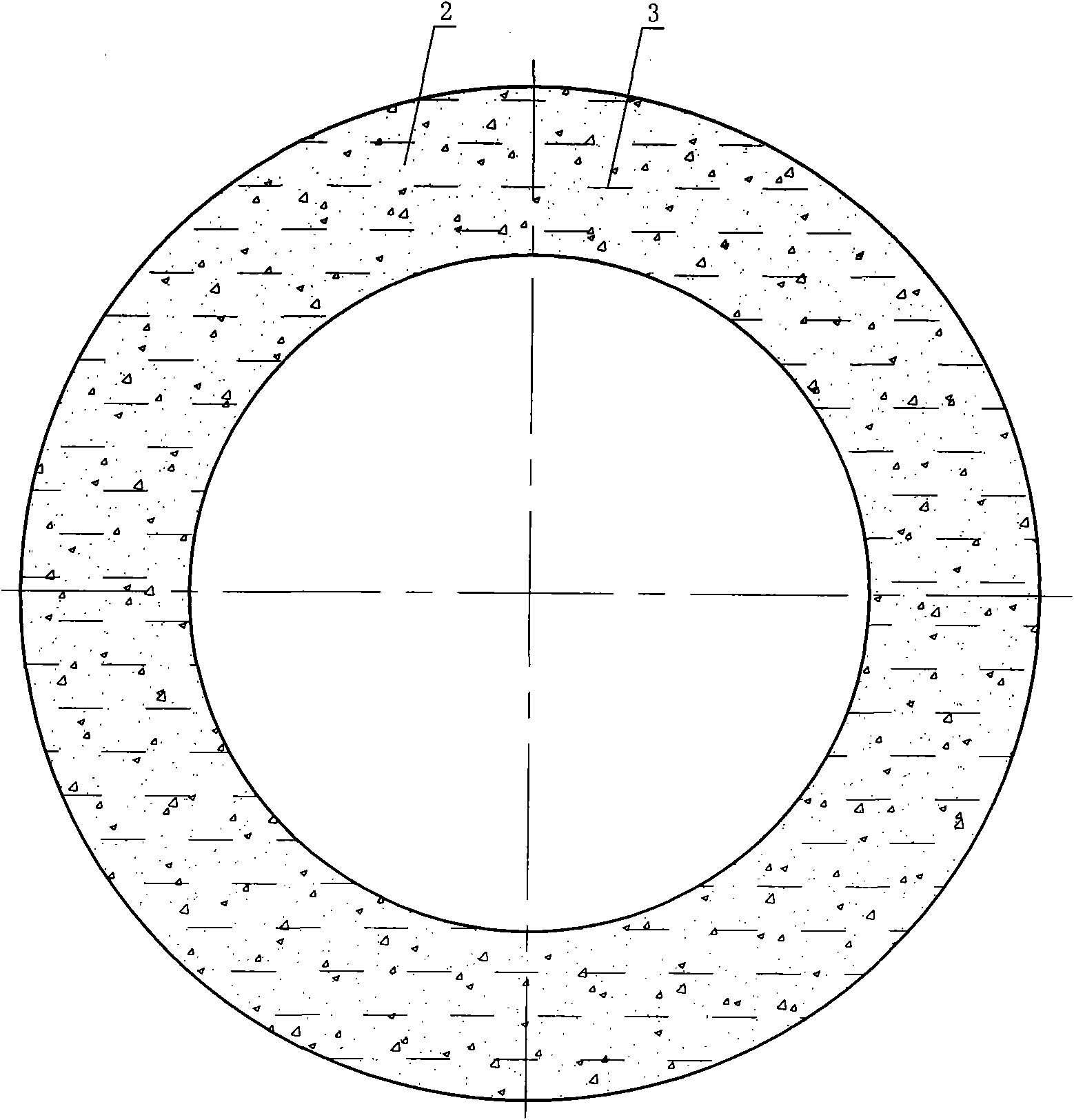

Mixed fiber concrete pipe

The invention relates to a mixed fiber concrete pipe, wherein mixed fiber concrete for forming the pipe comprises the following components according to the parts by weight: 322-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of cobbles, 0.2-20 parts of polymer fibers and 20-140 parts of steel fibers. The mixed fiber concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

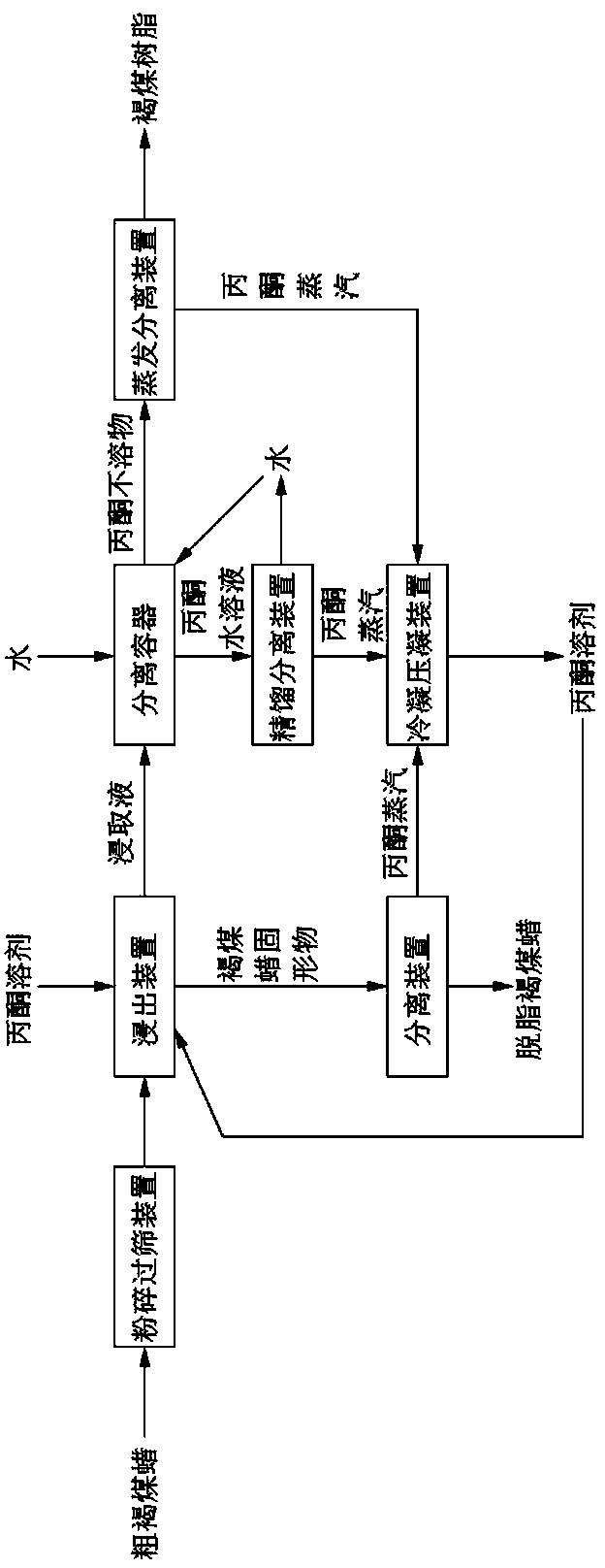

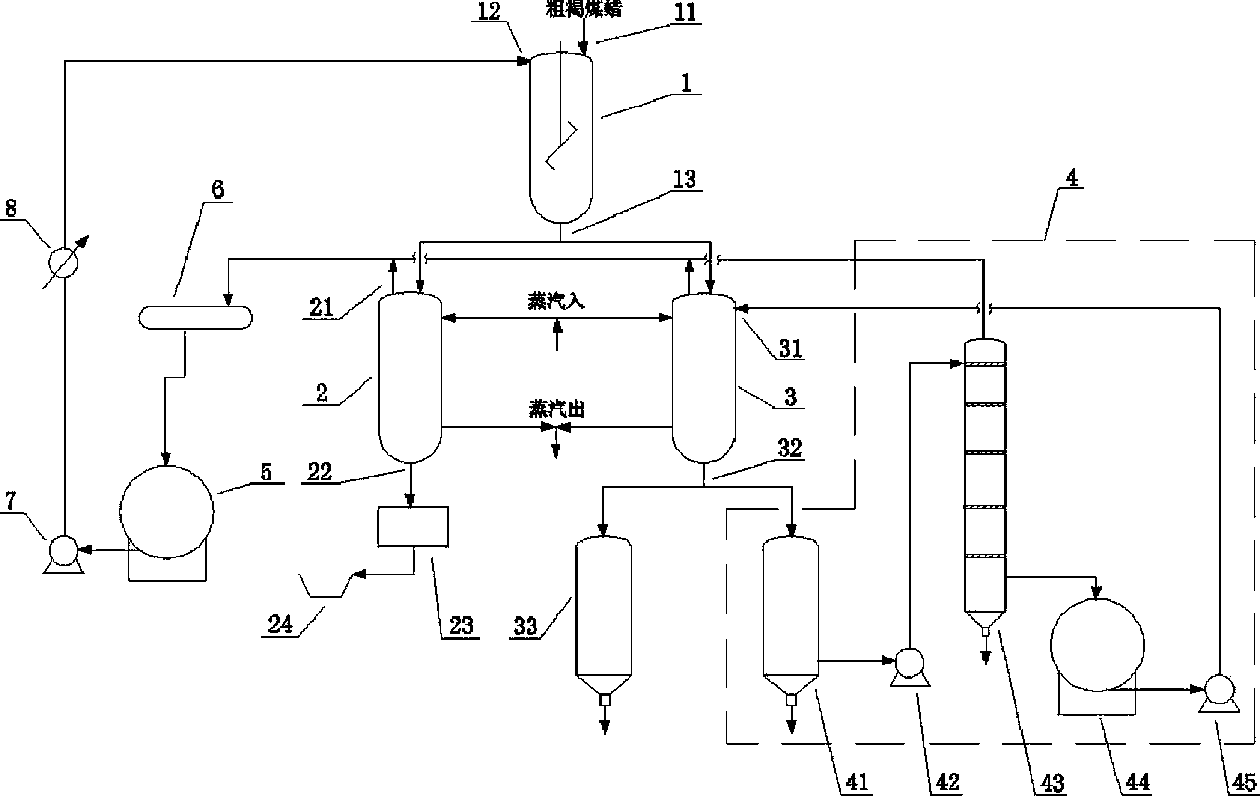

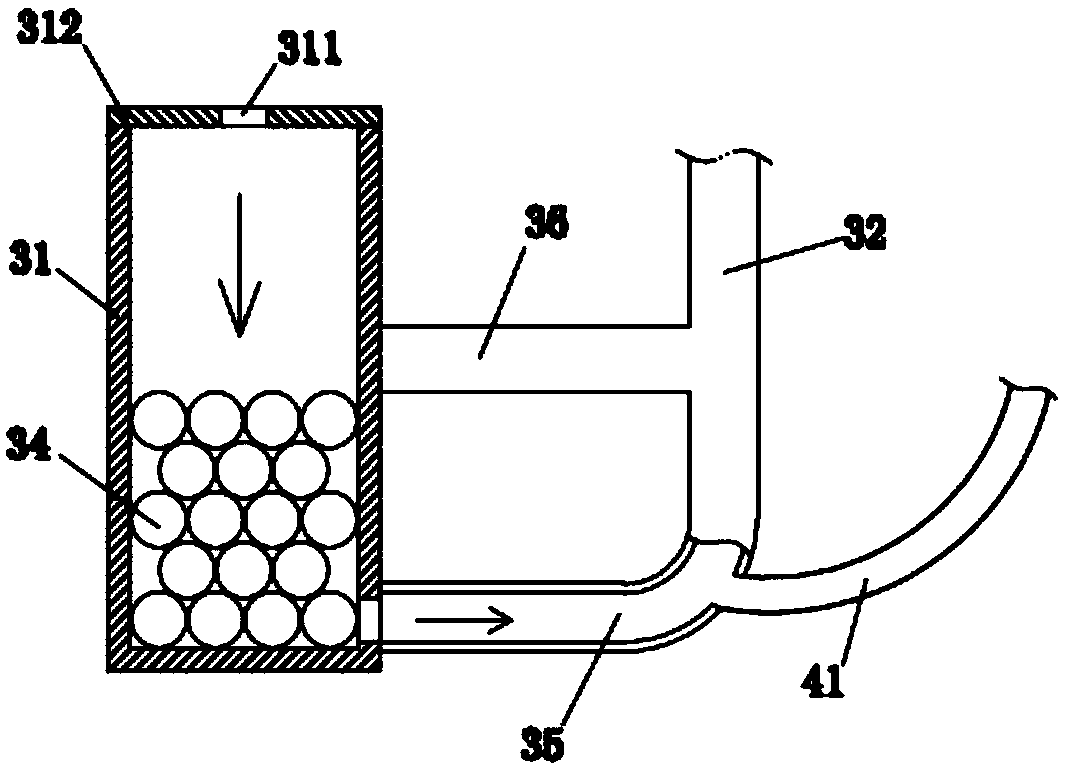

Energy-saving efficient resin-removing method and device for coarse lignite wax

ActiveCN103897734AEasy to recycleConsumableMineral wax recovery/refiningAqueous acetoneAqueous solution

The invention discloses an energy-saving efficient resin-removing method and device for coarse lignite wax. The resin-removing method comprises the following steps: smashing coarse lignite wax and sieving the smashed coarse lignite wax by a 0.5-3.0mm sieve; then, leaching the sieved lignite wax particles and acetone in a solid-to-liquid ratio of 1:1-1:8kg / L at constant temperature for 2-4 hours and separating to obtain a leaching liquid and a solid; placing the solid in a separating device, and heating, evaporating and removing residual acetone to obtain degreased lignite wax; placing the leaching liquid in a separating container, adding water to separate resin from acetone, and carrying out solid-liquid separation to obtain acetone insolubles and an acetone aqueous solution; and recovering acetone by rectifying the acetone aqueous solution; and evaporating the acetone insolubles to obtain walchowite. The degreasing device comprises a degreasing kettle, a ceride-removing desolventizing tank, a resin desolventizing separating tank, a rectifying device, an acetone storage tank and a condenser. According to the energy-saving efficient resin-removing method and device disclosed by the invention, as resin in lignite wax is easy to dissolve in acetone at constant temperature, wax and asphaltos are not dissolved, and the resin content in wax is reduced by digestion and separation at constant temperature, so that the device is simple and energy-saving and environment-friendly in process.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Method for preparing water purifying agent containing polyaluminum sulfate from aluminum ash, sulfuric acid and optional red mud

InactiveCN109928472AReduce fluorine contentLow investment costWater/sewage treatment by flocculation/precipitationRed mudSlurry

The invention provides a method for preparing a water purifying agent containing polyaluminum sulfate from aluminum ash, sulfuric acid and optional red mud, and the method comprises the following steps: uniformly mixing the aluminum ash with sodium carbonate and / or sodium hydroxide and a calcium-containing raw material, roasting at 400-1000 DEG C in an oxidizing atmosphere, reacting a roasted product with the sulfuric acid and the optional red mud until the pH value of slurry filtrate is 3.0-4.0, Al2O3 accounts for 5-12m%, and the basicity is 40-75, filtering to obtain filtrate as the water purifying agent containing the polyaluminum sulfate, and washing filter residue to obtain solid residue for further utilization or tockpiling and landfill. Through the steps of mixing and roasting, theflammable and combustible problems of hydrogen released by metal aluminum hydrolysis or acidolysis, the ammonium nitrogen problem in purified water caused by entering of ammonium produced by acid hydrolysis of aluminum nitride into the water purifying agent, the activation problem of low-activity alumina, especially alpha-alumina, and the problems of stabilization and harmlessness of fluorine in the aluminum ash which need two or three steps to be treated in the prior art can be solved in one time. The hardness of treated water increases slightly during the use of the water purifying agent product.

Owner:山东铝晖环保科技有限公司

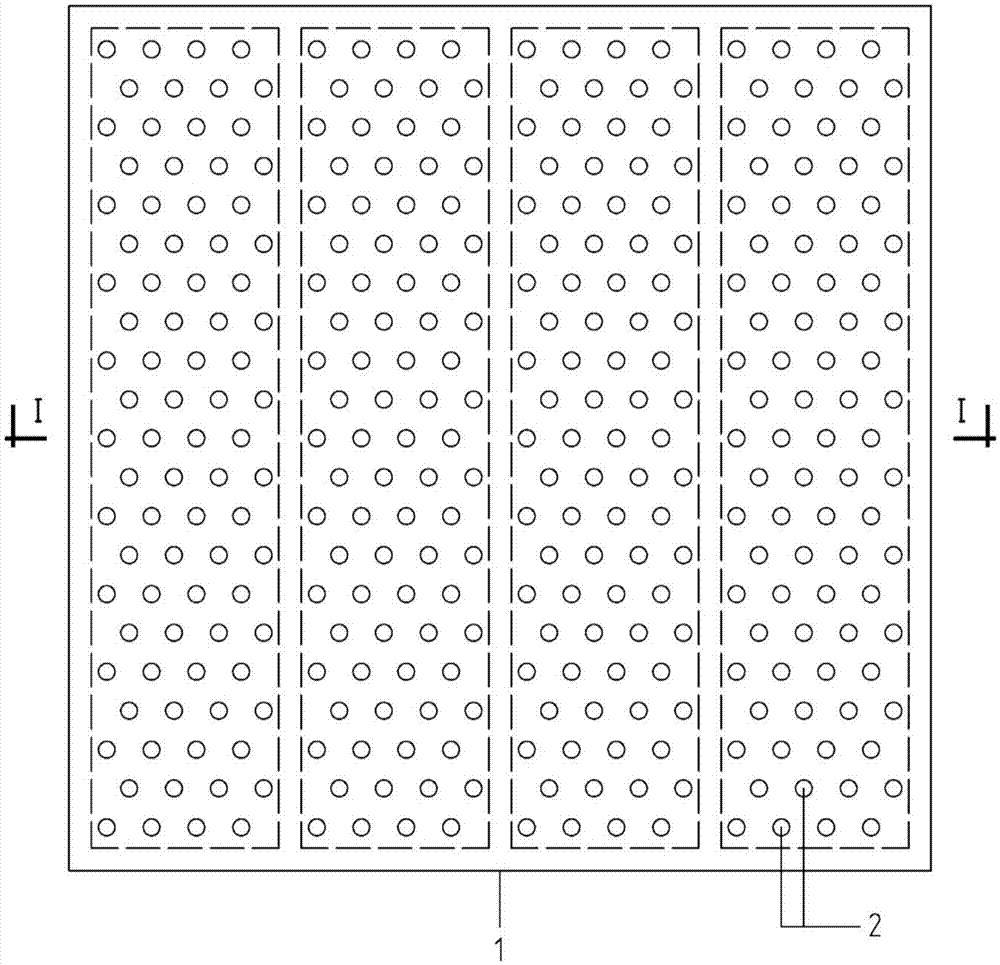

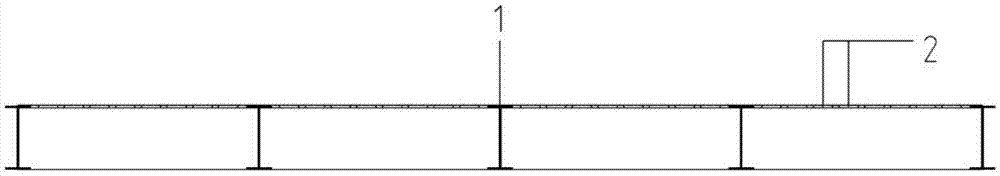

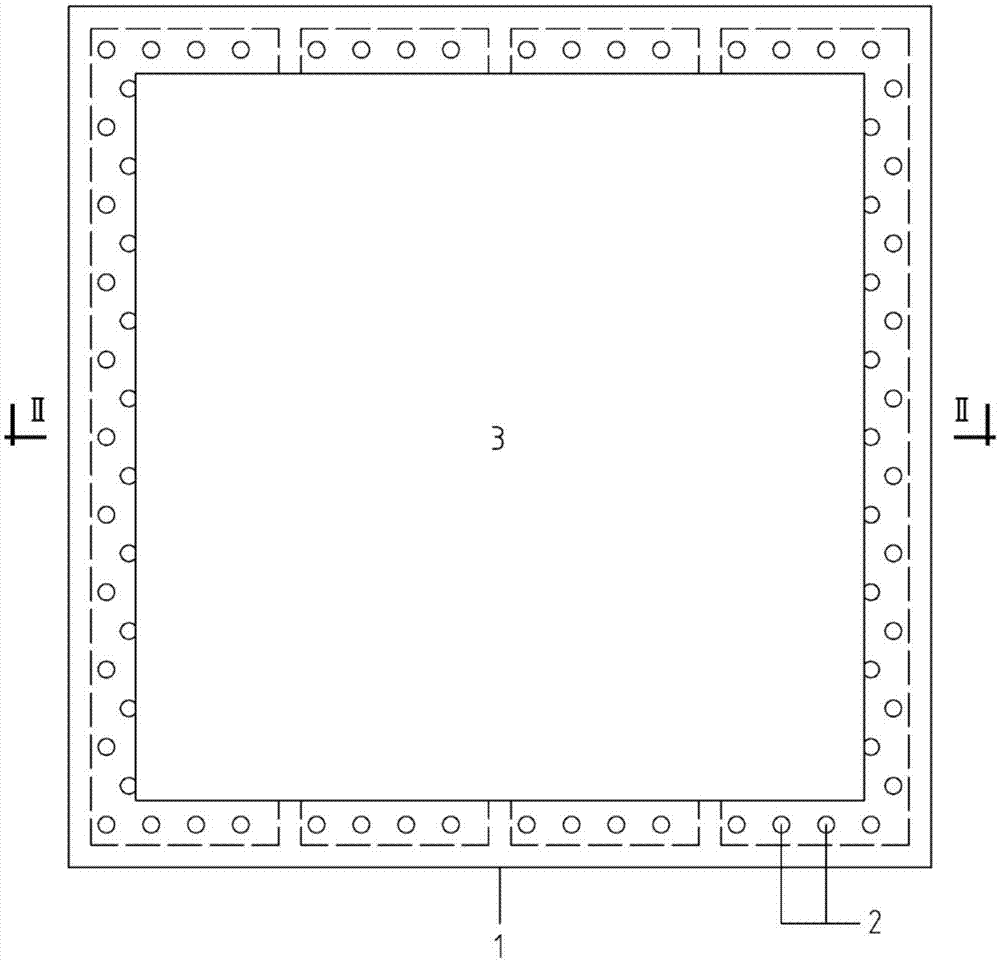

Method for pasting face bricks in prefabrication of concrete floor and concrete wallboard

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

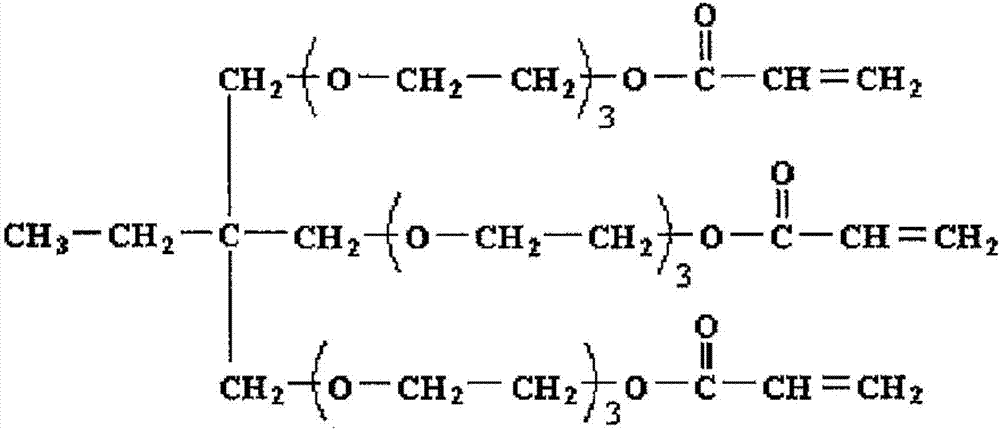

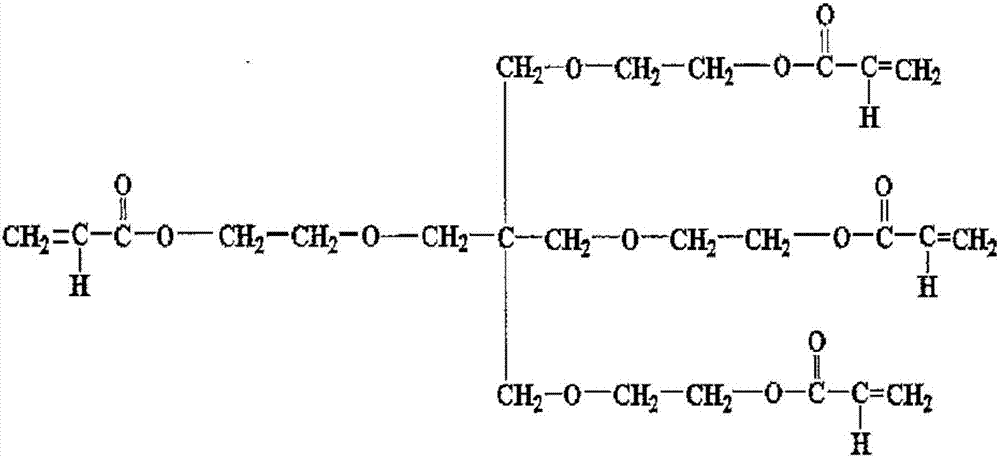

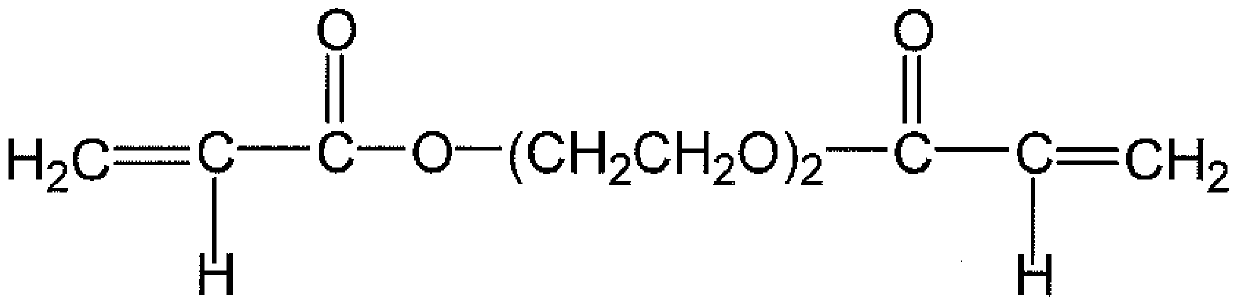

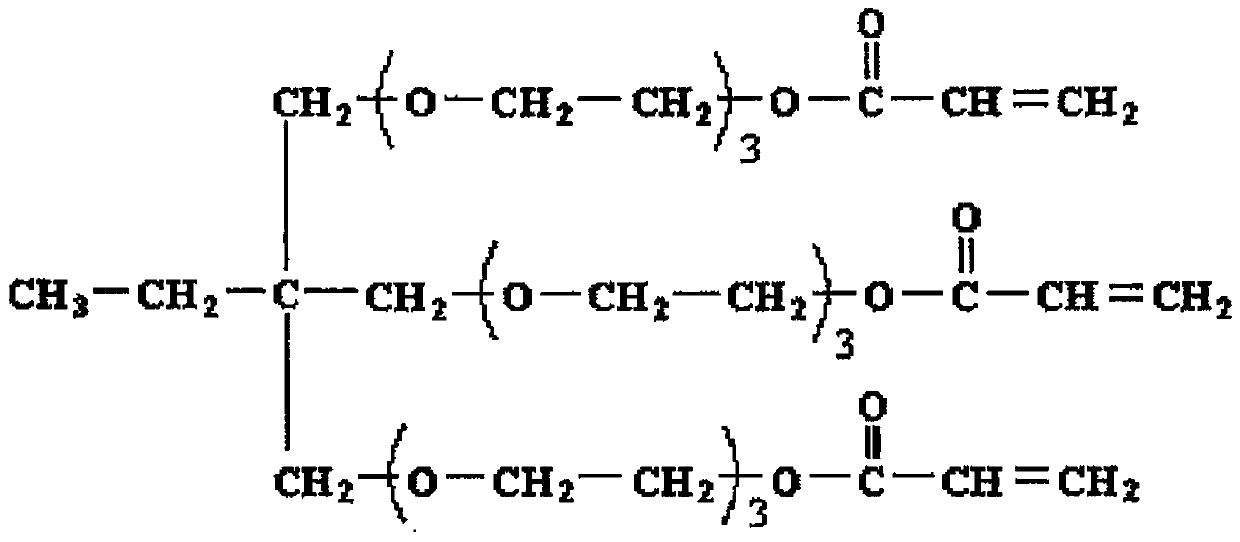

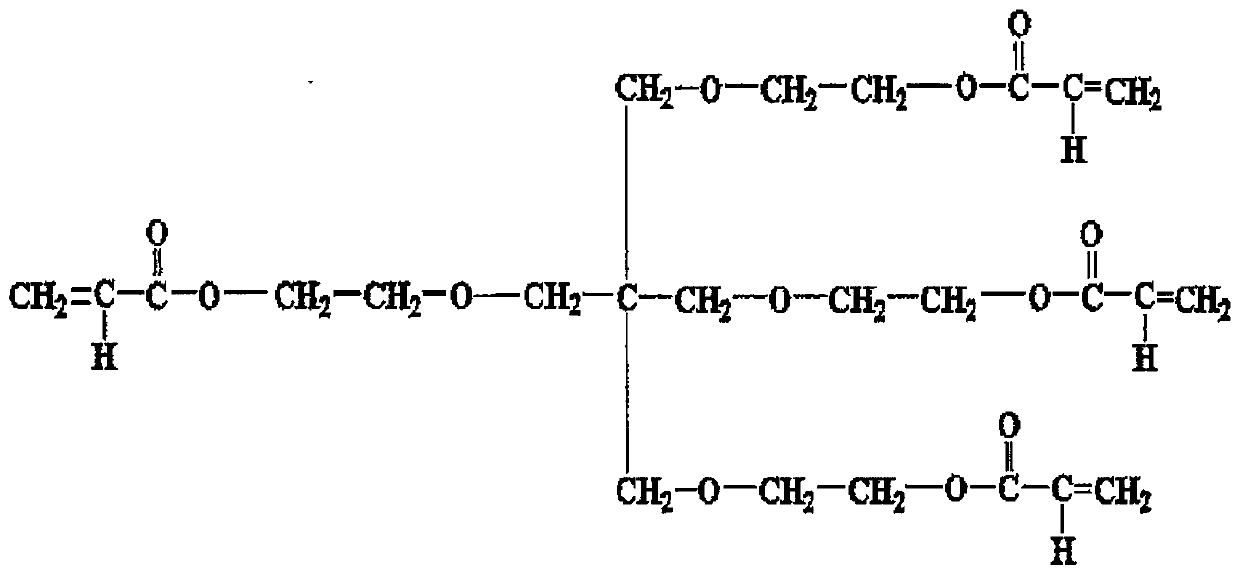

Two-part anti-fouling paint composition, anti-fouling paint film, anti-fouling base member, and method for manufacturing anti-fouling base member

ActiveCN107109082ASufficiently curableHigh film strengthAntifouling/underwater paintsSynthetic resin layered productsChemical compoundEther

Provided is a two-part anti-fouling paint composition which can exhibit excellent wastage sustainability and long-term anti-fouling properties against marine organisms. The two-part anti-fouling paint composition according to the present invention is characterized by comprising (A) a first component comprising a (meth)acrylic ester component, (B) a second component comprising an amino-group-containing compound, and (C) an anti-fouling agent contained in either the first component or the second component, wherein the (meth)acrylic ester component (A) and / or the amino-group-containing compound (B) has an ether structure, a trifunctional or higher (meth)acrylic ester is contained in an amount of 50% by weigh or more relative to the total weight of the (meth)acrylic ester component (A), and the amino-group-containing compound (B) is contained in an amount of 20 to 100 parts by weight relative to 100 parts by weight of the (meth)acrylic ester component (A).

Owner:CHUGOKU MARINE PAINTS

Visible light response photocatalyst and preparation method thereof

InactiveCN102962078AImprove photocatalytic performanceImprove stabilityWater/sewage treatment by irradiationCatalyst activation/preparationPotassium hydroxideCopper oxide

The invention discloses a visible light response photocatalyst and a preparation method thereof. The preparation method comprises the steps of weighing analytically pure silver nitrate, copper oxide, niobium pentoxide and tantalum pentoxide according to AgCuNb1-xTaxO4 (wherein x is greater than or equal to 0 and less than or equal to 1) and placing into an autoclave, and using potassium hydroxide as a mineralizer to obtain a composite oxide with favorable visible light photocatalytic property through a hydro-thermal synthesis process. The visible light response photocatalyst has high visible light catalytic activity in dyeing water and favorable stability and can be recycled. The visible light response photocatalyst is simple in equipment, low in energy consumption and easy in popularization.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Concrete pipe with steel fibers

The invention relates to a concrete pipe with steel fibers, which comprises the following components according to the parts by weight: 32-540 parts of cement, 140-220 parts of water, 475-828 parts of sand, 864-1,306 parts of pebbles and 20-140 parts of steel fibers. The concrete pipe has low raw material cost, light weight, high tensile strength, flexural strength, shearing strength and torsional strength, better durability and fatigue resistance, stronger capacities of shock resistance, abrasion resistance and cavitation resistance and better crack resistance, conforms to an energy saving and emission reduction policy and is a renewal product of the existing concrete pipes.

Owner:TIANJIN WATERLINE PIPELINE ENG CO LTD

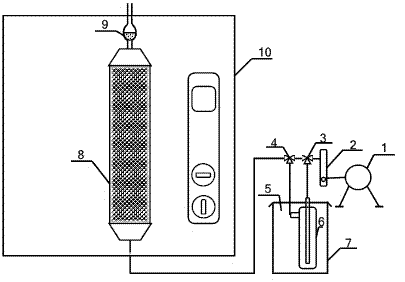

Adsorbent adsorption-regeneration presentation device and presentation method thereof

InactiveCN104332083AHigh degree of visualizationShort timeEducational modelsProcess engineeringSorbent

The invention relates to an adsorbent adsorption-regeneration presentation device and a presentation method thereof. An air pump of a presentation device is connected to the bottom of an adsorber through a pipeline, a steam detector is mounted at the top of the adsorber, the whole adsorber is arranged in a microwave reactor, the adsorber is filled with adsorbate cobaltic discoloration silicone, adsorbate detection agent anhydrous cupric sulfate is placed in the steam detector, a flow controller and two three-way valves are arranged on the pipeline, and the two three-way valves are connected to a steam inlet and a steam outlet in the top and the side wall of an adsorption bottle respectively. Firstly, adsorbate steam is inputted to the adsorber through the pipeline, adsorbent discolors after adsorbing the steam, the adsorption process is presented, input of adsorbate is stopped, the adsorbent restores colors after removing the steam by the aid of the rapid microwave regeneration process, and the regeneration process is presented. Visual teaching is realized, the device can be repeatedly used, and experimental teaching quality and efficiency are improved.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

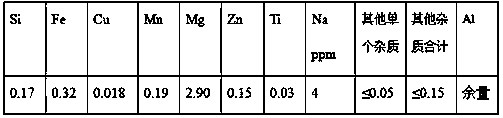

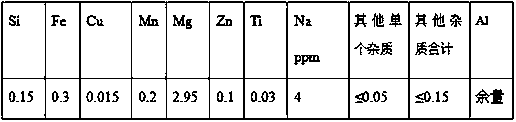

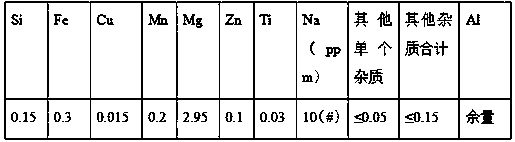

Preparation method of aluminum alloy for aerosol bottle cap

ActiveCN108642344AOvercoming technical deficienciesSolve problems such as slag inclusionSlagImpurity

The invention provides a preparation method of an aluminum alloy for an aerosol bottle cap. The method comprises the steps of S1, preparing a cast ingot through alloy components based on the mixing ratio; S2, milling the cast ingot; S3, uniformly thermally processing the cast ingot; S4, performing hot rolling on the cast iron to obtain a blank; S5, performing cold rolling to the blank which is subjected to hot rolling until the intermediate annealing thickness is reached; S6, washing the surface with weak alkali; S7, completely recrystallizing and annealing the middle; S8, performing pass rolling on a finished product; S9, stably chemically processing the finished product; and S10, stretching and bending and correcting back roll. According to the method, the Na content is effectively decreased based on the component mixing ratio and the technical method; the range of Na element which easily causes Na embrittlement in a high-magnesium alloy is avoided, and thus the problem of Na embrittlement is solved; and meanwhile, the component fluctuation is well controlled, and the problem that the magnesium element easily results to slag inclusion is solved; and meanwhile, the problem of liquid leaking caused by impurities adhering to the surface can be solved by a special weak alkali washing technology in the middle process; and the produced aluminum alloy for the aerosol bottle cap is high in stability in batch.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

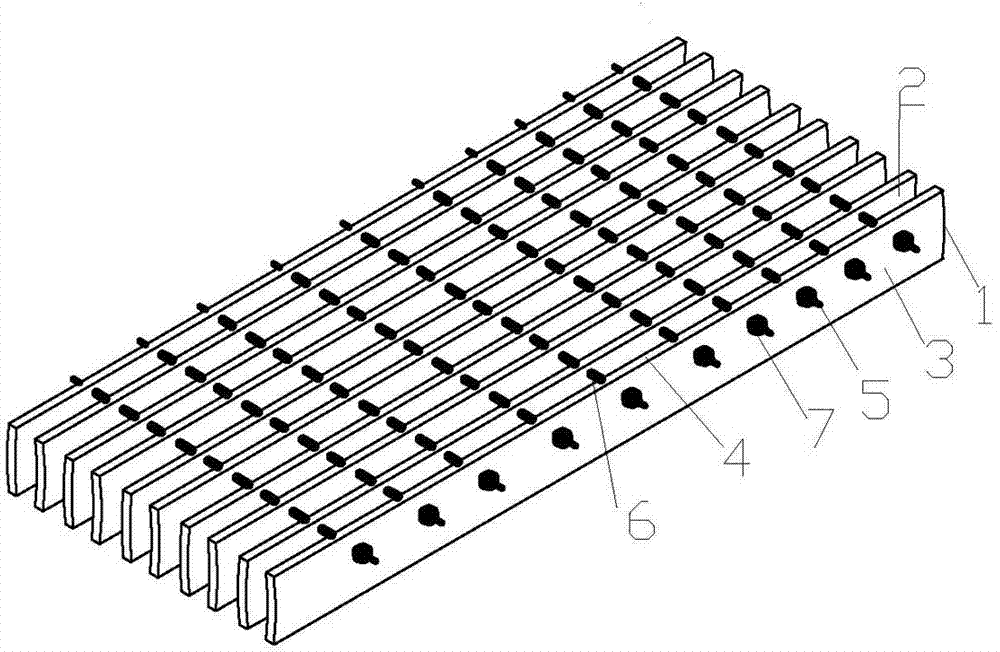

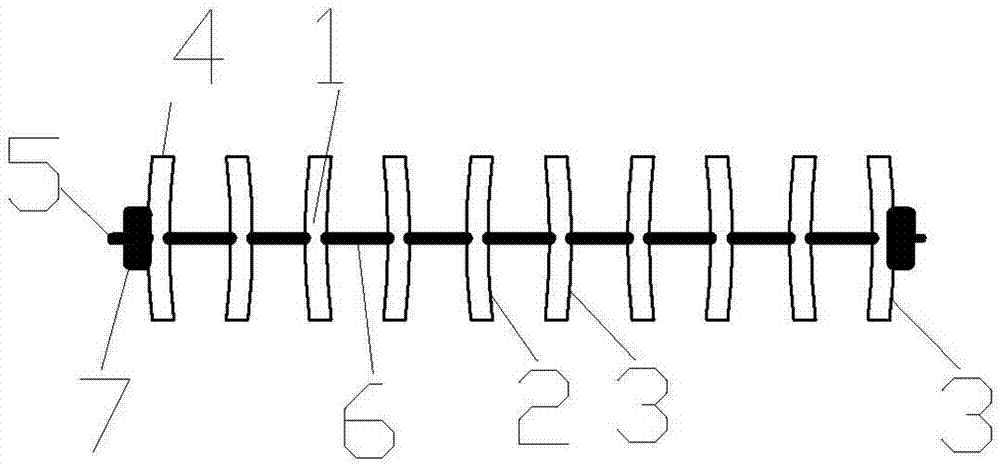

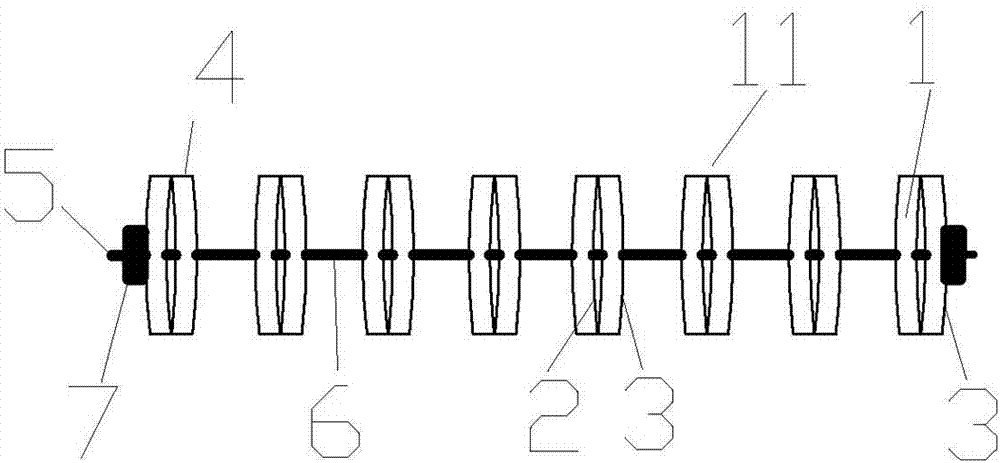

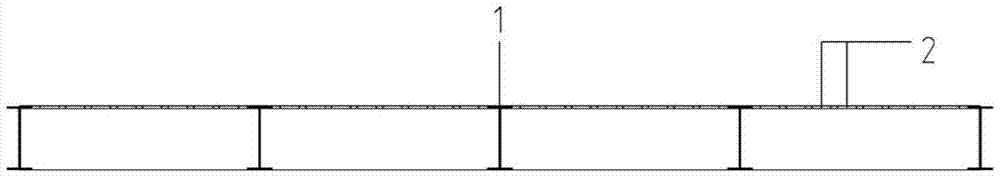

Bamboo excrement-leakage board structure

InactiveCN102919147ALeakage effect is goodConsumableBird housingsCrop livestockAgricultural engineering

The invention relates to devices of livestock raising technique, in particular to a bamboo excrement-leakage board structure. The bamboo excrement-leakage board structure comprises long-strip flat bamboo bars (1) used as supporting main bodies, the bamboo bars (1) arranged side by side are combined in series mode through connecting ribs (5), the bamboo bars (1) are provided with penetration holes used for penetration of the connecting ribs (5), locating devices used to fix positions of the bamboo bars (1) are arranged between the bamboo bars (1) arranged side by side, and locking devices used to lock the whole structure are arranged on outer ends of two bamboo bars (1) disposed at the outermost portions of two sides. The bamboo excrement-leakage board structure is simple and stable in structure, good in excrement-leakage effect and easy to clean, disinfect and install.

Owner:安吉县荣昌竹木制品厂

Method for preparing water purifying agent containing poly-aluminum chloride from aluminum ash, hydrochloric acid and optional red mud

InactiveCN109761323AReduce fluorine contentLow investment costWater/sewage treatment by flocculation/precipitationLow activityChemistry

The invention provides a method for preparing a water purifying agent containing poly-aluminum chloride from aluminum ash, hydrochloric acid and optional red mud. The method comprises the following steps that the aluminum ash, sodium carbonate and / or sodium hydroxide and a calcium-containing raw material are mixed uniformly and calcined at an oxidizing atmosphere at 400-1000 DEG C, the calcinationproduced material is reacted with hydrochloric acid and the optional red mud until the pH of the slurry filtrate is 3.5-4.5, Al2O3 is 3-12m%, the basicity is 40-100 and calcium is 0.01-0.5mol / L, filtering is performed, the filtrate is the water purifying agent containing poly-aluminum chloride, and solid residues obtained by washing filter residues is further utilized or subjected to storage andlandfill. The step A solves the flammable and explosive problem of metal aluminum hydrolysis or acid hydrolysis hydrogen release which needs to be processed by two or three steps in the prior art, theproblem of water-ammonium-nitrogen after purification due to the fact that acid hydrolysis of aluminum nitride produces ammonium to enter the water purifying agent, the activation of low-activity alumina, especially alpha-alumina, and the stabilization and detoxification of aluminum ash containing fluorine; and during the use of water purifying agent products, the hardness of treated water is less increased.

Owner:山东铝晖环保科技有限公司

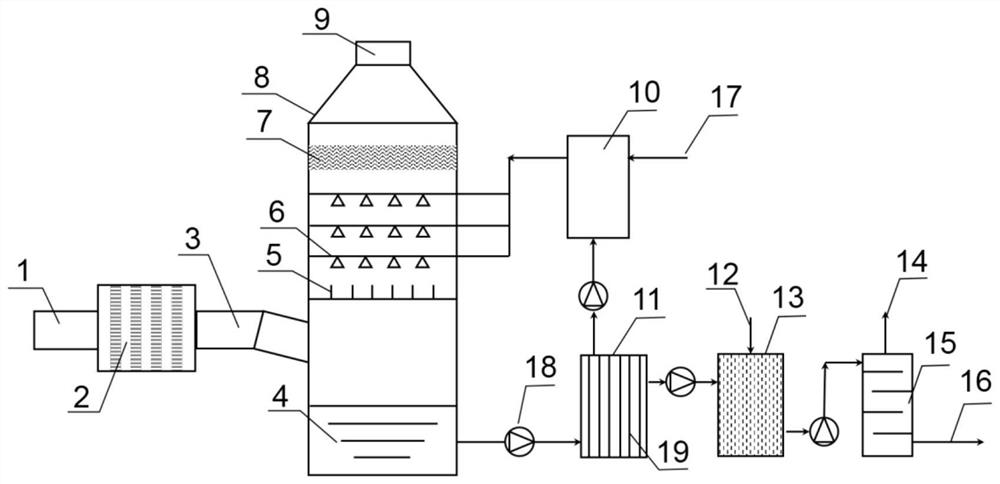

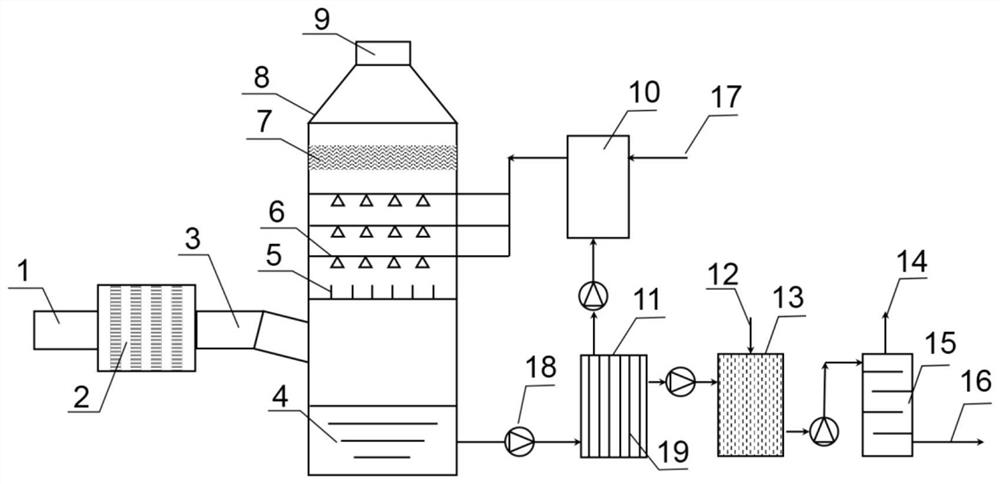

Method and system for preparing urea by coupling denitration with electrocatalytic reduction

ActiveCN112920087ARealize resourcesPromote absorptionUrea derivatives preparationGas treatmentFlue gasNitrate salts

The invention relates to a method and a system for preparing urea by coupling denitration with electrocatalytic reduction. Specifically, the method provided by the invention comprises the following steps of introducing an absorption liquid containing nitrite and nitrate, which is generated by carrying out a denitration process on flue gas containing nitric oxide, into a separation process to separate the nitrite and the nitrate so as to obtain a solution rich in the nitrite and the nitrate, and introducing the solution rich in nitrite and nitrate generated in the separation process into an electro-catalysis process, and carrying out electro-catalytic reduction in the presence of carbon dioxide or carbonate so as to generate a urea solution. The system comprises a denitration device, a separation device connected with the denitration device, and an electro-catalysis device connected with the separation device. The method and the system provided by the invention can be used for deeply removing the nitric oxide in the industrial flue gas at a relatively low temperature, and can realize the recycling of nitrogen.

Owner:TSINGHUA UNIV

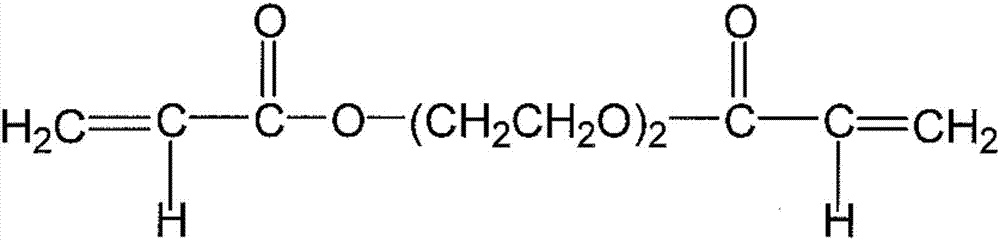

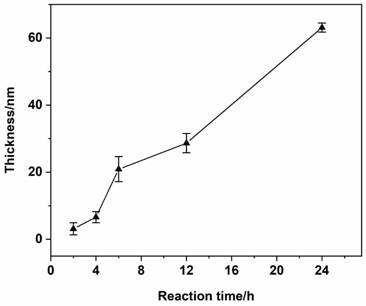

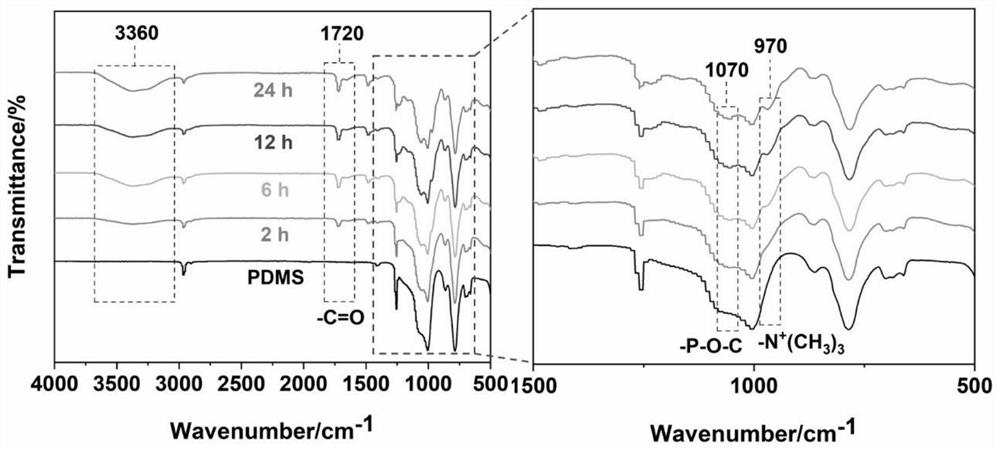

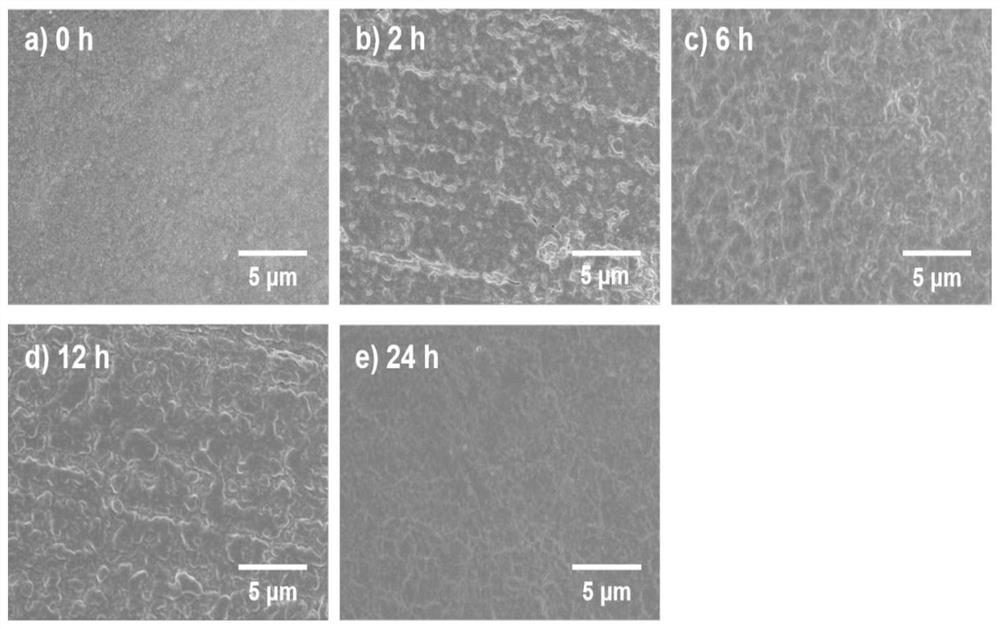

Underwater super-oleophobic polymer brush coating and preparation method thereof

InactiveCN112691872AMild reaction conditionsEasy to controlPretreated surfacesCoatingsPolymer scienceMeth-

The invention discloses a preparation method of an underwater super-oleophobic polymer brush coating. The method comprises the following steps of by using 2-methacryloyloxyethyl phosphorylcholine (MPC) as a raw material, selecting hydrophilic ferrous gluconate and tert-butylperoxy 2-ethyl hexyl carbonate (TBEC) to form a redox initiation system; and a zwitterionic polymer brush coating is constructed on the surface of a base material by utilizing a surface-initiated polymerization reaction. The coating prepared by the method has excellent underwater super-oleophobicity and biological adhesion prevention performance.

Owner:BEIHANG UNIV +1

A method for pasting facing bricks in prefabricated concrete floor and wall panels

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

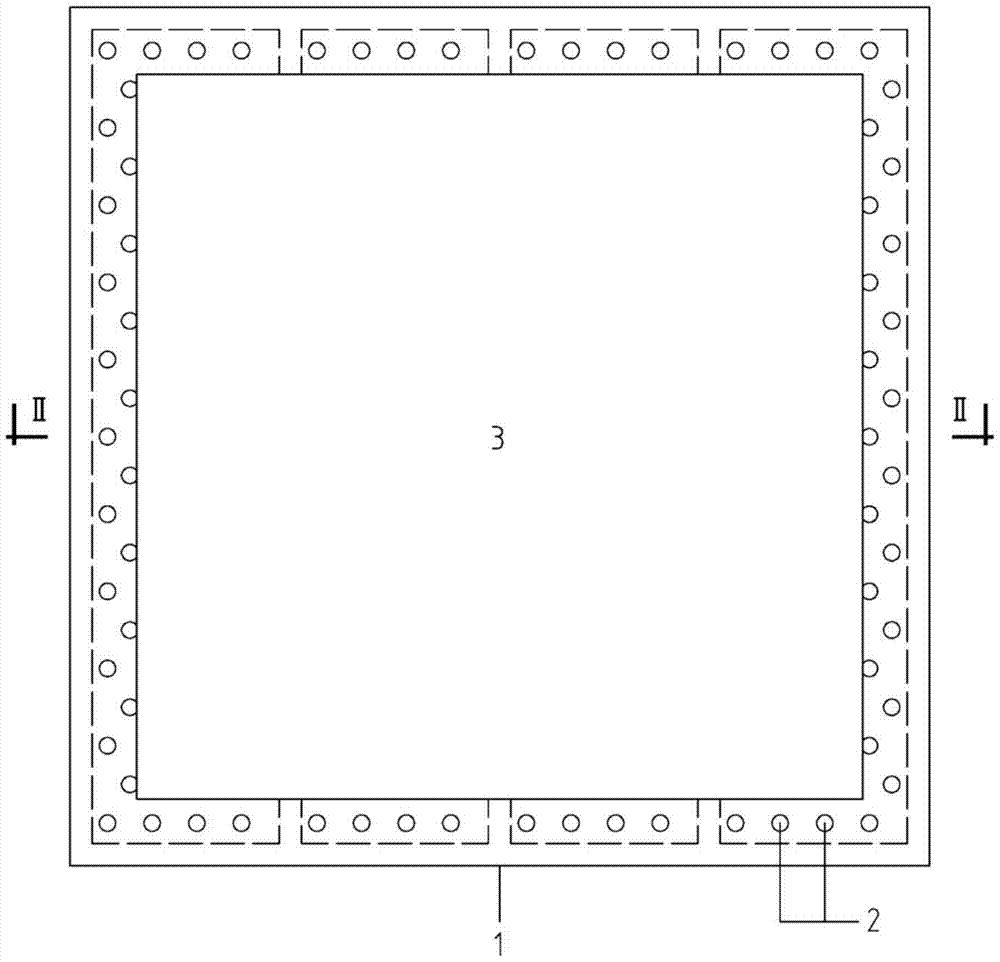

Insert assembly type automobile trimming-punching die

The invention discloses an insert-assembled automobile trimming and punching die, comprising an upper die and a lower die, the upper die is arranged just above the lower die, an upper bottom plate is arranged at the end of the upper die away from the lower die, and the upper The mold and the upper bottom plate are integrally formed, and the upper bottom plate is used to fix the upper mold on the stamping power source. The end of the upper mold away from the upper bottom plate is provided with trimming inserts on both sides, and the trimming inserts are "Z" shaped. In addition, one end of the "Z" shape is fixedly connected with the upper mold through the first locking device, and the position corresponding to the trimming insert is provided with an insert groove and a mounting hole. In the present invention, the mold is split, so that the frequently worn parts such as trimming inserts, punch inserts, lower molds and stamping inserts can be disassembled and replaced. When the above parts are seriously worn, only the parts need to be replaced , the main body of the mold can continue to be used, which greatly reduces the loss of the mold and reduces the production cost.

Owner:CHUZHOU DASHI AUTO PARTS

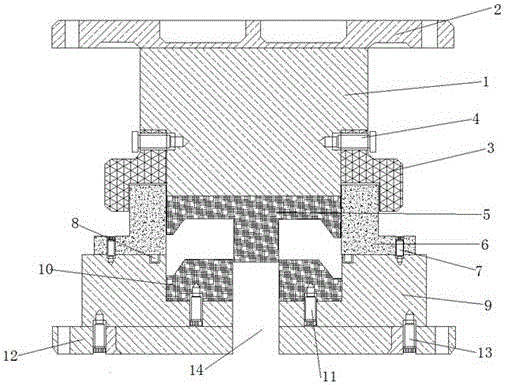

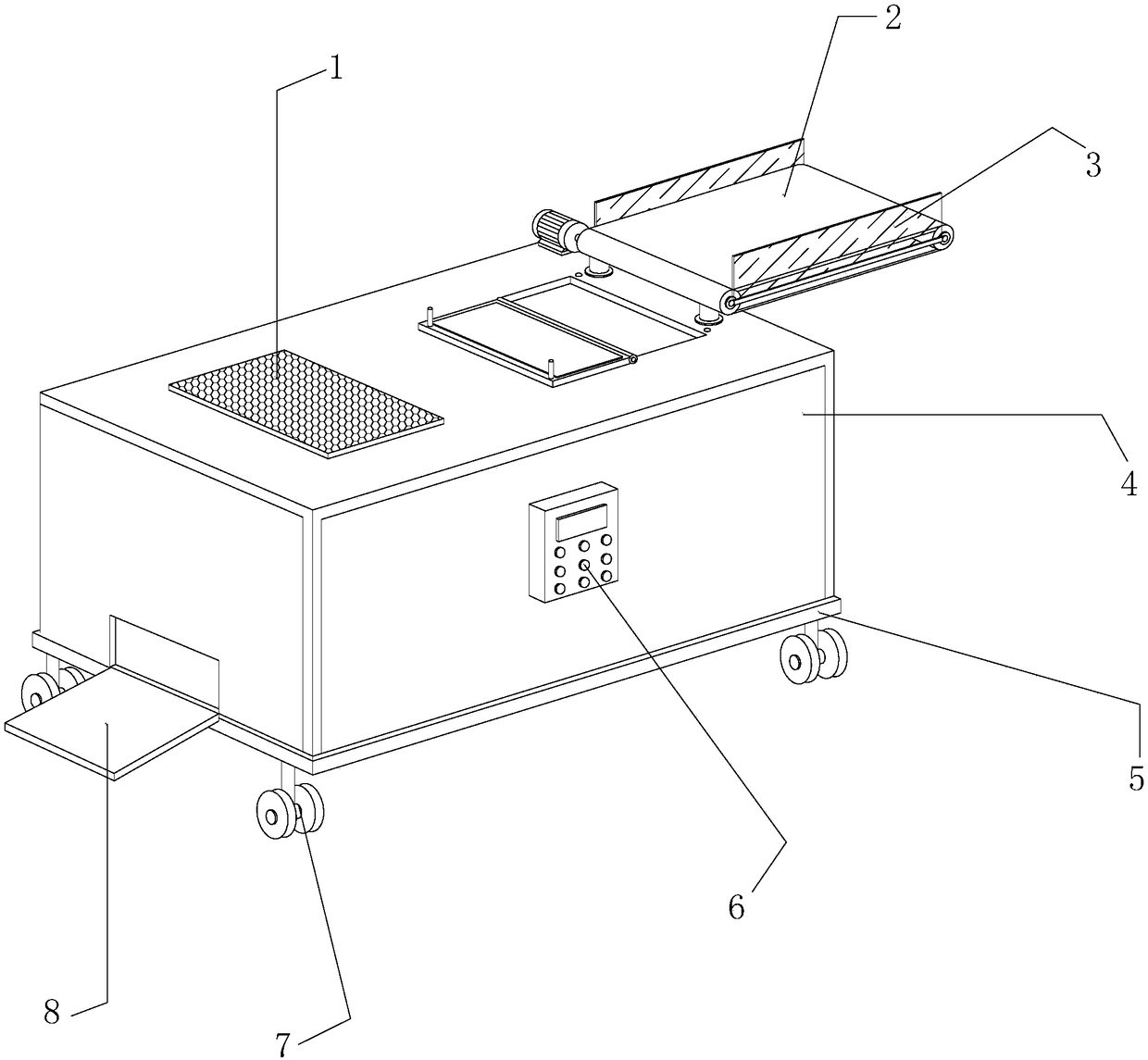

Automatic forage cutting device

The invention discloses an automatic forage cutting device, which comprises a heat dissipation net cover, a feeding conveyor, glass baffles, a forage cutting and drying device, a bottom frame, a monitoring controller, universal casters and a discharge guide plate, wherein the feeding conveyor is arranged on the top of the forage cutting and drying device and fixed on the forage cutting and dryingdevice, and the two are cooperated with each other, and the glass baffles are provided on both sides of the feeding conveyor. The feeding conveyor automatically feeds forage into the forage cutting and drying device, a cutting mechanism can quickly cut and mix the wild weeds and crops stems or leaves to facilitate consumption by livestock, and the cut forage can be dried by a drying mechanism. Thenutrients of the forage are retained, and the storage time is prolonged. The dried forage can be cut into blocks by the cutting mechanism and output through a discharge conveyor, which facilitates accessing, and stacking and storing.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

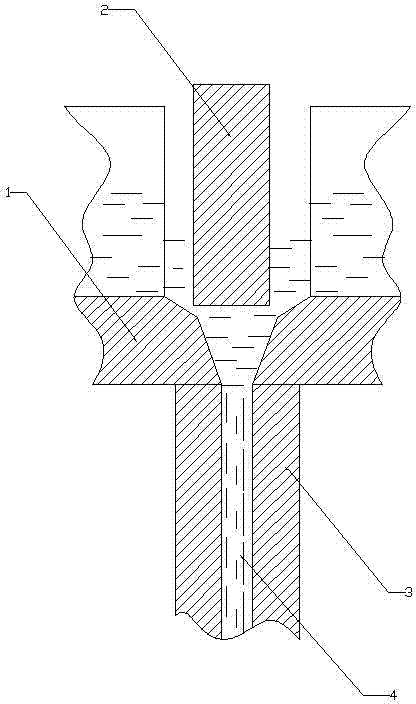

Vertical sliding lead-down forming method for plate glass chute

InactiveCN104761127AReduce manufacturing costReduce consumptionGlass drawing apparatusFlat glassChemical stability

The invention discloses a vertical sliding lead-down forming method for a plate glass chute. The vertical sliding lead-down forming method for the plate glass chute is characterized by comprising the following steps: with a solid material which is low in friction coefficient, high in heat conductivity coefficient, small in expansion coefficient, good in chemical stability, low in permeability and heat-resistant, and has a polishing function as a vertical chute, carrying out vertical sliding lead-down forming on glass metal in a slot, and pulling and leading out a glass tape with required thickness and width.

Owner:徐林波

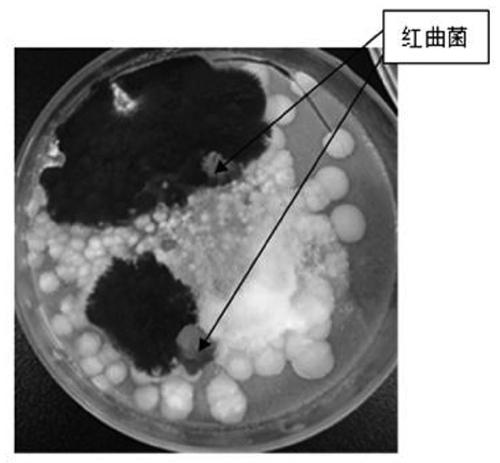

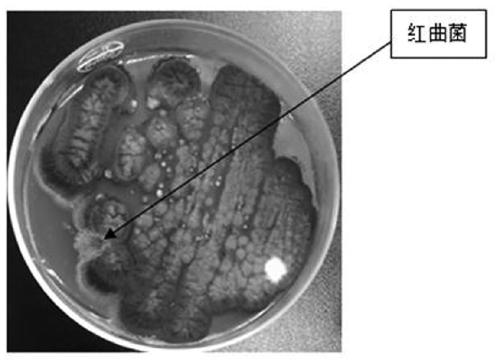

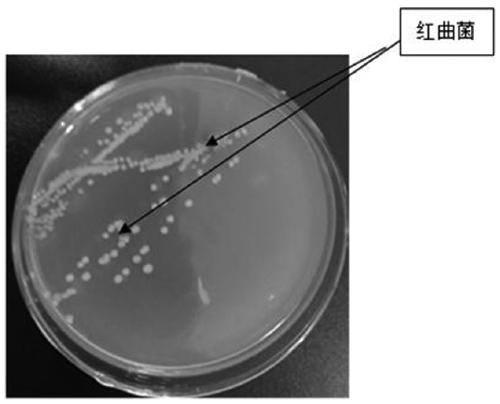

Simple monascus solid separation method

InactiveCN110229753AConsumableReduce distractionsFungiMicroorganism based processesEnrichment cultureCulture mediums

The invention discloses a simple monascus solid separation method and belongs to the technical field of microbial separation. The method comprises five steps as follows: preparation of a culture medium, addition of an inhibitor, enrichment culture, marking separation and dibbling. The self-made malt agar culture medium containing an inhibitor is used for efficient solid enrichment of monascus in red kojic rice and separation and purification. The separation method is convenient to operate, high in separation speed and good in separation effect.

Owner:福建生物工程职业技术学院

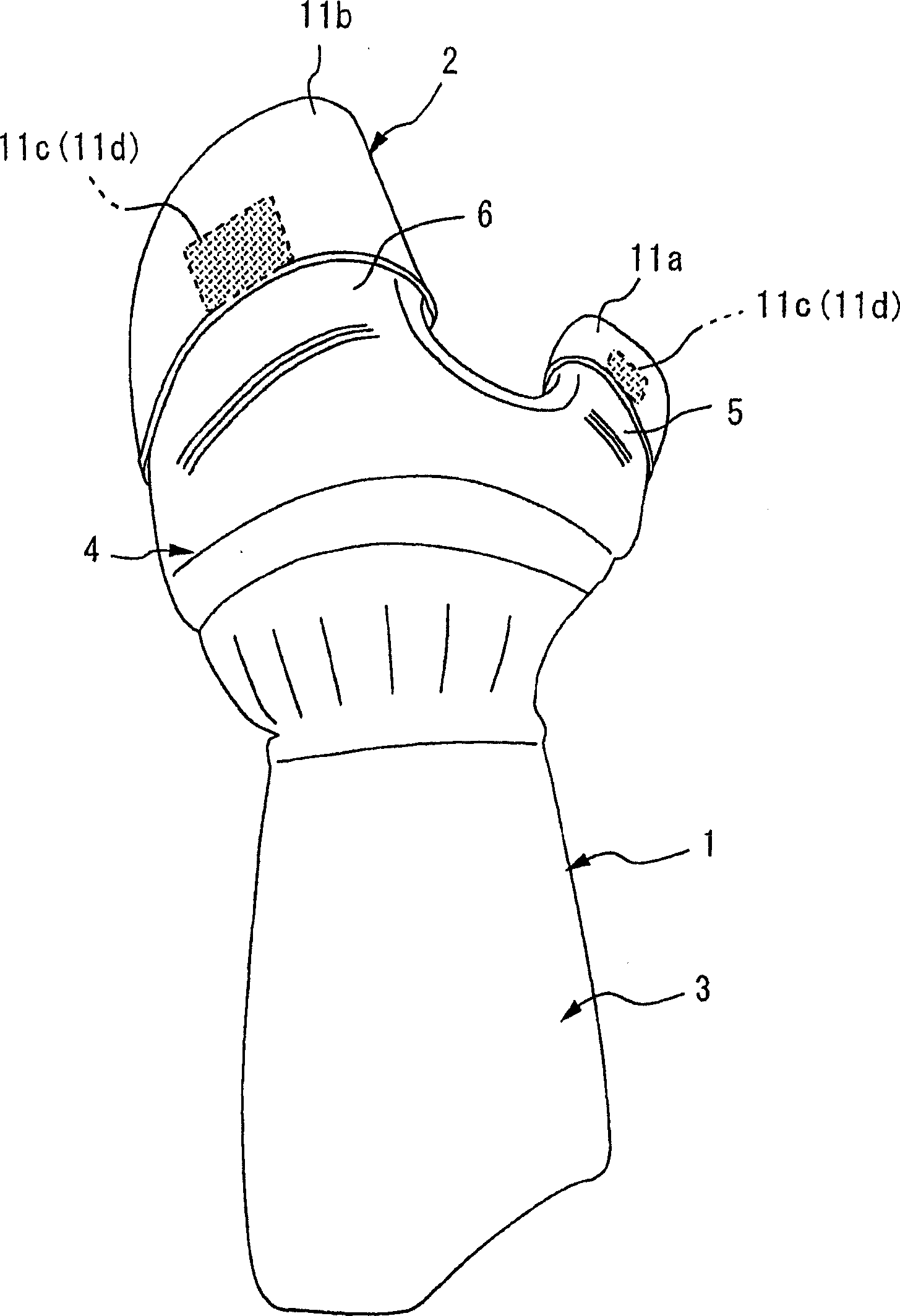

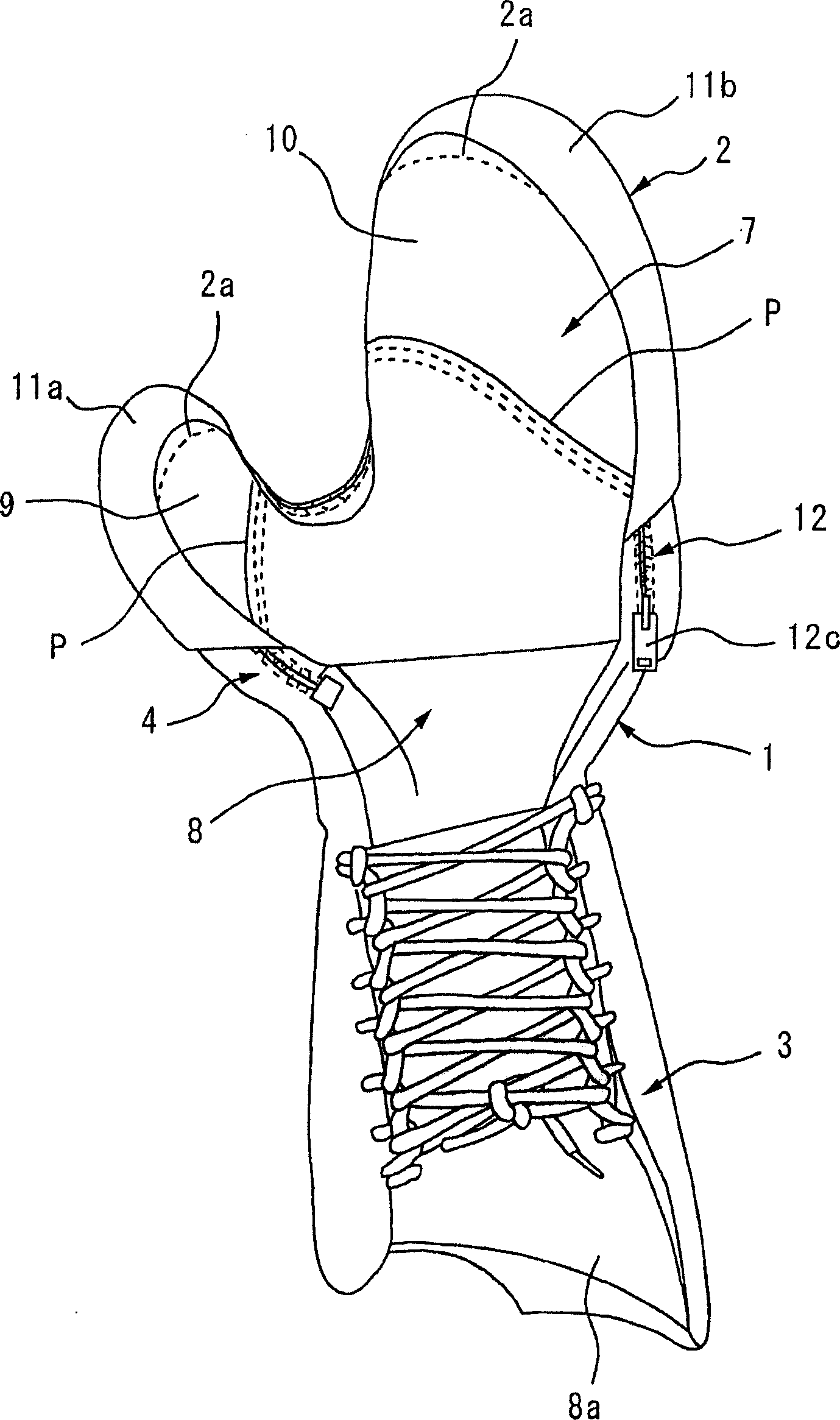

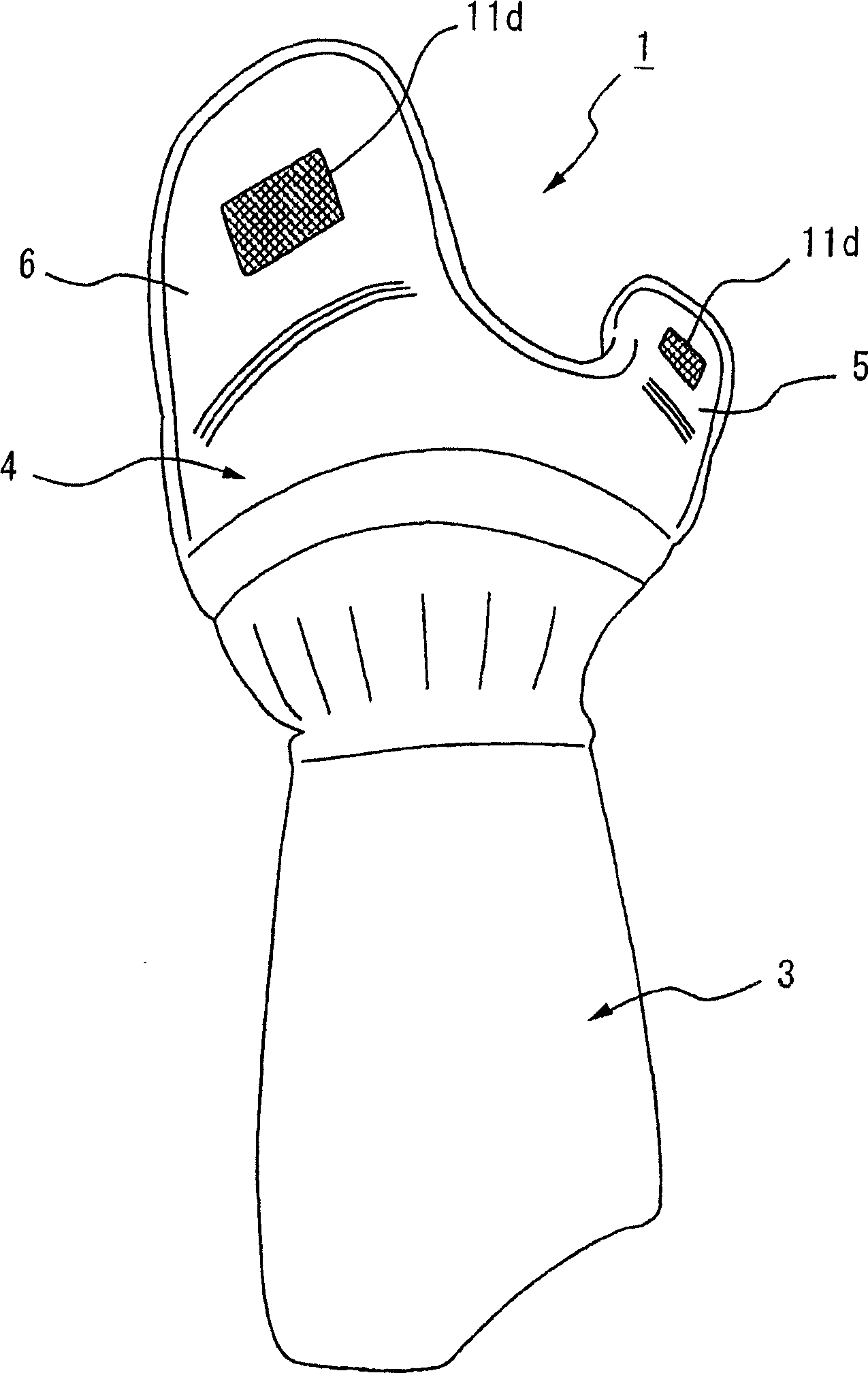

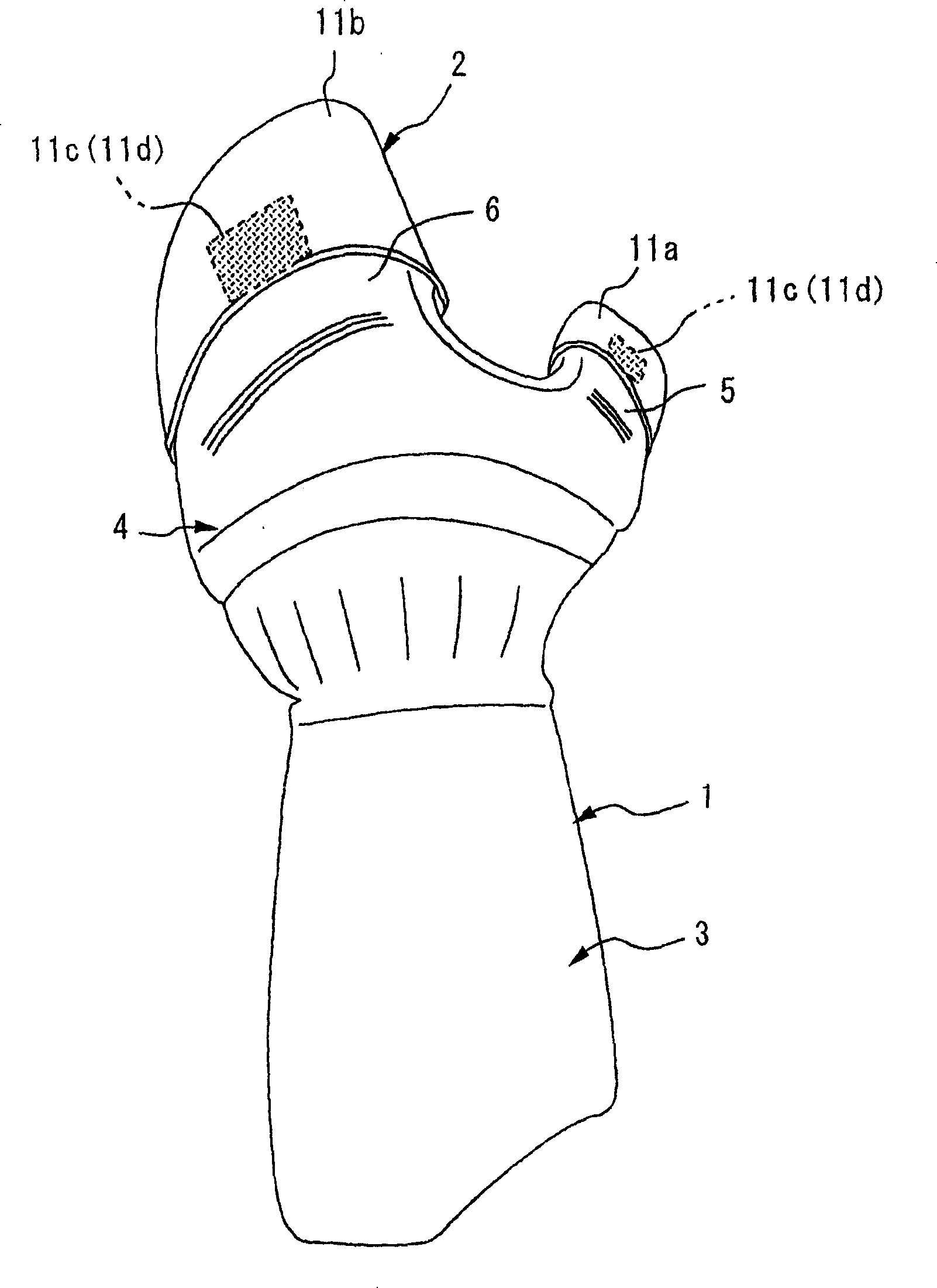

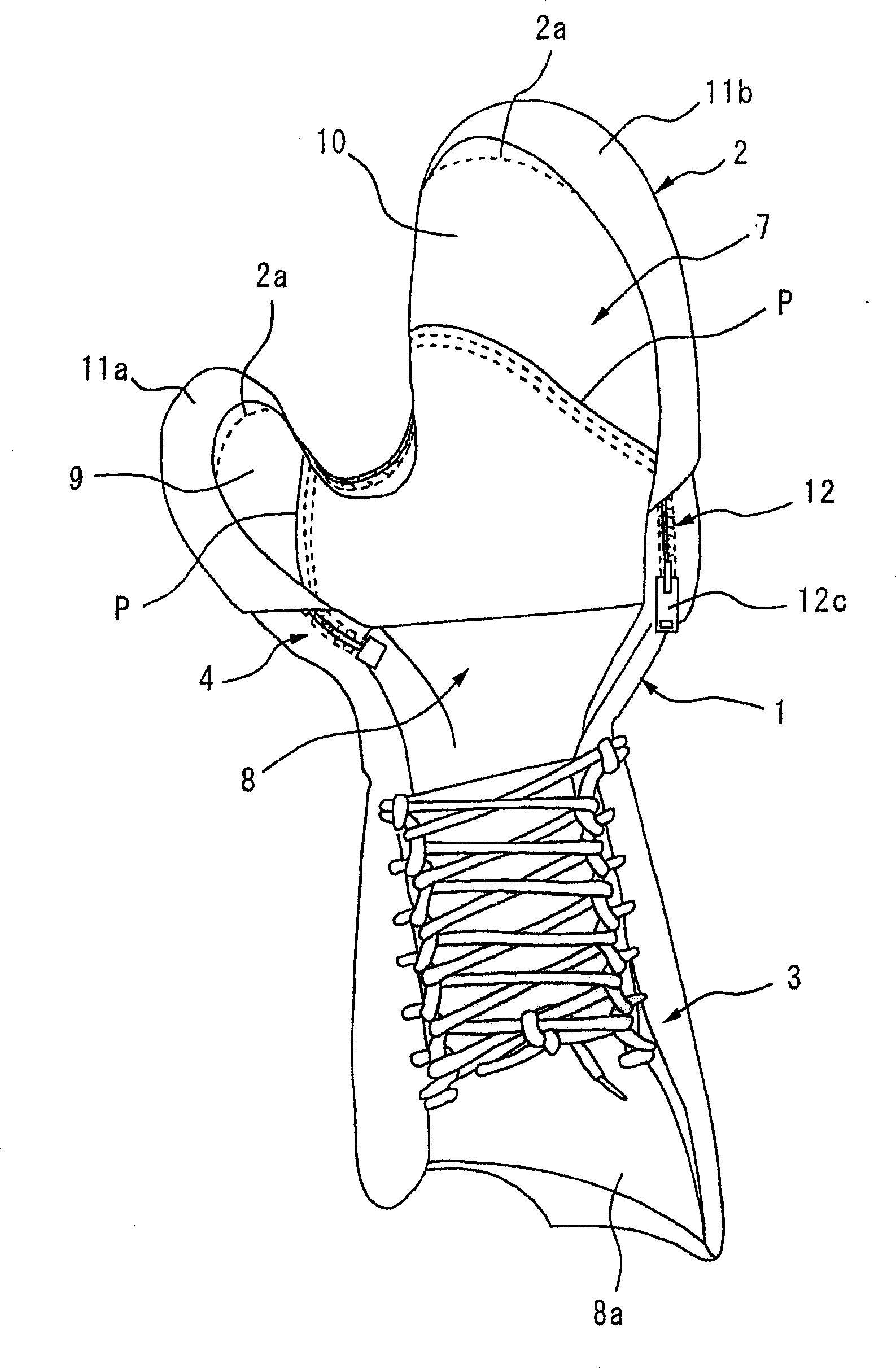

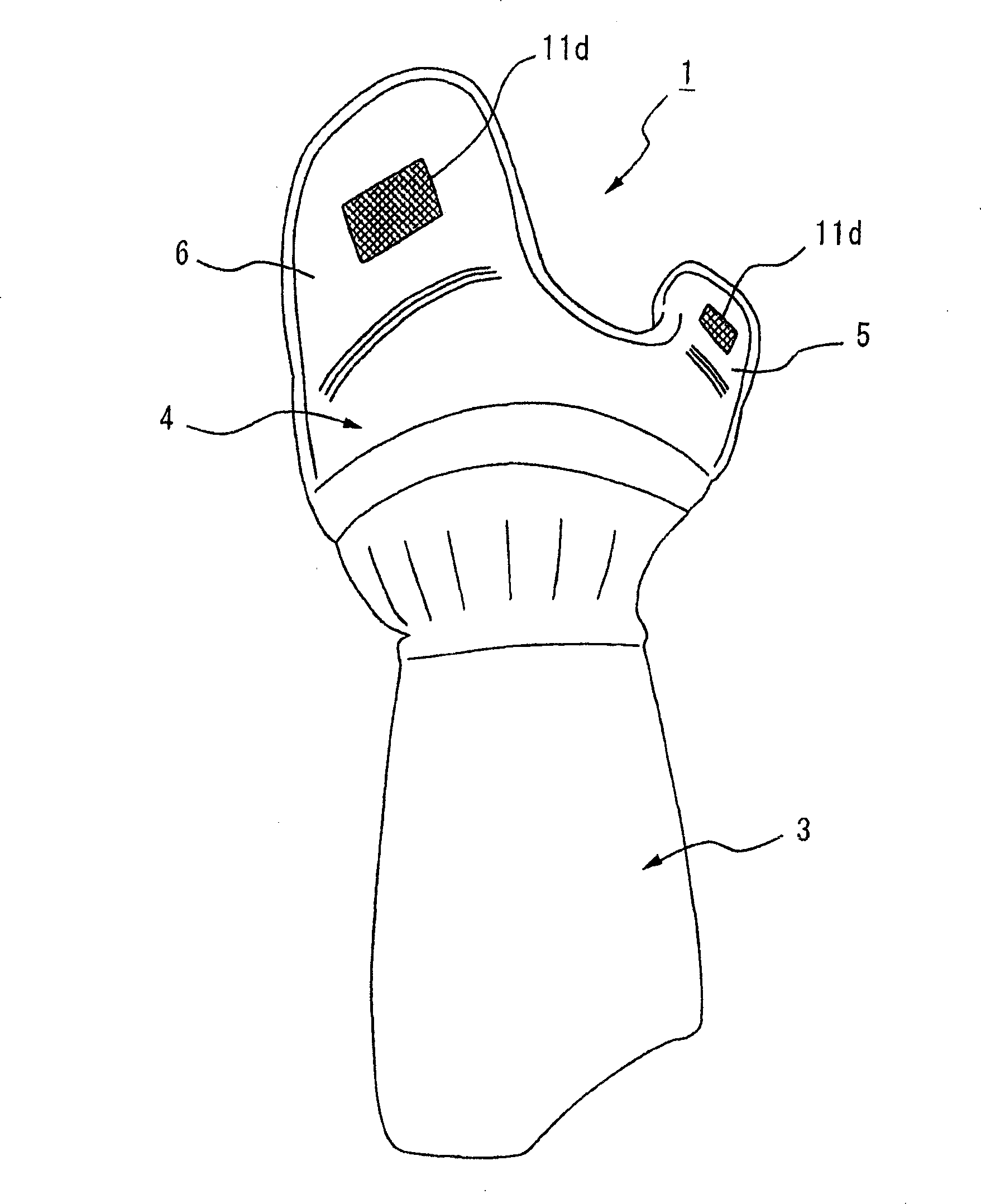

Glove for japanese fencing

A glove for a Japanese fencing, comprising a glove quilt member formed by joining a glove tube quilt part protecting a front arm to a glove head quilt part having a thumb protective part and a four-finger protective part at the tip thereof and protecting the tip portion of a wrist, a hand inner member detachably fitted to at least the glove head quilt part of the glove quilt member, and a mounting means for detachably mounting the hand inner member on the glove quilt member. A separation prevention means locked to at least the tip part of the thumb protective part and / or the four-finger protective part of the glove head quilt part to prevent the glove quilt member from being separated off the hand inner member in use is fitted to the hand inner member. Thus, not only the hand inner part is formed detachable, a repair cost can be reduced, and corrosion and offensive small can be prevented from occurring by cleaning but also, even if the violent collision thereof with an opponent occurs or an impact such as hitting and passing by a bamboo sword acts thereon during playing or training, the glove quilt member can be prevented from being separated off the hand inner member, and the hand fingers can be completely protected. So it is a safe glove for a Japanese fencing.

Owner:长谷川株式会社

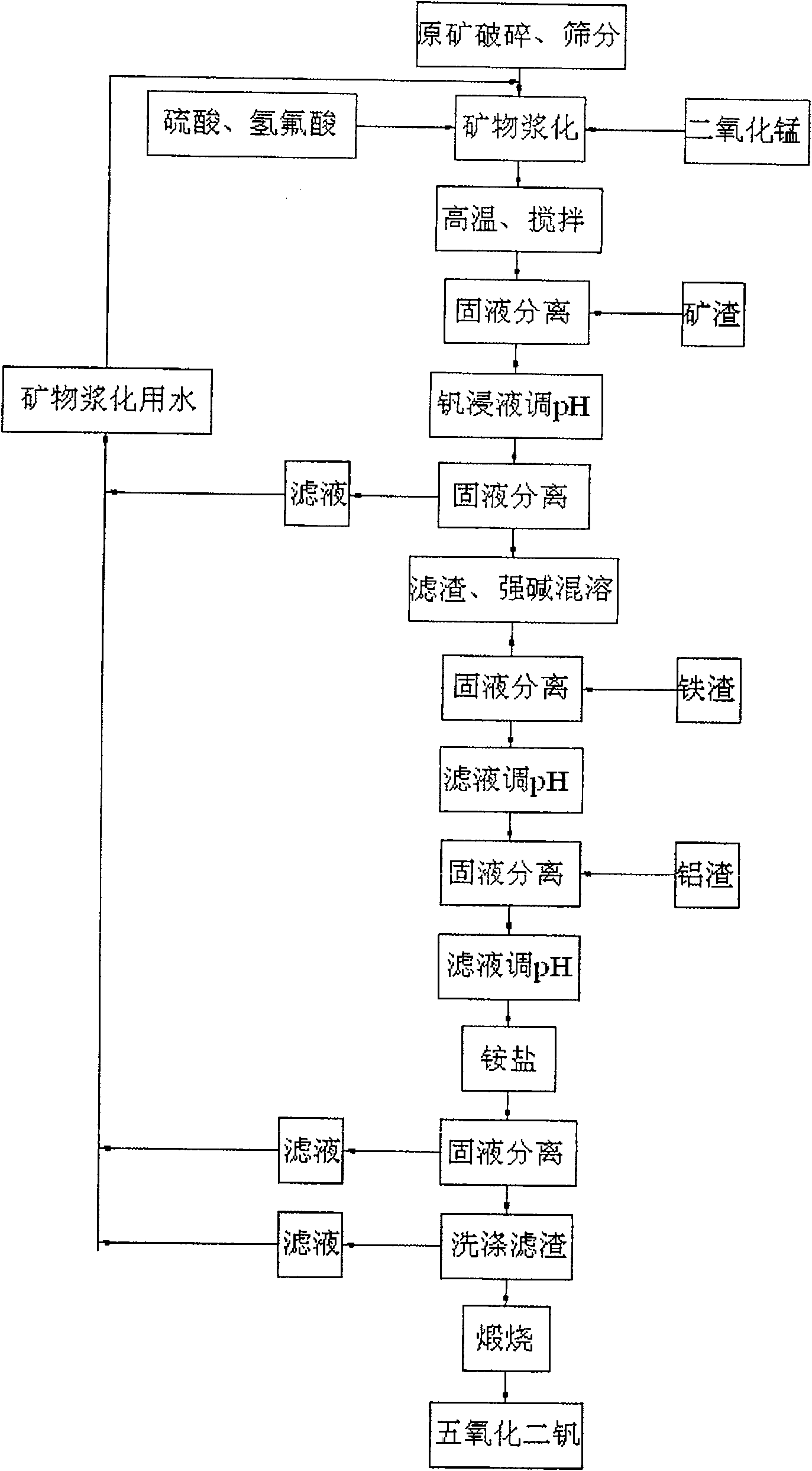

Alum extracting technique for clay ore by wet method

InactiveCN100588727CImprove use valueShort processVanadium oxidesProcess efficiency improvementFluohydric acidAmmonium metavanadate

The invention relates to a wet process vanadium extraction technology of clay ore, providing a valuable metal technology for extracting vanadium by wet process from vanadium clay ore, which belongs tothe non-ferrous metal metallurgical technology field. The invention is characterized in that disintegrating clay ore, proceeding thermostatic mixing acid leaching reaction as adding sulfuric acid, fluohydric acid and oxidation agent under certain liquid solid volumetric ratio, separating solid and liquid, removing out iron and aluminum and recycling to utilize after leaching solution being treated by multistep pH value regulation and alkali deposition solubilization reaction, depositing vanadium by ammonium salt after purified vanadium being regulated pH value, filtering, drying and calciningammonium metavanadate which is prepared to obtain vanadium pentoxide powder. The invention directly leaches clay ore mixing with acid, has high acid leaching rate, lower energy consumption, short technical process, easy operation and control, low productive cost, environment-friendly and safety, realizes zero discharge in the production process, has no waste gas generation, and recycles waste water and valuable metal, and the recycle rate of vanadium reaches 70-75%, purity of vanadium pentoxide of the product is larger than 99%.

Owner:UNIV OF SCI & TECH BEIJING

Glove for japanese fencing

A glove for a Japanese fencing, comprising a glove quilt member formed by joining a glove tube quilt part protecting a front arm to a glove head quilt part having a thumb protective part and a four-finger protective part at the tip thereof and protecting the tip portion of a wrist, a hand inner member detachably fitted to at least the glove head quilt part of the glove quilt member, and a mounting means for detachably mounting the hand inner member on the glove quilt member. A separation prevention means locked to at least the tip part of the thumb protective part and / or the four-finger protective part of the glove head quilt part to prevent the glove quilt member from being separated off the hand inner member in use is fitted to the hand inner member. Thus, not only the hand inner part is formed detachable, a repair cost can be reduced, and corrosion and offensive small can be prevented from occurring by cleaning but also, even if the violent collision thereof with an opponent occurs or an impact such as hitting and passing by a bamboo sword acts thereon during playing or training, the glove quilt member can be prevented from being separated off the hand inner member, and the hand fingers can be completely protected. So it is a safe glove for a Japanese fencing.

Owner:HASEGAWA CORPORATION

Method and system for preparing urea by denitrification coupled with electrocatalytic reduction

ActiveCN112920087BRealize resourcesPromote absorptionUrea derivatives preparationGas treatmentNitrate saltsFlue gas

The invention relates to a method and a system for preparing urea by denitrification coupled with electrocatalytic reduction. Specifically, the method of the present invention includes: introducing the absorbing liquid containing nitrite and nitrate produced by the denitrification process of the flue gas containing nitric oxide into the separation process to separate the nitrite and nitrate, thereby obtaining A solution rich in nitrite and nitrate; the solution rich in nitrite and nitrate produced in the separation process is introduced into the electrocatalytic process, and electrocatalytic reduction is carried out in the presence of carbon dioxide or carbonate, thereby generating urea solution. The system of the present invention includes: a denitration device, a separation device connected with the denitration device, and an electrocatalytic device connected with the separation device. The method and system of the invention can be used for deep removal of nitrogen oxides in industrial flue gas at relatively low temperature, and can realize nitrogen resource utilization.

Owner:TSINGHUA UNIV

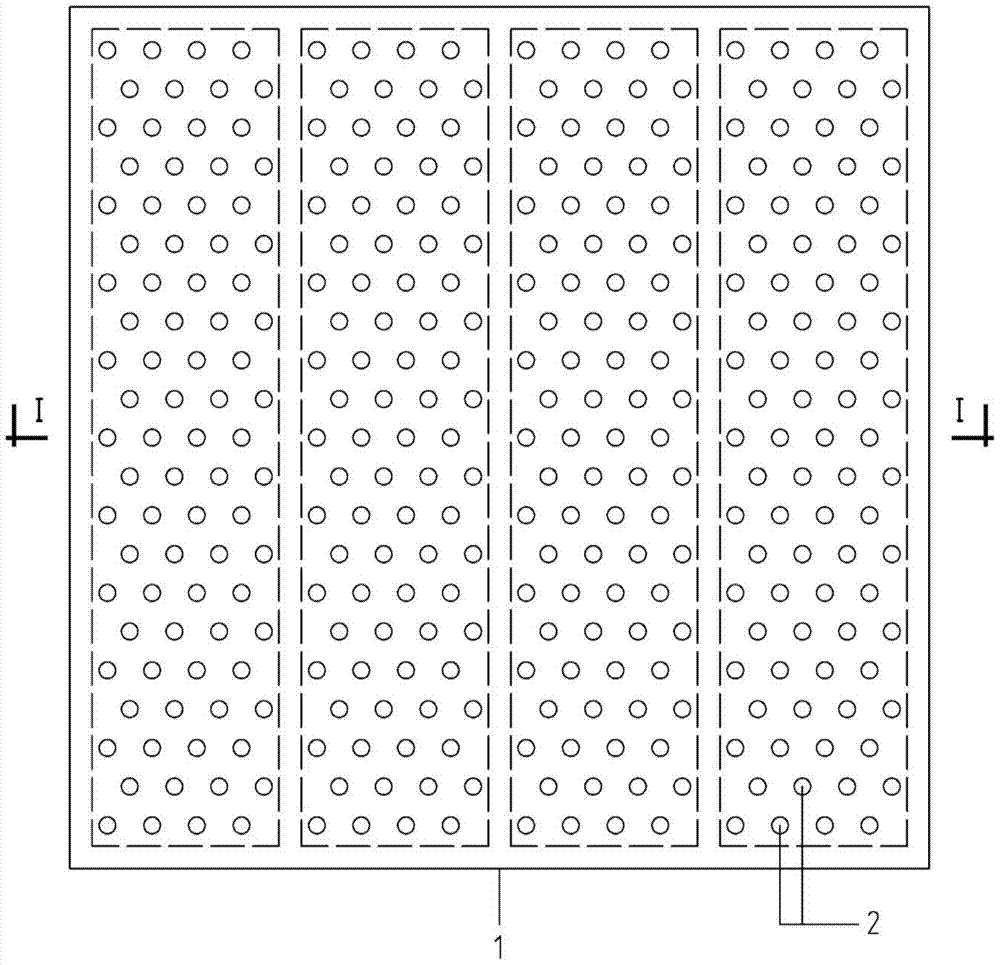

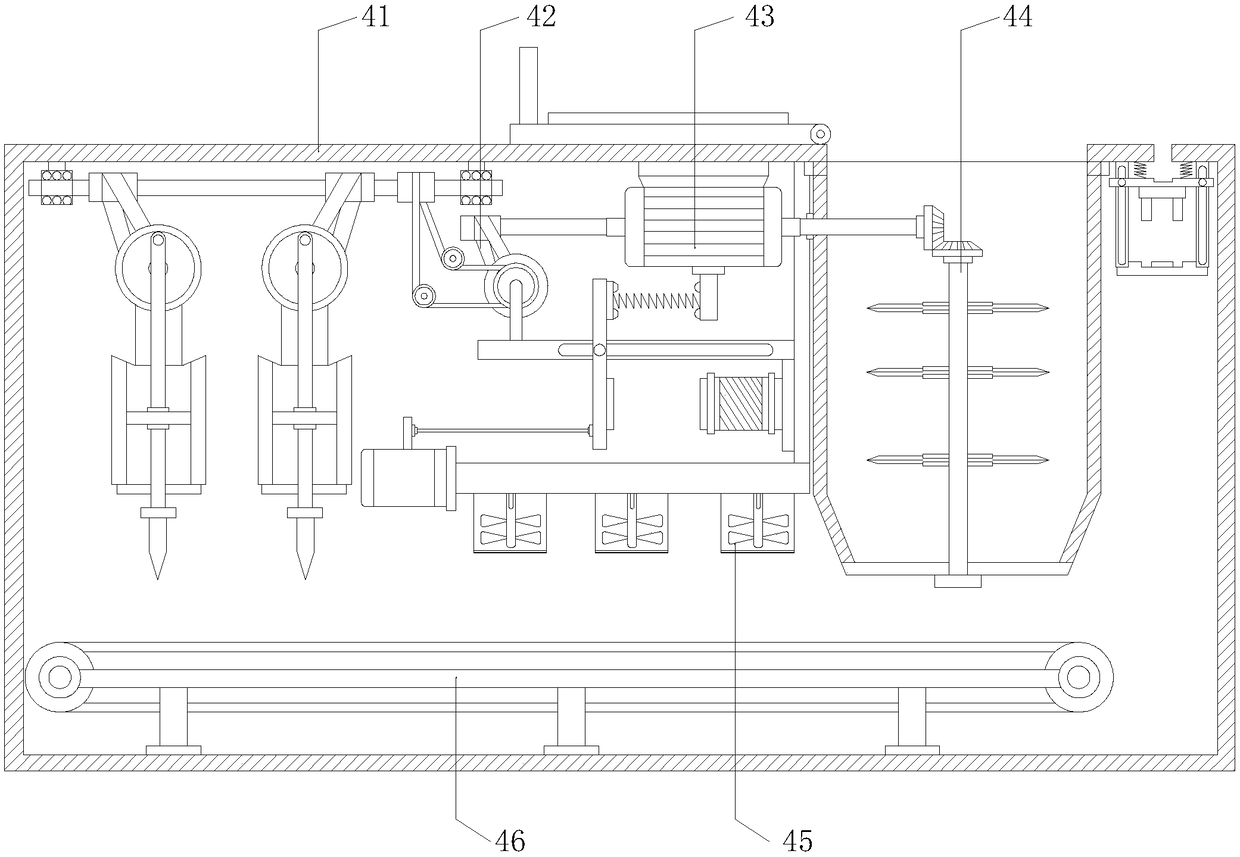

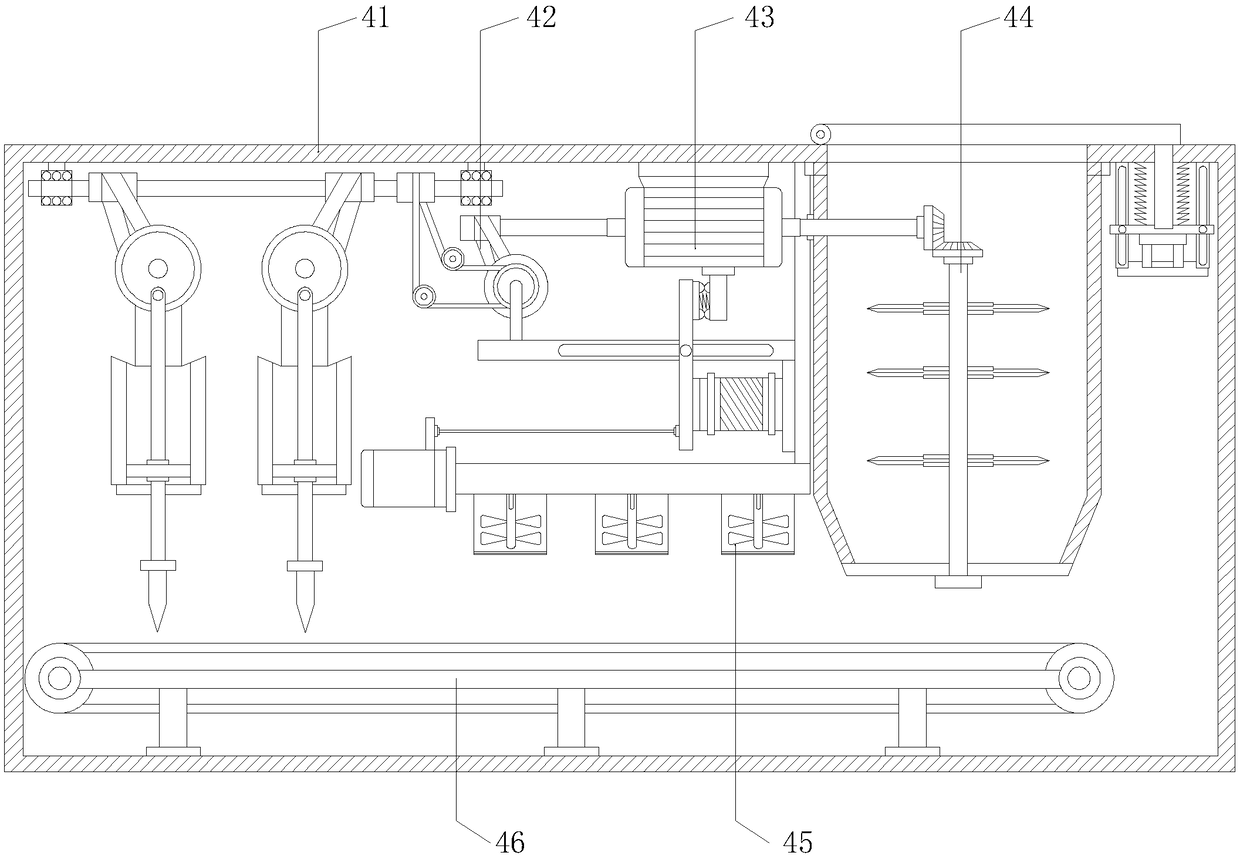

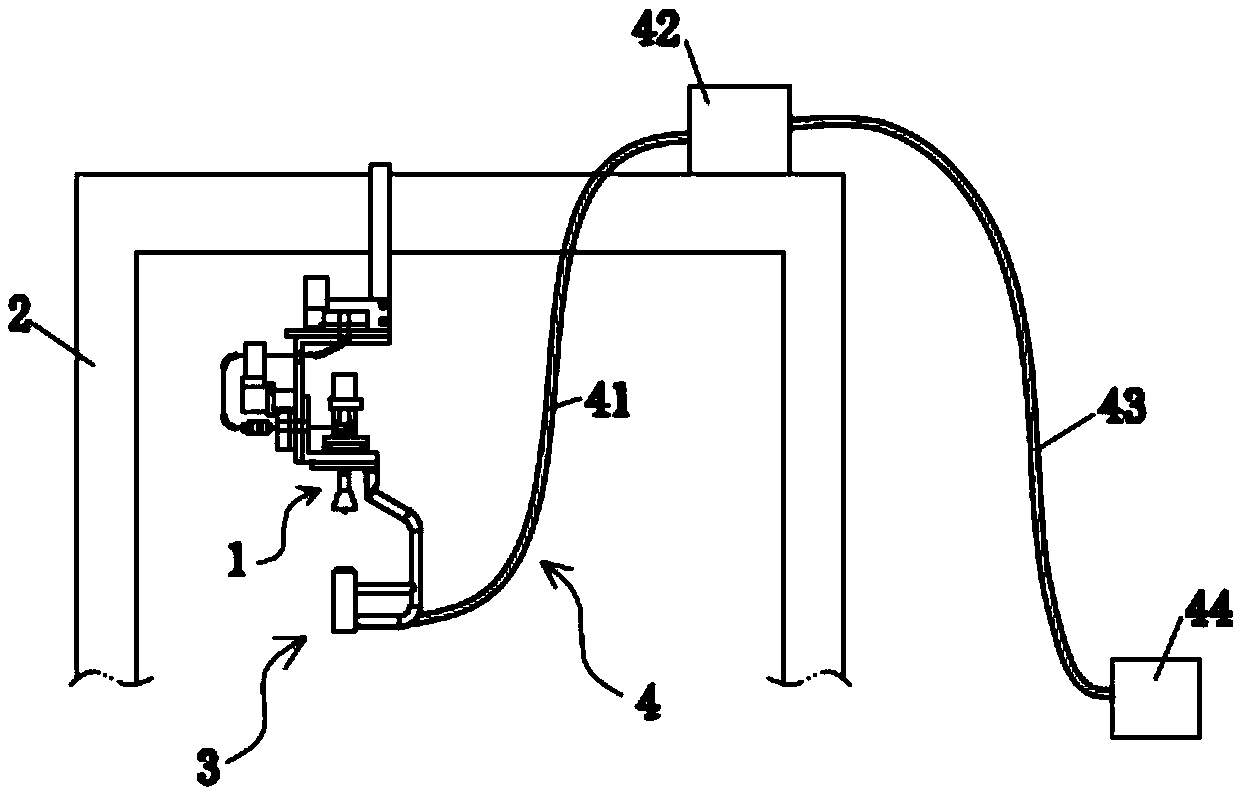

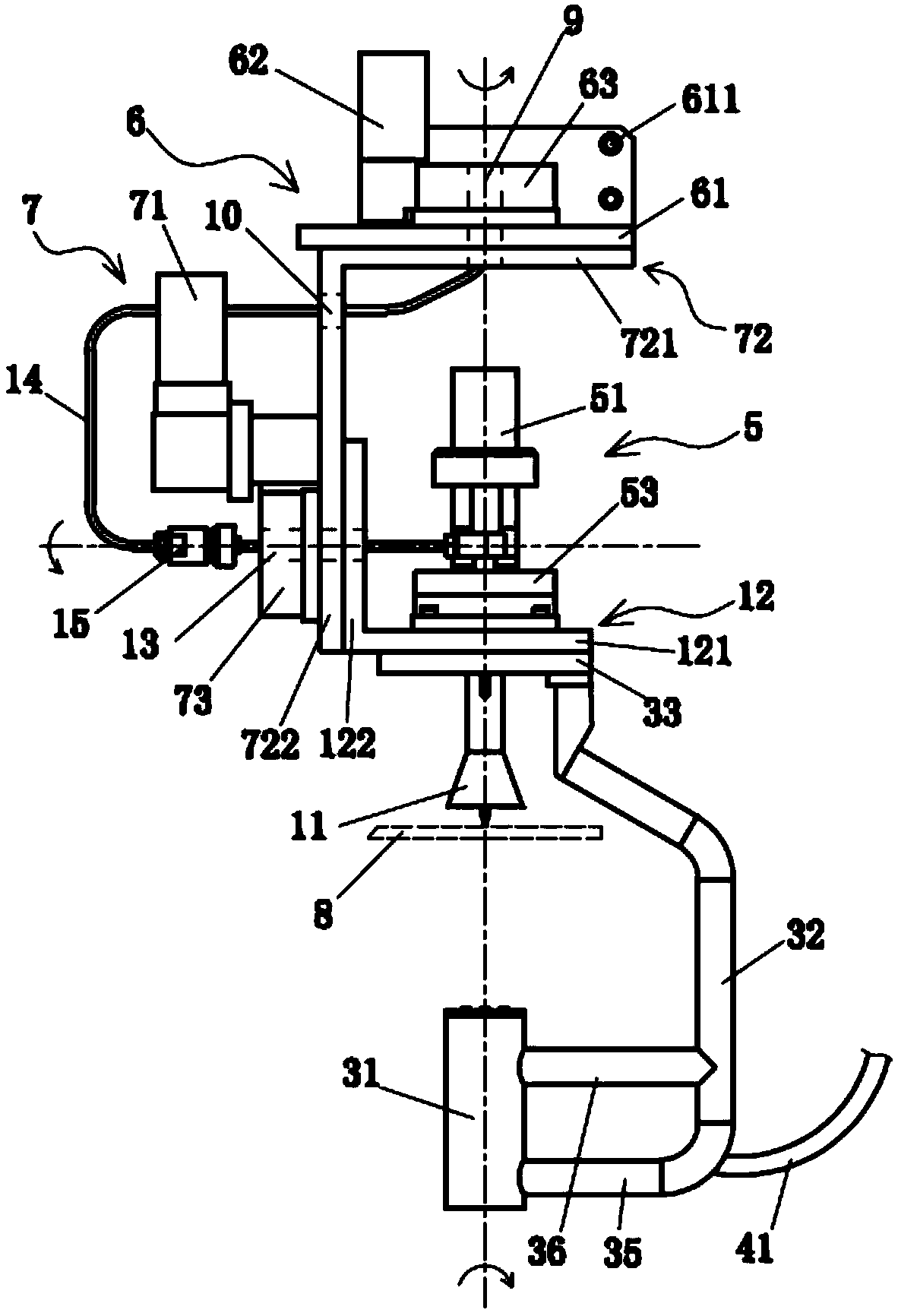

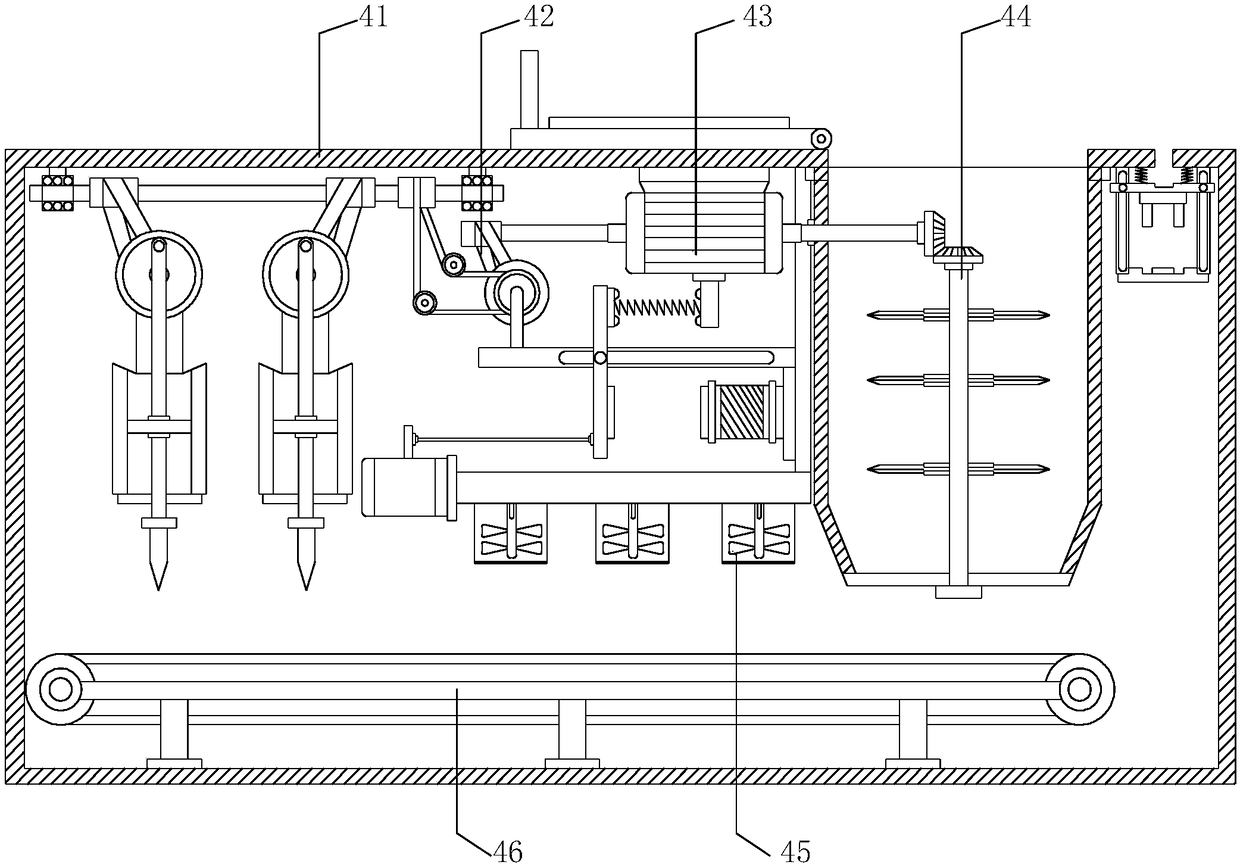

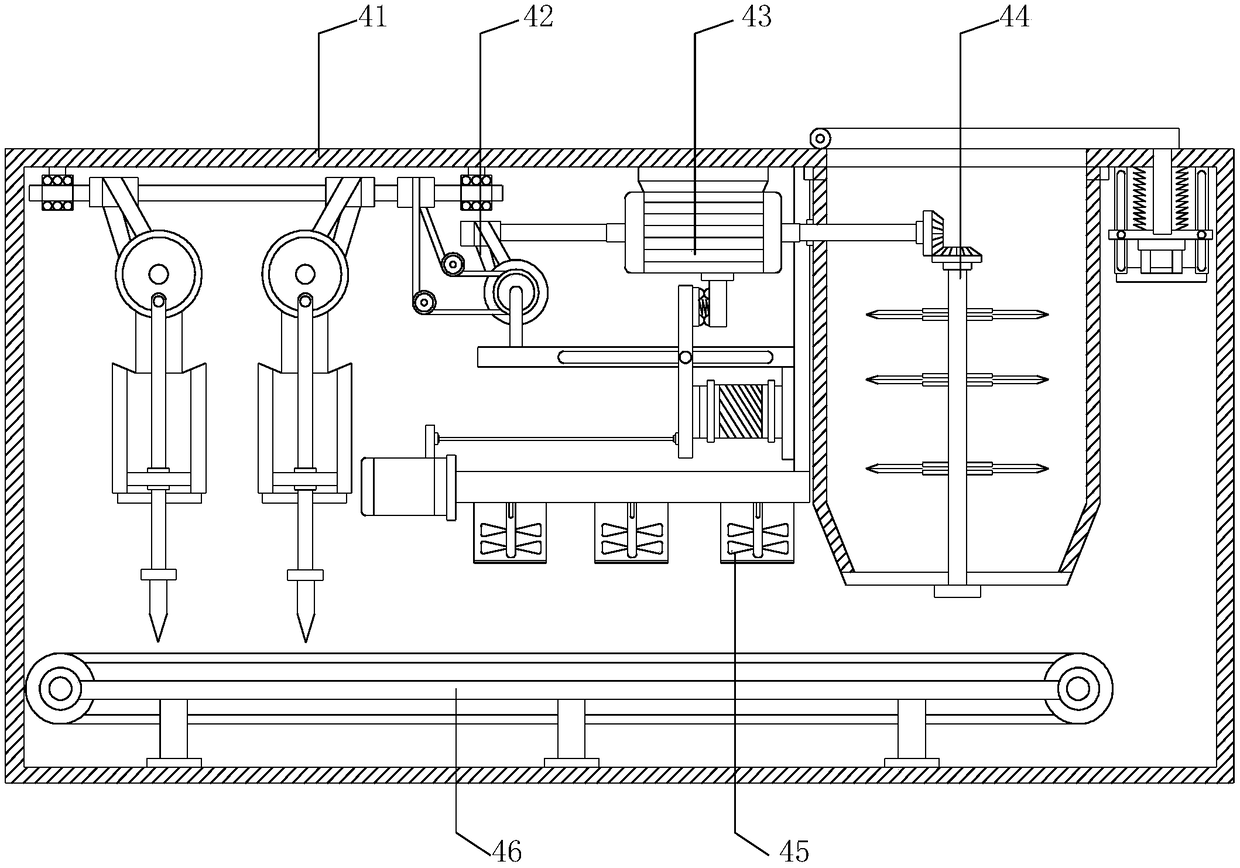

A water jet machine tool with a mobile water sand collection device

ActiveCN106799684BNot easy to fly outGuaranteed smoothnessAbrasive feedersAbrasive machine appurtenancesDot matrixMovable type

The invention discloses a water-jet cutter machine tool provided with a movable type water and sand collecting device. The water-jet cutter machine tool comprises a cutter head component and a moving frame capable of allowing the cutter head component to move in the horizontal direction and in the vertical direction; and the cutter head component comprises a nozzle. The water-jet cutter machine tool further comprises a collecting device body which moves along with the nozzle and is used for collecting a water and sand mixture blown out by the nozzle; the collecting device body comprises a container; a water collecting hole is formed in the outer wall of the container, and is opposite to the nozzle; a connecting piece is arranged on the container; a first driving mechanism capable of allowing the collecting device body to rotate around the axis of the nozzle is connected between the connecting piece and the cutter head component; and the container is connected with a drainage device. The water-jet cutter machine tool provided with the movable type water and sand collecting device moving along with the nozzle can cut a workpiece fixed by a flexible dot matrix tool system, and the machining field is wider. Furthermore, the connecting piece on the collecting device body can not collide the workpiece under the control of the first driving mechanism, so that the smoothness of the cutting process of the workpiece is guaranteed.

Owner:广州华臻机械设备有限公司

A kind of method of crushing pcb board

ActiveCN105538547BEasy to crushEasy to break awayPlastic recyclingMechanical material recoveryEngineeringPre cooling

A method for crushing a PCB (printed circuit board) comprises the following steps: (1) crushing; (2) soaking; (3) preheating; (4) pre-cooling; (5) thermal shock; (6) crushing twice. The method disclosed by the invention is simple, and easy to operate; crushed particles are small, sorting and recovery rate is high, and recovery utilization rate reaches up to 98 percent; the method is high in crushing efficiency, short in crushing time, low in machine loss and cost, economic, environmental friendly and has less pollution.

Owner:AOSHIKANG TECH CO LTD

Forage cutting device for livestock industry

The invention discloses a forage cutting device for livestock industry. The forage cutting device comprises a heat dissipation net cover, a feeding conveyor, glass baffles, a forage cutting and dryingdevice, a bottom frame, a monitoring controller, universal casters and a discharge guide plate, wherein the feeding conveyor is arranged on the top of the forage cutting and drying device and fixed on the forage cutting and drying device, and the two are cooperated with each other, and the glass baffles are provided on both sides of the feeding conveyor. The feeding conveyor automatically feeds forage into the forage cutting and drying device, a cutting mechanism can quickly cut and mix the wild weeds and crops stems or leaves to facilitate consumption by livestock, and the cut forage can bedried by a drying mechanism. The nutrients of the forage are retained, and the storage time is prolonged. The dried forage can be cut into blocks by the cutting mechanism and output through a discharge conveyor, which facilitates accessing, and stacking and storing.

Owner:LIXIN COUNTY FENGYASONG ELECTROMECHANICAL TECH CO LTD

Ddos attack defense method and device based on browser fingerprint recognition

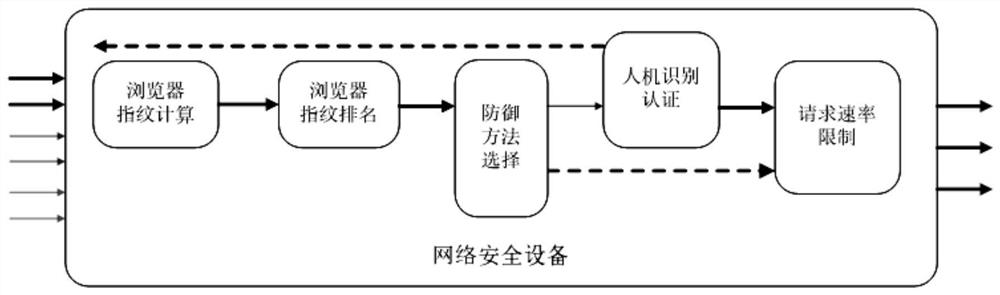

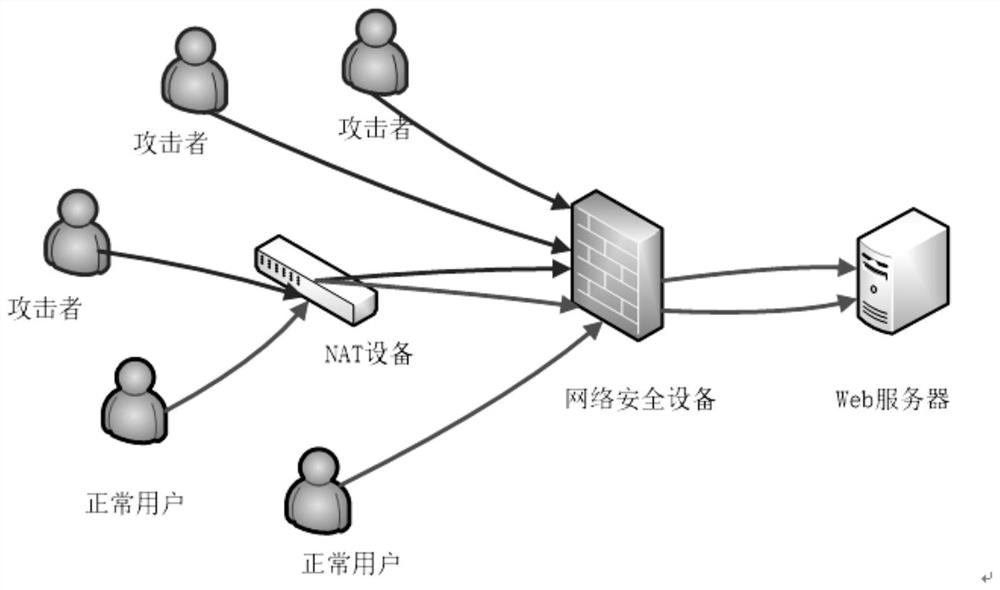

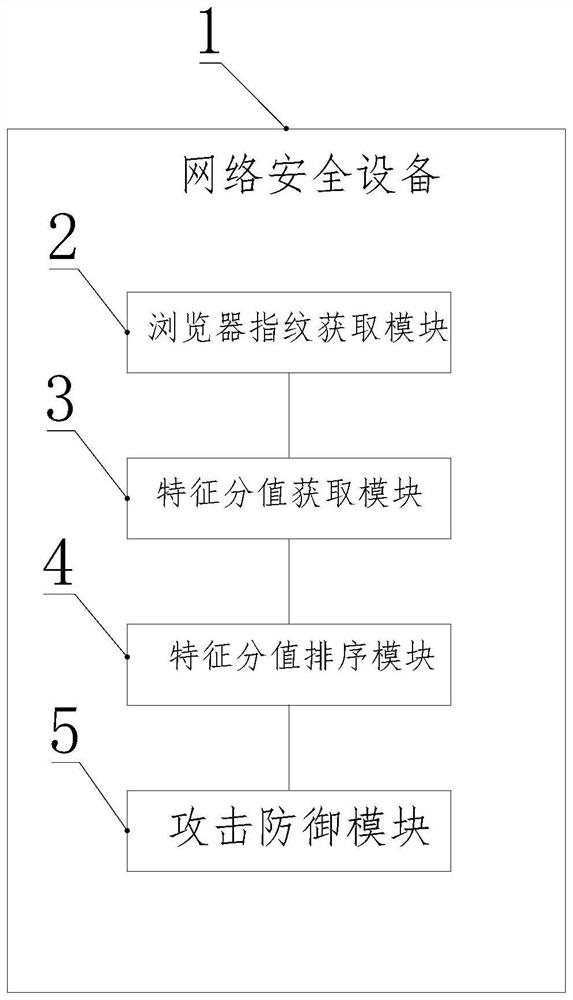

The DDoS attack defense method and device based on browser fingerprint identification set up the network security device at the front end of the Web server, and filter the HTTP request sent to the Web server through the network security device; when the network security device receives the HTTP request, according to The preset statistical period extracts the fingerprint of the browser that sends the HTTP request to obtain the browser fingerprint ID; when each statistical period ends, the HTTP request feature calculation is performed to obtain the feature score, and the feature score is sorted from high to low to obtain the ranking Top N browser fingerprint IDs; captcha authentication and request rate limit are performed on the top N browser fingerprint IDs in each statistical cycle. The invention solves the problems that the prior art cannot distinguish the attack flow, easily causes serious impact on other users in the same source IP and has poor defense effect.

Owner:江南信安(北京)科技有限公司

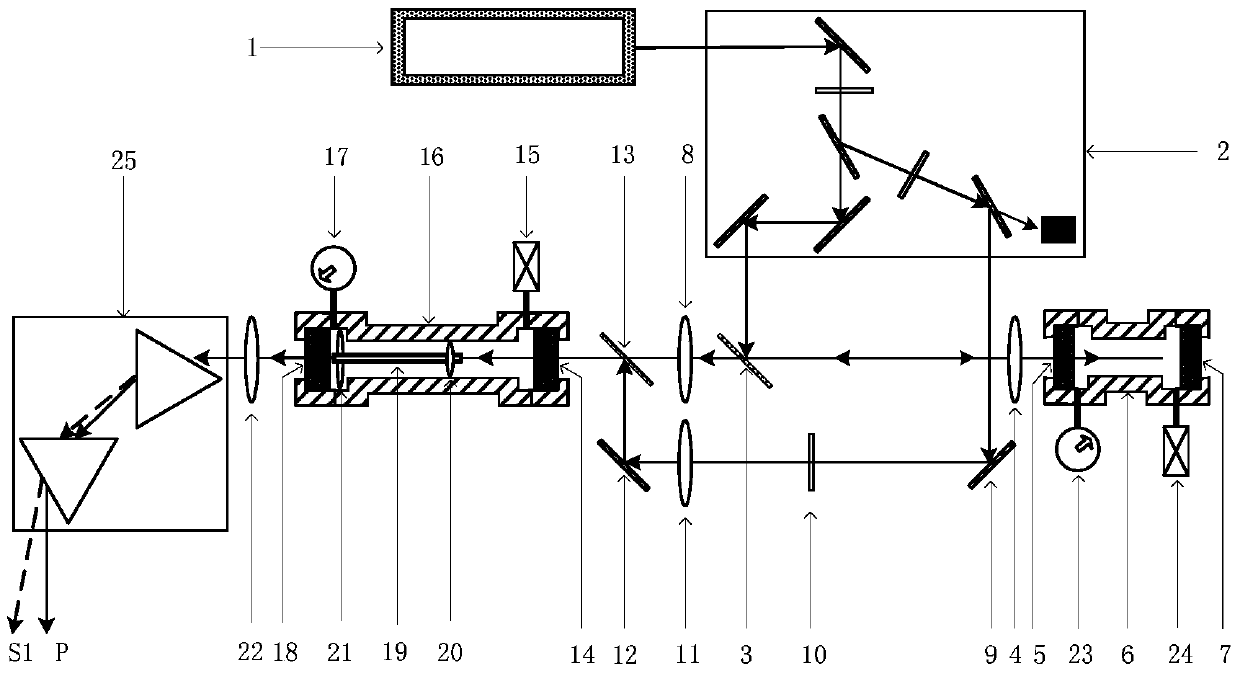

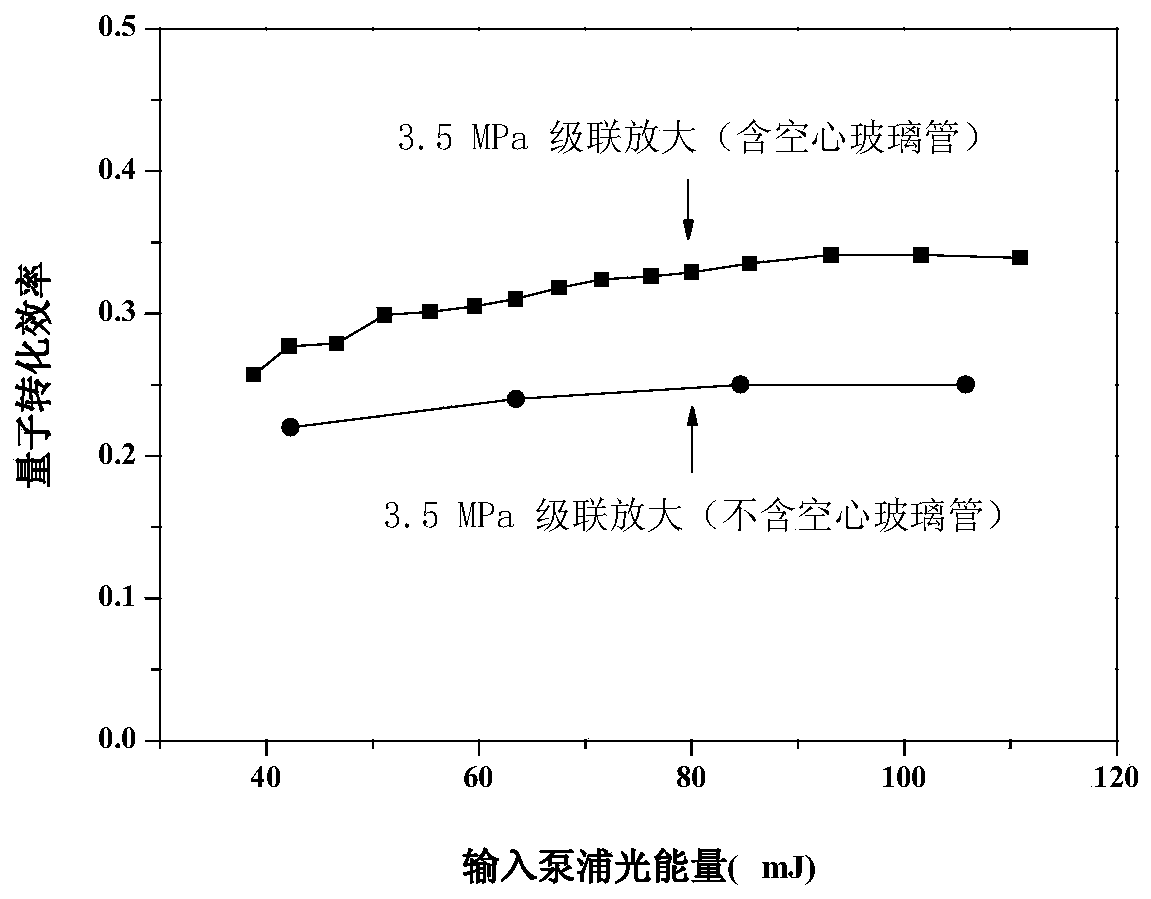

A gas-stimulated Raman amplifier based on a hollow glass tube with its own seed light

InactiveCN104716560BImprove power densityFacilitate the scattering amplification processLaser using scattering effectsOptical resonator shape and constructionBeam splitterDichroic prism

The invention provides a gas-stimulated Raman amplifier based on a hollow glass tube with Raman seed light, including a pump laser, a spectroscopic system, a first Raman cell, and a second Raman cell , a hollow glass tube and a group of optical prisms. The pumping light source is divided into two beams of pumping light through the beam splitting system, wherein the first beam of pumping light is introduced into the first Raman cell through the first dichroic mirror to generate backward Raman seed light; the second beam of pumping light passes through the optical path The delayed Raman seed light and the backward Raman seed light arrive at the second dichroic mirror at the same time and are combined, and then they are introduced into the hollow glass tube placed in the second Raman cell in the form of grazing incidence together for stimulated Raman amplification. Finally, a single amplified Raman light is obtained by combining the light through a dichroic prism. Experimental results show that, compared with the traditional double cascaded Raman cell, the invention can obtain stimulated amplified Raman light with higher conversion efficiency. The invention can be widely used in the fields of military affairs, medical treatment, environment monitoring and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Two-component antifouling paint composition, antifouling coating film, antifouling substrate, and method for producing antifouling substrate

ActiveCN107109082BExhibits long-term stain resistanceConsumableAntifouling/underwater paintsSynthetic resin layered productsEtherMethyl group

The present invention provides a two-component antifouling paint composition exhibiting excellent consumption durability and long-term antifouling properties against marine organisms. The two-component antifouling paint composition of the present invention is characterized in that it contains (A) a first component containing (meth)acrylate, a second component containing (B) an amino group-containing compound, and , the (C) antifouling agent in any one of the second components, either or both of the (A) (meth)acrylate and (B) amino group-containing compounds have an ether structure, and in (A) The total weight of (meth)acrylate contains 50% by weight or more of (meth)acrylate with more than three functional groups, and (B) the amino group-containing compound is 100 parts by weight of (A) (meth)acrylate 20 to 100 parts by weight.

Owner:CHUGOKU MARINE PAINTS

Visible light response photocatalyst and preparation method thereof

InactiveCN102962078BImprove photocatalytic performanceImprove stabilityWater/sewage treatment by irradiationCatalyst activation/preparationPotassium hydroxideCopper oxide

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Rolling Cooling Process for Reducing Iron Scale of Low Carbon Steel Wire Rod for Wire Drawing

InactiveCN102896159BFully oxidizedOxidation GuaranteedWork treatment devicesMetal rolling arrangementsTemperature controlRoom temperature

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com