Automatic forage cutting device

A cutting device, fully automatic technology, applied in the direction of cutting equipment, agricultural machinery and tools, applications, etc., can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

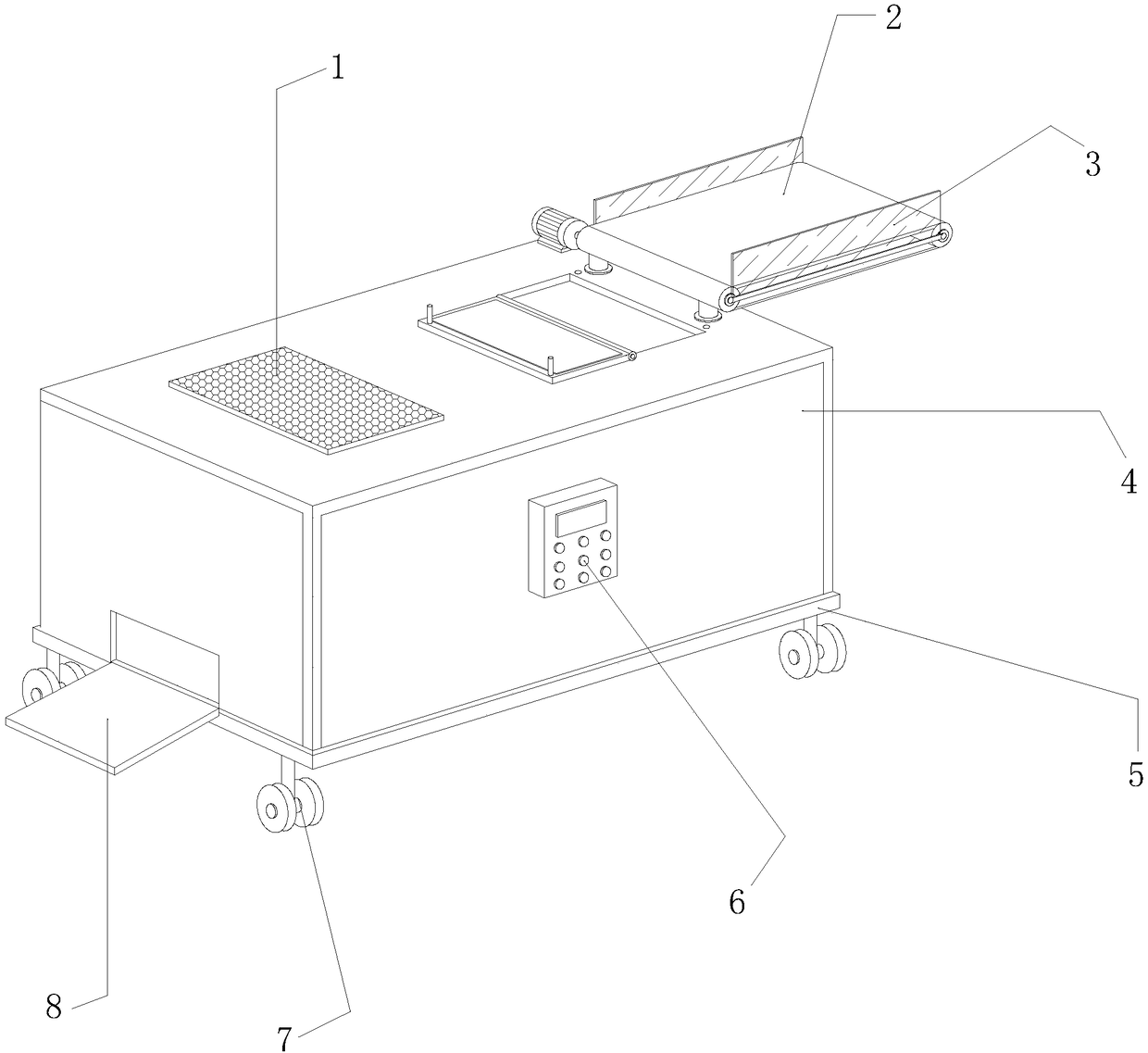

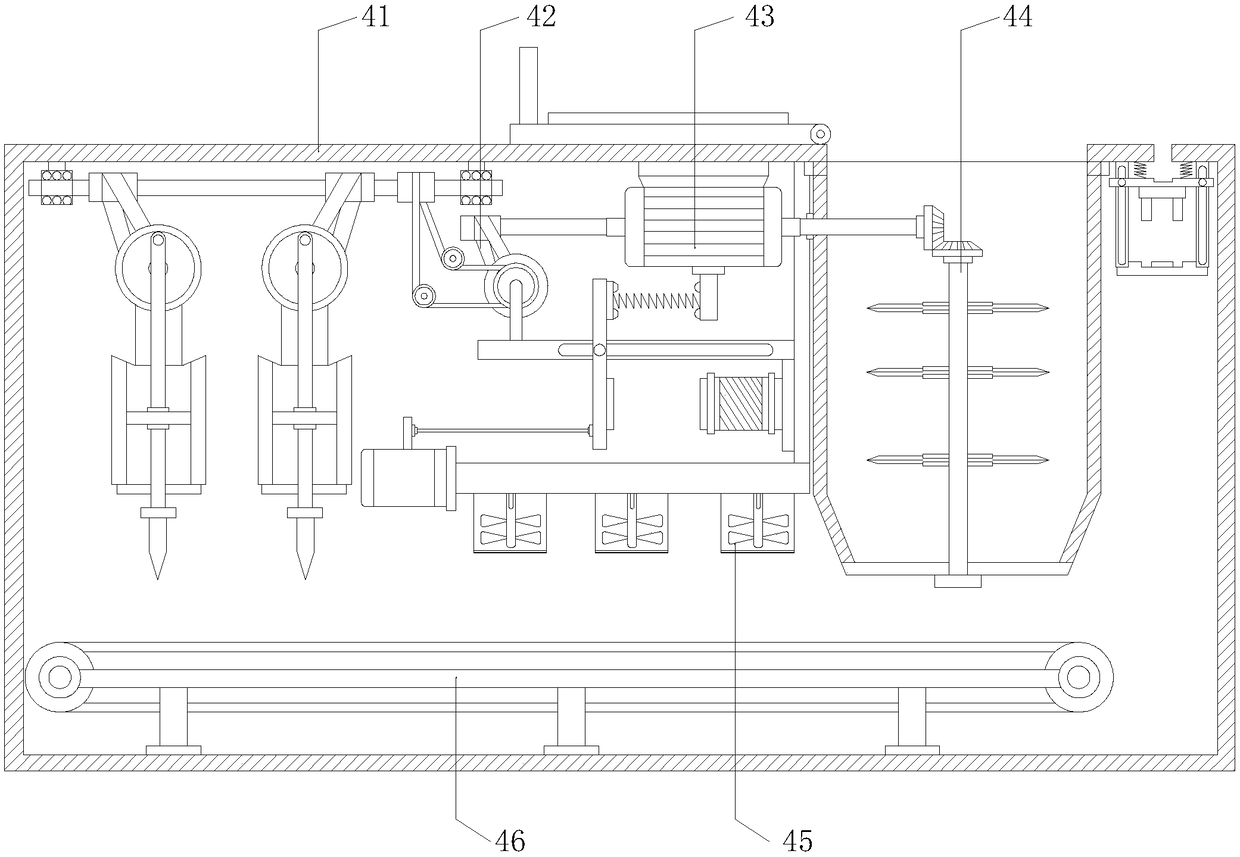

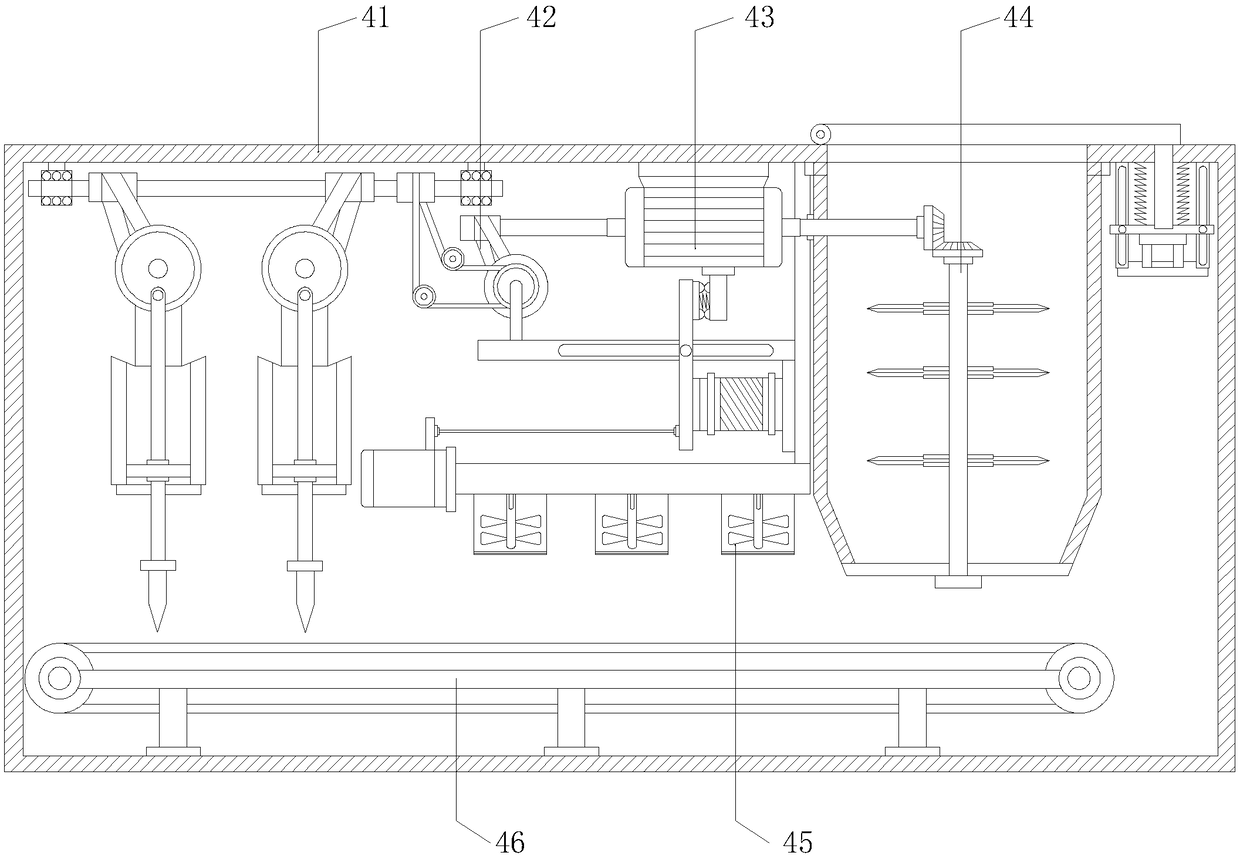

[0027] see Figure 1-Figure 6 , The present invention provides a fully automatic grass cutting device, the structure of which includes a heat dissipation net cover 1, a feeding conveyor 2, a glass baffle 3, a grass cutting and drying device 4, a bottom frame 5, a monitoring controller 6, a universal caster 7, The discharge guide 8, the bottom of the bottom frame 5 is evenly provided with four universal casters 7, the universal casters 7 and the bottom frame 5 are threadedly connected, and the top of the bottom frame 5 is provided with forage cutting ovens. The drying device 4 and the two are interlocked. The monitoring controller 6 is provided on one side of the forage cutting and drying device 4 and the two are matched. The two are hinged, and the top of the forage cutting and drying device 4 is installed with a feeding conveyor 2. The feeding conveyor 2 includes a feeding bracket 21, a first transmission roller 22, a second transmission roller 23, a feeding The feeding moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com