A water jet machine tool with a mobile water sand collection device

A collection device, mobile technology, applied in abrasive feeding device, used abrasive processing device, metal processing equipment, etc., can solve the problem of limited water jet processing field, short circuit of control circuit, inability to collect water-sand mixture, etc. problems, to achieve the effect of low equipment cost, extended service life and strong kinetic energy conversion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

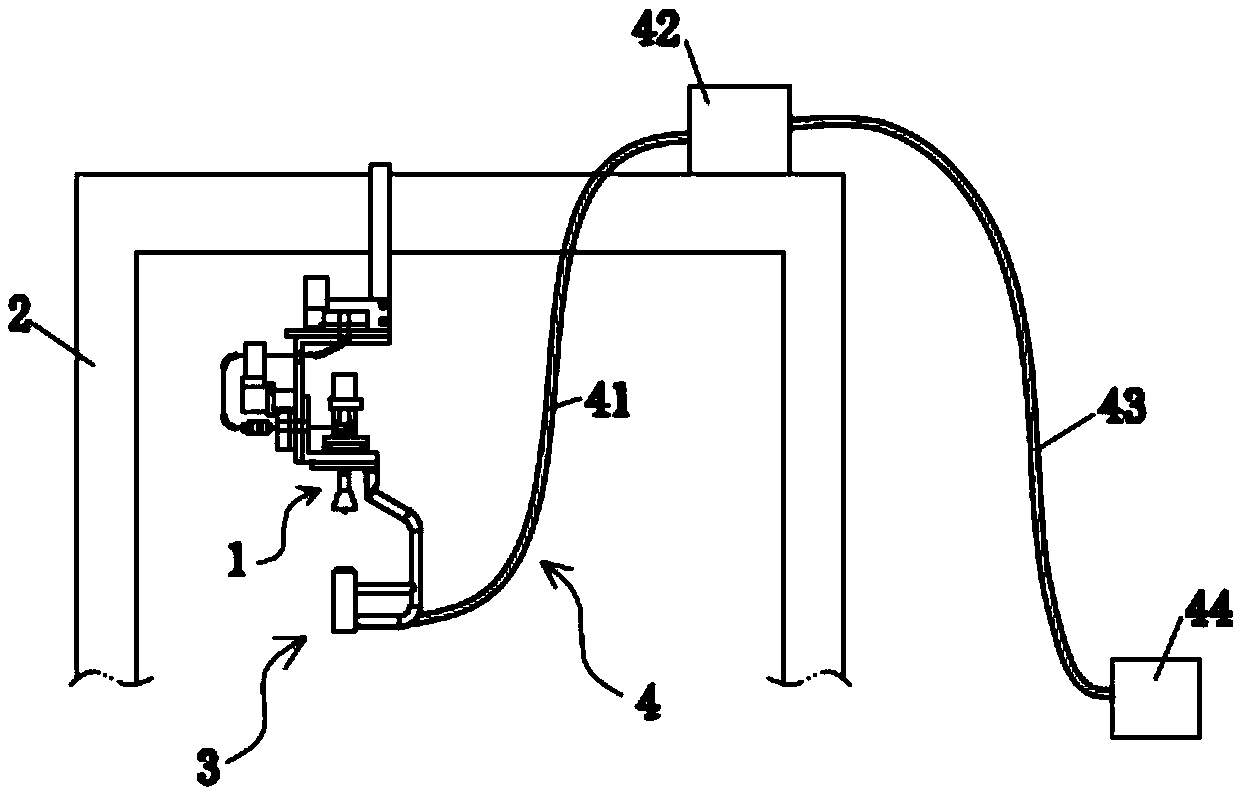

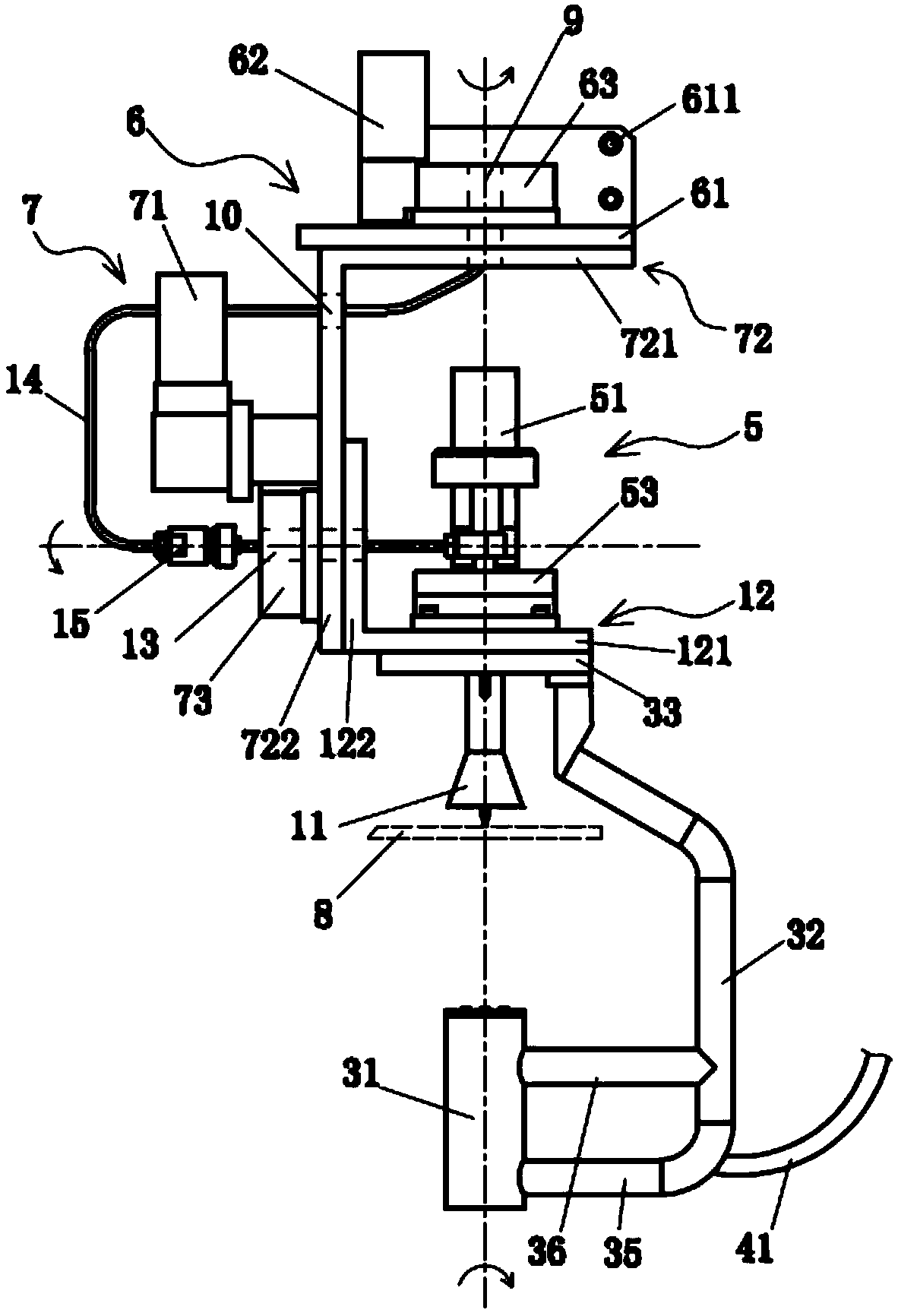

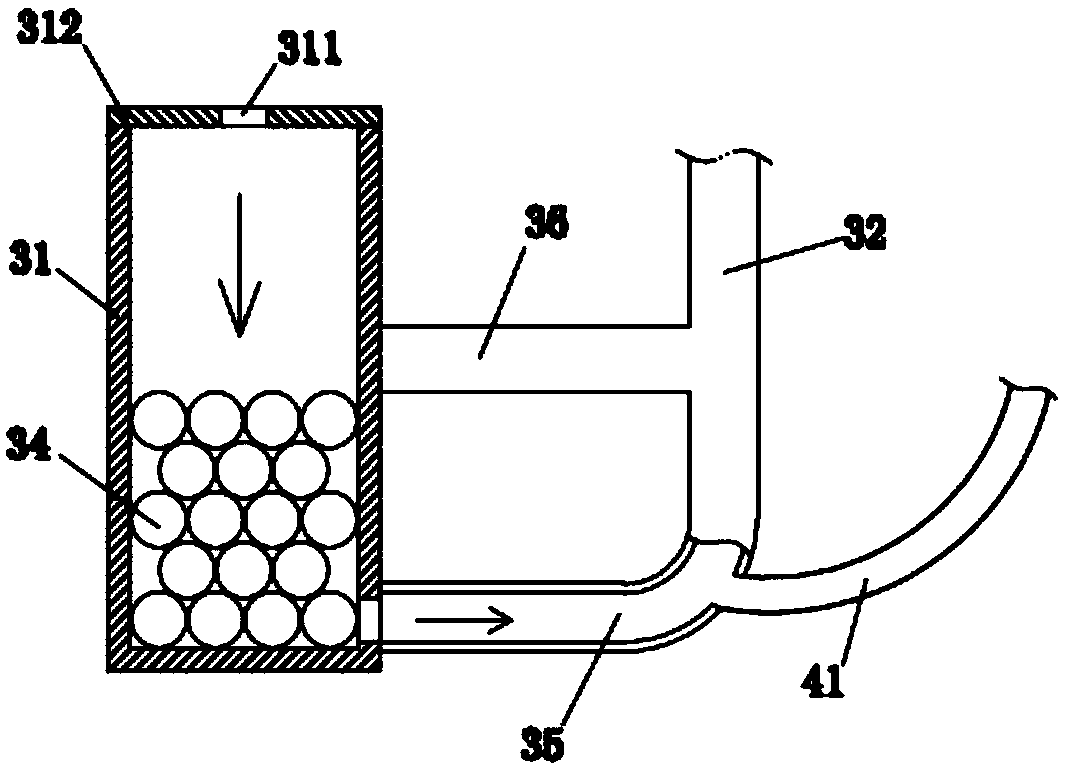

[0032] The specific embodiment of the present invention is as Figure 1 to Figure 4 As shown, a water jet machine tool with a mobile water and sand collection device includes a cutter head assembly 1 and a moving frame 2 that can move horizontally and vertically. The moving frame 2 can be a cantilever structure or a gantry structure , The mobile frame 2 in this embodiment is a gantry structure. Cutter head assembly 1 comprises nozzle 11, also comprises the collection device 3 that moves jointly with nozzle 11, is used to collect the water-sand mixture that it ejects, and this collection device 3 comprises the container 31 that outer wall is provided with water collection hole 311, and water collection hole 311 is arranged opposite to the nozzle 11, and the diameter of the water collecting hole 311 is 1cm-3cm. A connecting piece is provided on the container 31 , and a first driving mechanism 5 capable of rotating the collecting device 3 around the axis of the nozzle 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com