High-temperature-resistant direct-current brushless cooling fan

A brushless DC, cooling fan technology, applied to the components, electromechanical devices, electrical components, etc. of the pumping device for elastic fluid, can solve the problem that the magnetic force cannot be adjusted freely, the temperature of the stator coil is increased, and the reliability of the fan is reduced, etc. problems, to achieve the effect of expanding the heat conduction and heat dissipation area, reducing the failure rate and facilitating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0044] The invention relates to a DC brushless heat dissipation fan, in particular to a high temperature resistant DC brushless heat dissipation fan. The product of the invention can be applied in a high-temperature environment, and can operate without failure for a long time in a working environment of 120°C. The invention aims to solve the problem that the fan itself cannot be directly applied to a high-temperature environment for a long time in the prior art.

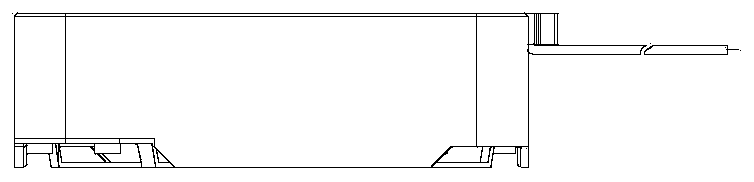

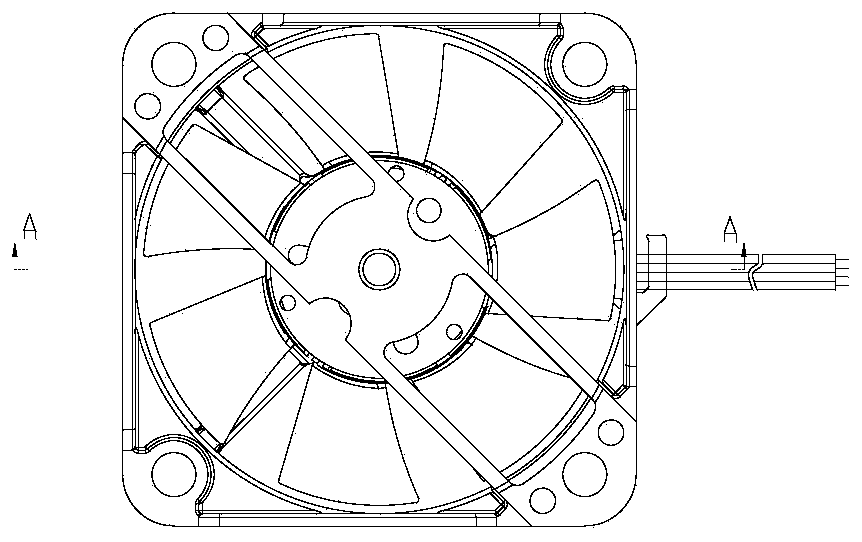

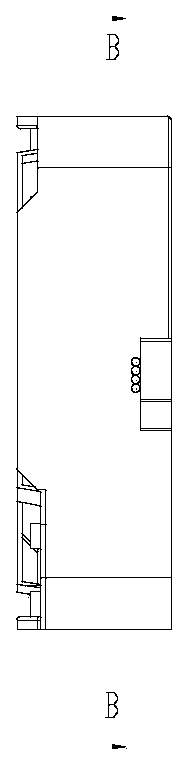

[0045] Such as Figure 1-Figure 11 As shown, a high-temperature-resistant DC brushless cooling fan includes a casing 1, a bearing sleeve 4 is fixed on the lower part of the casing 1, a bearing 7 is wrapped inside the bearing sleeve 4, and a corresponding mated axis 5;

[0046] The bottom of the bearing sleeve 4 passes through the casing 1, and the bottom of the bearing sleeve 4 has at least one c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com