Energy-saving efficient resin-removing method and device for coarse lignite wax

A montan wax and resin removal technology, applied in the field of coal chemical industry, can solve the problems of low resin removal efficiency, high resin content in wax, and low yield of degreasing wax, so as to save steam consumption, reduce the loss of pure wax, and save energy in the process and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

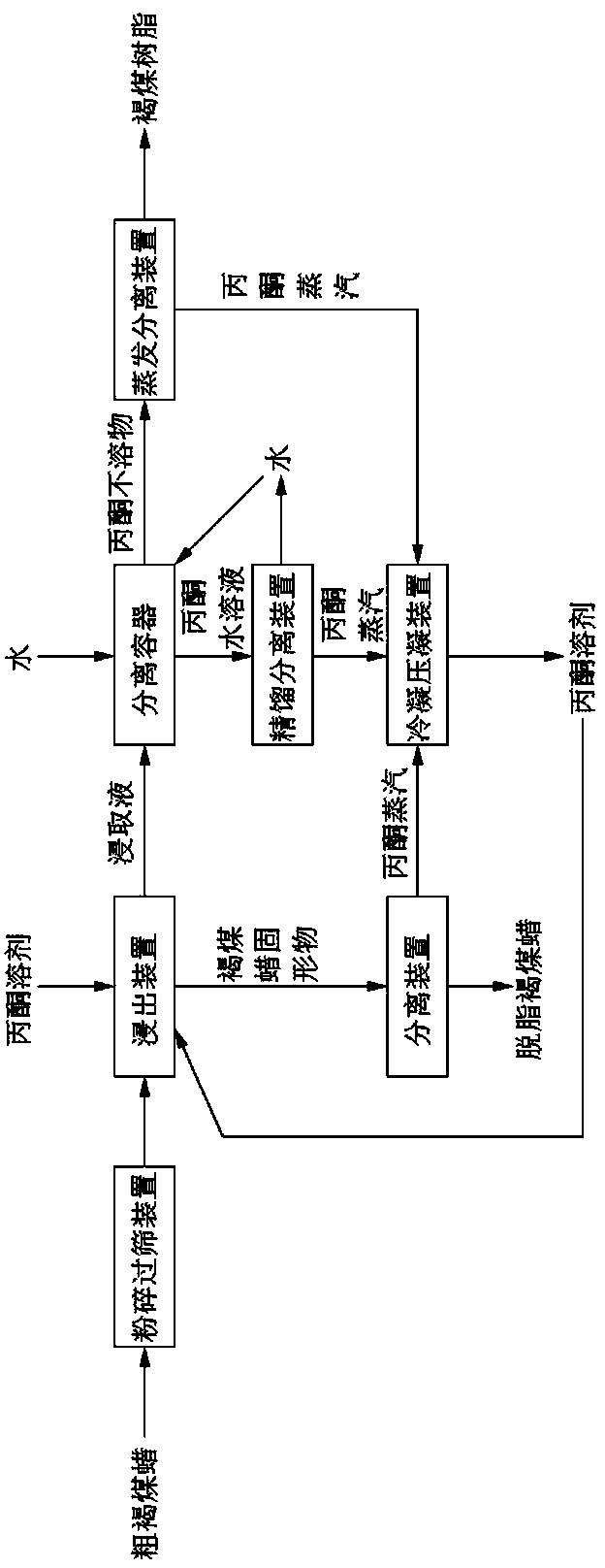

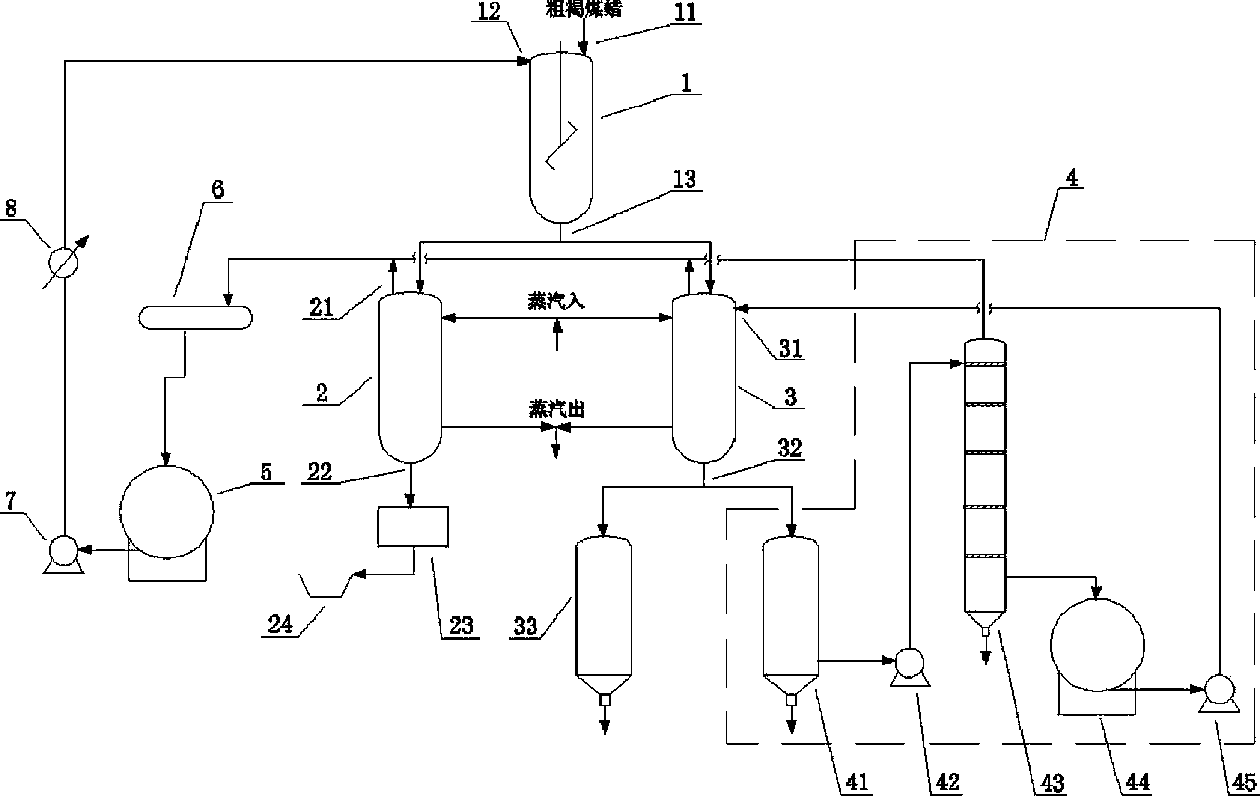

[0043] Such as figure 1 As shown, take the crude montan wax whose resin content accounts for 26.7%, after pulverization, sieve through sieves with apertures of 0.5 mm and 1.5 mm to remove fine powder and coarse particles, and obtain montan wax particles with a particle size of 0.5 to 1.5 mm; Put 50kg of montan wax particles and 250L of acetone solvent into the leaching device, soak and stir at 20°C for 4 hours, and then separate the solid and liquid to obtain the leaching solution and montan wax solids; put the montan wax solids into the separation device, heat Remove the remaining acetone by evaporation to obtain deresinized montan wax and acetone with a resin content of 1.6%; put the leaching solution in a separation container, add water to separate the resin from acetone, and obtain acetone insolubles and acetone aqueous solution through solid-liquid separation , the acetone aqueous solution recovers acetone through rectification, the separated water is recycled, and the ac...

Embodiment 2

[0045] Take the crude montan wax with a resin content of 28.4%, and after crushing, sieve through sieves with apertures of 1.5 mm and 3.0 mm to remove fine powder and coarse particles, and obtain montan wax particles with a particle size of 1.5 to 3.0 mm; crush and sieve the montan wax particles 30kg is placed in a continuous leaching device. Before the first leaching, the liquid level of acetone solvent in the leaching device is higher than the height of the pre-leached montan wax particles. During leaching, 30L of acetone solvent is gradually added, and continuously soaked for 4 hours at an ambient temperature of 10°C After the solid-liquid separation, the leaching solution and the montan wax solids are obtained; the montan wax solids are placed in a separation device, and the remaining acetone is removed through heating and evaporation to obtain deresinized montan wax and acetone with a resin content of 1.8%; Put the leaching solution into a separation container, add water t...

Embodiment 3

[0047] Take the crude montan wax with a resin content of 28.1%, crush it and sieve through sieves with apertures of 1.0 mm and 2.0 mm to remove fine powder and coarse particles, and obtain montan wax particles with a particle size of 1.0 to 2.0 mm; crush and sieve the montan wax particles Put 30kg into the leaching device, spray 240L of acetone solvent on the top of the lignite particles at an ambient temperature of 15°C, extract and spray the solvent leaked from the bottom, and separate the solid and liquid after 2 hours to obtain the leaching solution and solid montan wax Thing; Put the montan wax solid into the separation device, remove the remaining acetone through heating and evaporation, obtain the deresinized montan wax and acetone with a resin content of 1.4%; put the leaching solution into the separation container, add water to make the resin and acetone Acetone separation, acetone insoluble matter and acetone aqueous solution are obtained through solid-liquid separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com