Patents

Literature

34results about How to "Lower latent heat of vaporization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

High-content environmental alcohol ether fuel used for compression ignition engine

InactiveCN105505484AEmission reductionLarge latent heat of evaporationLiquid carbonaceous fuelsFuel additivesAlkaneAlcohol fuel

The invention discloses a high-content environmental alcohol ether fuel used for a compression ignition engine, which belongs to the technical field of alcohol ether fuel clean energy. The alcohol ether fuel comprises the following raw materials: methanol or ethanol or a mixture of methanol and ethanol, toluene, stearic acid, hexamethylphosphoric triamide, a nitryl solvent, acetone, fatty acid methyl ester, n-alkane, N-toluidine, plant oil, an alcohol fuel ether stabilizing agent, a catalysis combustion-supporting agent, an anti-knock reinforcing agent, a cetane number regulator, an eduction agent, an alcohol fuel recognition agent, an alcohol fuel rubber / plastic part corrosion and swelling inhibitor, an alcohol fuel metal corrosion inhibitor, an antioxidant anti-gum inhibitor, a metal deactivator, a corrosion inhibitor, an antistatic agent, a purification dispersant, an anti-wear repair agent, and an alcohol fuel sterilizing agent. The high-content environmental alcohol ether fuel has the advantages of stable performance, strong power, full combustion, good anti-knock property, good acceleration speed, easy starting, no air resistance, and low fuel consumption, and is especially suitable for the compression ignition engine.

Owner:SICHUAN ZHENGJIA NEW ENERGY TECH CO LTD

Liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent

InactiveCN110052117AAchieve enrichmentReduce total fluid volumeDispersed particle separationAir quality improvementFluid phaseEnvironmental engineering

The invention provides a liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent. The liquid-liquid phase-change absorbent for capturing the carbon dioxidecomprises, by mass, 20%-60% of synergist, 10%-50% of organic amine, 0%-5% of auxiliary agent and the balance water. The liquid-liquid phase-change absorbent for capturing the carbon dioxide has the advantages that the liquid-liquid phase-change absorbent can be automatically layered into liquid-liquid phases when loading a certain amount of CO2 in the absence of energy consumption, wherein CO2 gathers in a rich phase layer, and a lean phase layer hardly loads CO2, so that CO2 can be effectively concentrated in the rich phase, the total amount of liquid entering a regenerating column is decreased through desorption of the CO2 rich phase, and energy consumption for regeneration and capture cost are reduced.

Owner:HUANENG POWER INT INC +1

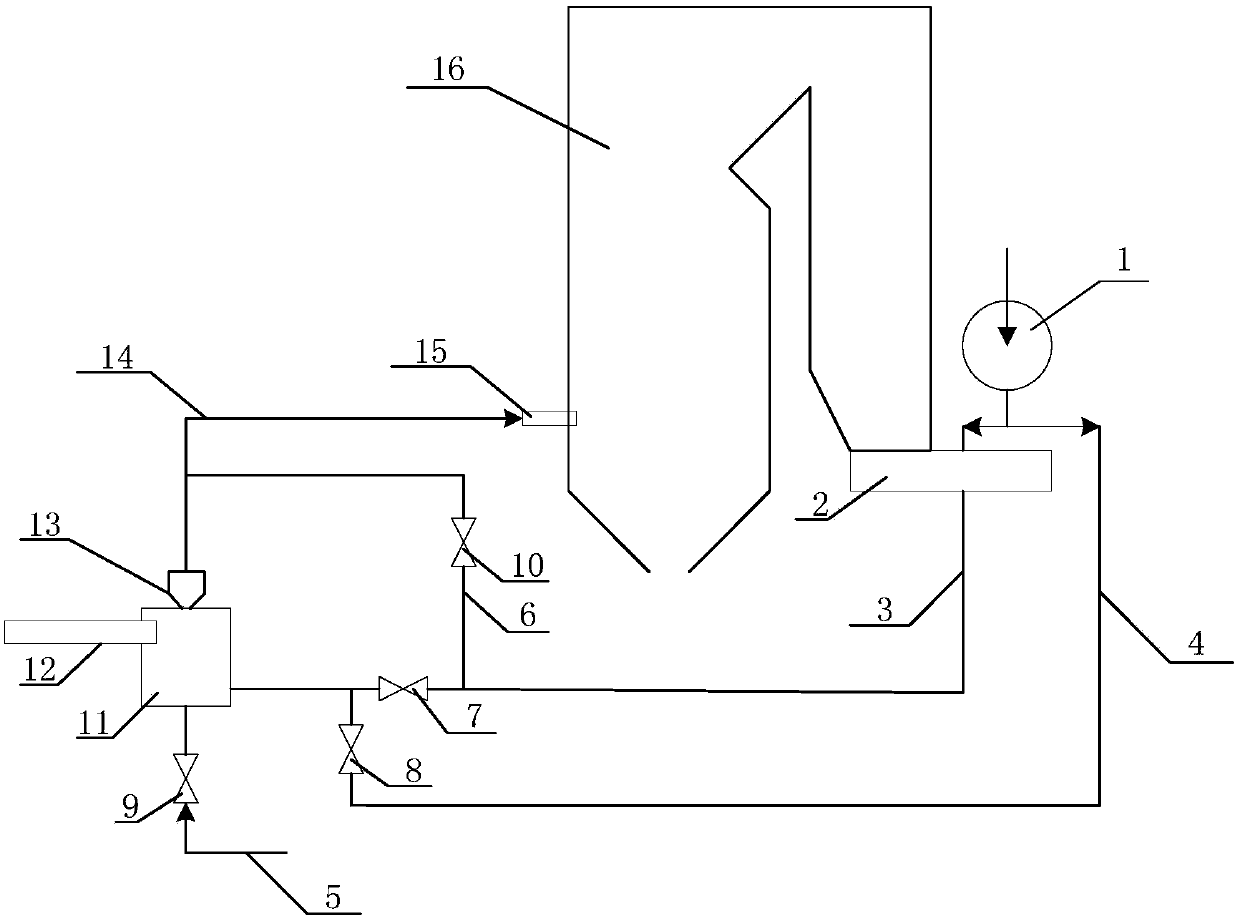

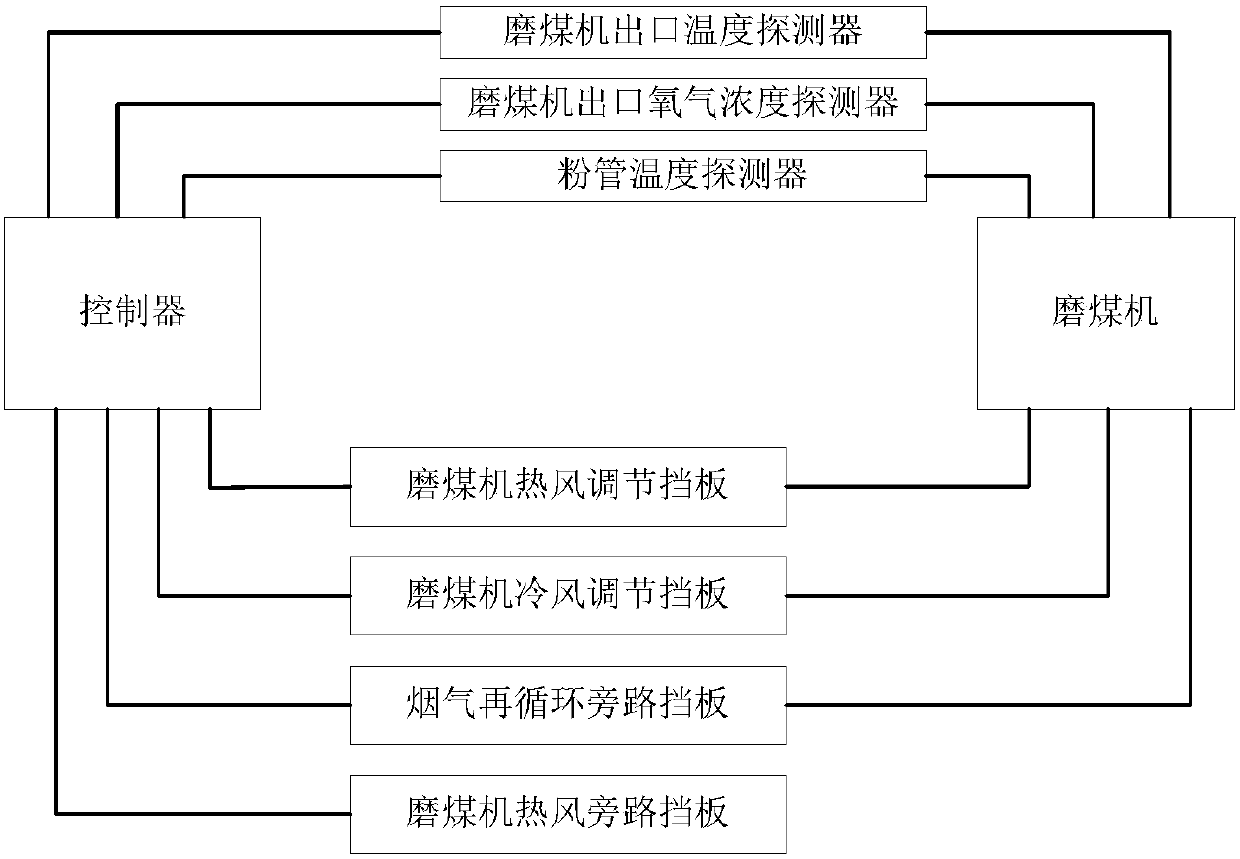

Energy-saving optimal control system and method for outlet temperature of medium-speed coal mill in supercritical unit

ActiveCN107855210AHigh outputImprove combustion stabilityIndirect carbon-dioxide mitigationGrain treatmentsCold airCombustor

The invention discloses an energy-saving optimal control system and method for the outlet temperature of a medium-speed coal mill in a supercritical unit. The system comprises a primary draught fan, an air pre-heater, a hot primary air pipe, a cold primary air pipe, a smoke recycling bypass pipeline, a coal mill hot air bypass pipeline, a coal mill hot air adjusting baffle, a coal mill cold air adjusting baffle, a smoke recycling bypass baffle, a coal mill hot air bypass adjusting baffle, a coal mill, a coal feeder, a rough powder separator, a primary air powder pipeline, a combustor, a boiler, a controller, a coal mill outlet temperature detector, a coal mill outlet oxygen concentration detector and a powder pipe temperature detector. By means of the energy-saving optimal control system and method, the smoke recycling bypass pipeline is additionally arranged in a medium-speed coal mill direct blowing type powder manufacturing system, the outlet temperature of the coal mill is increased, and single powder consumption is reduced; and the coal mill hot air bypass pipeline is additionally arranged at the outer portion of the coal mill so that decoupling control over the outlet temperature of the coal mill and the air powder temperature in the primary powder pipe is achieved, the coal powder fire catching and combustion stabilizing performance is improved, and the adaptability of acoal-fired powder unit participating in depth peak regulating is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

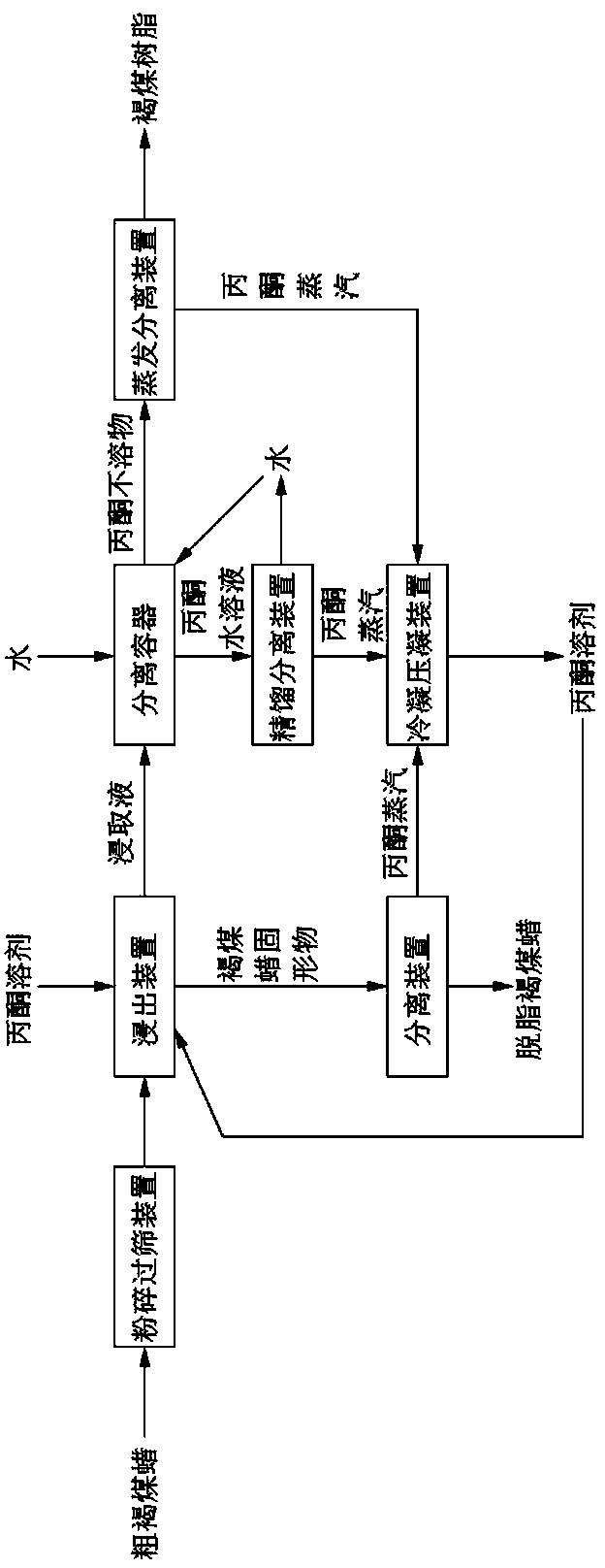

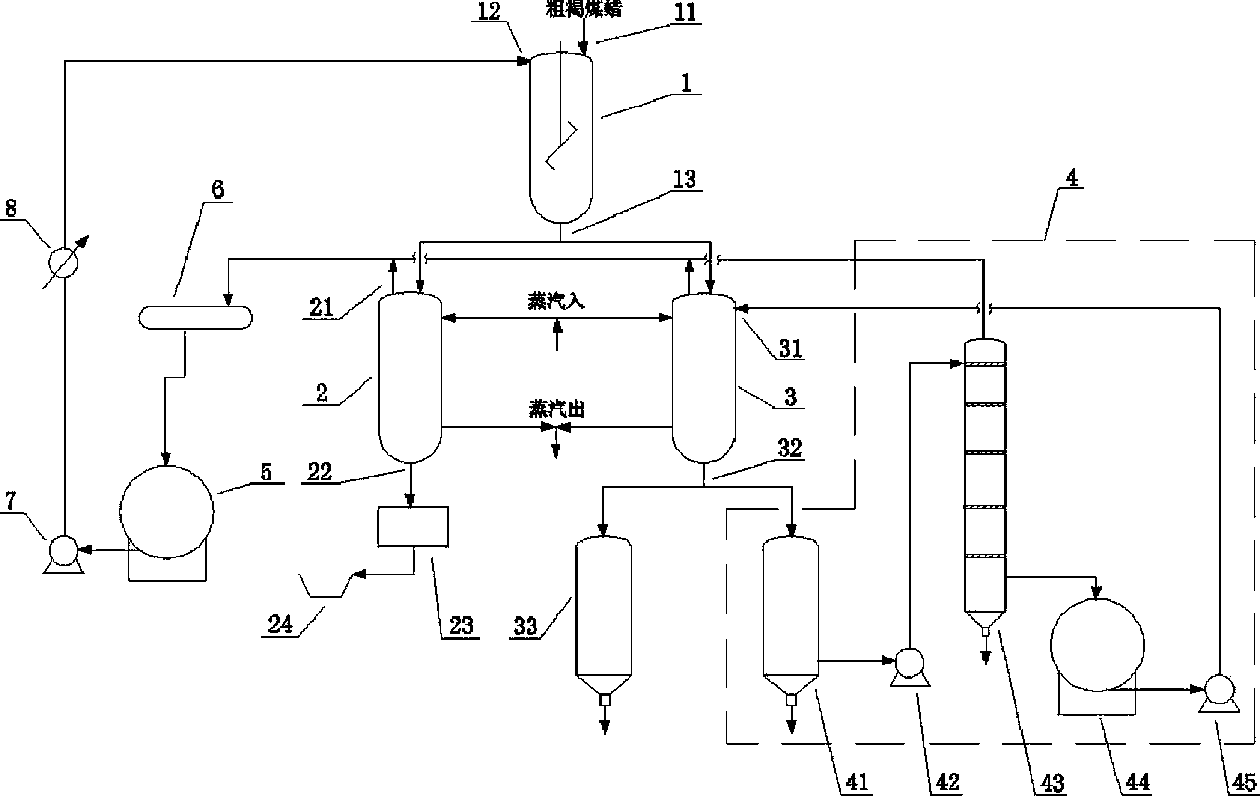

Energy-saving efficient resin-removing method and device for coarse lignite wax

ActiveCN103897734AEasy to recycleConsumableMineral wax recovery/refiningAqueous acetoneAqueous solution

The invention discloses an energy-saving efficient resin-removing method and device for coarse lignite wax. The resin-removing method comprises the following steps: smashing coarse lignite wax and sieving the smashed coarse lignite wax by a 0.5-3.0mm sieve; then, leaching the sieved lignite wax particles and acetone in a solid-to-liquid ratio of 1:1-1:8kg / L at constant temperature for 2-4 hours and separating to obtain a leaching liquid and a solid; placing the solid in a separating device, and heating, evaporating and removing residual acetone to obtain degreased lignite wax; placing the leaching liquid in a separating container, adding water to separate resin from acetone, and carrying out solid-liquid separation to obtain acetone insolubles and an acetone aqueous solution; and recovering acetone by rectifying the acetone aqueous solution; and evaporating the acetone insolubles to obtain walchowite. The degreasing device comprises a degreasing kettle, a ceride-removing desolventizing tank, a resin desolventizing separating tank, a rectifying device, an acetone storage tank and a condenser. According to the energy-saving efficient resin-removing method and device disclosed by the invention, as resin in lignite wax is easy to dissolve in acetone at constant temperature, wax and asphaltos are not dissolved, and the resin content in wax is reduced by digestion and separation at constant temperature, so that the device is simple and energy-saving and environment-friendly in process.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

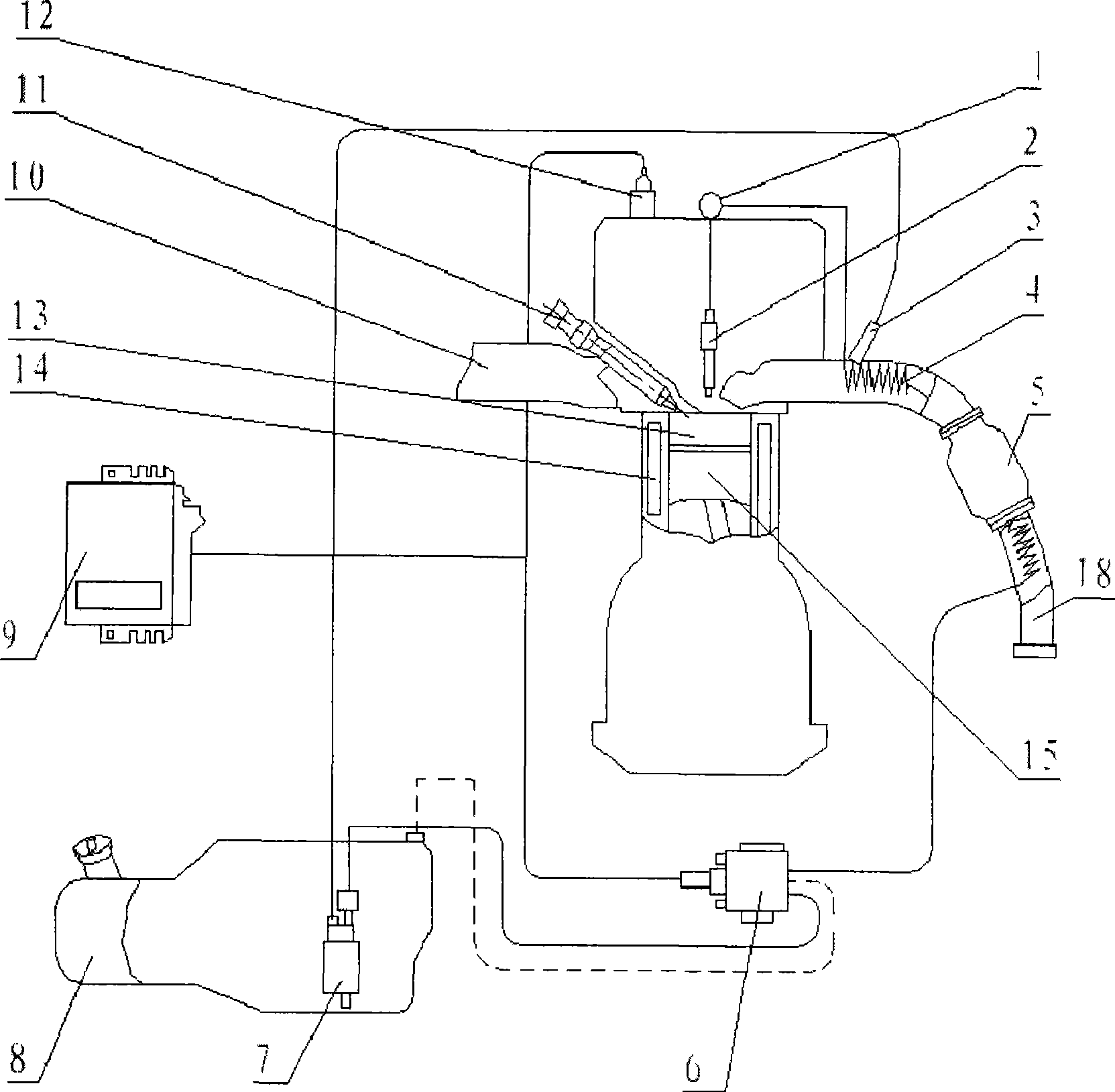

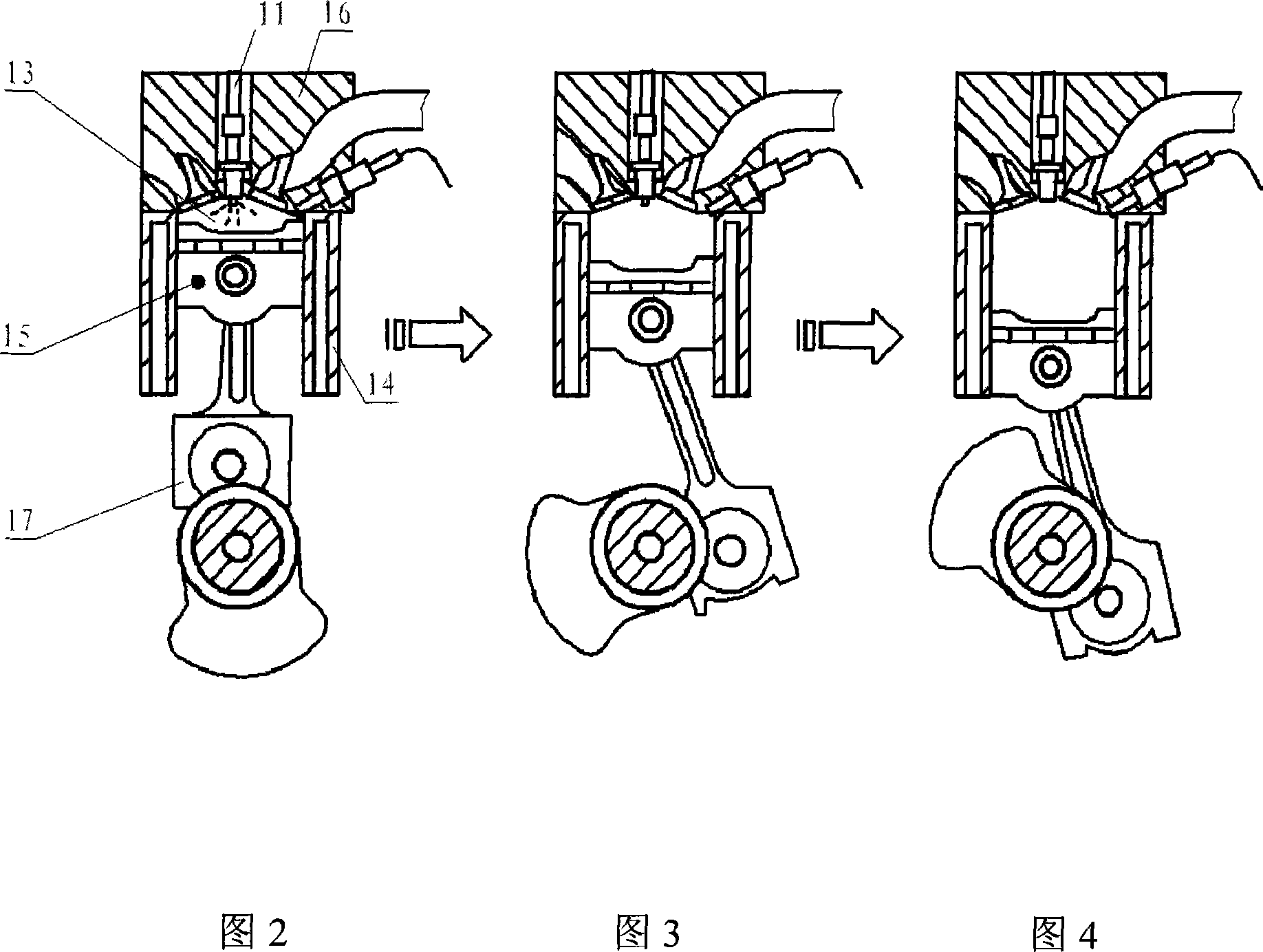

Subcritical steam auxiliary power gasoline engine

InactiveCN101457713AEfficient emissionsReduce fuel consumptionInternal combustion piston enginesNon-fuel substance addition to fuelPipingInjector

The invention relates to a subcritical vapor auxiliary work done gasoline engine which comprises a water injector in a cylinder of the gasoline engine, wherein, the water injector comprises a water tank, an electric control unit, and water pumps, a water guideway, a water injection nozzle and a temperature sensor which are controlled by the electric control unit. The water injector is characterized in that the water pumps comprise a low pressure water pump and a high pressure water pump pressurizing water to be above 200bar, the low pressure water pump is arranged in the water tank and is communicated with the high pressure water pump, the high pressure water pump is communicated with the water guideway by a high pressure water pipe, the water injection nozzle is communicated with the water guideway, and a water injection opening extends into a combustion chamber of the gasoline engine. The gasoline engine also comprises a gasoline engine exhaust pipe used for heating water to above 250 DEG C and not more than 374.2 DEG C, and a high pressure water pipe penetrates through the exhaust pipe and then is communicated with the water guideway. The gasoline engine utilizes the waste heat of engine tail gas to do work circularly, thereby saving oil; the temperature of water injected into the cylinder is in a subcritical state, and the water is instantaneously vaporized in the cylinder under the pressure condition, thereby increasing the explosion pressure of the cylinder; and the torque output and the power are improved under the premise that the oil injection amount is not increased.

Owner:MIANYANG XINCHEN ENGINE

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN100412175CImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideAlcohol

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

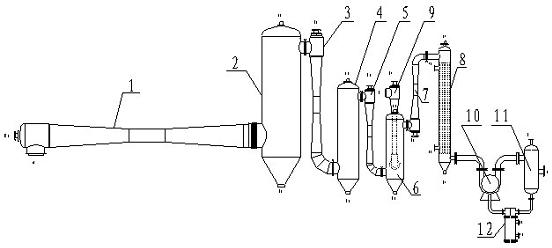

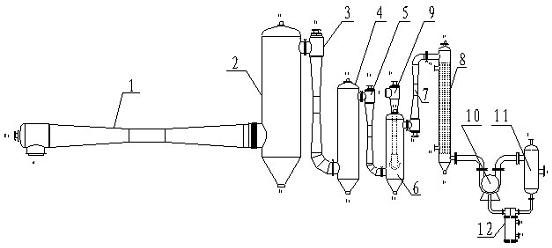

Butanediol spraying vacuum pump and working method thereof

ActiveCN102536919AReduce energy consumptionReduce maintenanceJet pumpsMachines/enginesContinuous operationMoving parts

The invention relates to a butanediol spraying vacuum pump. The pump of the invention is characterized in that a primary butanediol sprayer is connected with a lower portion of a primary condenser, an upper portion of the primary condenser is connected with an upper portion of a secondary butanediol sprayer, a lower portion of the secondary butanediol sprayer is connected with a lower portion of a secondary condenser, an upper portion of the secondary condenser is connected with an upper portion of a third butanediol sprayer, a lower portion of the third butanediol sprayer is connected with a lower portion of a third condenser, an upper portion of the third condenser is connected with a lower portion of a fourth butanediol sprayer, a third auxiliary steam sprayer is communicated with an upper end of the third condenser, an upper portion of the fourth butanediol sprayer is communicated with an upper portion of a fourth condenser, a lower portion of the fourth condenser is connected with a vapor-liquid separator by a liquid-ring vacuum pump, one end of a heat exchanger is communicated with the liquid-ring vacuum pump and the other end of the heat exchanger is communicated with the vapor-liquid separator. The butanediol spraying vacuum pump has the advantages that: no waste liquid is discharged; the energy consumption is reduced; the steam spray vacuum pump in the invention has no moving part during runtime, the butanediol spraying vacuum pump is suitable for long-term and continuous operation, and the maintenance period is prolonged.

Owner:杭州华达喷射真空设备有限公司

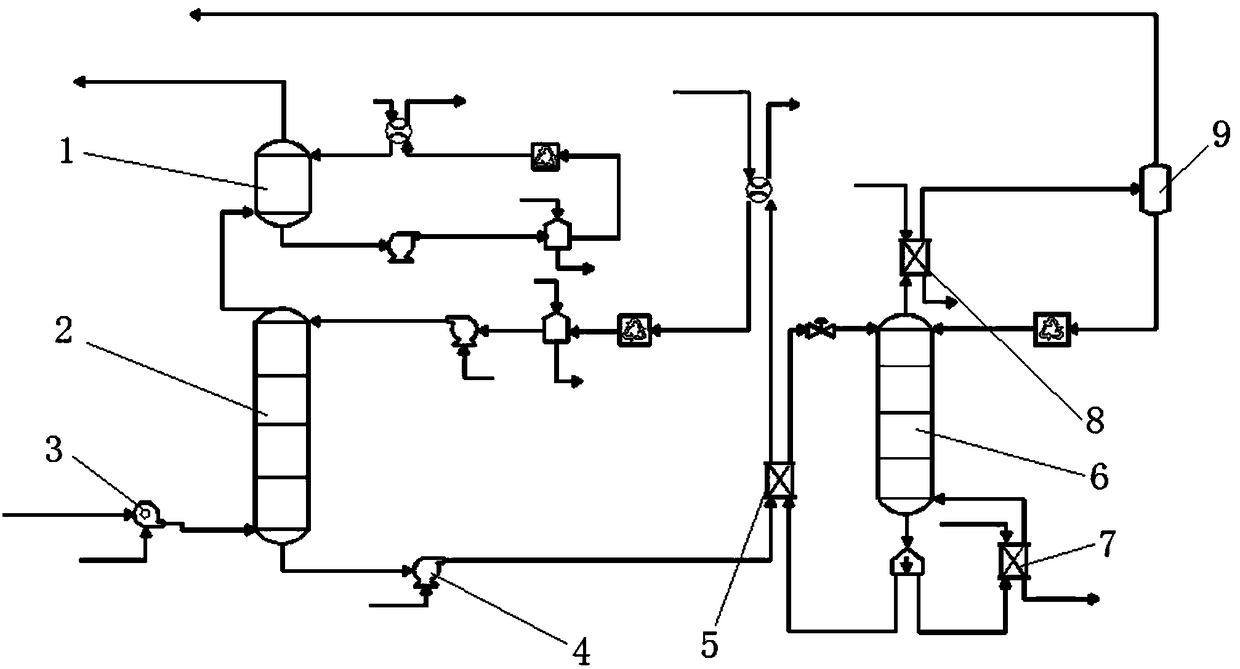

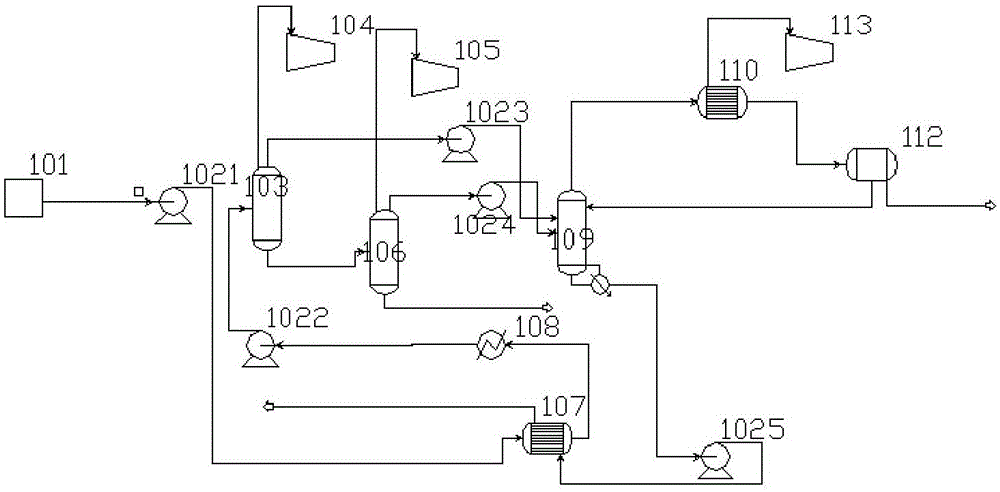

Optimized carbon dioxide capture process

InactiveCN108568192AFull recoverySolve the problem of energy consumptionGas treatmentDispersed particle separationVapor–liquid separatorReboiler

The invention discloses an optimized carbon dioxide capture process, which solves the problems of high regeneration energy consumption and high investment in the carbon dioxide capture process of theprior art and has the effects of reducing heat loss, sufficiently recovering solution in tail gas and reducing cost. The technical scheme is characterized in that the optimized carbon dioxide captureprocess comprises the following steps: under the function of a fan, exhaust gas is dehydrated and cooled and then gets into an absorption tower to flow from bottom to top, alkanolamine solution is fedas absorption solution from the top of the absorption tower, and the absorption solution is in countercurrent contact with the exhaust gas to remove carbon dioxide; the purified decarbonized exhaustgas gets into a water scrubbing tower; enriched liquid absorbed from the bottom of the absorption tower is sent into a heat exchanger by an enriched liquid pump, the enriched liquid gets in from the top of a regeneration tower after heat exchange, and after stripping desorption, the enriched liquid is sent into a reboiler and reboiled; gas mixture which is discharged from the top of the regeneration tower is guided into a heat exchanger to undergo water cooling, and then gets into a gas-liquid separator to undergo gas-liquid separation, and separated liquid is guided into the water scrubbing tower.

Owner:青岛海山减碳环保科技有限公司

Absorption distillation method for using adsorption resin to treat waste water containing dimethyl formamide

InactiveCN101693668BImprove adsorption capacityReduce dosageCarboxylic acid amide separation/purificationWater/sewage treatment by sorptionDesorptionWastewater

The invention provides an absorption distillation method for using adsorption resin to treat waste water containing dimethyl formamide, belonging to the technical field of treatment of waste water containing dimethyl formamide, and solving the defects of the multi-column distillation and extraction-distillation process in prior art. The absorption distillation method for using adsorption resin totreat the waste water containing dimethyl formamide comprises the steps of using macroporous absorption resin to absorb before distillation of the waste water containing dimethyl formamide, using desorption agent to desorbing the resin, getting the mixed liquid of dimethyl formamide DMF and the desorption agent, delivering the mixed liquid into a rectifying column to implement normal pressure separation or reduced pressure separation, and getting the distillated dimethyl formamide DMF from the bottom of the rectifying column. Compared with the prior art of DMF waste water energy-saving recovery, the invention further reduces DMF recovering energy consumption without causing secondary pollution under the condition of ensuring high DMF recovery ratio, and has good practicality and economic performance.

Owner:FUZHOU UNIV

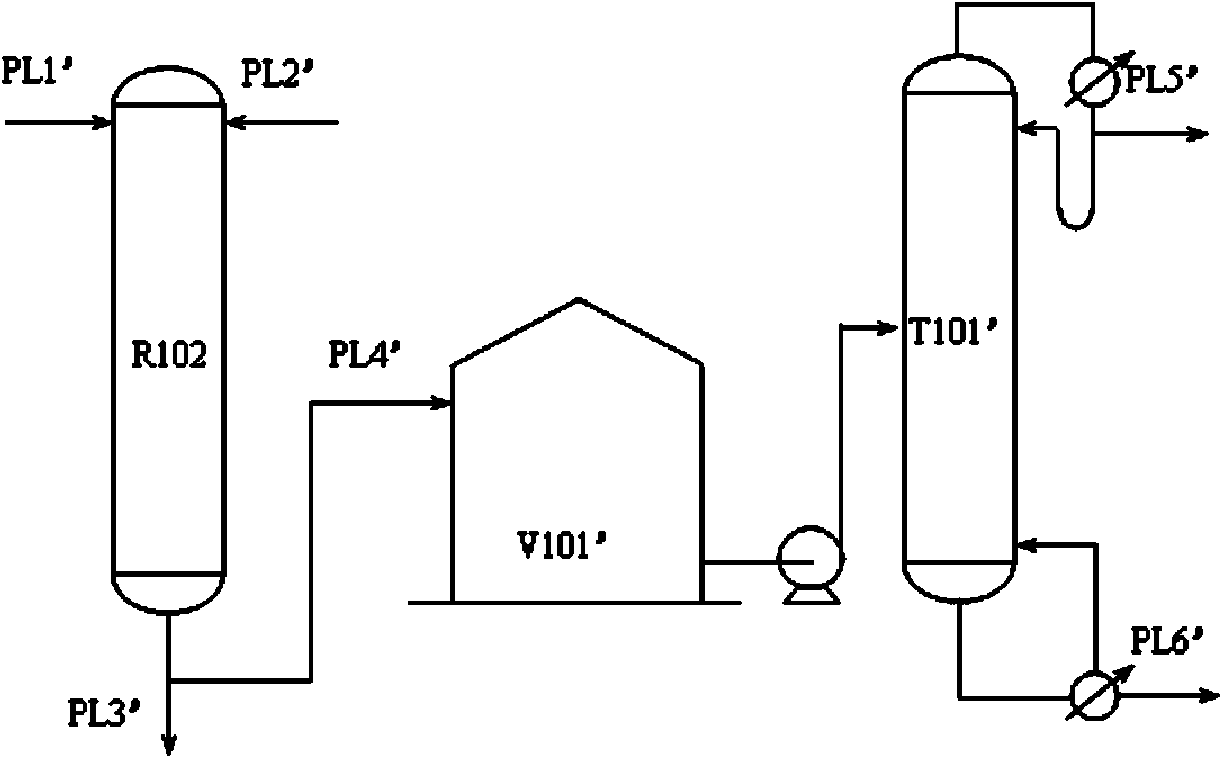

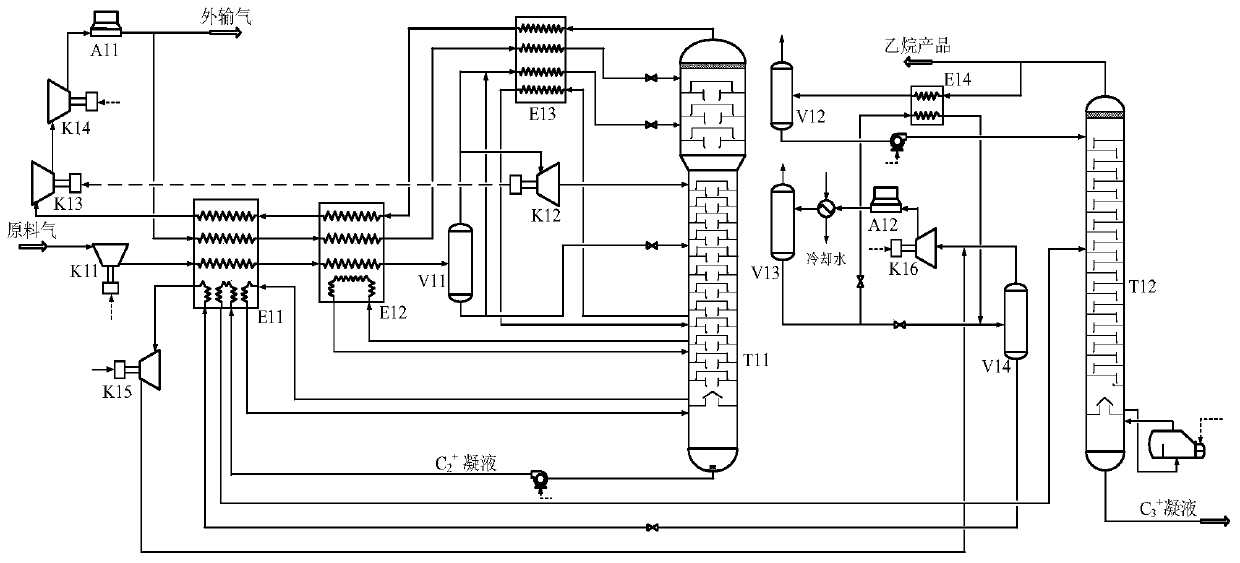

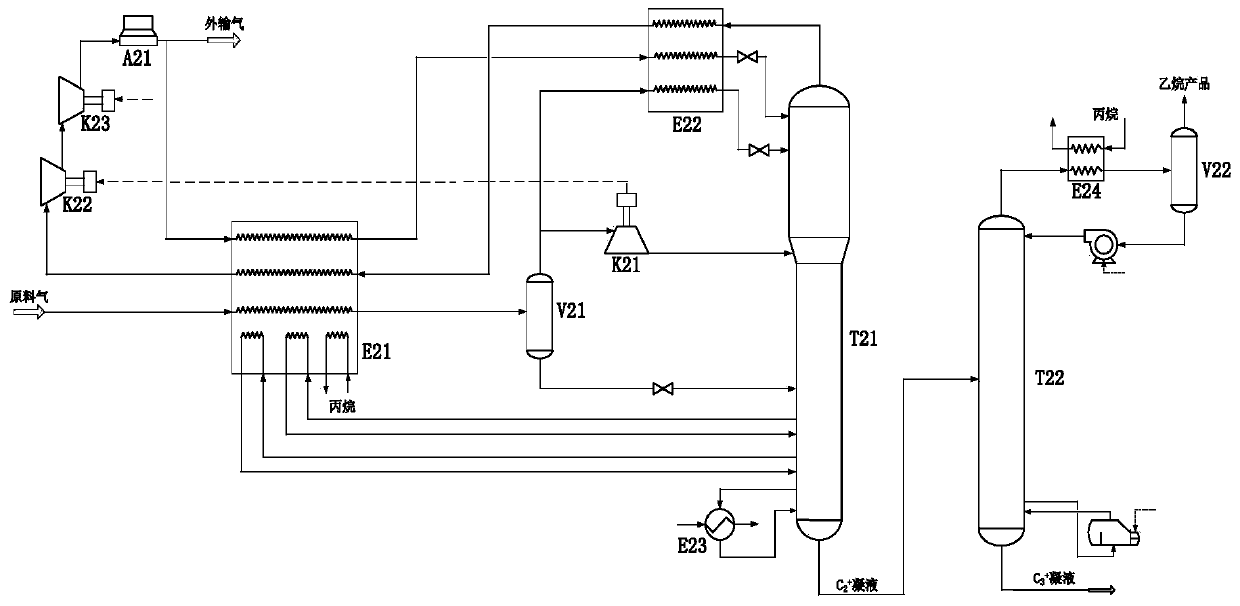

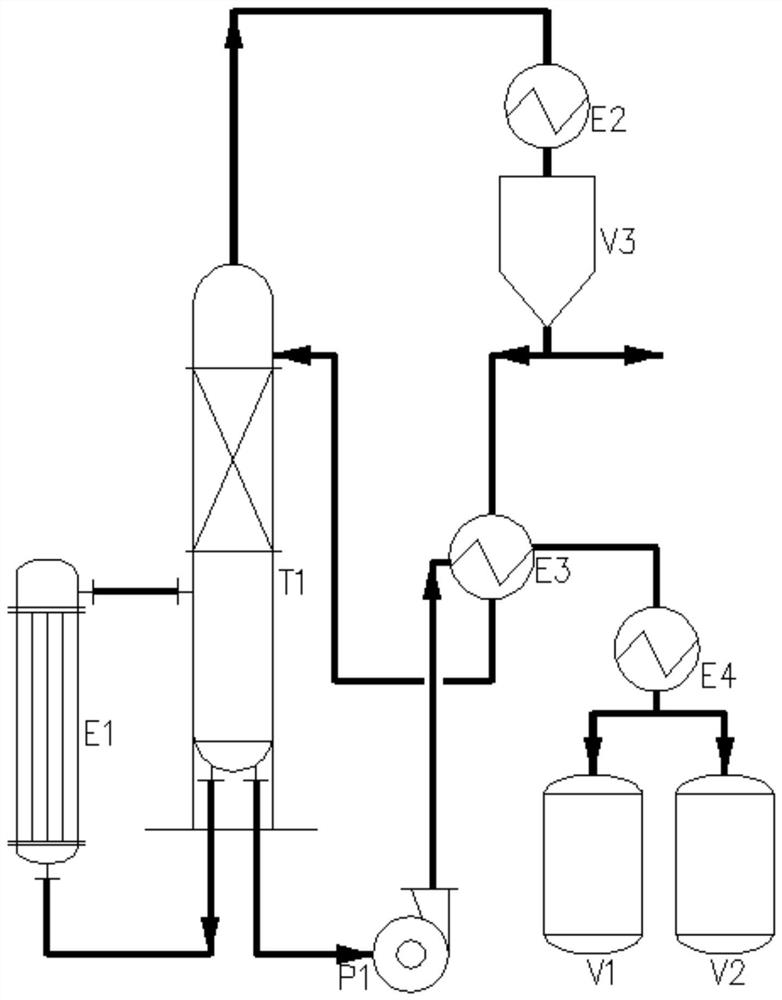

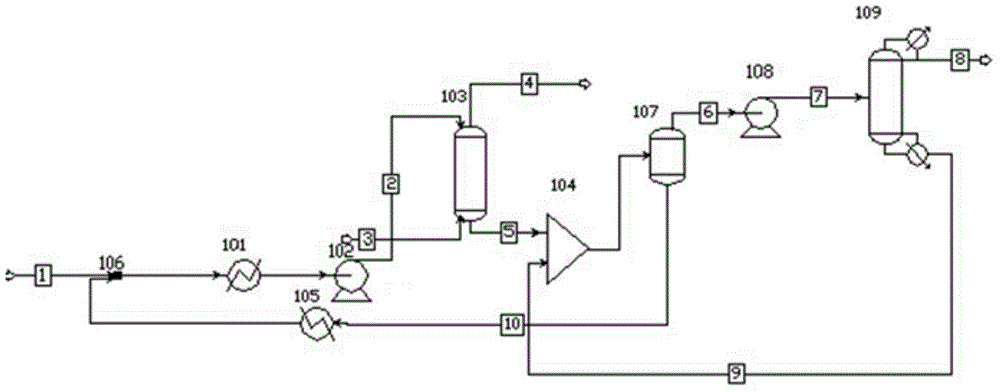

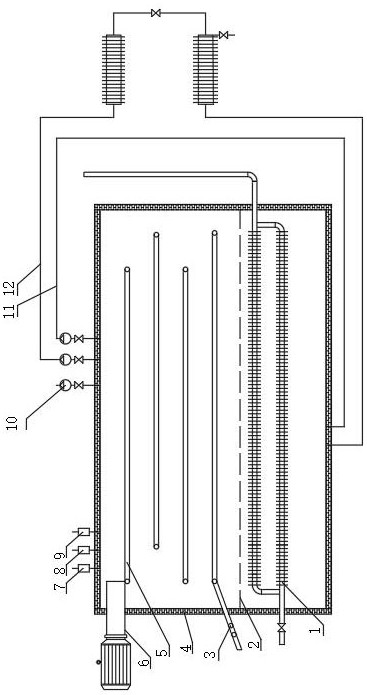

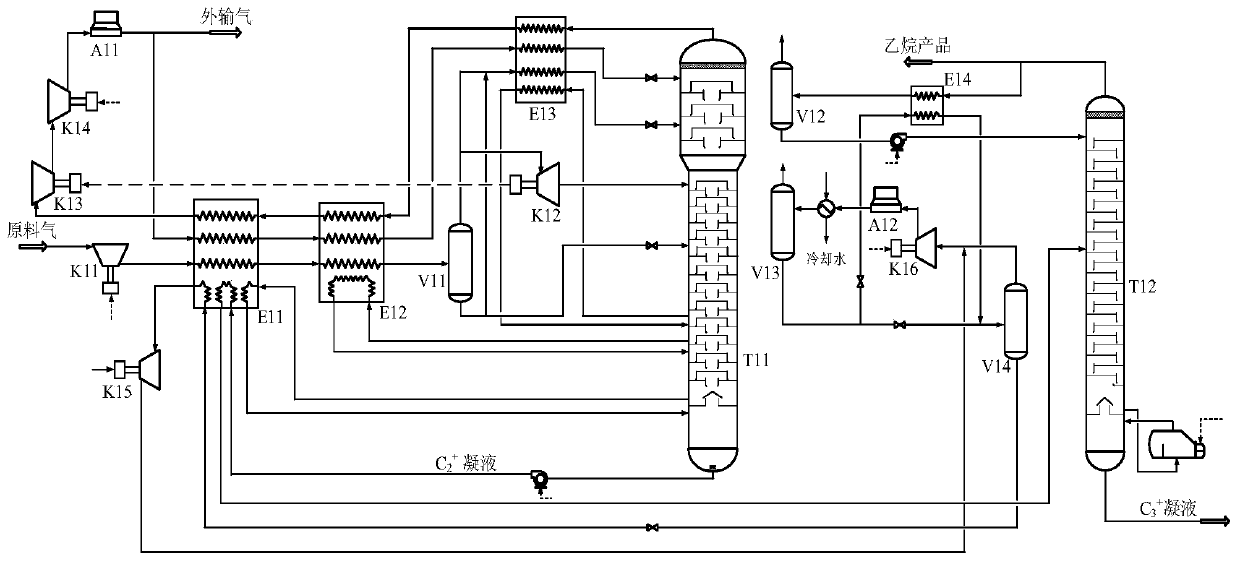

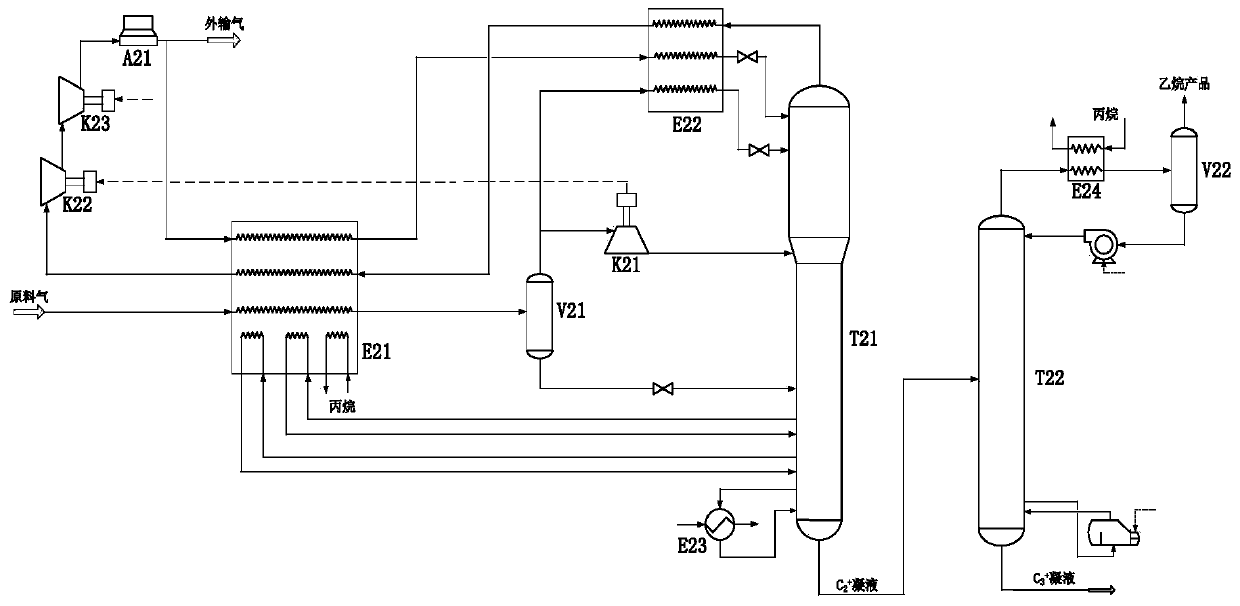

Ethane recovery method using combination of pre-pressurization and propane refrigeration

ActiveCN110563540AReduce circulationLower latent heat of vaporizationHydrocarbon purification/separationHydrocarbonsRecovery methodEngineering

The invention discloses an ethane recovery method using a combination of pre-pressurization and propane refrigeration, belonging to the technical field of natural gas processing. The method is established on the basis of a conventional ethane recovery process; directed at the characteristic that a low-pressure rich gas ethane recovery process has great demand for cooling capacity, the method adopts the combination of feed gas pre-pressurization and propane refrigeration; so the refrigerating capacity of an expansion machine can be increased under the working condition that the pre-cooling capacity of the feed gas is insufficient, and the ethane recovery process has a high ethane recovery rate (greater than 95%) under a low-pressure rich gas working condition. According to the method, a compressor is arranged at a process inlet to pressurize the feed gas, so latent heat of vaporization of the feed gas is effectively reduced in a high-pressure state, cooling quantity required by precooling of the feed gas is reduced, and the circulation quantity of propane is reduced; and thus, the energy consumption of a refrigeration cycle compressor and total energy consumption of the process arereduced under the condition that high ethane recovery rate is guaranteed. Meanwhile, compared with an ethane recovery process with the same ethane recovery rate and with a stepped refrigeration cycleor mixed refrigerant cycle, the whole process structure of the method in the invention is greatly simplified, and the design and operation of the method are easy.

Owner:SOUTHWEST PETROLEUM UNIV

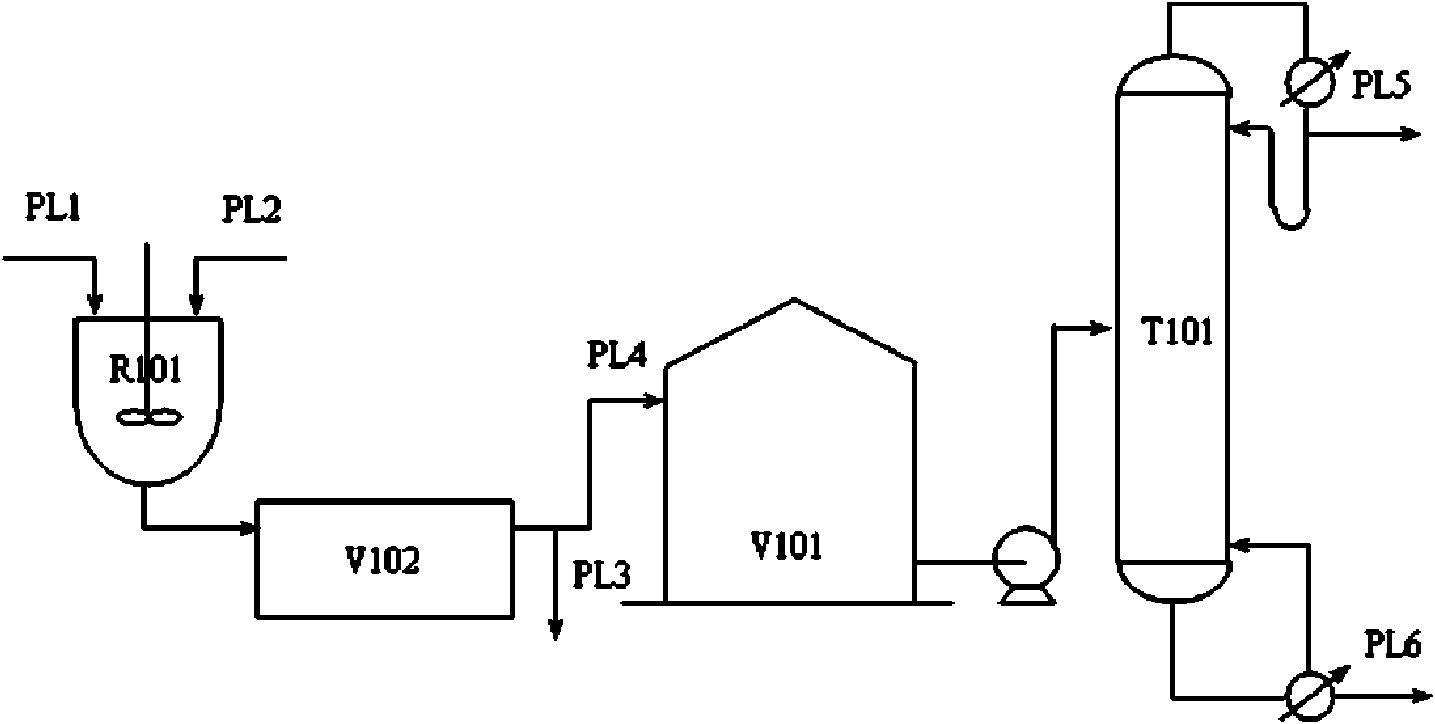

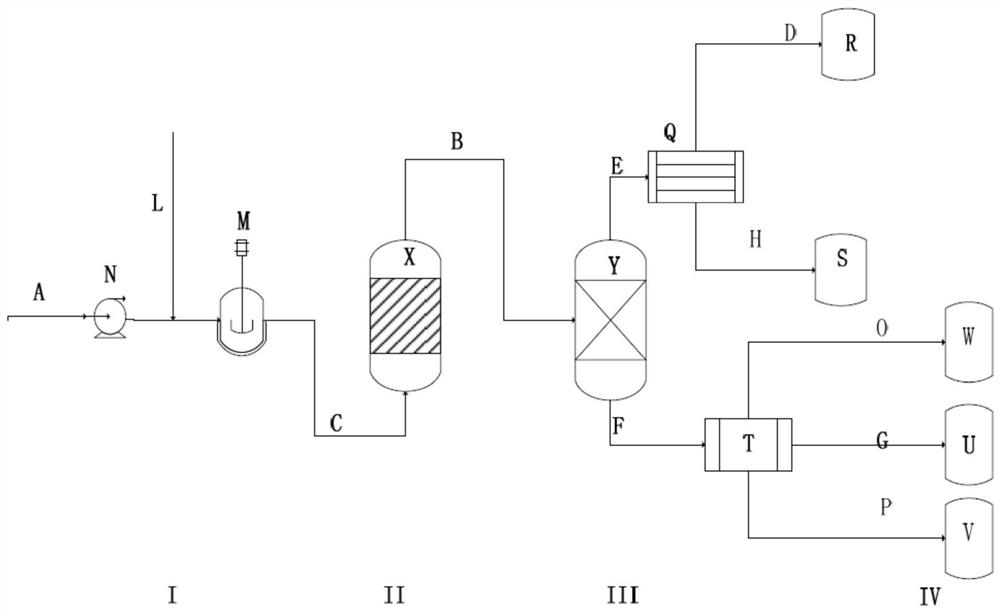

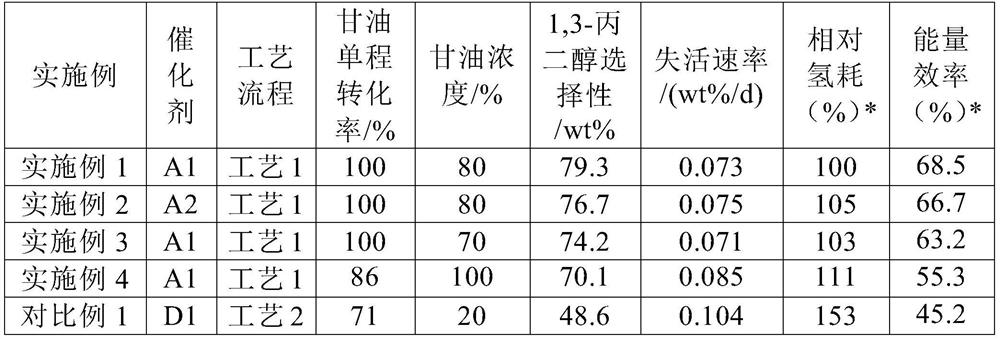

Method and system for preparing 1,3-propylene glycol from glycerol

PendingCN113527062ALower latent heat of vaporizationImprove solubilityOrganic compound preparationCatalystsSide productPropylene glycol

The invention provides a method and system for preparing 1,3-propylene glycol from glycerin; the method comprises the following steps: mixing a glycerin aqueous solution with hydrogen, introducing the obtained mixture into a hydrogenation unit, contacting the glycerin aqueous solution, hydrogen and a catalyst under reaction conditions, and carrying out a reaction to generate a hydrogenation mixed product containing 1,3-propylene glycol; and introducing the hydrogenated mixed product into a separation unit, and separating out 1, 3-propylene glycol and a by-product, wherein the catalyst comprises a carrier and an active component loaded on the carrier, the carrier comprises a carbide of a metal M and an oxide of the metal M, M is selected from a group VIB metal, and the active component is selected from one or more of metal components of a group VIII metal. According to the method, the specific catalyst is adopted in the selected system, the hydrogen and the glycerol pass through the process at one time, by means of the process, and the catalyst still keeps complete conversion of the glycerol at a high space velocity; meanwhile, the selectivity of the 1,3-propylene glycol is high, and industrial popularization is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethyl caproate by continuous esterification

InactiveCN101723828BTo avoidAvoid the defects of easy blackening and cokingOrganic compound preparationCarboxylic acid esters preparationPtru catalystAlcohol ethyl

The invention discloses a method for preparing ethyl caproate by continuous esterification, which comprises the following steps of: mixing caproic acid and ethanol in the mol ratio of 1: (1-1.5), then preheating, esterifying by a fixed bed catalyst layer, then entering an ethanol fractionating tower, extracting 95%(V / V) alcohol obtained at the tower top, using the 95%(V / V) alcohol as a mixture and recycling; discharging the caproic acid and water from the tower bottom, separating out the caproic acid and recycling again; and leading out the total liquid phase from the position above a feed opening in the middle of the tower and naturally layering, wherein the upper layer is the water which reflows into the tower, and the lower layer is an ethyl caproate crude product which is extracted and refined separately. The method has the advantages that the method can operate within a wider esterification range without considering the conversion rate of the caproic acid; the unreacted caproic acid is separated from the water, thereby avoiding the defects of influencing the flavor of the ethyl caproate and reducing the yield caused by blackening and coking of the caproic acid due to heating when in conventional production and recovery; a neutralization washing work procedure is saved, and no neutralizing waste water exists; and the production efficiency is high.

Owner:河北科正化工有限公司

Method for preparing panax notoginseng total saponin freeze drying powder through convection heat transfer type freeze drying

InactiveCN106389348ASublimation smoothImprove drying efficiencyPowder deliveryDrying solid materials without heatPANAX NOTOGINSENG ROOTFreeze-drying

The present invention relates to a method for preparing panax notoginseng total saponin freeze drying powder through convection heat transfer type freeze drying. According to the present invention, by using the convection heat transfer type freeze drying preparation method of the panax notoginseng total saponin, drying is performed according to the predetermined freeze-drying process to obtain the freeze drying product of the panax notoginseng total saponin or the composition thereof, wherein the water content is extremely low, and the time for achieving the complete freeze-drying state is short.

Owner:GUANGXI WUZHOU PHARMA GRP

Van type vacuum drying device for urban sludge

ActiveCN110395873AImprove drying rateWon't spillSludge treatment by de-watering/drying/thickeningSludgeProcess engineering

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

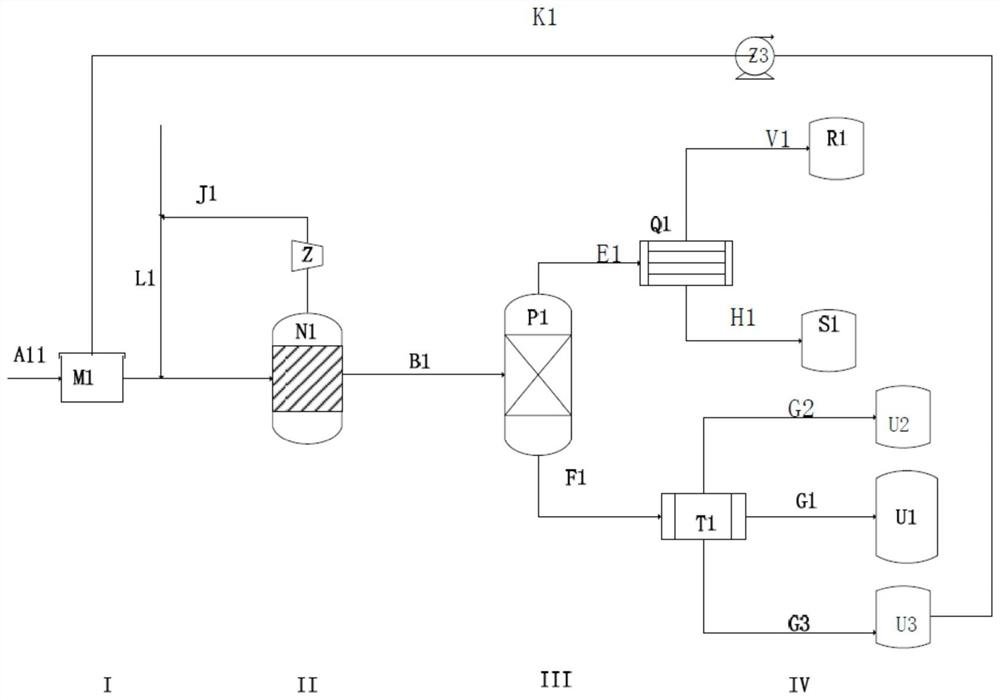

N-propyl acetate energy-saving process and process equipment

PendingCN111807959ALower latent heat of vaporizationSave energyOrganic compound preparationChemical industryProcess engineeringFluid phase

The invention provides an n-propyl acetate energy-saving process and process equipment. The equipment comprises a rectifying column, wherein a liquid phase outlet of the rectifying column is connectedwith a finished product extraction pump, the finished product extraction pump is connected to a finished product tank, a gas phase outlet of the rectifying column is connected to a tower top condenser, the column top condenser is connected to a phase splitter, and a split phase outlet of the phase splitter is connected to external extraction equipment and a reflux inlet of the rectifying column.Gas-phase extraction of finished ester is improved into liquid-phase extraction, so that latent heat of vaporization of the finished ester is saved; finished ester exchanges heat with a backflow component flowing back to the rectifying column from the phase splitter and then is conveyed to the finished product tank, so that sensible heat of the finished ester is fully utilized, energy is effectively saved, and consumption is reduced.

Owner:ZHEJIANG JIANYE CHEM

Applications of convection heat transfer method in dianhydrodulcitol freeze drying powder preparation process

ActiveCN106389402ASublimation smoothImprove drying efficiencyOrganic active ingredientsPowder deliveryDianhydrodulcitolFreeze-drying

The present invention relates to applications of a convection heat transfer method in a dianhydrodulcitol freeze drying process. According to the present invention, by using the convection heat transfer type freeze drying preparation method of the dianhydrodulcitol freeze drying powder, drying is performed according to the predetermined freeze-drying process to obtain the freeze drying product of the dianhydrodulcitol or the composition thereof, the melting point is high and is in the range of 99.5-103.5 DEG C, the time for achieving the complete freeze-drying state is short, the freeze drying product is the loose amorphous body, the melting point is not changed after the freeze drying product is stored for 200 days at a room temperature in a sealed manner, and the quality stability of the freeze drying product of the present invention is significantly superior to the quality stability of the dianhydrodulcitol freeze drying powder prepared in the prior art.

Owner:GUANGXI WUZHOU PHARMA GRP

Application of a Steam Heating Method in Freeze Drying

ActiveCN106403507BLower latent heat of vaporizationPromote gasificationDrying solid materials without heatFreeze-dryingEngineering

Owner:GUANGXI WUZHOU PHARMA GRP

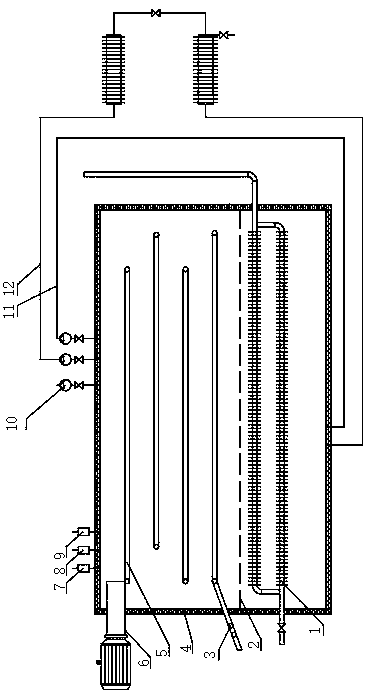

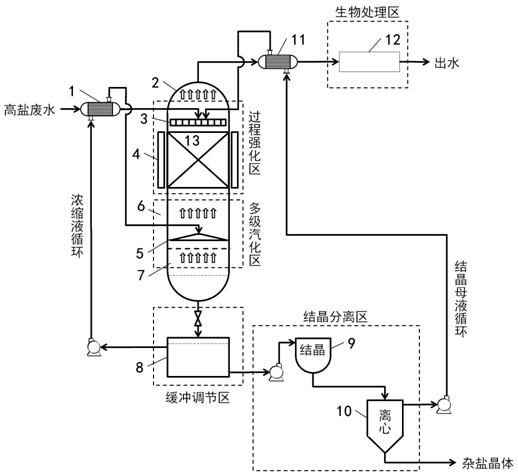

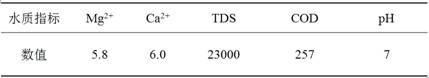

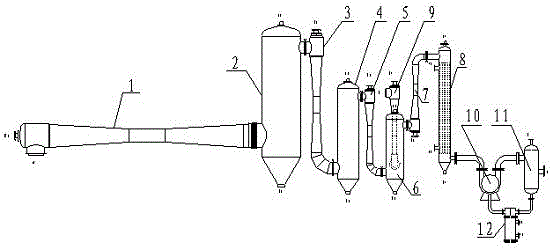

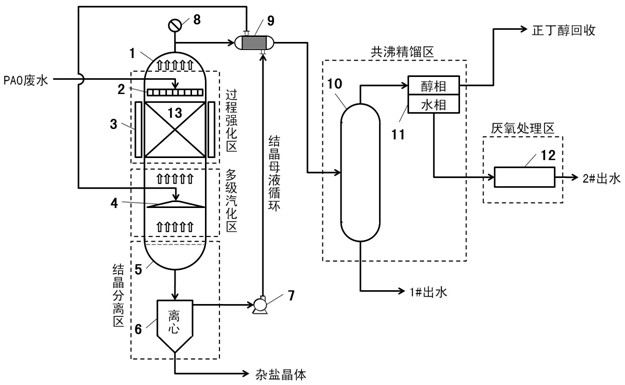

Method and device for treating high-salt organic wastewater

ActiveCN113121061AReduce salt contentReduce CODWater contaminantsWater/sewage treatment with mechanical oscillationsVaporizationSolvent

The invention relates to a method and a device for treating high-salinity organic wastewater. The method is realized through the following functional areas: a process strengthening area, a multi-stage vaporization area, a buffer regulation area, a crystallization separation area and a biological treatment area, the high-salinity organic wastewater passes through the process strengthening area and is subjected to process strengthening under the action of a filler and a field effect, and by changing the physicochemical properties of a solution, The vaporization temperature of A solvent is reduced. Then the solvent enters the multi-stage vaporization area at the lower part of the main reactor to accelerate the vaporization rate of the solvent. The buffer regulation area adjusts the liquid level of a tower kettle concentrated solution of the main reactor, and part of the concentrated solution is circulated back to the multi-stage vaporization area. The residual concentrated solution in the buffer regulation area enters the crystallization separation area, and carnallite in the concentrated solution is crystallized out. Vaporized steam is condensed, and condensate enters a biological treatment area to remove organic matter. According to the method, the salt content and COD in the high-salinity wastewater are effectively reduced, the crystallization effect is good, the energy consumption is low, and corrosion of the wastewater to equipment is weakened under low-temperature operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of a convective heat transfer method in the preparation process of dehydrodulcitol freeze-dried powder

ActiveCN106389402BLower latent heat of vaporizationPromote gasificationPowder deliveryOrganic active ingredientsDianhydrodulcitolMetallurgy

Owner:GUANGXI WUZHOU PHARMA GRP

Process method for recycling acetone from exhaust gas

InactiveCN104130114AReduce loadLow saturated vapor pressureOrganic compound preparationCarbonyl compound separation/purificationDistillationEconomic benefits

The invention relates to a process method for recycling acetone from exhaust gas. The process method comprises the steps: firstly, the to-be-treated gas containing trace acetone is absorbed by absorption water in an absorption tower, then the diluted acetone water obtained at a tower bottom is separated in a liquid-liquid phase separator, one stream of the material liquid obtained from separation and having high acetone mass fraction is subjected to pressure reduction by a pressure reducer and then goes into a distillation tower for reduced pressure distillation, and the acetone product is extracted from a tower top. The process method improves the work efficiency and stability, can greatly reduce the energy consumption of the acetone recovery process, and has significant practicability and economic benefits.

Owner:HEBEI UNIV OF TECH

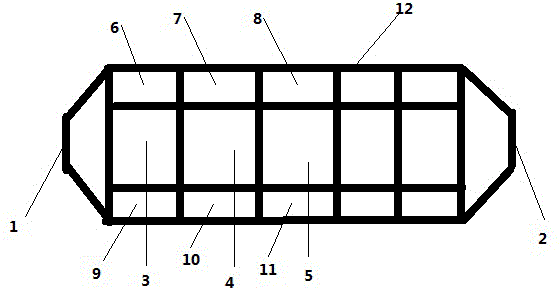

A box-type vacuum drying device for urban sludge

ActiveCN110395873BImprove drying rateWon't spillSludge treatment by de-watering/drying/thickeningSludgeSewage

The invention discloses a box-type vacuum drying device for urban sludge, which comprises a drying box connected with a vacuum pump; the drying box is provided with an air distribution plate to divide it into an upper material delivery area and a lower air supply area The air distribution channel is arranged on the air distribution plate; the material conveying system is arranged in the material conveying area, and the heat exchanger is installed in the air supply area. The air channel leads into the material conveying area to heat and dry the materials conveyed by the material conveying system; the drying box is also connected with a hot air circulation system. The invention is suitable for drying urban sludge, provides favorable material conveying conditions and heat medium pressure, temperature, and wind conditions for sludge drying, improves sludge drying rate, and has good environmental protection without foul smell in the drying process.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

An Ethane Recovery Method Combining Pre-pressurization and Propane Refrigeration

ActiveCN110563540BReduce circulationLower latent heat of vaporizationHydrocarbon purification/separationHydrocarbonsNatural-gas processingProcess engineering

The invention discloses an ethane recovery method using a combination of pre-pressurization and propane refrigeration, belonging to the technical field of natural gas processing. The method is established on the basis of a conventional ethane recovery process; directed at the characteristic that a low-pressure rich gas ethane recovery process has great demand for cooling capacity, the method adopts the combination of feed gas pre-pressurization and propane refrigeration; so the refrigerating capacity of an expansion machine can be increased under the working condition that the pre-cooling capacity of the feed gas is insufficient, and the ethane recovery process has a high ethane recovery rate (greater than 95%) under a low-pressure rich gas working condition. According to the method, a compressor is arranged at a process inlet to pressurize the feed gas, so latent heat of vaporization of the feed gas is effectively reduced in a high-pressure state, cooling quantity required by precooling of the feed gas is reduced, and the circulation quantity of propane is reduced; and thus, the energy consumption of a refrigeration cycle compressor and total energy consumption of the process arereduced under the condition that high ethane recovery rate is guaranteed. Meanwhile, compared with an ethane recovery process with the same ethane recovery rate and with a stepped refrigeration cycleor mixed refrigerant cycle, the whole process structure of the method in the invention is greatly simplified, and the design and operation of the method are easy.

Owner:SOUTHWEST PETROLEUM UNIV

Butanediol spraying vacuum pump and working method thereof

ActiveCN102536919BLower latent heat of vaporizationMeet the needs of continuous productionJet pumpsMachines/enginesLiquid wasteVapor–liquid separator

Owner:杭州华达喷射真空设备有限公司

Treatment system and method for percolate concentrated solution of garbage incineration power plant

InactiveCN109761426AFully filteredImprove filter qualityMultistage water/sewage treatmentCombustionPower station

The invention discloses a treatment system for a percolate concentrated solution of a garbage incineration power plant. The treatment system comprises a storage tank which is connected with a filtering system through a pipeline; the filtering system is connected with a conveying system through a pipeline; the conveying system is connected with a heating system through a pipeline; the heating system is connected with a spraying system through a pipeline. A treatment method for the percolate concentrated solution of the garbage incineration power plant comprises the following steps: firstly, collecting the percolate concentrated solution through the storage tank; opening a pipeline blowing system to carry out steam or air blowing on a conveying pipeline of the whole system, so as to ensure the cleanliness of the pipeline; closing the pipeline blowing system; then starting a conveying pump in the conveying system; under the power of the conveying pump, conveying the percolate concentratedsolution in the storage tank into the filtering system and carrying out second-grade filtering treatment; then conveying into the heating system and heating; heating the percolate concentrated solution to 80 to 90 DEG C; finally, conveying the heated percolate concentrated solution to the spraying system, and spraying into a furnace for combustion through a furnace-top spraying gun and a gun headof the spraying gun in the spraying system.

Owner:深圳市绿色东方环保有限公司

A kind of treatment method and device of high-salt wastewater produced by Pao

ActiveCN113121060BReduce salt contentImprove processing efficiencyWater/sewage treatment by centrifugal separationWater/sewage treatment with mechanical oscillationsDesalinationProcess engineering

The invention relates to a treatment method and a device for producing high-salt wastewater from PAO. The device mainly includes five regions: a process intensification zone, a multi-stage vaporization zone, a crystallization separation zone, an azeotropic distillation zone and an anaerobic treatment zone. The strengthening zone mainly includes liquid distributor I, packing and field effect processor, etc. The wastewater is strengthened under the action of packing and field effect; the liquid distributor II is set up in the multi-stage vaporization zone, and the liquid distributor II is the boundary. It is divided into I-level vaporization zone and II-level vaporization zone; the vaporized concentrate enters the crystallization separation zone, and the miscellaneous salts in the vaporized concentrate are crystallized; the vaporized vapor enters the azeotropic distillation zone after condensation, and n-butanol is separated; recovery After n-butanol, the aqueous phase enters the anaerobic treatment zone for treatment. The invention can efficiently desalinate and reduce COD, and reduce crystallization energy consumption and equipment corrosion, and at the same time of high-efficiency desalination, the recovery and utilization of azeotrope can also be realized, and the economy of the process is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

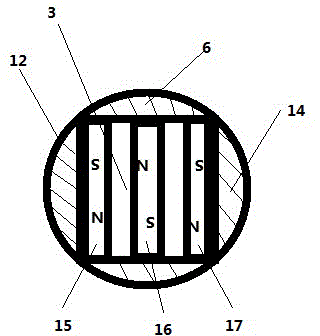

Water vapor phase change energy-saving apparatus

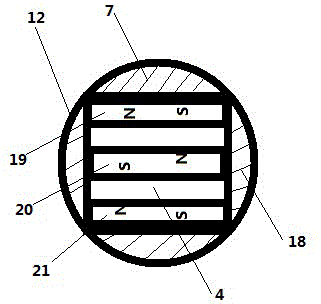

InactiveCN104402098AIncrease magnetic inductionUniform magnetic fieldWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment apparatusPower stationWater vapor

The invention provides a water vapor phase change energy-saving apparatus capable of reducing vaporization potential heat value under power station boiler and industrial boiler water supply system. The energy-saving apparatus comprises a water inlet, a water outlet, a shell, a magnetization unit and a magnetization unit fixing device; the magnetization unit has multiple groups which are fixed by the magnetization unit fixing device and tightly arranged along the axial direction of a water-supply-pipe; the magnetization unit and the magnetization unit fixing device occupy the pipe space besides the water inlet and the water outlet; the magnetization unit comprises multiple groups of paired rare earth permanent magnets; and the any adjacent two groups of magnetization units are fixed on the pipeline cross section with wide angle of rotation angle.

Owner:广东新奇节能科技有限公司

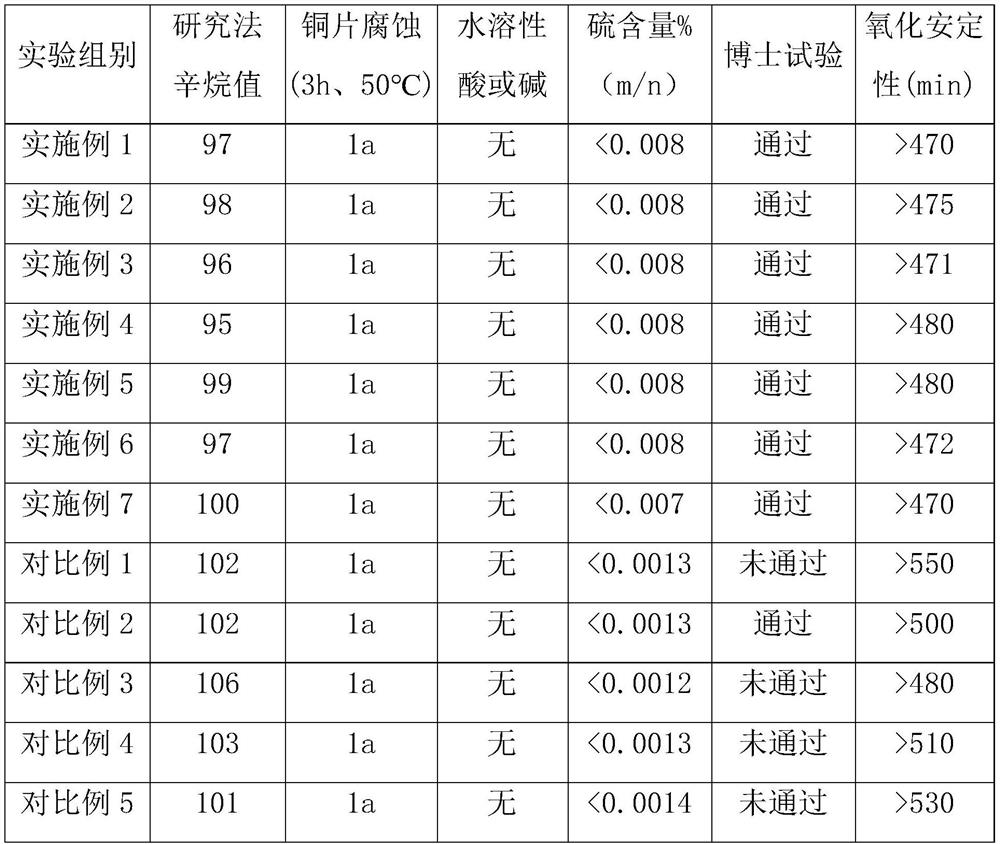

Hydrogen energy environment-friendly composite fuel and preparation method thereof

PendingCN114656995AAccelerated reaction rangeImprove combustion performanceLiquid carbonaceous fuelsFuel additivesXylyleneCyclohexylamines

The invention discloses a hydrogen energy environment-friendly composite fuel and a preparation method thereof.The composite fuel comprises, by weight, 15-30% of a modified methanol additive and 70-85% of a hydrocarbon ether additive, the modified methanol additive comprises, by weight, 6-10% of a core agent and 90-94% of refined methanol, the modified methanol additive is also called as a fuel oil purification synergist, and the hydrocarbon ether additive is also called as a fuel oil purification synergist. The hydrocarbon ether additive comprises aromatic hydrocarbon, xylene, trimethylbenzene, alkylate oil, MTBE, naphtha, raffinate oil and C5, and the core agent comprises isopropanol, cyclohexylamine, fatty acid methyl ester, isooctyl nitrate, 2 # jet fuel, dimethyl carbonate, methyl tert-butyl ether, zinc peroxide, 2, 6-butylated hydroxytoluene, ethyl ferrocene and tetraethyl lead. According to the hydrogen energy environment-friendly composite fuel adopting the structure and the preparation method of the hydrogen energy environment-friendly composite fuel, natural combustion of methanol is changed into catalytic combustion, combustion is more sufficient, oil consumption is reduced, power is increased, and tail gas emission is obviously reduced.

Owner:油源美华(北京)新能源技术研究院有限公司

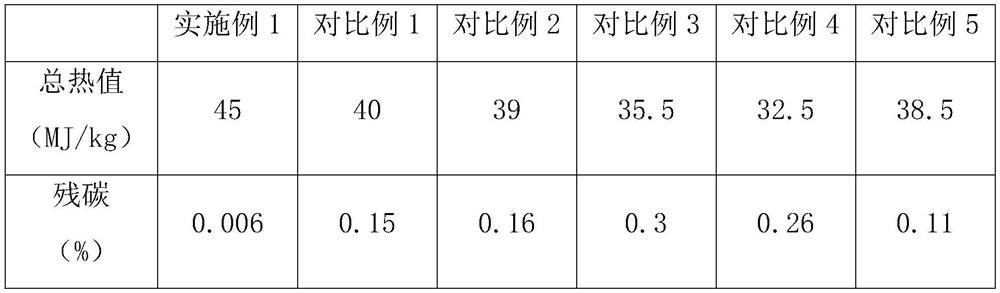

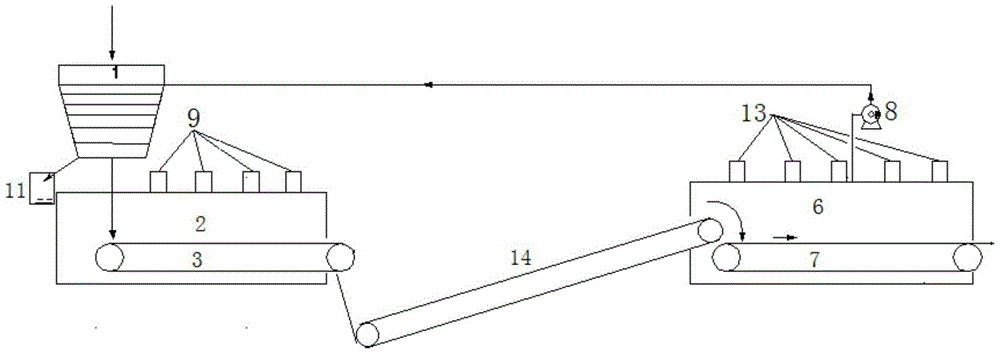

High-moisture coal segmental dehydration drying system and its application method

ActiveCN105157399BReduce drying loadLower latent heat of vaporizationDrying using combination processesDrying solid materials with heatMicrowaveHigh humidity

The invention discloses a segmented water removing and drying system for high-humidity coal and an application method for the segmented water removing and drying system. The system comprises a discharging mechanism. A first microwave drying mechanism is arranged below the discharging mechanism and internally provided with a first conveying mechanism. A solid-liquid separation mechanism is arranged at the tail end of the first conveying mechanism. A second conveying mechanism is arranged at an outlet of the solid-liquid separation mechanism. A second microwave drying mechanism is arranged at the tail end of the second conveying mechanism. The segmented water removing and drying system has the beneficial effects that a microwave heating manner and a non-heating manner are combined with the water removing and drying technology, a heat water removing manner and a non-heat water removing manner are organically combined, water in coal is removed in the form of a liquid state on the basis of low-rank coal microwave drying, and energy consumption of a microwave drying system is greatly reduced; raw coal is heated through the reutilization of residual heat and waste heat generated by the drying system, and the economical efficiency of the whole drying system is improved; and after deep drying is carried out, utilization of later finished coal is more flexible and safer, and the processing cost is reduced.

Owner:SHANDONG UNIV

Process method for recovering butanol-butyl acetate from antibiotic production wastewater

ActiveCN104151136BIncrease relative volatilityLow quality scoreOrganic compound preparationWater contaminantsDistillationAntibiotic Y

The invention relates to a process method for recycling butanol-butyl acetate from antibiotic production wastewater. The process method comprises the following steps: preheating wastewater of which the content of butanol-butyl acetate is 1-5 percentage by mass by using a tower bottom of a rectifying tower; further heating to 80-85 DEG C by using a heat exchanger, feeding into a flash column; feeding distillate from the top of the flash column into the rectifying tower; and separating the distillate. As a tubular type heat exchanger on the top of the rectifying tower is connected with a pressure reducer so that the shell pass of the rectifying tower and the tubular type heat exchanger is maintained to be less than 35kPa. The steam on the top of the tower is condensed and fed into a phase splitting tank, the light phase is fed into a tank to be detected, the heavy phase flows back, and the tower bottoms are cooled to 30-35 DEG C and discharged. By adopting the process method, the recycling rates of butanol and butyl acetate are greatly increased; by comprehensive utilization of pressure-reduced distillation and heat, the energy consumption can be reduced and remarkable practicability and economical efficiency are achieved.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com