Water vapor phase change energy-saving apparatus

An energy-saving device and water-vapor phase change technology, which is applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., and can solve the problems of insignificant effect, high cost, and complicated manufacturing of treatment devices. , to achieve the effect of high magnetic induction intensity and uniform magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further elucidated below in conjunction with specific illustrations.

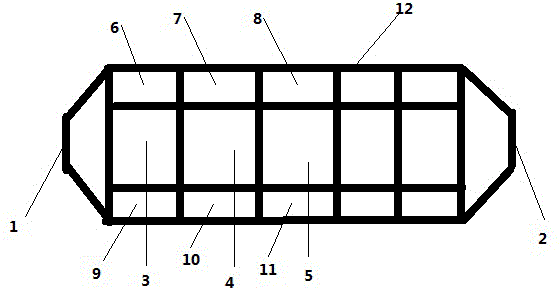

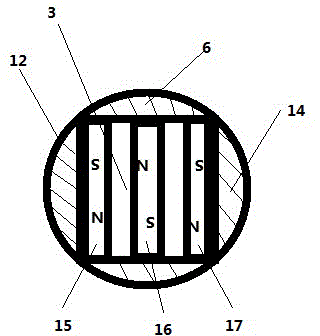

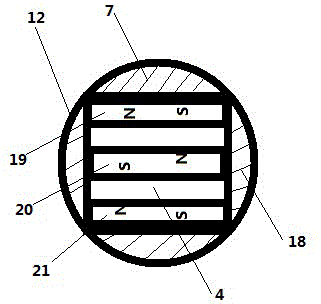

[0015] Such as figure 1 As shown, a water vapor phase change energy-saving device with reduced vaporization latent heat value is used for industrial and power plant boiler feed water circuits, including water inlet (1), water outlet (2), tube shell (12), magnetization unit (3) ~(5), and magnetizing unit fixing devices (6)~(11), (14)~(15); the magnetizing units have multiple groups, which are fixed by the magnetizing unit fixing devices, and are closely spaced along the axial direction of the water pipe arrangement.

[0016] Each group of magnetization units includes rare earth permanent magnets (15)~(17), (19)~(21), and the permanent magnets are placed in pairs; the permanent magnets have anti-embroidery and anti-corrosion functions, and have high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com