Magnetorheological pilot-operated overflow valve

A pilot-operated relief valve and magneto-rheological technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of small damping force, achieve good anti-wear performance, improve magnetic induction intensity, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the stated scope.

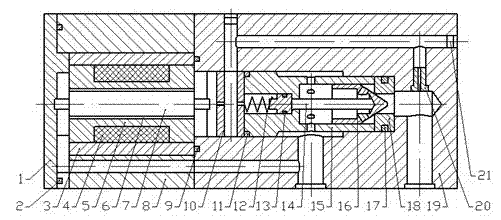

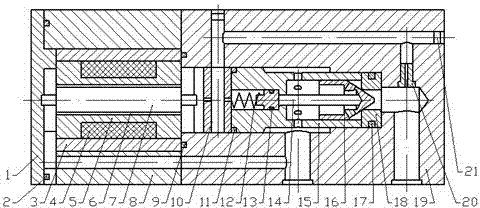

[0020] Implementation column 1: As shown in the figure, a magneto-rheological pilot relief valve consists of a pilot valve body 8, a damping block 10, a spring 12, a guide rod 14, a main valve sleeve 15, a main valve core 16, and a main valve seat 18, main valve body 19, damper 20, plug 21 form main valve. A pilot valve is also connected to the outlet of the main valve.

[0021] The pilot valve includes an end cover 1 , a magneto-rheological valve casing 3 , a coil 4 , an iron core 5 and a valve core 7 . The iron core 5 is installed in the magneto-rheological valve housing 3. The core 5 has a through-hole structure on which the coil 4 is wound. The valve core 7 is inserted into the hole of the iron core 5. The iron core 5 and the valve core 7 A working gap 6 is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com