N-propyl acetate energy-saving process and process equipment

A technology of n-propyl acetate and process equipment, which is applied in the chemical industry and can solve the problems of excessive heat, steam consumption and no competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

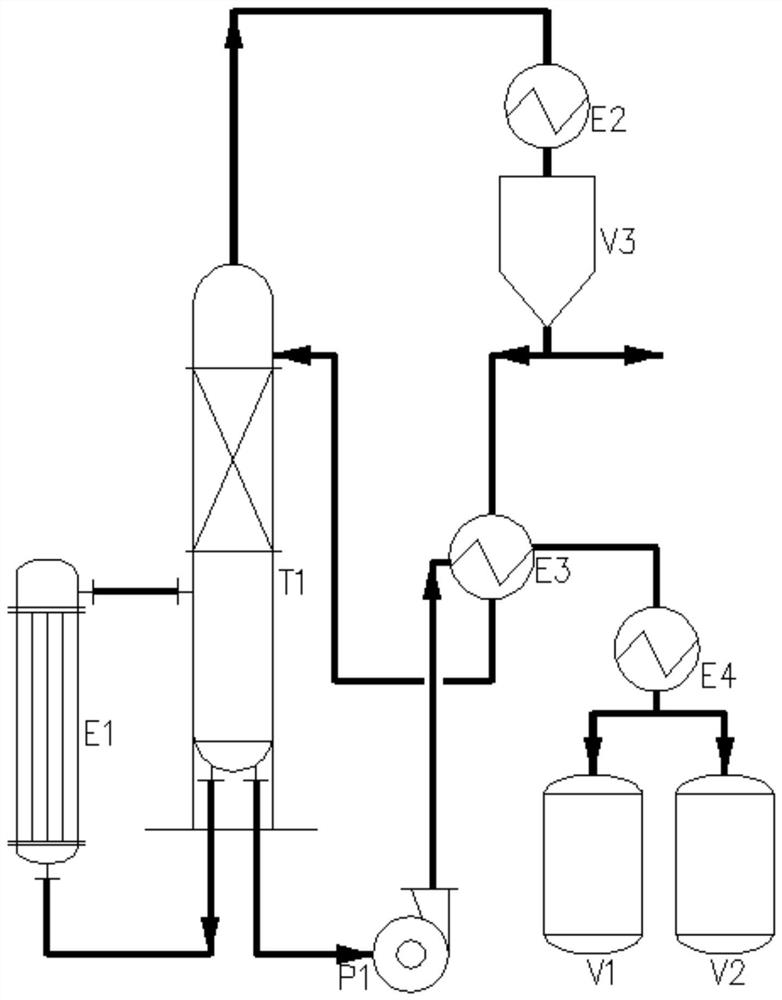

[0022] Such as figure 1 As shown, the present embodiment discloses a technique and equipment for an energy-saving n-propyl acetate process. The equipment mainly includes a rectification reboiler E1 and a rectification tower T1. The liquid phase outlet at the bottom of the rectification tower T1 is connected with a The finished product extraction pump P1 for the liquid phase extraction of the finished ester at the bottom of the tower is connected to the finished product tanks V1 and V2 through the heat exchanger E3 and the finished product condenser E4 in turn; the gas phase outlet at the top of the rectifying tower T1 is connected to the tower The top condenser E2 and the top condenser E2 are connected to the phase separation inlet at the top of the phase separator V3, and the phase separation outlet at the bottom of the phase separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com