Ethane recovery method using combination of pre-pressurization and propane refrigeration

A recovery method, propane technology, applied in chemical instruments and methods, hydrocarbons, purification/separation of hydrocarbons, etc., can solve the problem of decreased ethane recovery rate in the process, high energy consumption in the ethane recovery process, and increased energy consumption in compressors, etc. problem, to achieve the effect of reducing propane circulation, easy design and operation, and reducing cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

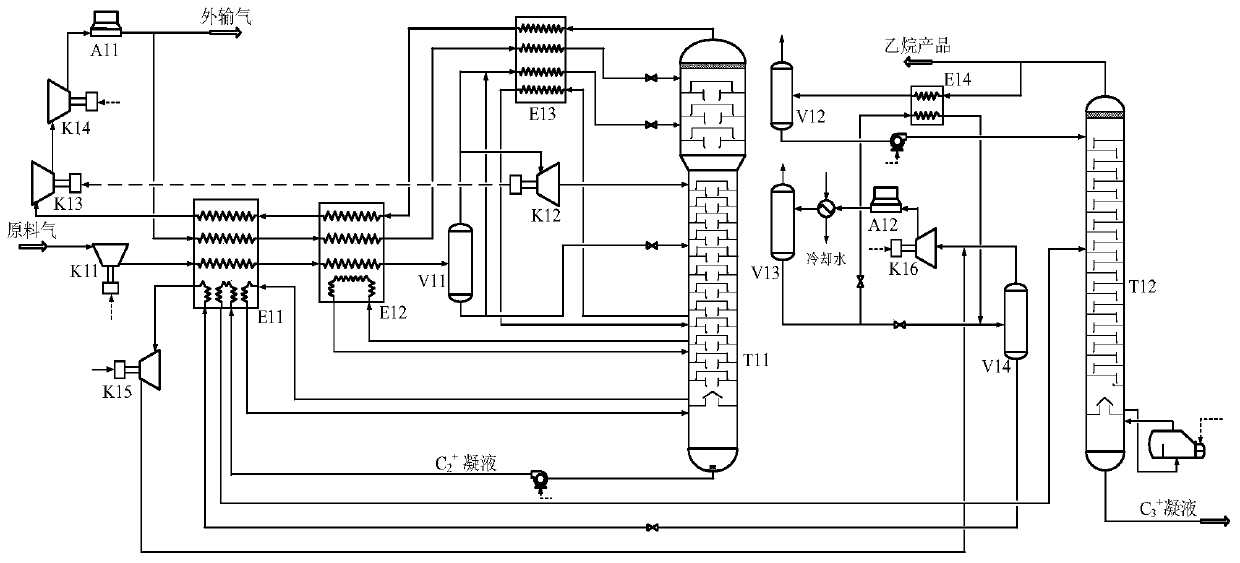

[0023] Such as figure 1 As shown, the composition and working conditions of raw gas are as follows:

[0024] Raw gas processing scale: 1500×10 4 m 3 / d

[0025] Raw gas pressure: 3980kPa

[0026] Raw gas temperature: 15°C

[0027] Dry gas output pressure: 4450kPa

[0028] The raw gas composition is shown in Table 1

[0029] Table 1 Feed gas composition

[0030] components H 2

he N 2

CO 2

C 1

C 2

C 3

iC 4

mol% 0.0948 0.0587 0.4551 1.2613 92.5405 4.45 0.7591 0.1178 components c 4

iC 5

c 5

C 6

C 7

C 8

C 9

mol% 0.1229 0.046 0.0239 0.033 0.0219 0.0132 0.001

[0031] Such as figure 1 As shown, the present invention discloses a method for recovering ethane combined with pre-pressurization and propane refrigeration, which is simulated in combination with the working conditions of the raw material gas in the examples. The specific process description and paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com