Method and system for preparing 1,3-propylene glycol from glycerol

A technology of propylene glycol and glycerin, which is applied in the preparation of hydroxyl groups, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of low catalyst activity, high catalyst cost, low space-time yield, etc., achieve high selectivity, and reduce latent heat of vaporization. , the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

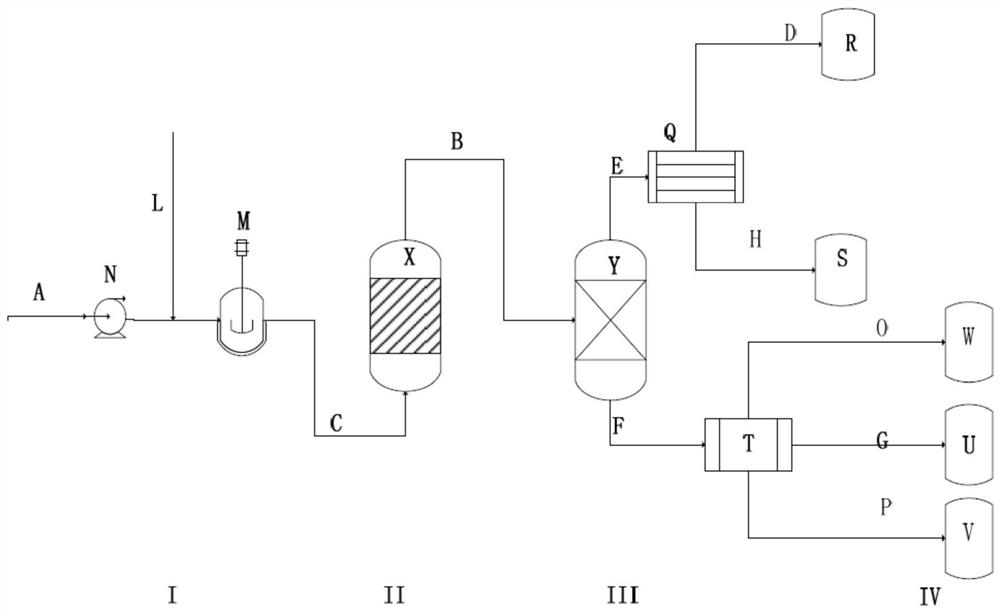

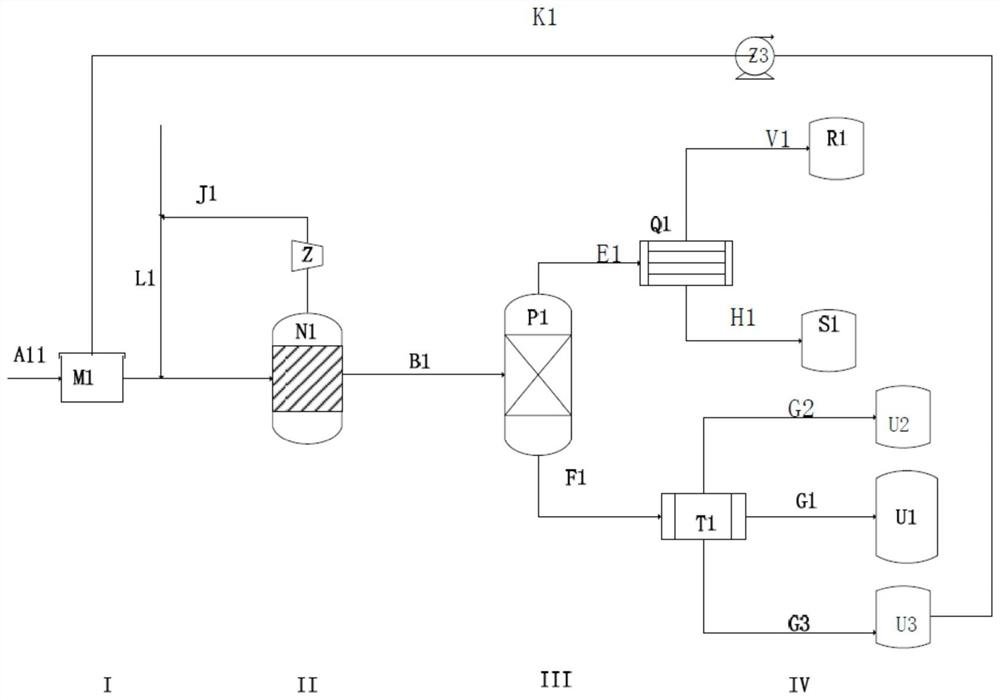

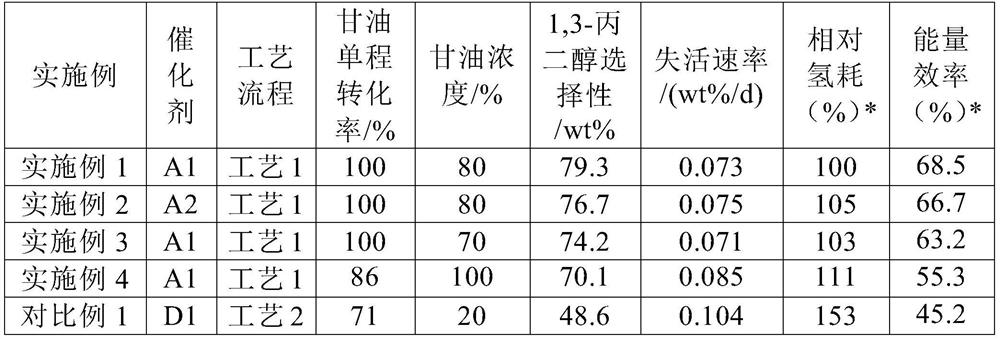

[0066] The method for preparing 1,3-propanediol of the present invention adopts aforementioned system to carry out, comprises the following steps:

[0067] S1, introducing the glycerin aqueous solution and hydrogen gas into the hydrogenation unit after mixing, and contacting the glycerin aqueous solution, hydrogen gas and catalyst under the reaction conditions, and reacting to form a hydrogenation mixed product containing 1,3-propanediol; and

[0068] S2, introducing the hydrogenated mixed product into a separation unit to separate 1,3-propanediol and by-products;

[0069] The concentration of the aqueous glycerin solution used in the present invention is 5-100% by weight. When the content reaches 100% by weight, the aqueous glycerin solution is pure glycerin, so the meaning of "aqueous glycerin solution" in the present invention includes pure glycerin. Preferably, the aqueous glycerin solution has a concentration of 7-98% by weight, more preferably 10-95% by weight.

[0070]...

preparation example 1

[0095] Add CH to 1.7g ammonium metatungstate 4 with H 2 The carbon-containing compound atmosphere with a volume ratio of 15:85 was set by the temperature program to raise the temperature to 800°C at a rate of 1°C / min, and then carbonized at a constant temperature for 6 hours, then switched to high-purity Ar gas, cooled to room temperature and kept at a constant temperature for 2 hours , then switched to O with an oxygen content of 0.2 vol% 2 with N 2 passivation treatment in a passivation atmosphere for 2 hours to obtain passivated tungsten carbide.

[0096] Put 5g of ammonium metatungstate in a muffle furnace and bake at 700°C for 3h to obtain tungsten oxide.

[0097] The passivated tungsten carbide and tungsten oxide were mixed at a weight ratio of 1:1, and ground for 2 hours in a high-purity Ar atmosphere in a planetary ball mill to obtain carrier Z1.

[0098] Dissolve 0.17 g of chloroplatinic acid solution with a platinum content of 2.375% by weight in 10 g of deionize...

preparation example 2

[0100] Add CH to 1.7g ammonium metatungstate 4 with H 2 The carbon-containing compound atmosphere with a volume ratio of 15:85 was set by the temperature program to raise the temperature to 800°C at a rate of 1°C / min, and then carbonized at a constant temperature for 6 hours, then switched to high-purity Ar gas, cooled to room temperature and kept at a constant temperature for 2 hours , then switched to O with an oxygen content of 0.2 vol% 2 with N 2 passivation treatment in a passivation atmosphere for 2 hours to obtain passivated tungsten carbide.

[0101] Put 5g of ammonium metatungstate in a muffle furnace and bake at 700°C for 3h to obtain tungsten oxide.

[0102] Mix the passivated tungsten carbide and tungsten oxide at a weight ratio of 1:2, and grind for 2 hours in a high-purity Ar atmosphere and a planetary ball mill to obtain the carrier Z2.

[0103] Dissolve 0.35 g of chloroplatinic acid solution with a platinum content of 2.375% by weight in 10 g of deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com