Energy-saving optimal control system and method for outlet temperature of medium-speed coal mill in supercritical unit

A supercritical unit and outlet temperature technology, applied in grain processing and other directions, can solve the problems of volatile matter precipitation in pulverized coal, high outlet temperature of coal pulverizers, and the outlet temperature of coal pulverizers cannot be too high, so as to reduce the latent heat of vaporization and The effect of burning heat, improving ignition and stable combustion performance, and reducing the unit consumption of pulverizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

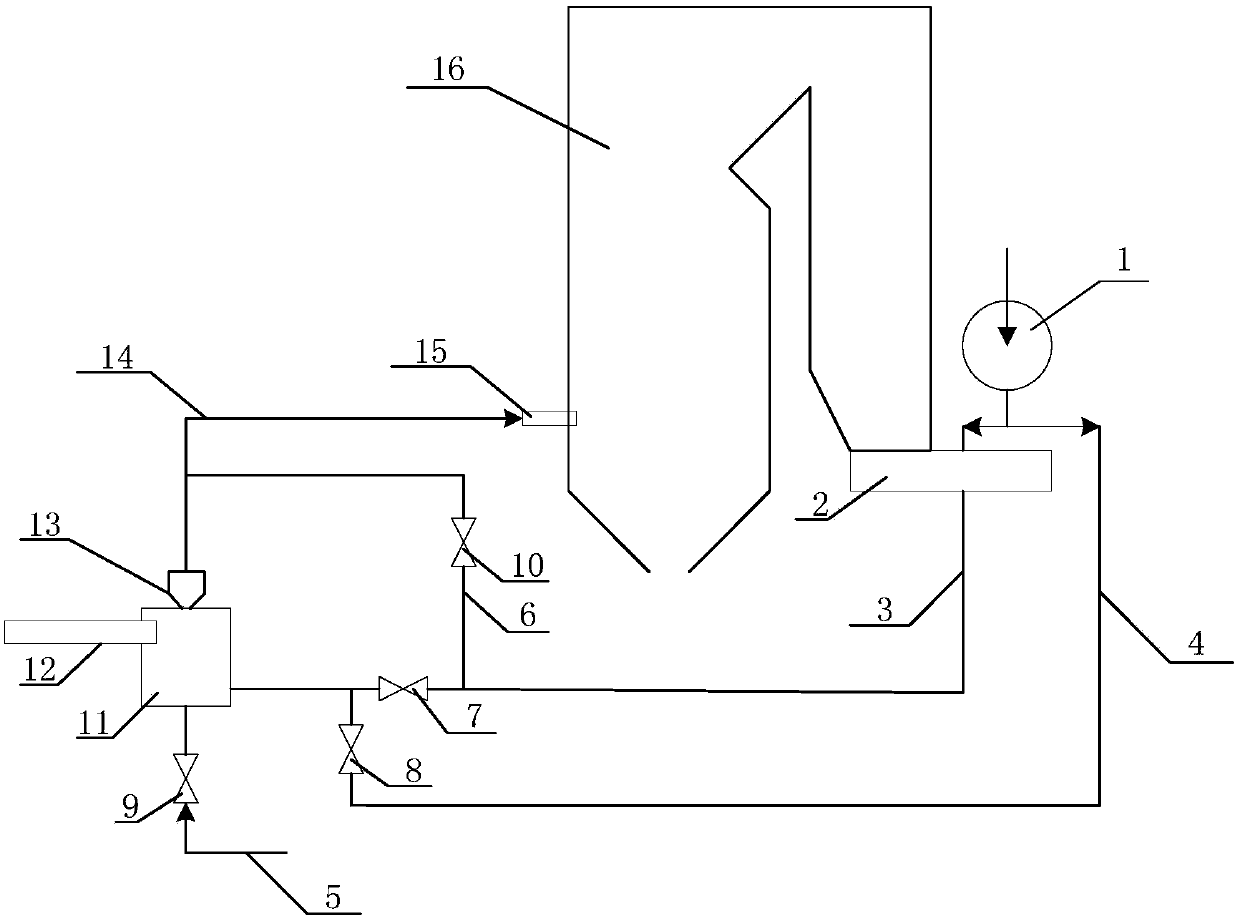

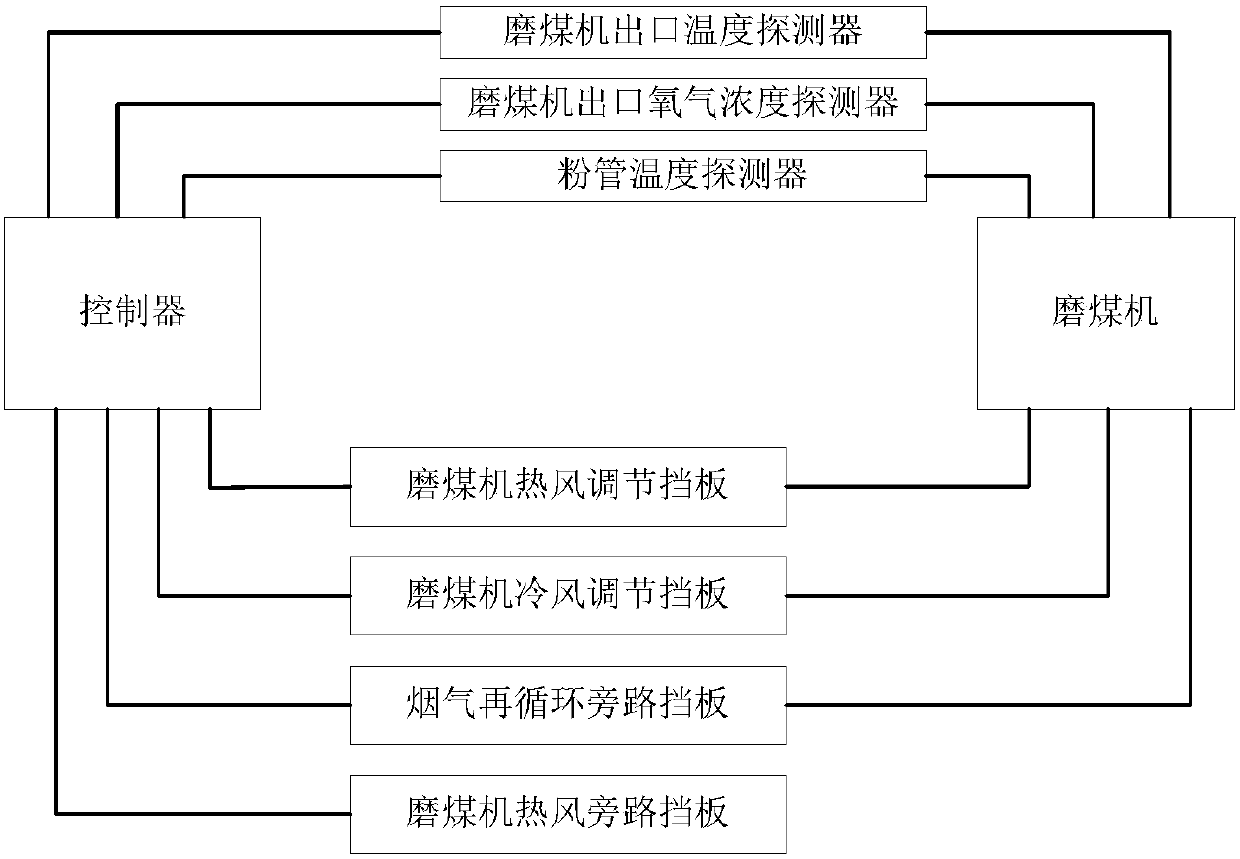

[0027] figure 1 It is a schematic diagram of the system structure of the embodiment of the present invention. The primary fan 1 is placed before the air preheater 2. The cold air is divided into two paths after being boosted by the primary fan 1. One path is heated by the air preheater 2 and enters the hot primary air duct 3. The other way directly enters the primary cold air duct 4, the hot air from the primary air duct 3 and the cold air from the primary air duct 4 are mixed before the coal mill 11 and enters the coal mill 11, the primary air duct 3 and the primary air duct 4 Adjusting baffles are arranged on the top, which are coal mill hot air adjusting baffle 7 and coal mill cold air adjusting baffle 8 respectively. The raw coal is sent into the coal mill 11 through the coal feeder 12 and then ground to form coal powder of a certain fineness. The mixed primary air dries the coal powder and blows it away from the coal mill 11 and enters the coarse powder separator 13. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com