Method and device for treating high-salt organic wastewater

A technology of organic wastewater and treatment methods, applied in the direction of mechanical oscillation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problem of high energy consumption in evaporation and crystallization unit treatment, and achieve long-term stable operation and increase The amount of solvent vaporization and the effect of reducing the latent heat of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

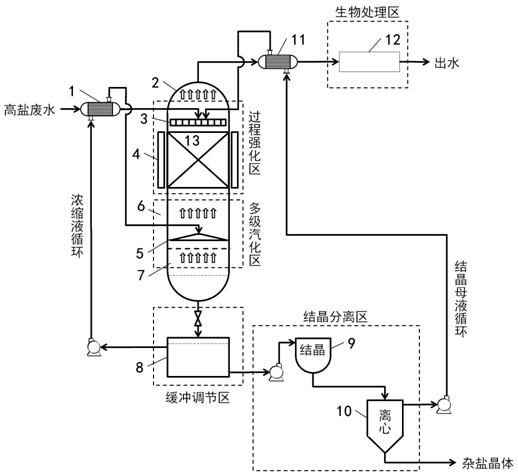

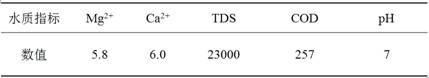

[0042] A high-salt organic wastewater includes reverse osmosis concentrated water, circulating water sewage, chemical water station drainage and some production wastewater. The water quality indicators after pretreatment are as follows:

[0043] Table 1 Water quality indicators of high-salt wastewater (unit mg / L, except pH value)

[0044]

[0045] Attached figure 1 The device treats high-salt organic wastewater, the packing is corrugated metal mesh packing, the field effect is magnetic field, and the processing scale is 1.5t / h. The main process parameters are:

[0046] Table 2 Main process parameters

[0047]

[0048] After the high-salt wastewater is treated, the TDS in the effluent is 130 mg / L, and the desalination rate is 99.4%; the COD is 37 mg / L, and the COD removal rate is 85.6%. The reactor has been in operation for 6 months without obvious corrosion.

Embodiment 2~7

[0050] With embodiment 1. The difference lies in: high-salt wastewater indicators, main process parameters, etc. are different. The indicators of high-salt wastewater, main process parameters and indicators of treated effluent are shown in Table 3.

[0051] Table 3 Treatment results of high-salt wastewater

[0052]

Embodiment 8

[0054] The composition of waste water quality is the same as in Example 1. The difference is: the field effect uses ultrasonic waves. After the wastewater is treated, the TDS in the effluent is 432mg / L, and the desalination rate is 98.1%; the COD is 42mg / L, and the COD removal rate is 83.7%. After 6 months of operation, the reactor has no obvious corrosion phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com