Patents

Literature

32results about How to "Improve catalytic combustion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite modifying alcohol ether fuel and catalytic fuel agent

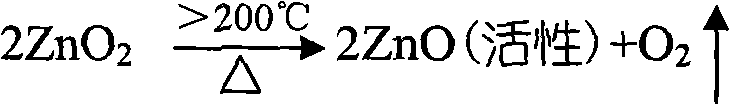

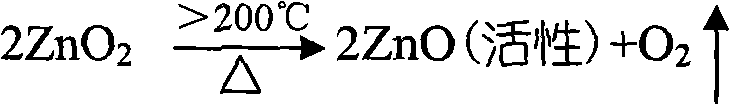

InactiveCN1944596AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCombustion

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Graphene oxide rare earth compound catalytic material and preparation method thereof

ActiveCN104307530AUnique Surface Interface StructureHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCombustionHydrazine compound

The invention discloses a graphene oxide rare earth compound catalytic material and a preparation method thereof. The catalytic material comprises the following raw materials in percentage by mass: 0.47-1.48% of graphene oxide, 11.71-28.25% of perovskite type rare earth oxide and 70.62-87.82% of an additive. The catalytic material is prepared from graphene oxide, perovskite type rare earth oxide and the additive by using a hydrothermal method; the perovskite type rare earth oxide is ABO3 oxide; the additives are ethanediamine, hydrazine hydrate or urea. The catalyst disclosed by the invention is excellent in methane combustion catalytic activity, the initial combustion temperature is 300 DEG C, complete conversion can be achieved at 405 DEG C, the activity effect is relatively good, the initial combustion temperature is identical, and the complete conversion temperature is reduced by 85 DEG C.

Owner:HEBEI UNIV OF TECH

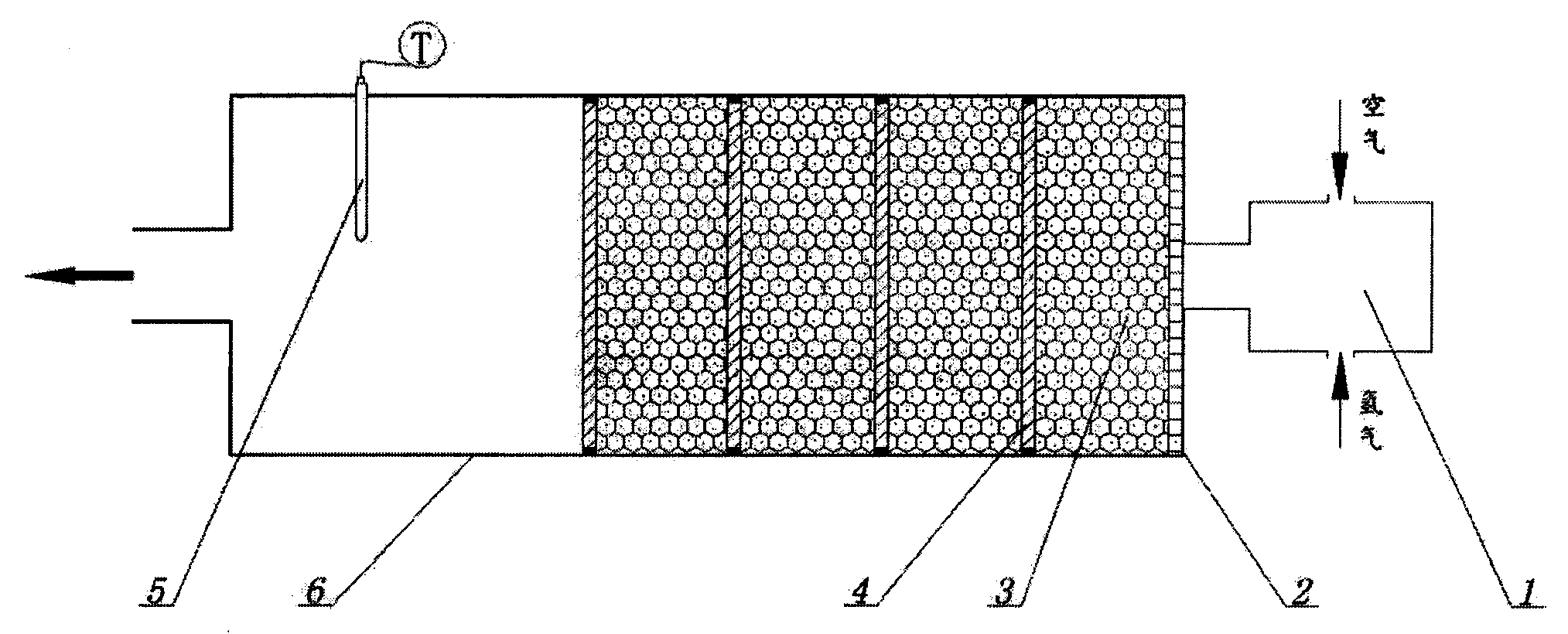

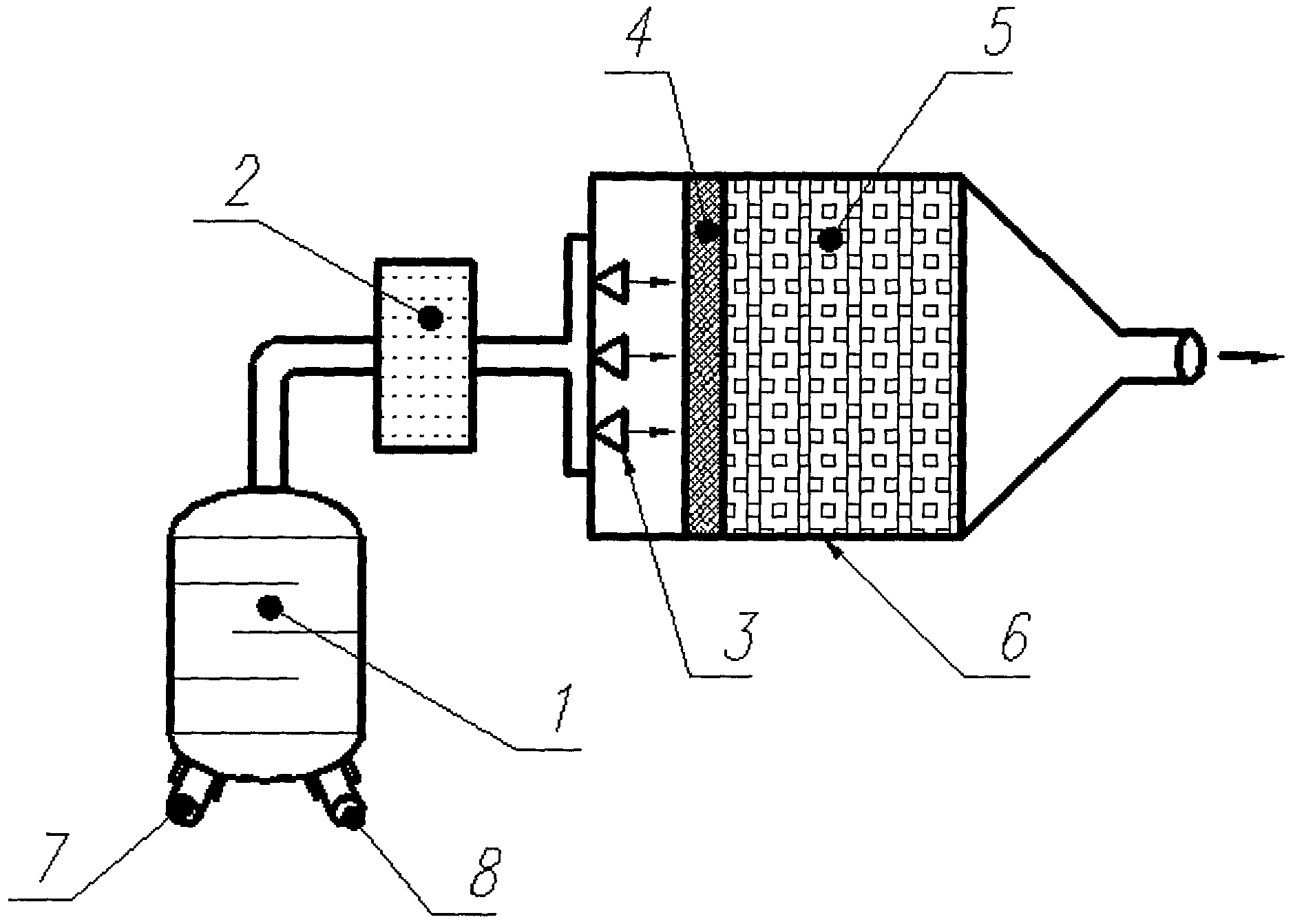

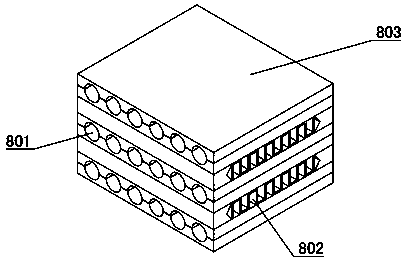

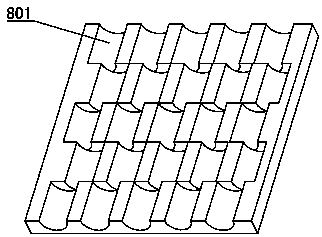

Hydrogen catalytic burner

InactiveCN103953929AReduced probability of "air leak"Suitable for heatingGaseous fuel burnerHydrogenProduct gas

The invention relates to a hydrogen catalytic burner, and belongs to the technical field of hydrogen catalytic combustion. The hydrogen catalytic burner is characterized by comprising a gas nixing cavity, a porous lining plate, catalyst layers, baffles, and a temperature sensor, wherein the porous lining plate is arranged at the bottom of the hydrogen catalytic burner, and the catalyst layer is a multilayer structure; the baffles are arranged between the catalyst layers. The hydrogen catalytic burner provided by the invention has the advantages of simple structure, good catalytic effect, convenience in use, high catalytic combustion efficiency, low emission and the like, and is particularly suitable for use for warming homes and office places.

Owner:CHINA JILIANG UNIV

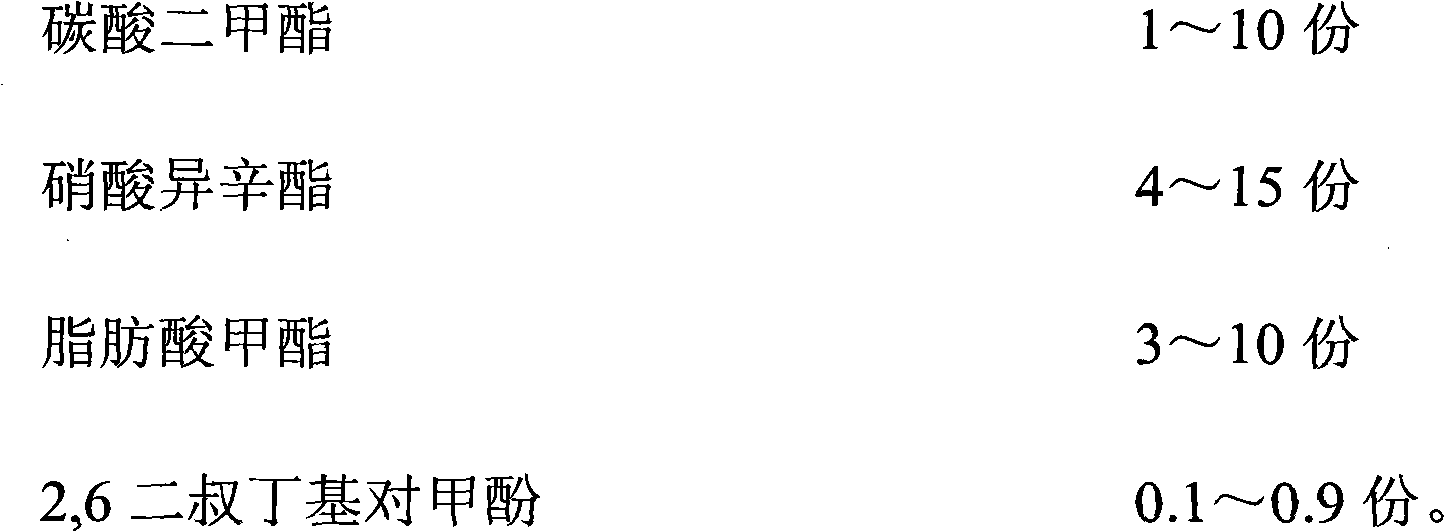

Modified methanol and preparation method thereof

InactiveCN102051236AImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCresol

The invention relates to modified methanol. The modified methanol is prepared from the following components in part by weight: 80 to 90 parts of methanol and 3.16 to 15.38 parts of methanol modified additive; and the methanol modified additive is prepared from the following components in part by weight: 50 to 90 parts of isopropanol, 3 to 20 parts of cyclohexane, 5 to 10 parts of aviation kerosene No.1, 0.1 to 0.9 part of zinc peroxide, 1 to 10 parts of dimetyl carbonate, 4 to 15 parts of isooctyl nitrate, 3 to 10 parts of fatty acid methyl ester, and 0.1 to 0.9 part of 2,6-di-tert-butyl-4-methylpenol. The invention has the advantages that: the cyclohexane and the 2,6-di-tert-butyl-4-methylpenol are compounded, so that the modified methanol has high corrosion resistance and swelling resistance; the isopropanol and the fatty acid methyl ester are compounded, so that the water resistance of vehicle methanol gasoline is improved by more than two times; surfactant fatty acid methyl ester, the fatty acid methyl ester and the isopropanol are compounded, so that the added methanol and fossil gasoline can be mutually dissolved according to any proportion, and the problems of low-temperature layering and emulsification layering of the methanol gasoline are solved thoroughly; and the aviation kerosene No.1 is added so as to solve the problem of low-temperature cold boot of the methanol gasoline.

Owner:北京校产企联科技有限公司

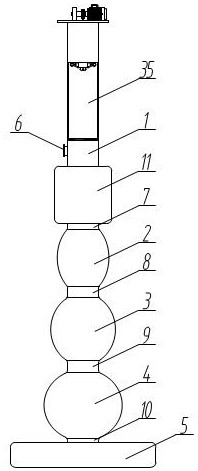

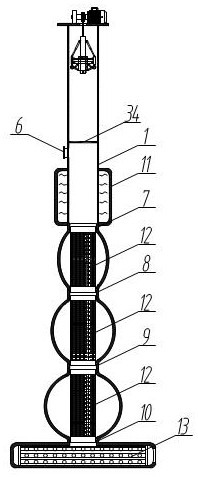

Spontaneous combustion type hydrogen-catalysis combustor

InactiveCN103398378ASimple structureImprove securityGaseous fuel burnerSpontaneous combustionCombustor

The invention relates to a spontaneous combustion type hydrogen catalysis combustor, and belongs to the technical field of hydrogen catalysis combustion. The spontaneous combustion type hydrogen catalysis combustor is characterized in that a gas nozzle is installed inside the spontaneous combustion type hydrogen-catalysis combustor, the spontaneous combustion type hydrogen-catalysis combustor is of a double layer structure, the first layer is a low temperature catalysis combustion layer, the second layer is a high temperature catalysis combustion layer, the low temperature catalysis combustion layer is arranged at the front end of the high temperature catalysis combustion layer, and a partition plate is arranged between the low temperature catalysis combustion layer and the high temperature catalysis combustion layer. The spontaneous combustion type hydrogen-catalysis combustor has the advantages of being simple in structure, good in safety, convenient to use, free of external heating for ignition, high in catalytic combustion efficiency, and low in emission, thereby being particularly suitable for being used for heating family houses and work places.

Owner:CHINA JILIANG UNIV

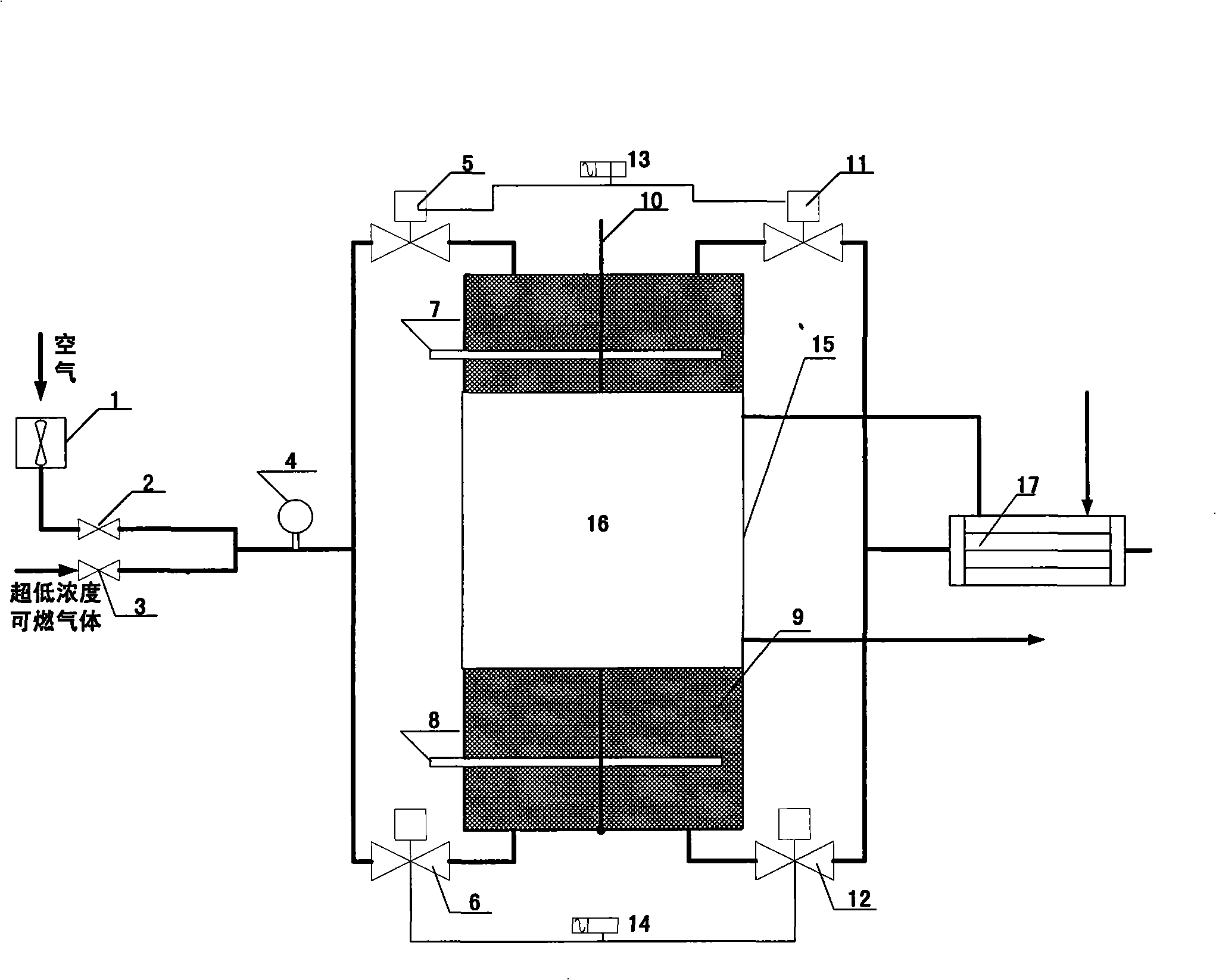

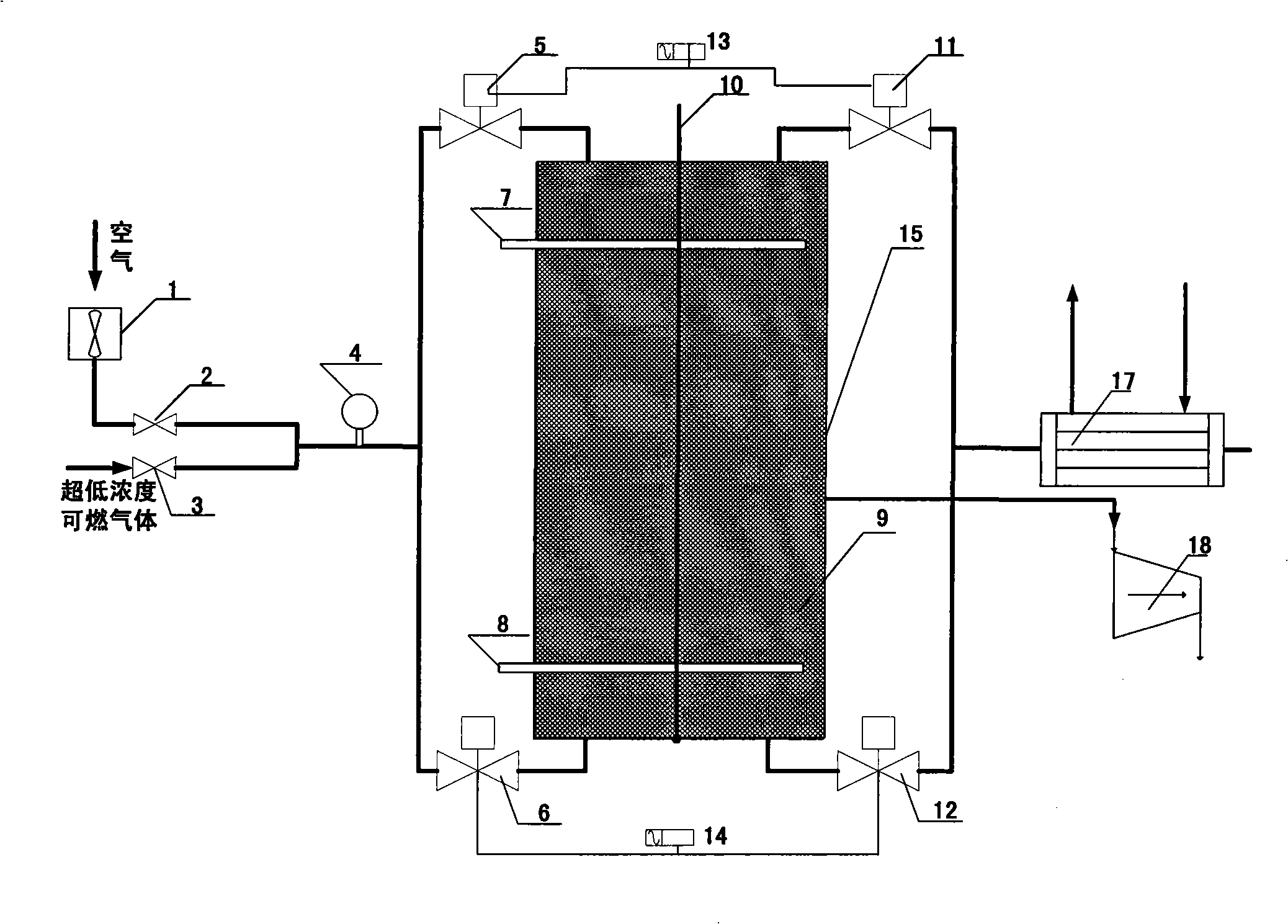

Combustion of ultra-low concentration combustible gas and its thermal energy step utilization system

InactiveCN101319781ASmall pressure lossImprove heat transfer efficiencyFuel supply regulationCombustion using catalytic materialThermal energyCombustion chamber

The invention relates to a system for the combustion and the heat energy cascade utilization of combustible gas with ultra low concentration. A magnet valve and a pipeline are formed into a gas circuit with periodically changed air flow direction, to be connected with a combustion chamber internally provided with heat storage medium and a heat exchanger; the heat transmission is realized between the gas and the heat storage medium and the heat exchanger. When the heat storage medium loads different catalyzer, lower initiation temperature can be realized; when the amount of the heat storage medium is sufficient, higher gas preheating temperature can be realized; through changing the amount of the catalyzer and the heat storage medium, higher operating temperature and lower combustion concentration limit can be realized, and through changing the category of the catalyzer and the commutation cycle of the magnet valve, better gas adaptability and load adjustment can be realized. Through the heat exchange of the working medium in the internal heat exchanger and the high-temperature gas after being burnt or through the high-temperature flue gas after the system is reacted, the utilization of the high grade heat energy can be realized; through reducing the exhaust fume temperature of the final product, the utilization of the low grade heat energy can be realized.

Owner:XI AN JIAOTONG UNIV

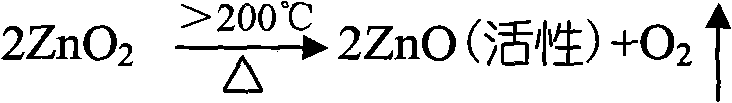

Methanol denaturation additive and preparation method thereof

InactiveCN102051238AImprove water resistanceSolve low temperature stratificationLiquid carbonaceous fuelsFuel additivesZinc peroxideOxygen

The invention relates to a methanol denaturation additive, which is prepared from the following components in part by weight: 50 to 90 parts of isopropanol, 3 to 20 parts of cyclohexane, 5 to 10 parts of No.1 aviation kerosene, 0.1 to 0.9 part of zinc peroxide, 1 to 10 parts of dimethyl carbonate, 4 to 15 parts of isooctyl nitrate, 3 to 10 parts of fatty acid methyl ester, and 0.1 to 0.9 part of 2,6-di-tert-butyl paracresol. The methanol denaturation additive has the advantages that: the zinc peroxide has extremely strong activity after pyrolysis in an engine, can clear organic peroxides generated when the methanol is in anoxic combustion, discharges trace oxygen during pyrolysis, and generates 'micro blasting effect'; and the trace 'oxygen bomb' is enough to make the formaldehyde substance generated by anoxic combustion of the methanol generate 'blasting' combustion so as to promote full combustion of alcohol ether fuels such as methanol and the like.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Composite modifying alcohol ether fuel and catalytic fuel agent

InactiveCN100412175CImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideAlcohol

The composite modifying catalyst for alcohol-ether fuel is compounded with zinc peroxide 5-15 weigh portions, dimethyl carbonate 15-35 weigh portions, vat yellow GCN 5-15 weigh portions, cyclohexylamine 3-10 weigh portions, and isooctyl nitrate 15-30 weigh portions, and through mixing at normal temperature. The alcohol-ether fuel with the composite modifying catalyst may have great methanol adding ratio while ensuring the combustion efficiency, fuel consumption, dynamic performance and other indexes.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

Diesel oil improver component containing biological enzyme and preparation method and application thereof

InactiveCN103421552AImprove catalytic performanceHigh-speed catalytic performanceLiquid carbonaceous fuelsFuel additivesAldehyde oxidasePeroxidase

The invention provides a diesel oil improver component containing biological enzyme, which comprises cetane number improver and biological enzyme, wherein the weight part ratio of the cetane number improver to the biological enzyme is 1:(0.01-1); the biological enzyme is the mixture of sulpho enzyme, alcohol oxidase, aldehyde oxidase, amine oxidase, sulfhydryl oxidase, methyl mercaptan oxidase, methyl naphthoquinone oxidase, peroxidase, ferrochelatase, decarboxylase, aldolase, oxyacid lyase, demethylase, alcohol dehydratase, acid dehydratase, esters dehydratase, desulfhydrase, desulfurization methyl enzyme, cobalt chelating enzyme and magnesium chelating enzyme. According to the diesel oil improver component containing the biological enzyme, provided by the invention, the high speed catalytic performance can be realized under the temperate environment through utilizing properties of the biological enzyme, and the component is combined with the conventional cetane number improver for use, the catalytic combustion efficiency of the cetane number improver in diesel oil is greatly improved, and the combustion performance of the diesel oil is further improved.

Owner:英杰惠能(北京)能源新技术有限公司

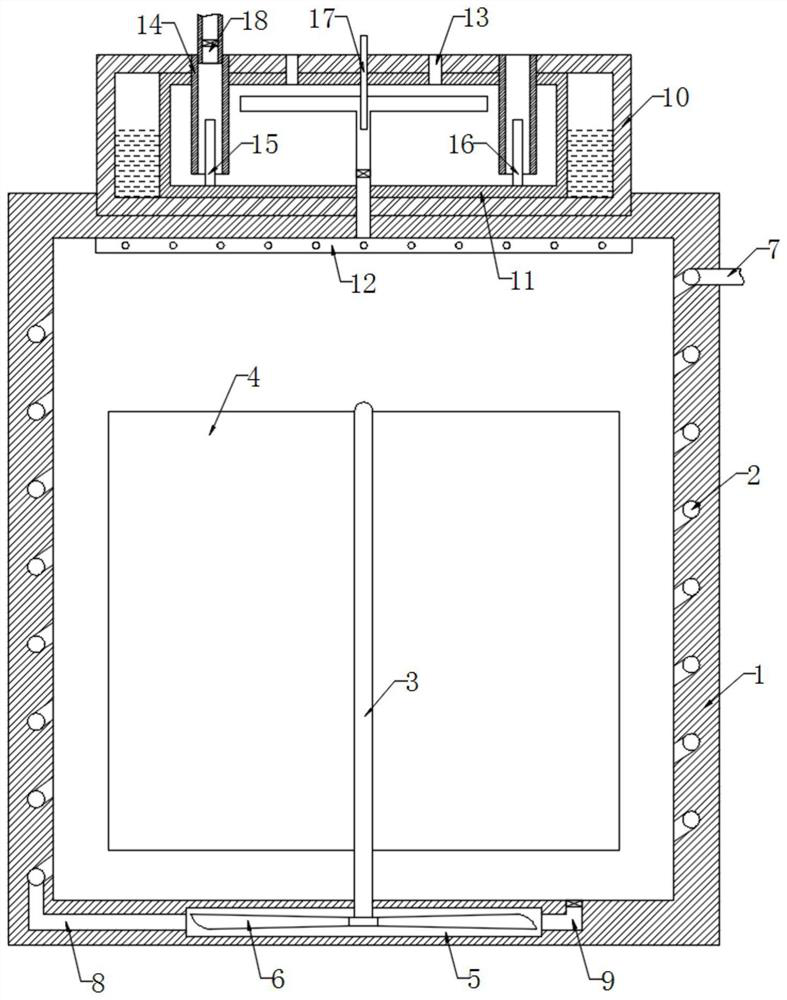

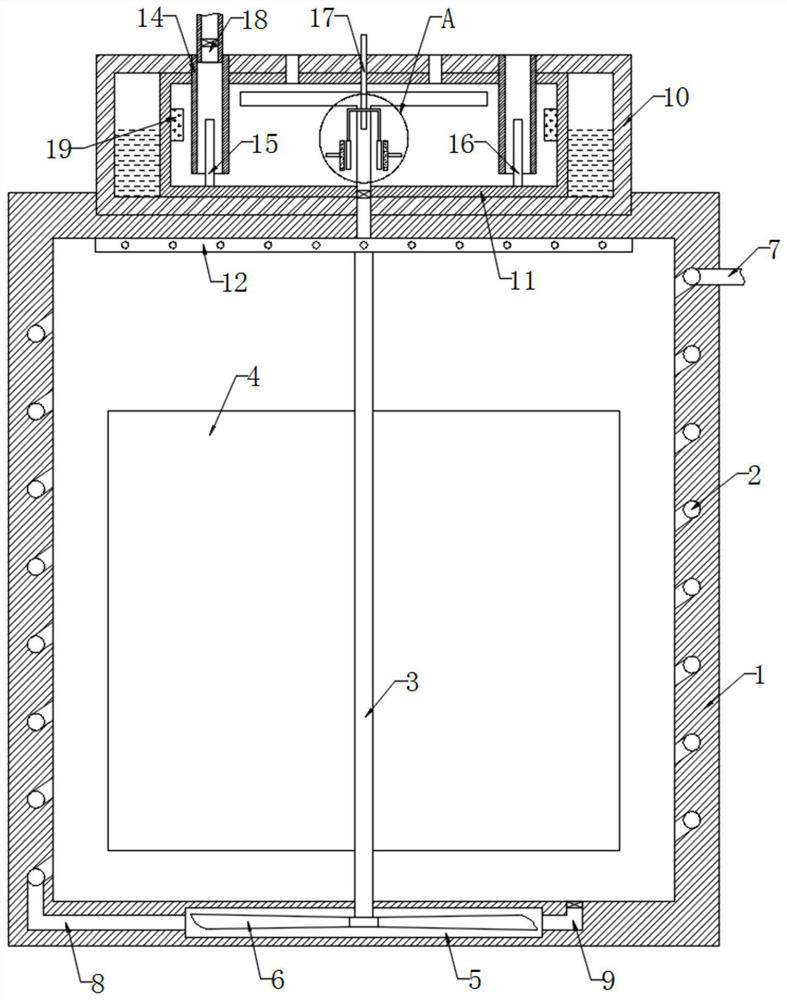

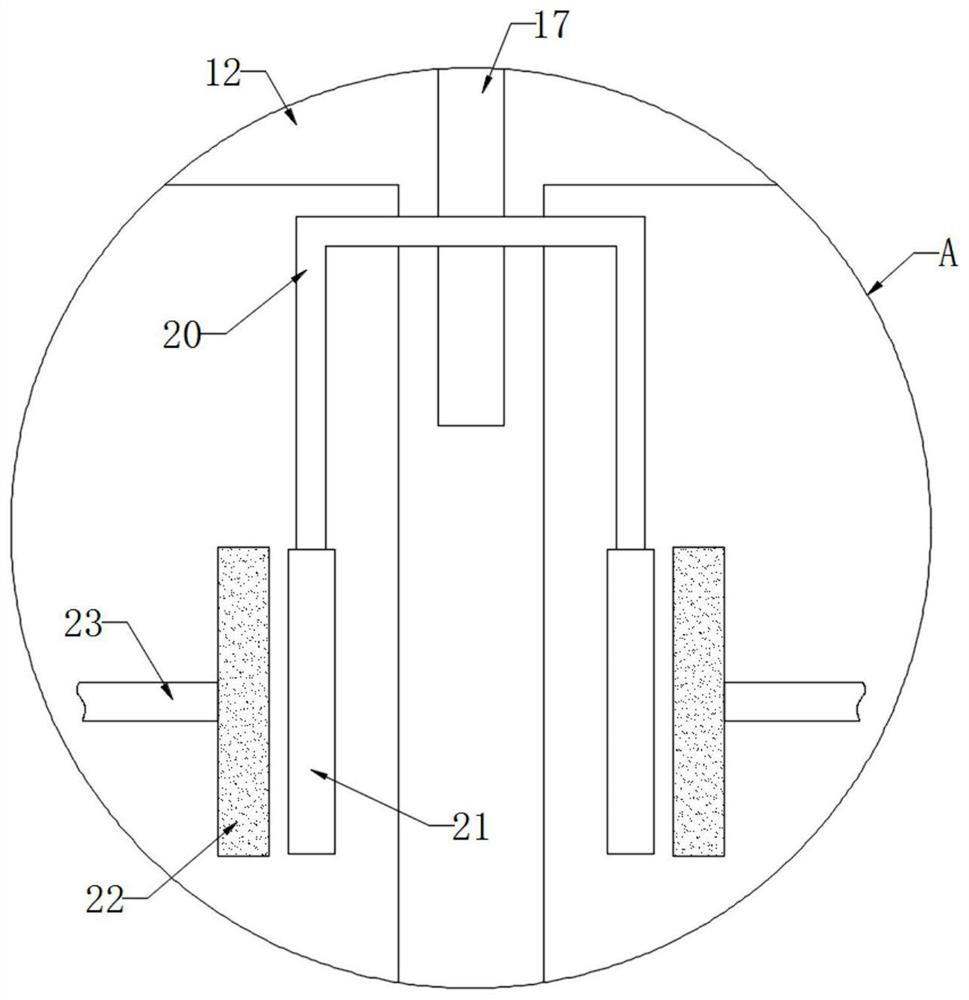

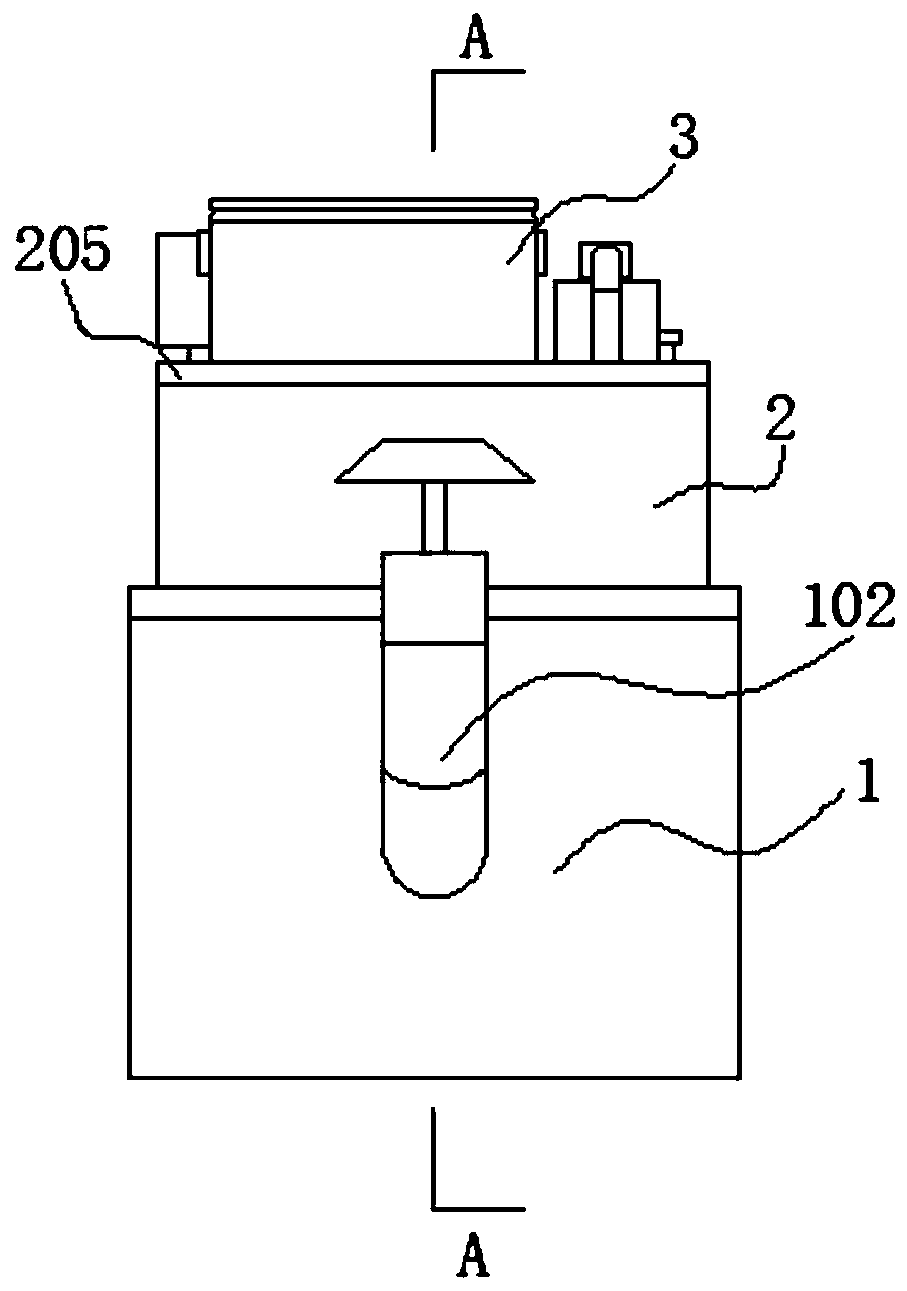

Waste gas catalytic combustion equipment for garbage disposal

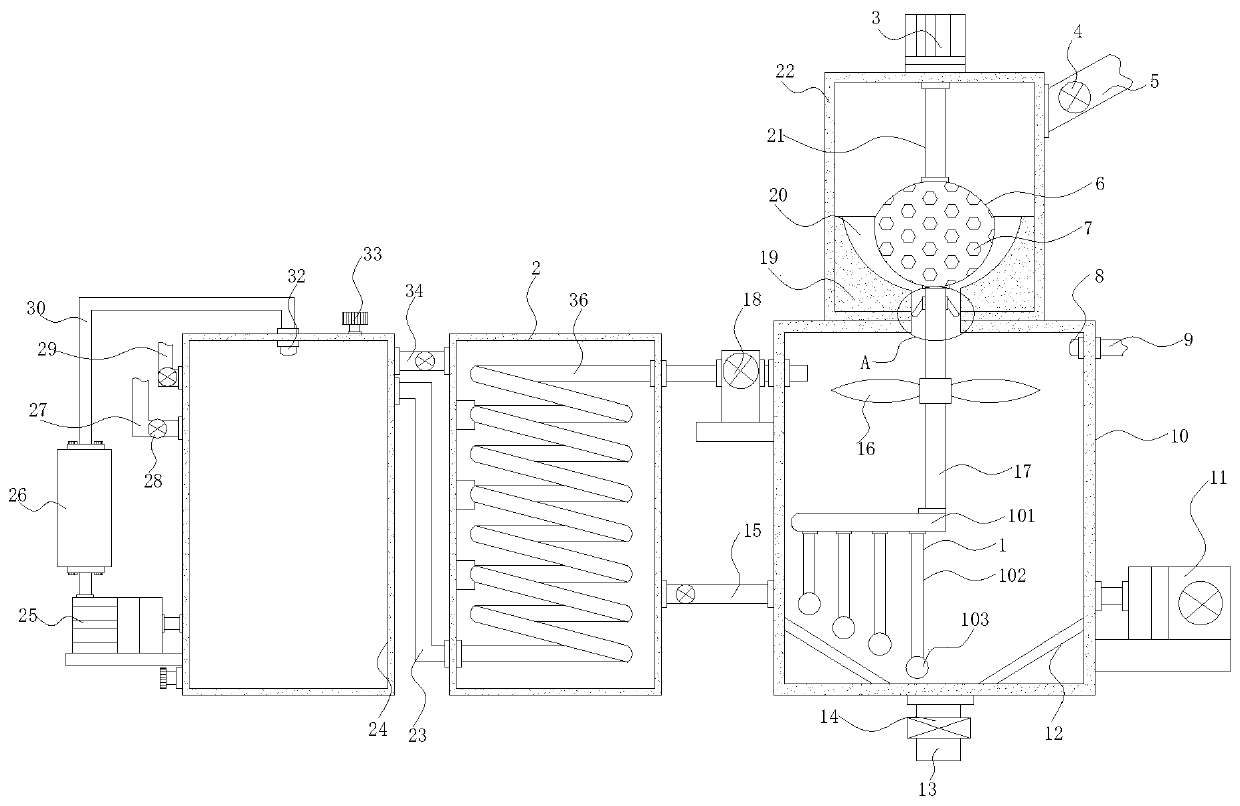

PendingCN111664462AImprove catalytic combustion efficiencyIncrease contact areaIncinerator apparatusGenerators/motorsCombustion chamberPtru catalyst

The invention discloses waste gas catalytic combustion equipment for garbage disposal. The waste gas catalytic combustion equipment comprises a combustion chamber, a spiral heating cavity is formed inthe inner wall of the combustion chamber, a rotating shaft is rotationally connected to the bottom in the combustion chamber, a plurality of stirring blades are fixedly connected to the side wall ofthe rotating shaft, a circular cavity is formed in the lower end of the combustion chamber, the lower end of the rotating shaft penetrates through the lower end of the combustion chamber and extends into the circular cavity, a wind wheel is fixedly connected to the lower end of the rotating shaft, and the side wall of the combustion chamber is connected with one end of the spiral heating cavity through an air inlet pipe. According to the waste gas catalytic combustion equipment, the wind wheel rotates to drive the stirring blades to rotate to stir a catalyst in the combustion chamber, so thatwaste gas is in full contact with the catalyst, and the waste gas is subjected to full combustion treatment; and heat contained in water vapor can enable the two ends of a temperature difference powergeneration piece to generate a large temperature difference, so that a positive electrode electrolysis rod and a negative electrode electrolysis rod are used for electrolyzing water, oxygen generatedby water electrolysis enters an incinerator, and the incineration efficiency during garbage incineration is improved.

Owner:曾晓云

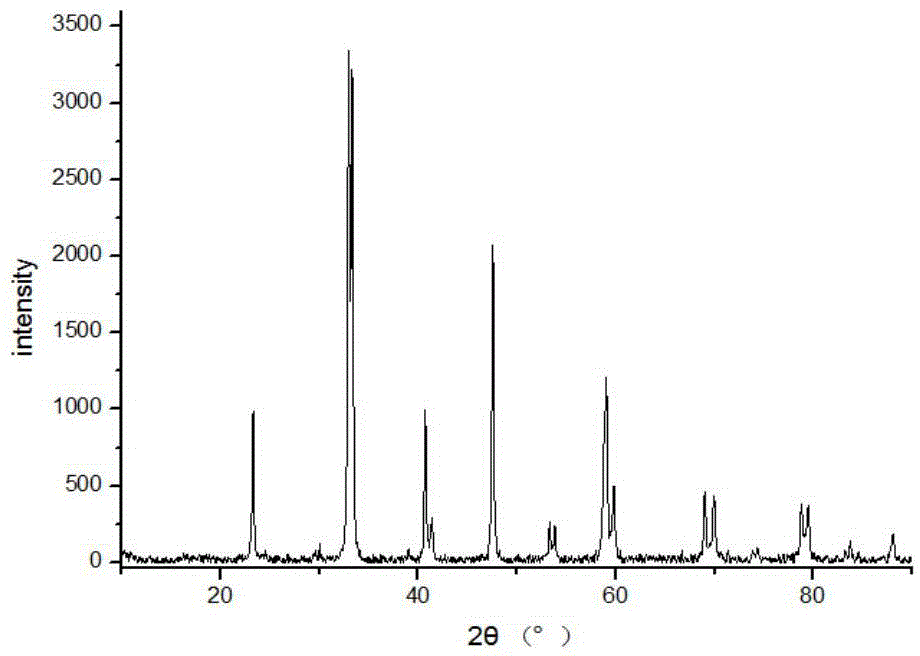

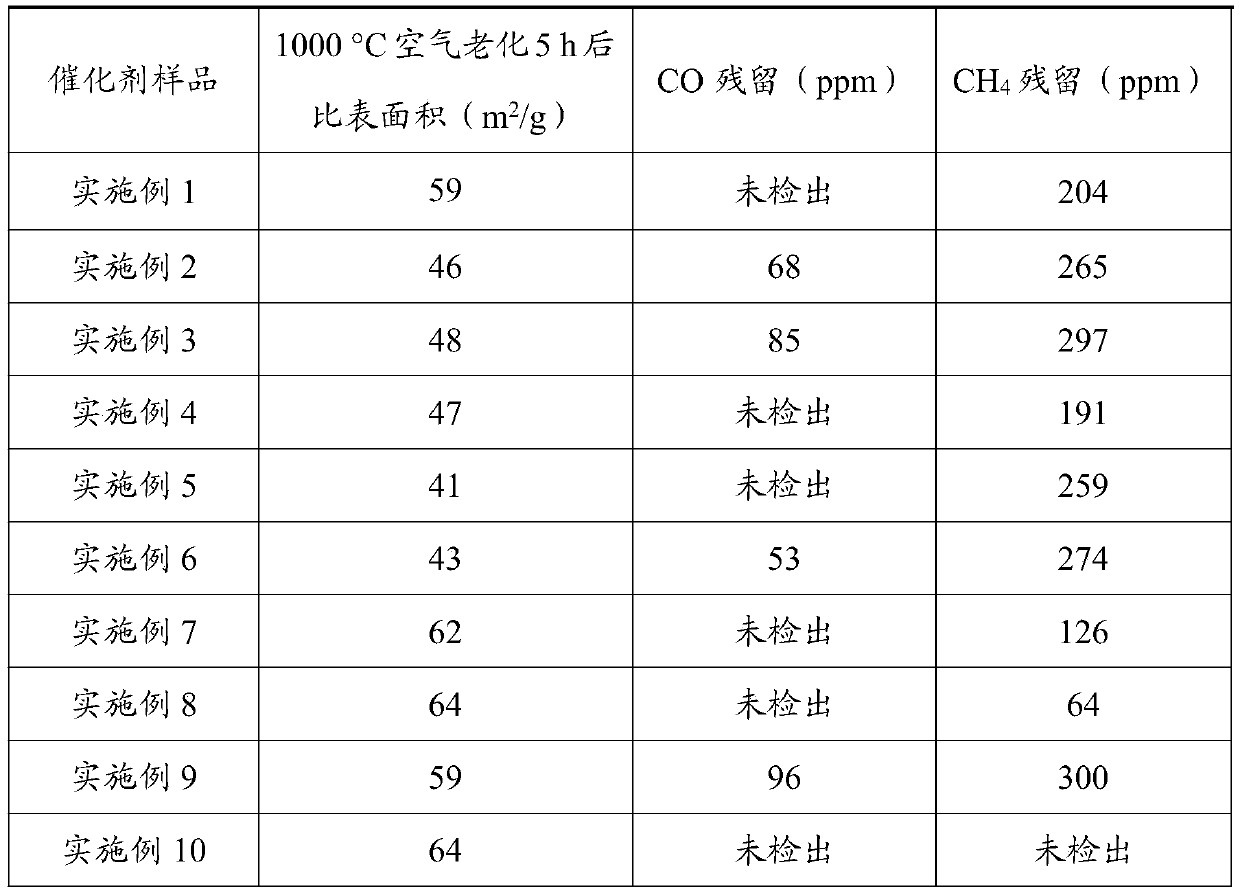

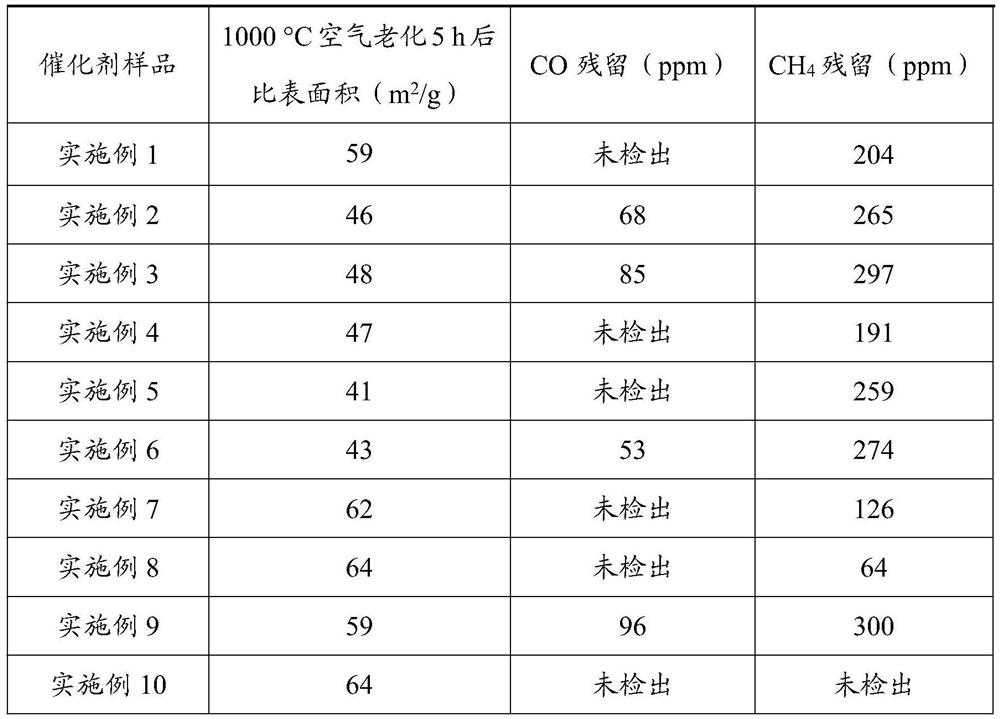

Liquid nitrogen washed tail gas high temperature catalytic combustion catalyst, and preparation method and applications thereof

ActiveCN110152660AImprove activity stabilityImprove thermal stabilityHeterogenous catalyst chemical elementsIncinerator apparatusLiquid nitrogenCatalytic combustion

The invention belongs to the technical field of tail gas combustion catalyst, and especially relates to a liquid nitrogen washed tail gas high temperature catalytic combustion catalyst, and a preparation method and applications thereof. The liquid nitrogen washed tail gas high temperature catalytic combustion catalyst possesses a stable structure and large specific surface area; after 5h of roasting aging of the catalyst at 1000 DEG C in the air, the specific surface area is still larger than 40m<2> / g. The catalyst is capable of realizing stable high efficiency reaction of liquid nitrogen washed tail gas catalytic combustion at 800 DEG C for longer than 10000h, liquid nitrogen washed tail gas catalytic combustion efficiency is extremely high, liquid nitrogen washed tail gas CO concentration can be reduced to be lower than 50ppm, CH4 concentration can be reduced to be lower than 300ppm, H2 can be removed completely, and energy saving emission reducing effect is obvious.

Owner:KUNMING UNIV OF SCI & TECH

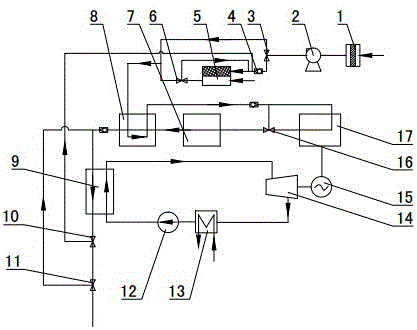

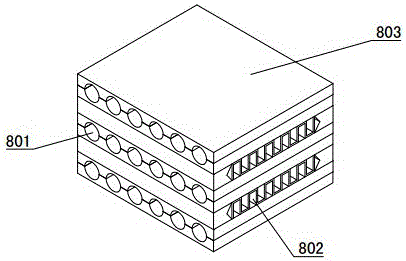

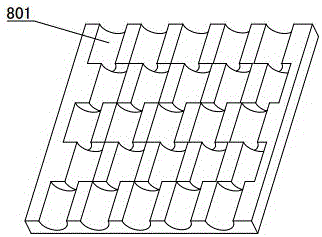

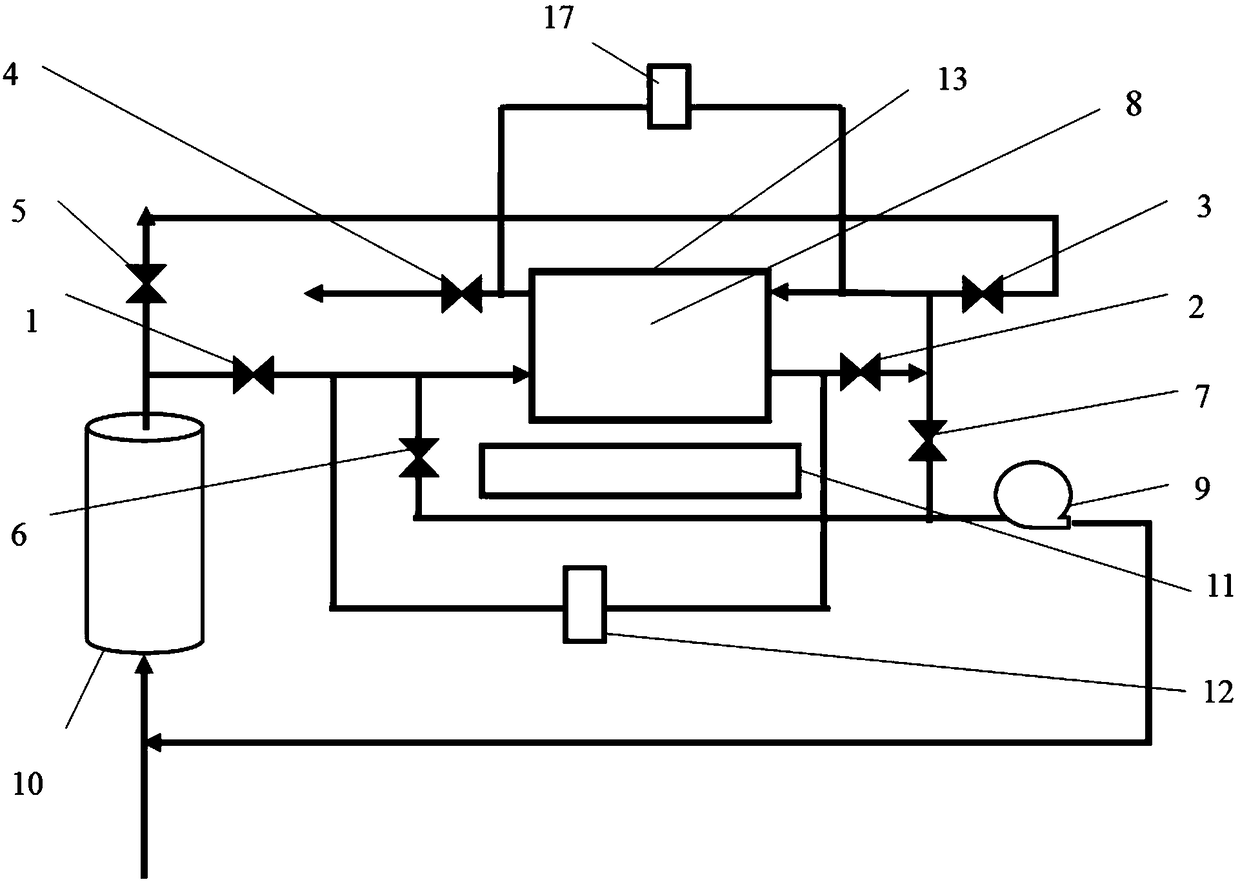

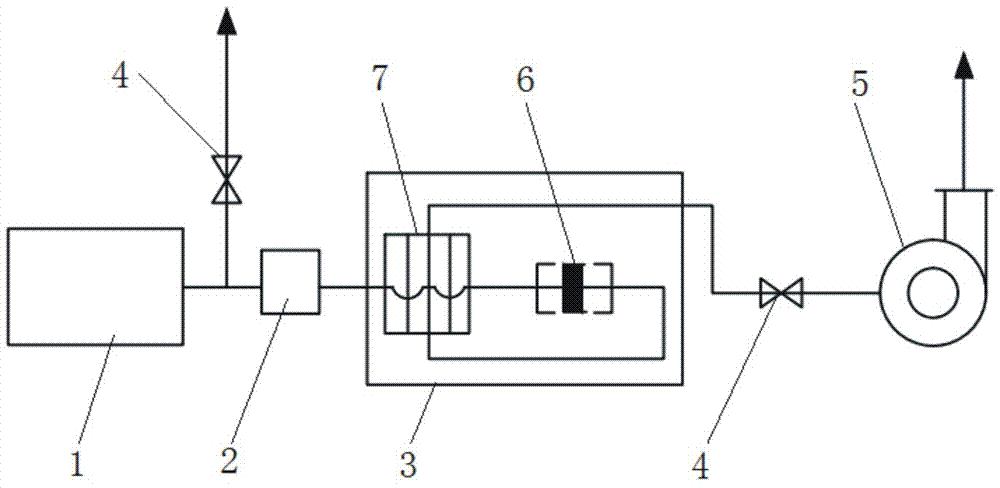

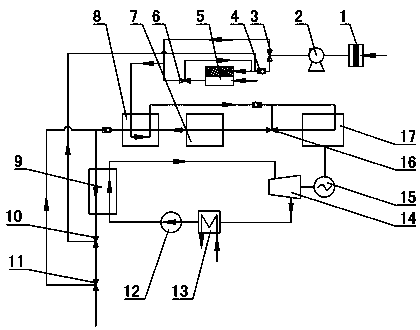

Efficient VOC treatment system and treatment process flow adopting novel heat exchanger

ActiveCN106369617AGuaranteed concentrationBurn fullyDispersed particle filtrationSteam engine plantsAtmospheric airRecuperator

The invention discloses an efficient VOC treatment system and treatment process flow adopting a novel heat exchanger, and belongs to the technical field of waste gas treatment equipment. The efficient VOC treatment system is characterized in that the gas outlet end of a pre-treatment module communicates with the gas inlet end of a catalytic combustion module; the gas outlet end of the catalytic combustion module communicates with the atmosphere; a heat exchange unit is arranged between a power generation unit and the gas outlet end of the catalytic combustion module; and the power generation module is electrically connected with the catalytic combustion module through a wire and provides electricity for the catalytic combustion module. By adoption of the efficient VOC treatment system adopting the novel heat exchanger, environment pollution is avoided, and heat generated after VOC waste gas is combusted can be fully reutilized, so that self energy supply is guaranteed, and energy waste is effectively avoided; the VOC waste gas is effectively treated by pre-treating the VOC waste gas and exhausting the VOC waste gas into the atmosphere after catalytic combustion; and low-temperature gas after catalytic combustion and primary heat exchange is utilized for heat-exchange power generation by the power generation module through the heat exchange unit, electric energy is provided for heating of the catalytic combustion module, and the utilization rate of the energy sources is increased accordingly.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Nano combustion catalyst and preparation method thereof

InactiveCN108311157ASolve the problem of excessive emissionsHigh activityHeterogenous catalyst chemical elementsCatalyst activation/preparationCerium(IV) oxideManganese oxide

The invention provides a nano combustion catalyst. The nano combustion catalyst is prepared from the following raw materials: aluminium oxide, silicon dioxide, cerium oxide, ferric oxide and manganeseoxide with the weight ratio being (40-60):(20-30):(1-5):(10-30):(5-10), wherein cerium oxide is nano cerium oxide, ferric oxide is nano ferric oxide, and manganese oxide is nano manganese oxide. Theinvention also provides a preparation method of the nano combustion catalyst. The preparation method comprises the following steps of: weighing aluminium oxide, silicon dioxide, cerium oxide, ferric oxide and manganese oxide according the weight percent, and mixing with water to obtain preparation raw materials; placing the preparation raw materials into a ball mill for ball milling; adopting a forming process to prepare the ball-milled preparation raw materials into spheres or cylinders; placing in a roasting furnace for roasting, then taking out, and cooling to room temperature. The nano combustion catalyst provided by the invention has the beneficial effects that the problem of exceeding-standard tail-gas emission caused by failure of the three-way catalyst due to poisoning and ageing can be solved, and the activity and the efficiency are high.

Owner:天津爱蓝天环保科技有限公司

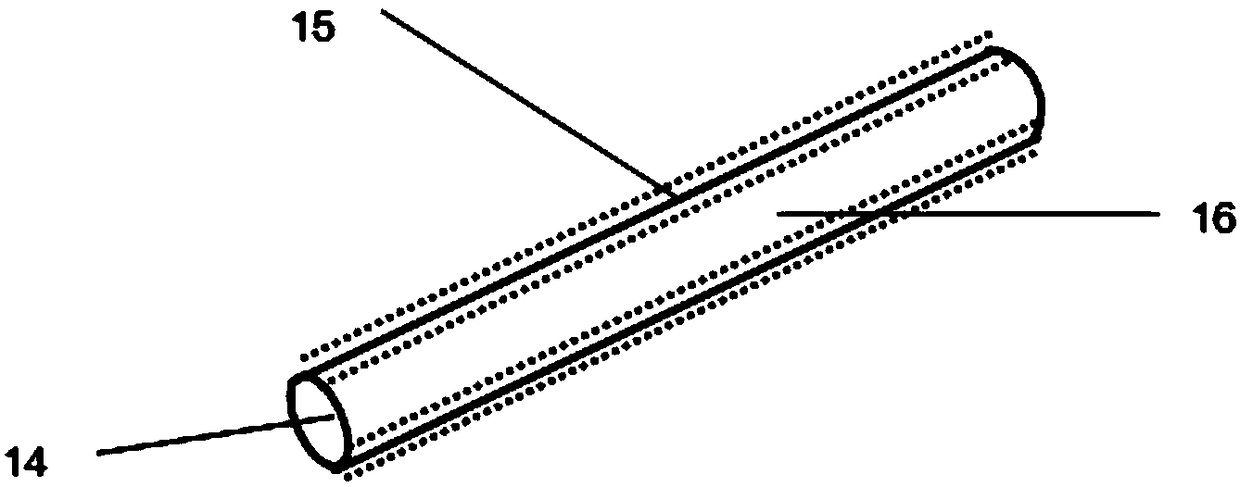

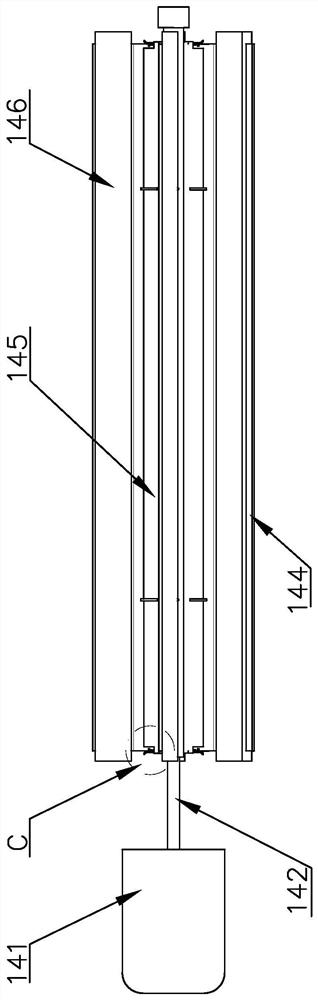

Gas phase organic substance catalytic combustion device and method based on two-dimensional zeolite catalyst

PendingCN109185902ALarge amount of processingTake advantage ofGas treatmentDispersed particle separationAtmospheric airGas phase

The invention discloses a gas phase organic substance catalytic combustion device and method based on an ultra-thin two-dimensional zeolite catalyst. A filter, a catalytic ceramic membrane module, a vacuum pump and two differential pressure controllers are included; the inner and outer walls of a tube pass of the catalytic ceramic membrane module are each coated with an ultra-thin two-dimensionalzeolite catalyst layer, an outlet of the filter is connected to a tube-pass inlet and a shell-pass inlet of the catalytic ceramic membrane module through pipes provided with valves, a tube-pass outletand a shell-pass outlet of the catalytic ceramic membrane module communicate with the atmosphere through pipes provided with valves, an inlet of the vacuum pump is connected to the tube-pass inlet and the shell-pass inlet of the catalytic ceramic membrane module through the valves, an outlet of the vacuum pump is connected to an inlet of the filter, and the two differential pressure controllers are used for detecting pressure differences between the tube-pass inlet and the tube-pass outlet of the catalytic ceramic membrane module and between the shell-pass inlet and the shell-pass outlet of the catalytic ceramic membrane module. The gas phase organic substance catalytic combustion device and method have the beneficial effects that the combustion efficiency is high, environmental protection is achieved, energy consumption is low, secondary pollution is avoided, repeated utilization can be achieved, and the catalytic combustion process of gas phase organic pollutants is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Waste gas recovery and management circulation system

InactiveCN107020010ADecompose fullyReduce consumptionGas treatmentDispersed particle separationPlate heat exchangerProcess engineering

The present invention discloses a waste gas recovery and management circulation system, which comprises a catalysis chamber, an exhaust fan, a catalytic reaction device and a heat exchanger, wherein the catalytic reaction device and the heat exchanger are arranged in the catalysis chamber. According to the present invention, through the action of the exhaust fan, organic waste gas can sequentially enter the heat exchanger and the catalytic reaction device while the burned high-temperature gas passes through the heat exchanger to pre-heat the organic waste gas, such that the gas circulation is achieved so as to save the energy source; and with the waste gas recovery and management circulation system, the organic waste gas can be sufficiently decomposed while the organic waste gas to be decomposed can be pre-heated by recycling the heat generated during the catalytic burning so as to improve the catalytic burning efficiency, reduce the energy source consumption, and protect the environment.

Owner:佛山市顺德区春祥包装材料有限公司

Composite catalyzing alcohol ether gasoline with no lead, and method of preparation

InactiveCN100462423CImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideIsobutanol

This invention relates to a method for preparing leadless composite gasoline added with methanol and ethers. The leadless composite gasoline is composed of: methanol 50-80 parts, gasoline product 10-30 parts, naphtha 20-30 parts, isobutanol 0.5-14 parts, methyl-tert-butyl ether 1-8 parts, petroleum benzene 0.1-10 parts, petroleum ether 0.3-10 parts, additives 0.1-3 parts and assistant liquid 0.2-0.5 part. The additives are mixed from zinc peroxide, dimethyl carbonate, and vat yellow, cyclohexylamine and isooctyl nitrate. The assistant liquid is prepared from n-butanol, petroleum benzene and cyclohexylamine. The method comprises: (1) preparing the additives; (2) preparing the mother gasoline; (3) preparing modified methanol; (4) preparing modified naphtha; (5) preparing the synthetic liquid; (6) mixing with the assistant liquid to obtain leadless composite gasoline. The obtained leadless composite gasoline has high methanol content.

Owner:鲁希诺

Organic waste gas catalytic combustion device

InactiveCN108072040ACatalytic combustion is efficientCatalytic combustion continuesIncinerator apparatusAir pumpEngineering

The invention discloses an organic waste gas catalytic combustion device. The organic waste gas catalytic combustion device comprises a reaction device and an air inlet device. The air inlet device comprises an air inlet pipe, a gas flow controller A and a control valve A. The reaction device comprises a copper pipe arranged inside, an induction coil arranged on the copper pipe, high-frequency induction heating equipment connected with the induction coil, and a plurality of metal porous plates. An air inlet is formed in the bottom of the reaction device and is in threaded connection with the air inlet pipe. The air inlet pipe arranged in the device is provided with a plurality of fan-shaped nozzles, an air return port is formed in the top of the reaction device, and the air return port isconnected with an air return way arranged on the outer side of the reaction device; and an air outlet is formed in the bottom of the air return way, and the air outlet is externally connected with a sucking pump. By means of the device, efficient organic waste gas catalytic combustion can be finished, the catalytic combustion efficiency is improved, and energy is saved.

Owner:成都瀚川环境科技有限公司

Diesel oil improver component containing biological enzyme and preparation method and application thereof

InactiveCN103421552BImprove catalytic performanceHigh-speed catalytic performanceLiquid carbonaceous fuelsFuel additivesPeroxidaseLyase

The invention provides a bioenzyme-containing diesel oil booster composition, comprising a cetane number improver and a bioenzyme at a weight ratio of 1:0.01-1; the bioenzyme is sulfonase, alcohol oxidase, aldehyde Oxidase, amine oxidase, sulfhydryl oxidase, methylmercaptan oxidase, menaquinone oxidase, peroxidase, ferrochelatase, decarboxylase, aldolase, oxoacid lyase, demethylation Mixture of enzymes, alcohol, acid, ester dehydratase, desulfhydrylase, desulfomethylase, cobalt chelatase, magnesium chelatase. A bio-enzyme-containing diesel oil booster composition of the present invention can realize high-speed catalytic performance in a mild environment by utilizing the characteristics of a bio-enzyme, and is used in combination with the existing cetane number improver, The catalytic combustion efficiency of the cetane number improver in diesel is significantly improved, and the combustion performance of diesel is further improved.

Owner:英杰惠能(北京)能源新技术有限公司

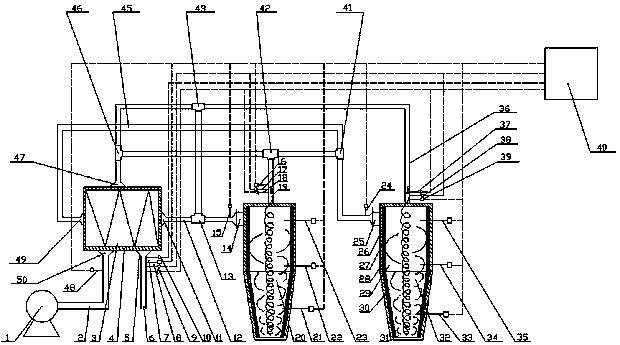

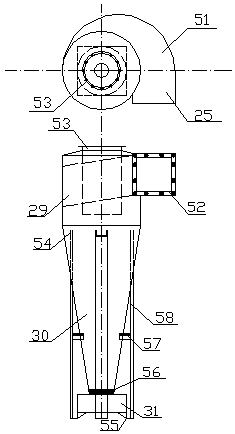

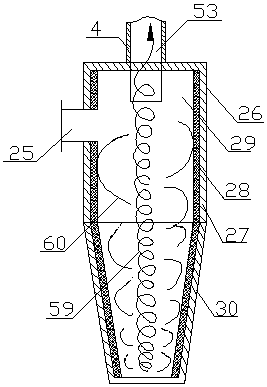

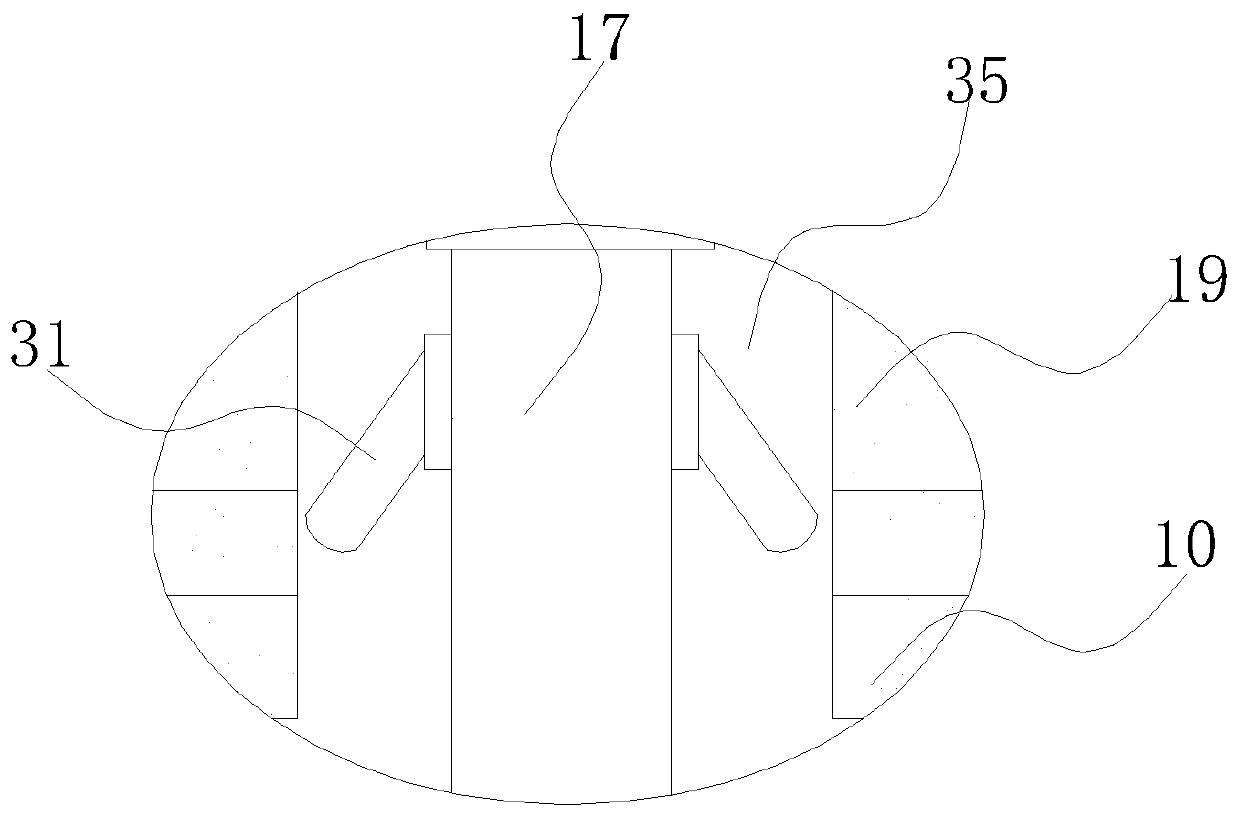

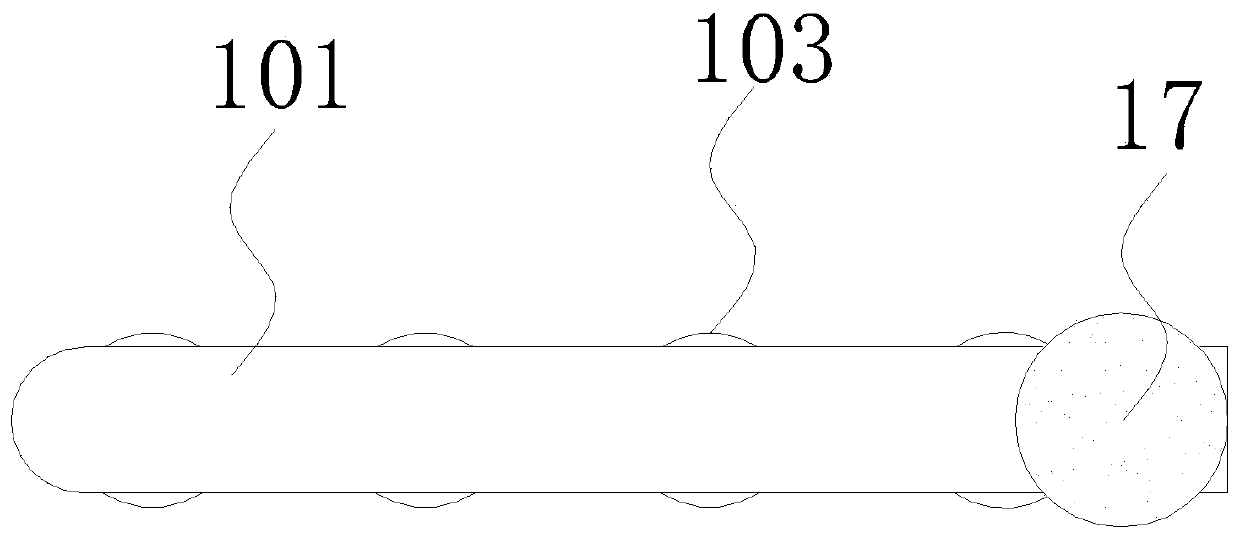

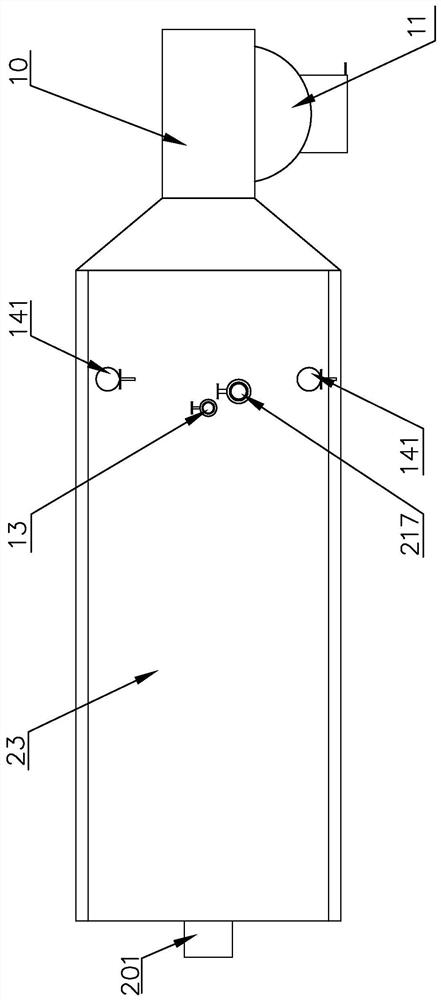

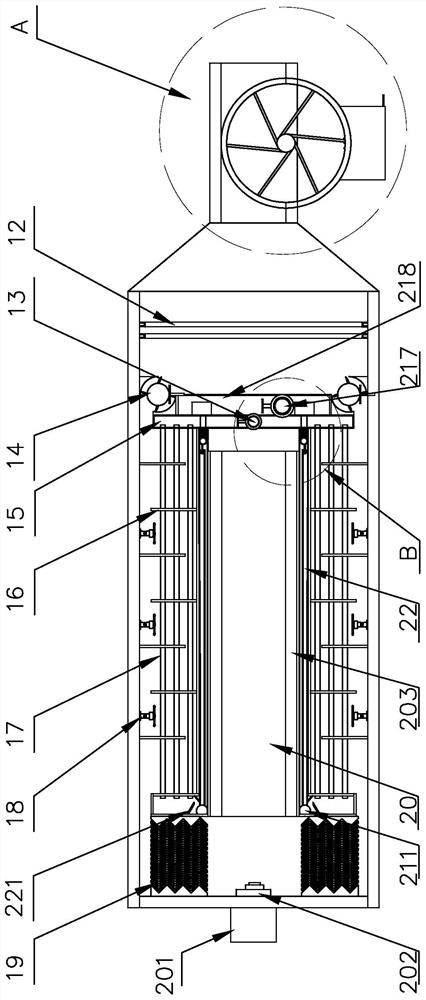

Cyclonic coal mine ventilation air methane (VAM) catalytic oxidization reactor

PendingCN108926996AExtended stayReduce dust concentrationDispersed particle separationControl systemCatalytic oxidation

A cyclonic coal mine ventilation air methane catalytic oxidization reactor belongs to the technical field of ultralow concentration methane catalytic oxidization and comprises: a gas feeding / dischargesystem, a preheating system, a reaction system, a pipeline system, and a test and control system. The VAM is preheated in a preheater and is fed into a first reactor in a volute tangential entering direction; the gas then rotates from the top to the bottom along an inner wall of the reactor and is reacted with a catalyst coating the inner wall of the reactor to generate CO2 and H2O; meanwhile, dust particles in the VAM are removed after falling into an ash hopper along the inner wall of the reactor; after the reaction, high-temperature gas rotates upwardly along axis and is finally dischargedthrough an exhaust pipe and fed into a second reactor; then the gas is subjected to the same reaction in the second reactor, a large amount of heat being released; the processes are repeatedly and alternately carried out to achieve auto-operation of the apparatus. The reactor can treat the VAM being 0.1-5% of concentration, can reach 1000 m<3> / h in maximum treatment load and 0.35 m / s in gas flowspeed, can reach 1000 DEG C in maximum working temperature and is more than 80% in removal rate.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

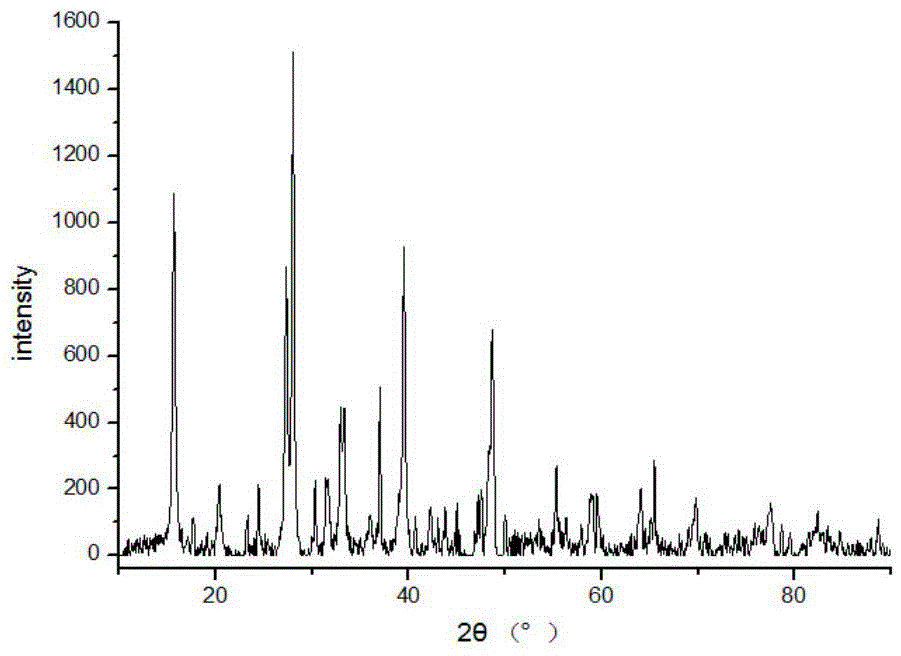

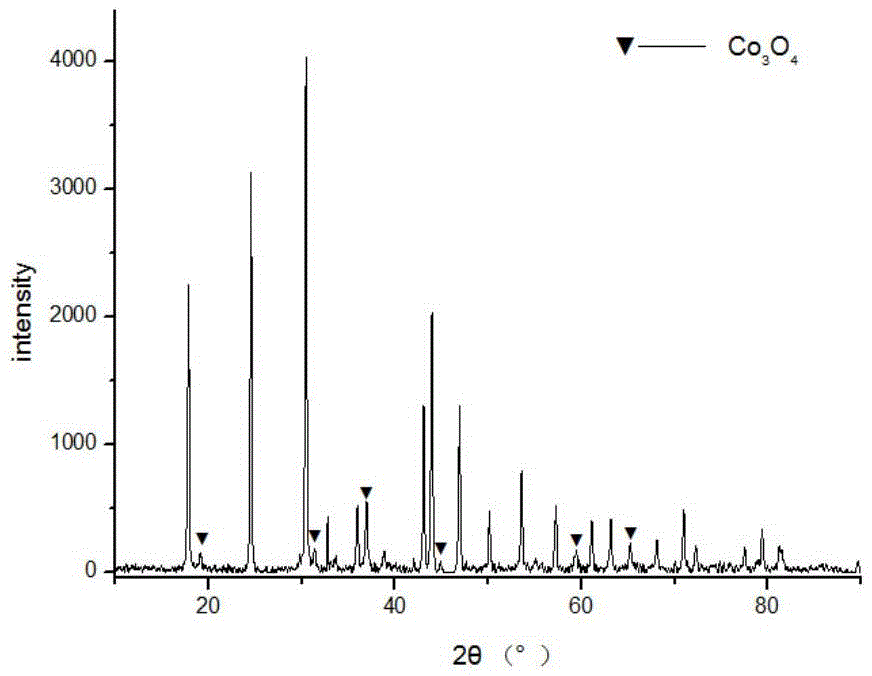

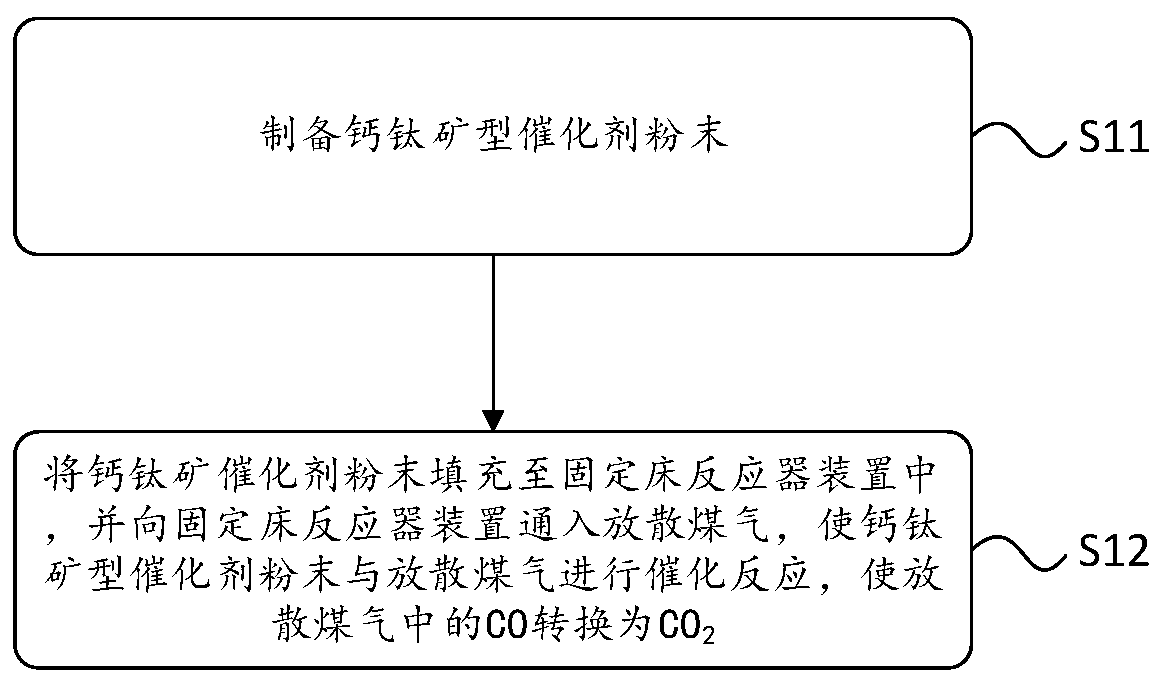

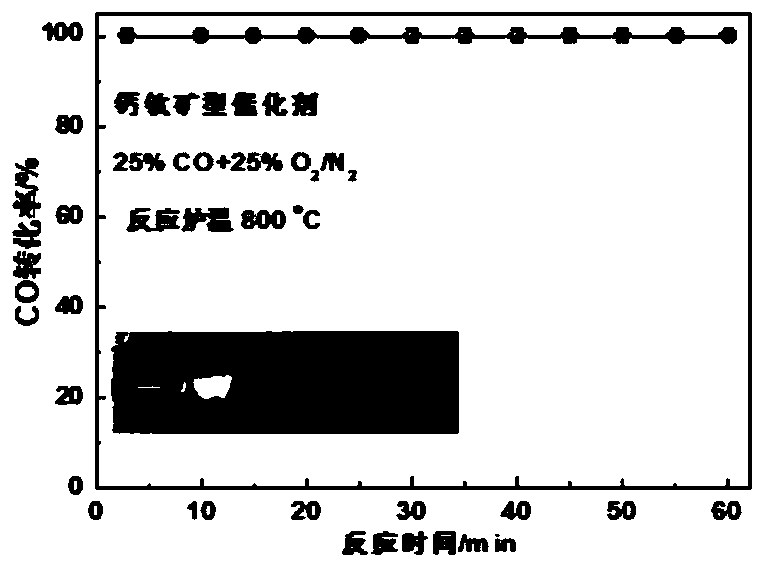

Method for self-sustained combustion of converter released coal gas based on perovskite catalyst

InactiveCN111549198AImprove catalytic combustion efficiencyHigh waste heat utilization qualityManufacturing convertersIncinerator apparatusPtru catalystThermodynamics

The embodiment of the invention relates to a method for self-sustained combustion of converter released coal gas based on perovskite catalyst. The method comprises the steps that perovskite catalyst powder is prepared; and the interior of a fixed bed reactor device is filled with the perovskite catalyst powder, released coal gas is lead into the fixed bed reactor device, and the perovskite catalyst powder has a catalytic reaction with the released coal gas, so that CO in the released gas is converted into CO2. Therefore, the method is simple in process and easy to control, CO catalytic combustion efficiency is high, smoke waste heat use quality is high, external heat supply is not needed, running cost is low, the method is used for treating the high-temperature released coal gas, the emission standards of the nation or regions can be achieved, the waste heat use quality is improved, the waste heat use manner can be widened, and the considerable economic benefits can be created.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

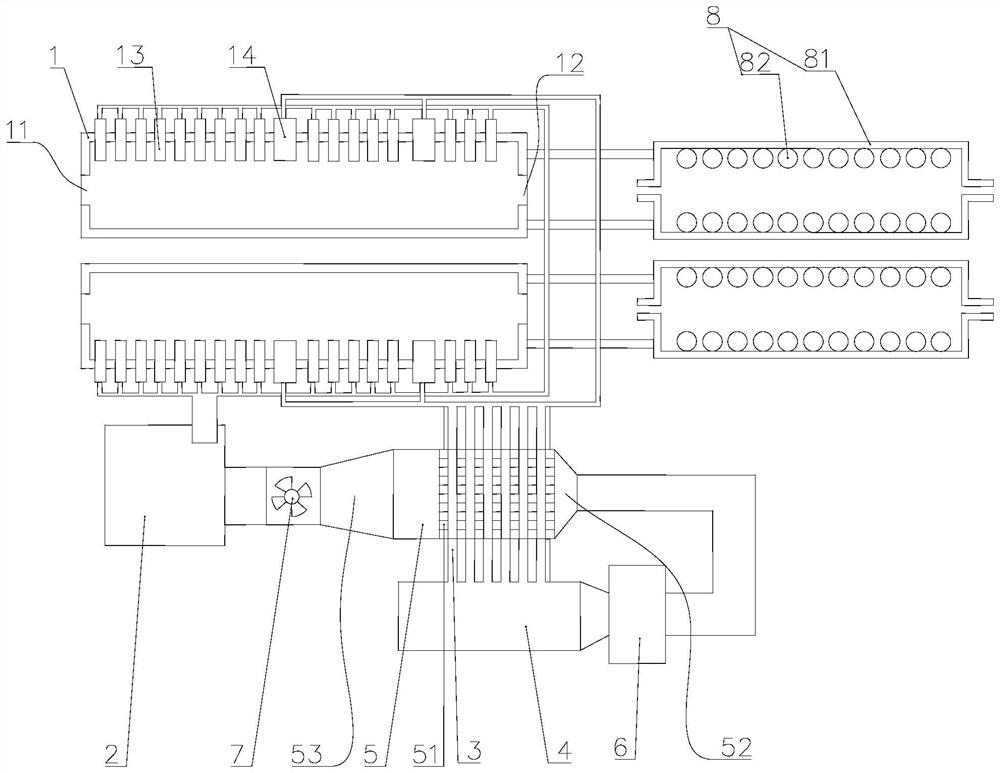

Color plate color coating circulation drying and curing equipment and method

InactiveCN111992467AIncrease profitRealize secondary usePretreated surfacesCoatingsPtru catalystCombustion

The invention discloses color plate color coating circulation drying and curing equipment and method. The color plate color coating circulation drying and curing equipment comprises drying ovens, a main combustion furnace, catalytic tubes, a waste gas combustion furnace and a catalytic box, wherein drying chambers are arranged in the drying ovens, feeding ports and discharging ports which communicate with the drying chambers are formed in the two horizontal ends of the drying ovens correspondingly, a plurality of air blowing openings and air return openings are formed in the inner side wall ofthe top and / or the bottom of the drying chamber, an outlet of the main combustion furnace communicates with the air blowing openings of the drying oven, the main combustion furnace can introduce high-temperature gas into the drying chamber, inlets of the catalytic tubes communicates with suction openings of the drying ovens, an inlet of a waste gas combustion furnace communicates with outlets ofthe catalytic tubes, catalysts are uniformly arranged in the catalytic box, a gas inlet and a gas outlet are arranged in the catalytic box, the gas inlet of the catalytic box communicates with an outlet of the waste gas combustion furnace, the gas outlet of the catalytic box communicates with an inlet of the main combustion furnace, and the two drying ovens are stacked in the vertical direction, the multiple catalytic tubes are arranged in the catalytic box in a penetrating mode, and inlets and outlets of the catalytic tubes penetrate out of the catalytic box.

Owner:苏州林昊板业科技有限公司

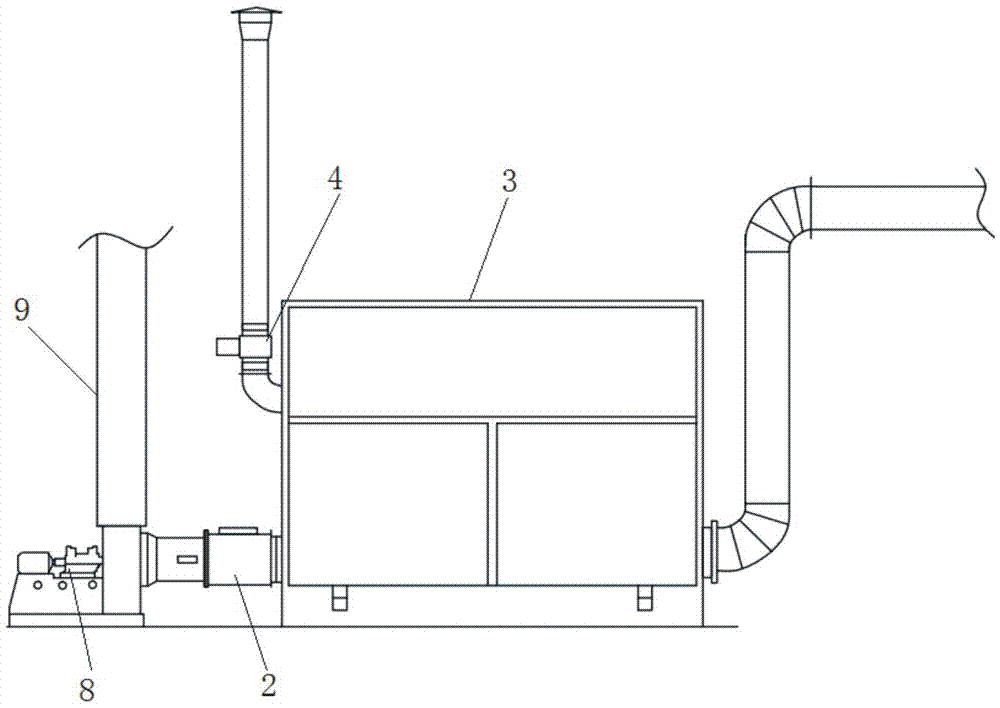

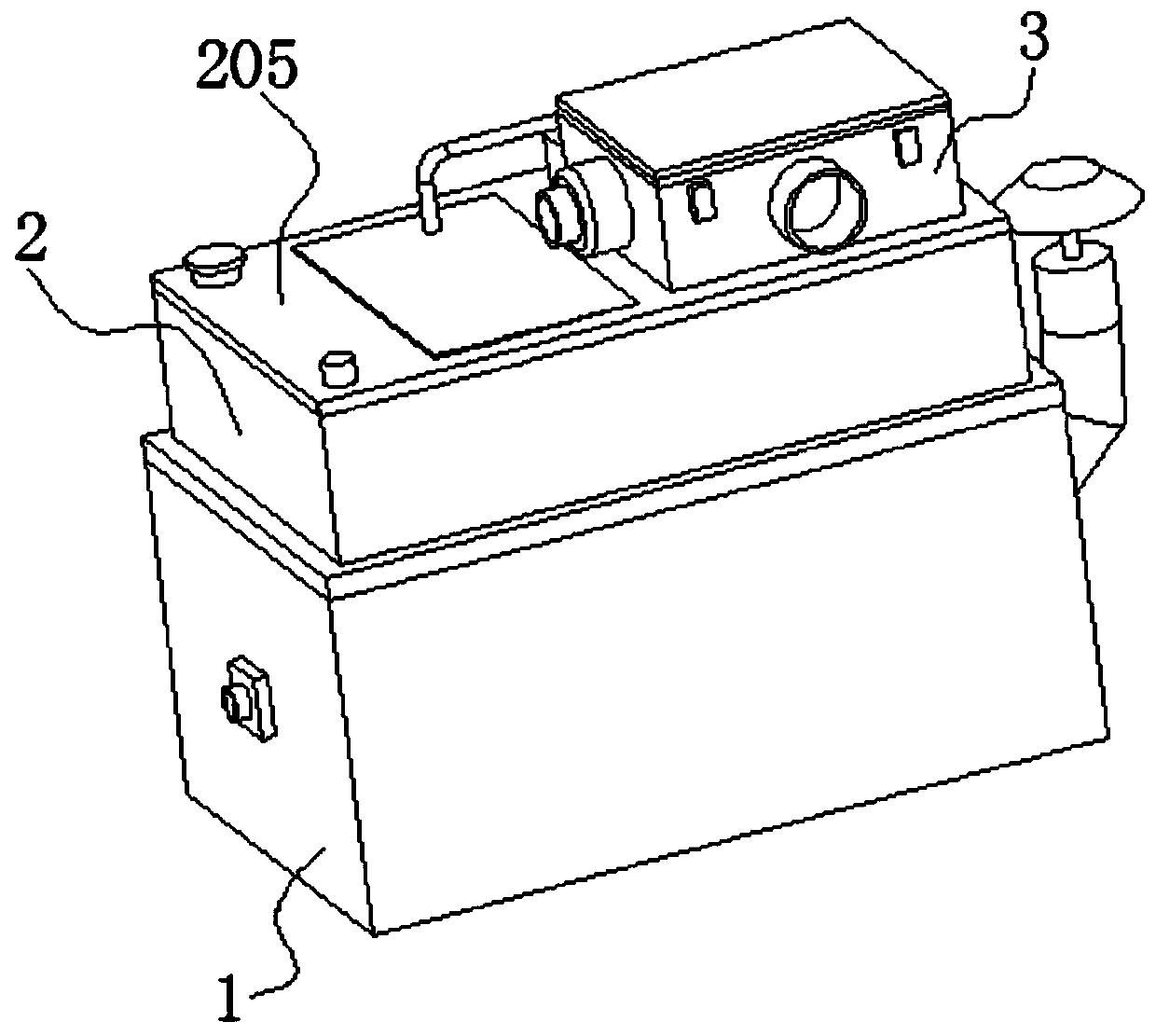

RCO catalytic combustion equipment for waste gas treatment in industrial production

PendingCN114459043AEasy to replaceImprove catalytic combustion efficiencyIncinerator apparatusThermodynamicsCombustion chamber

The invention discloses RCO catalytic combustion equipment for waste gas treatment in industrial production, the RCO catalytic combustion equipment is provided with a preheating chamber, a catalytic combustion chamber, a heat exchange chamber and a heat recovery device, the heat recovery device is connected with the preheating chamber, the preheating chamber is provided with a gas inlet, the heat exchange chamber is provided with a gas outlet, waste gas enters from the gas inlet, and the catalytic combustion chamber is communicated with the gas outlet. The gas sequentially passes through the preheating chamber, the catalytic combustion chamber and the heat exchange chamber and is finally exhausted through the gas outlet, and the heat recovery device transmits heat of the combusted gas in the heat exchange chamber to the preheating chamber. The catalytic combustion efficiency is improved, and the catalyst is convenient to replace.

Owner:江苏中车云汇科技有限公司

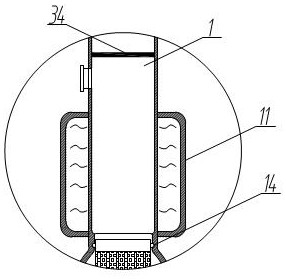

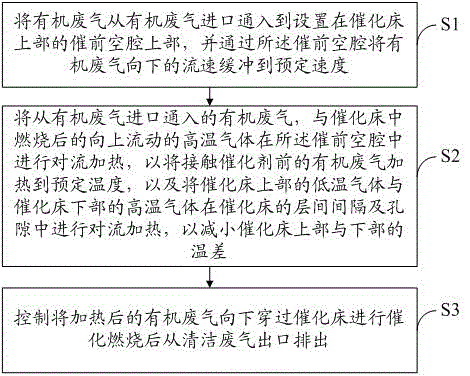

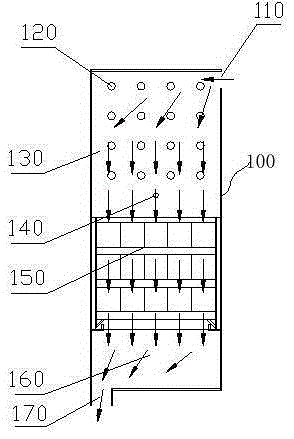

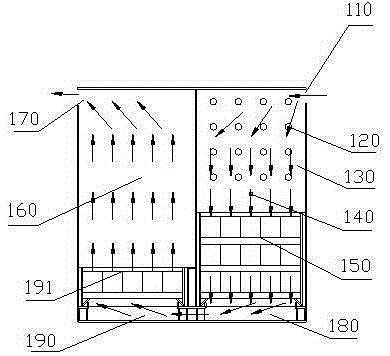

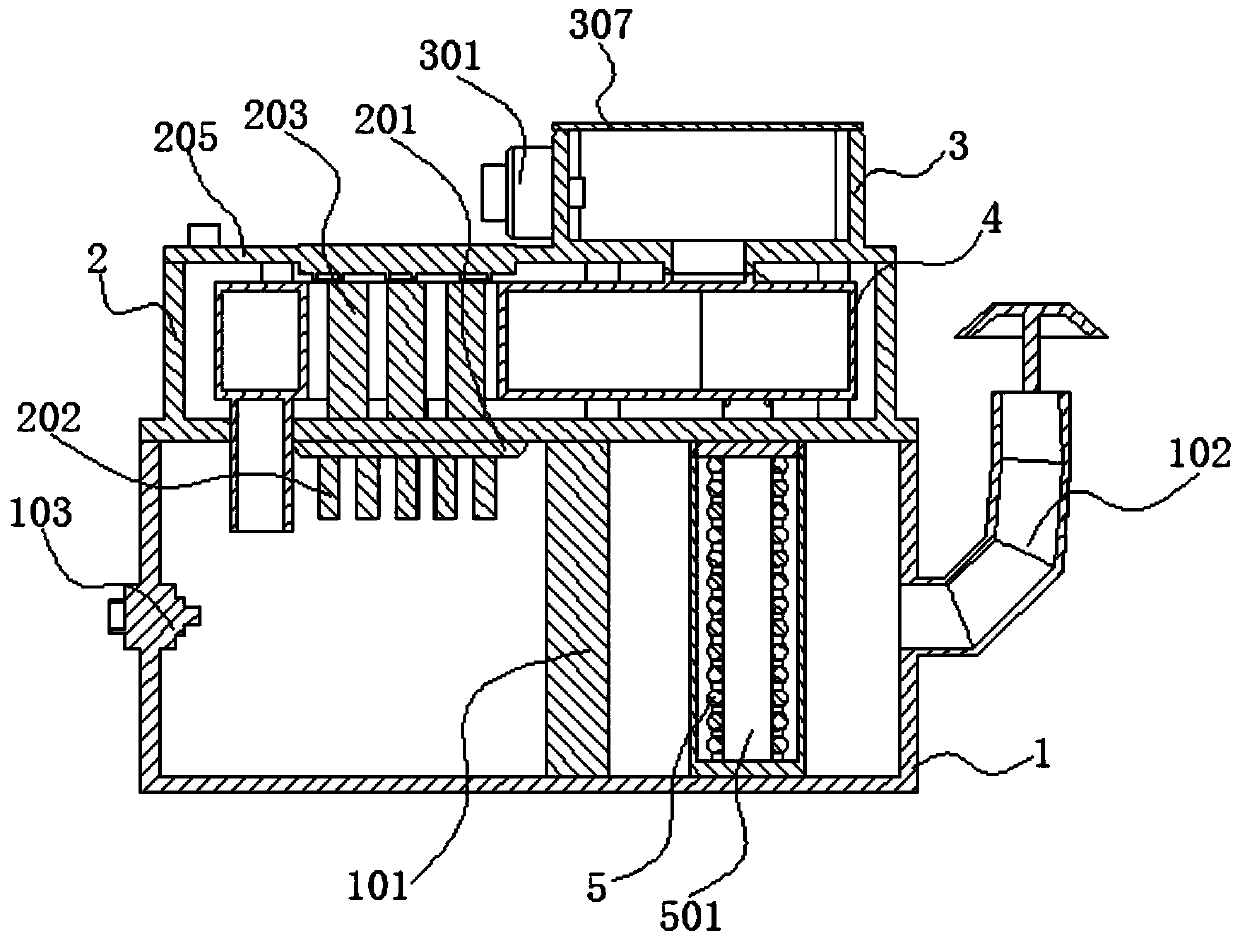

A convective catalytic combustion method, burner and application thereof

InactiveCN103062779BIncrease temperatureReduce working temperature differenceIncinerator apparatusStationary plate conduit assembliesExhaust fumesEnvironmental engineering

Disclosed are a convection-type catalytic combustion method, a combustor and use thereof. The convection-type catalytic combustor comprises a combustor body, wherein an organic waste gas inlet for feeding organic waste gas and a clean waste gas outlet used for discharging clean waste gas are arranged on the combustor body, and a pre-catalysis cavity, a first catalytic bed and a post-catalysis cavity are arranged in sequence between the organic waste gas inlet and the clean waste gas outlet.

Owner:周开勇

Modified methanol and preparation method thereof

InactiveCN102051236BImprove catalytic combustion efficiencyEmission reductionLiquid carbonaceous fuelsZinc peroxideCresol

The invention relates to modified methanol. The modified methanol is prepared from the following components in part by weight: 80 to 90 parts of methanol and 3.16 to 15.38 parts of methanol modified additive; and the methanol modified additive is prepared from the following components in part by weight: 50 to 90 parts of isopropanol, 3 to 20 parts of cyclohexane, 5 to 10 parts of aviation kerosene No.1, 0.1 to 0.9 part of zinc peroxide, 1 to 10 parts of dimetyl carbonate, 4 to 15 parts of isooctyl nitrate, 3 to 10 parts of fatty acid methyl ester, and 0.1 to 0.9 part of 2,6-di-tert-butyl-4-methylpenol. The invention has the advantages that: the cyclohexane and the 2,6-di-tert-butyl-4-methylpenol are compounded, so that the modified methanol has high corrosion resistance and swelling resistance; the isopropanol and the fatty acid methyl ester are compounded, so that the water resistance of vehicle methanol gasoline is improved by more than two times; surfactant fatty acid methyl ester, the fatty acid methyl ester and the isopropanol are compounded, so that the added methanol and fossil gasoline can be mutually dissolved according to any proportion, and the problems of low-temperature layering and emulsification layering of the methanol gasoline are solved thoroughly; and the aviation kerosene No.1 is added so as to solve the problem of low-temperature cold boot of the methanol gasoline.

Owner:北京校产企联科技有限公司

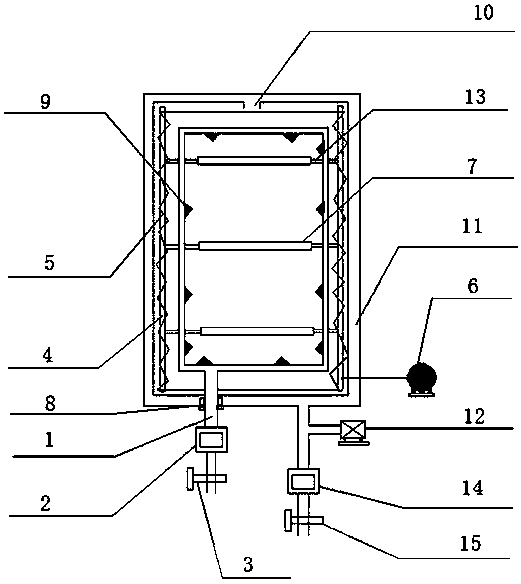

An adsorption concentration type regenerative catalytic combustion device

InactiveCN110056901BEasy to burnBurn fullyDispersed particle filtrationLump/pulverulent fuel preparationElectric machineDust control

The invention discloses an adsorption concentration heat storage type catalytic combustion device, and relates to the technical field of catalytic combustion. The adsorption concentration heat storagetype catalytic combustion device comprises a loosening and tidying mechanism, a preheating box, a combustion box and a dust removal box. The top of the combustion box is fixedly connected with a discharging box, one side of the discharging box fixedly communicates with a feeding pipe, and the feeding pipe is fixedly provided with a feeding valve. A fixed grinding table is fixedly connected to thebottom of the inner side of the discharging box. A grinding groove is formed in the top of the fixed grinding table. A discharging channel is formed in the fixed grinding table and communicates withthe interior of the combustion box. The top of the discharging box is fixedly connected with a motor. The top of the inner side of the discharging box is rotationally provided with a second rotation rod. An output shaft of the motor penetrates through the discharging box through a coupler and is fixedly connected with the top end of the second rotation rod, the bottom end of the second rotation rod is fixedly connected with a smashing roller, and smashing teeth are welded to the outer side face of the smashing roller. The adsorption concentration heat storage type catalytic combustion device is good in catalytic combustion effect, capable of saving energy and environment-friendly.

Owner:河北中科能源有限公司

Catalytic combustion device for industrial waste gas treatment

InactiveCN112344355AImprove catalytic combustion efficiencyIncrease contact areaIncinerator apparatusSolid removalCombustion chamberPtru catalyst

The invention discloses a catalytic combustion device for industrial waste gas treatment, which comprises a gas inlet pipe, a dust removal device, a filter plate, flow equalizing mechanisms, a heat exchange pipe, a flow guide plate, a turbulent flow fan, a plate type catalyst, a combustion chamber, an air duct, a dust baffle plate, a back flushing device, a buffer chamber and a gas outlet pipe; the air inlet pipe is arranged at one side of a box body; the dust removal device is arranged inside the air inlet pipe; the dust removal device comprises a shell, a dust filtering plate, a rotating shaft, shifting teeth, ventilation openings, a dust storage box and a baffle; the ventilation openings are arranged at the two sides of the shell; the rotating shaft is arranged in the shell and fixedlyconnected with the dust filtering plate; the dust storage box is arranged at the bottom of the shell and communicated with the shell; the shifting teeth are arranged between the dust storage box and the shell; the filter plate is arranged at an air outlet of the gas inlet pipe; and flow equalizing mechanisms are respectively arranged above and below one side of the filter plate. Waste gas can be fully degraded, waste heat utilization is achieved, and an internal air duct can be cleaned.

Owner:山东天智信息科技有限公司

An electromagnetic heat storage combustion purification system for treating organic waste gas

ActiveCN109084312BIncrease temperatureImprove purification effectIndirect carbon-dioxide mitigationIncinerator apparatusHeat conductingExhaust fumes

The invention discloses an electromagnetic heat storage combustion purification system for treating organic waste gas, and relates to the technical field of exhaust gas treatment. The electromagneticheat storage combustion purification system comprises a combustion box, a heat storage box is fixedly arranged at the top of the combustion box, a processing box is fixedly arranged at the top of theheat storage box, and a heat conduction box is fixedly arranged in the heat storage box. The top surface of the combustion box is fixedly connected with the bottom surface of the heat storage box, thecombustion box is internally and fixedly provided with a heat exchanger, the heat exchanger is used for absorbing heat generated by combustion gas in the combustion box, and a group of heat conduction columns is fixedly arranged in the heat exchanger. The electromagnetic heat storage combustion purification system is provided with the heat conducting columns on the heat exchanger, the heat conduction columns are located in the heat storage box, and at the same time, a heat absorbing rod and a heat conducting plate are arranged at the position of the combustion box to absorb the heat in the combustion box and discharge the heat to water in the heat storage box through the heat conducting rod, the gas in the heat conducting box is preheated by the heat conduction of the hot water in the heat storage box, and the problem that an existing combustion purification system has low catalytic combustion due to poor heat storage effect is solved.

Owner:安徽尘缘节能环保科技有限公司

A high-efficiency voc treatment system using a new type of heat exchanger and its treatment process

ActiveCN106369617BGuaranteed concentrationBurn fullyDispersed particle filtrationSteam engine plantsProcess engineeringCatalytic combustion

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A high-temperature catalytic combustion catalyst for washing tail gas with liquid nitrogen, its preparation method and application

ActiveCN110152660BImprove activity stabilityImprove thermal stabilityHeterogenous catalyst chemical elementsIncinerator apparatusPtru catalystPhysical chemistry

Owner:KUNMING UNIV OF SCI & TECH

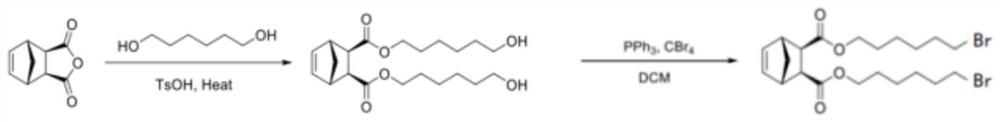

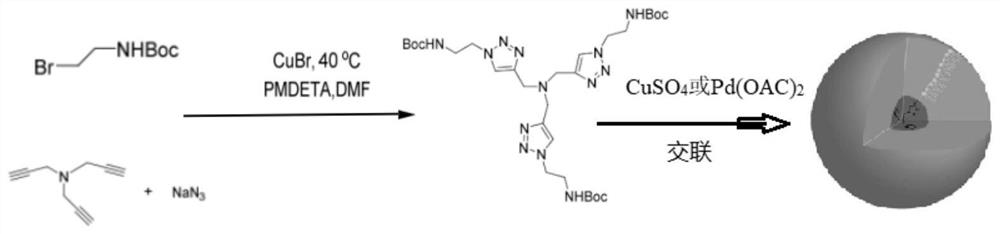

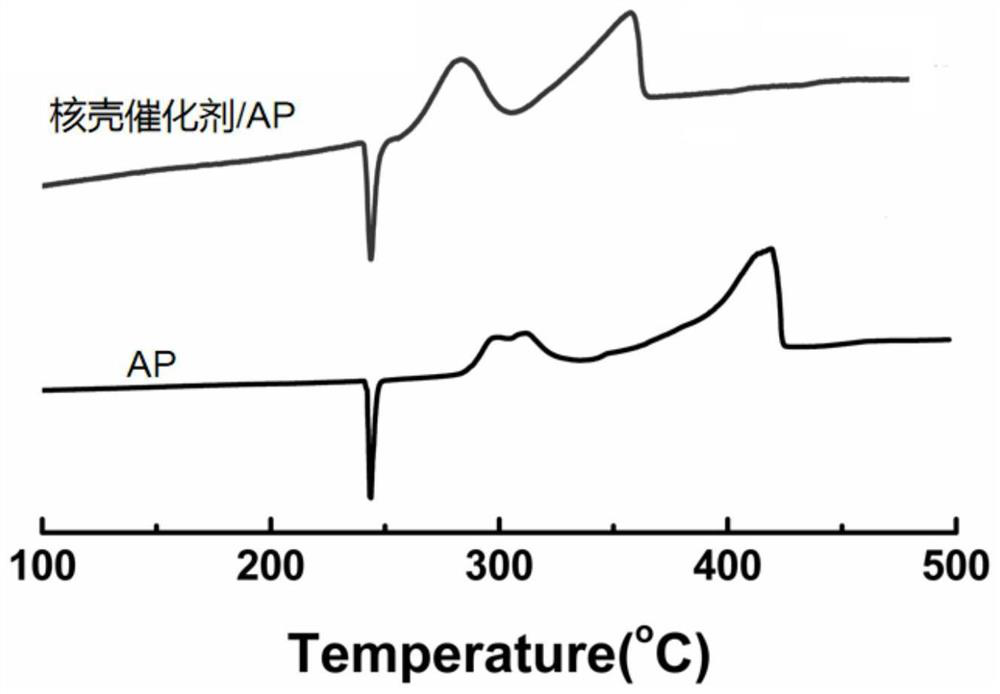

Nano core-shell combustion catalyst and preparation method thereof

ActiveCN113754506AHigh catalytic activityHigh activityNon-explosive/non-thermic compositionsPolymer sciencePtru catalyst

The invention provides a nano core-shell combustion catalyst and a preparation method thereof. The preparation method comprises the following steps: taking cis-5-norbornene-exo-2, 3-dicarboxylic anhydride, hexanediol, p-toluenesulfonic acid and dichloromethane to prepare a dibromide monomer sample; taking pure triamine, cis-5-norbornene-exo-2, 3-dicarboxylic anhydride and a toluene solvent to prepare a cross-linking agent; and taking a dibromide monomer, a catalyst, copper sulfate or palladium acetate to prepare a nano core-shell combustion catalyst. The method has the advantages and positive effects that: the two problems of agglomeration of metal active molecules and incapability of accurately controlling the shell thickness are solved. A dibromide monomer with an active center at the tail end is synthesized through a ring-opening metathesis polymerization reaction, then a cross-linking agent is added for further cross-linking so as to form a combustion catalyst with a compact shell structure composed of linear macromolecular arms and a core containing a ligand structure, the particle size of the combustion catalyst is in the nanometer size, the activity is high, the catalytic combustion efficiency is high, and the preparation method is beneficial to large-scale production.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com