A high-temperature catalytic combustion catalyst for washing tail gas with liquid nitrogen, its preparation method and application

A combustion catalyst and high-temperature catalysis technology, applied in combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of catalyst deactivation, low catalyst thermal stability, and difficulty in realizing high-temperature catalytic combustion of liquid nitrogen washing tail gas, etc. problems, to achieve the effect of improving catalytic activity, promoting oxygen transport capacity, and efficient and rapid catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

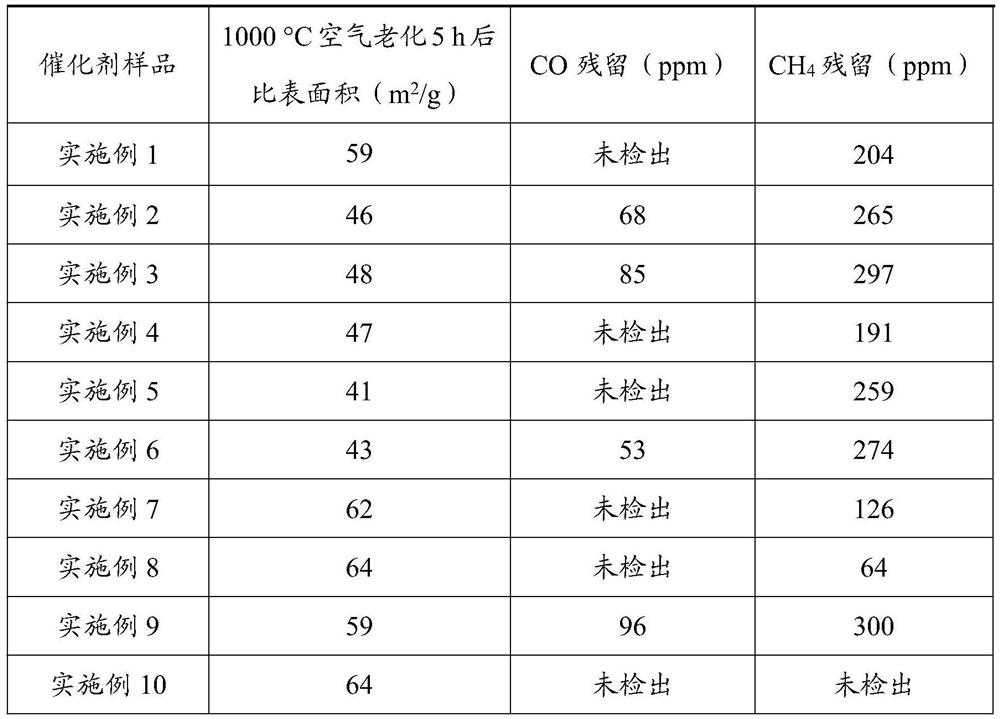

Examples

preparation example Construction

[0031] The present invention provides a method for preparing a high-temperature catalytic combustion catalyst for washing tail gas with liquid nitrogen described in the above technical solution, comprising the following steps:

[0032] 1) mixing lanthanum nitrate, manganese nitrate, a first metal nitrate compound, citric acid and water, and complexing the obtained first mixture to obtain a gel;

[0033] 2) performing a first calcination on the gel to obtain a first carrier product;

[0034] 3) mixing the first carrier product, aluminum nitrate, the second metal nitrate compound and water, and performing a precipitation reaction on the obtained second mixture under the action of a buffer to obtain a precipitate;

[0035] 4) Carrying out the second roasting of the precipitate to obtain the second carrier product;

[0036] 5) immersing the second carrier product in a palladium nitrate solution for impregnation, and then drying the obtained mixture in sequence and third roasting ...

Embodiment 1

[0054] Weigh 86.21g of lanthanum nitrate, 35.10g of manganese nitrate and 3.39g of yttrium nitrate in a beaker of 1000mL deionized water, stir at 1500rpm for 30min to form a homogeneous solution, then add 84.29g of citric acid, wherein citric acid and total metal atoms The molar ratio is 1:1. After stirring evenly, transfer to a water bath for heating, stir in a constant temperature water bath at 80°C for 4 to 6 hours to form a wet gel, and then dry at 80°C for 2 days to obtain a xerogel. After grinding the glue to 100 mesh, carry out the first roasting at 500°C for 3 hours to obtain the first carrier product; weigh 353.06g aluminum nitrate, 1.70g barium nitrate, and 2.70g lanthanum nitrate in a beaker of 1000mL deionized water, stir well , add 50g of the first carrier product, continue to stir to form a uniform turbid liquid, and carry out precipitation reaction with a buffer prepared with a molar ratio of sodium carbonate and ammonia water of 1:1. After the precipitation reac...

Embodiment 2

[0056] Take by weighing 86.21g lanthanum nitrate, 35.10g manganese nitrate and 3.39g yttrium nitrate in the beaker that 1000mL deionized water is housed, stir under 1300rpm rotating speed and form homogeneous solution, then add 84.29g citric acid in described solution, wherein The molar ratio of citric acid to total metal atoms is 1:1. After stirring evenly, transfer to a water bath for heating, and stir at 80°C for 4h to form a wet gel. Dry the wet gel at 80°C for 2d to obtain dry coagulation After grinding the xerogel to 80 mesh, the first calcination was carried out at 500°C for 3 hours to obtain the first carrier product; weigh 353.06g of aluminum nitrate, 1.70g of barium nitrate, and 2.75g of zirconium nitrate in 1000mL of deionized water In the beaker, after stirring evenly, add 50g of the first carrier product, continue to stir to form a uniform turbid liquid, carry out the precipitation reaction with a buffer prepared with a molar ratio of sodium carbonate and ammonia w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com