Catalytic combustion device for industrial waste gas treatment

A catalytic combustion and industrial waste gas technology, applied in the direction of combustion type, combustion method, clean heat transfer device, etc., can solve the problems of waste of resources, low purification efficiency, complex components, etc., and achieve long residence time, improved efficiency, and large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

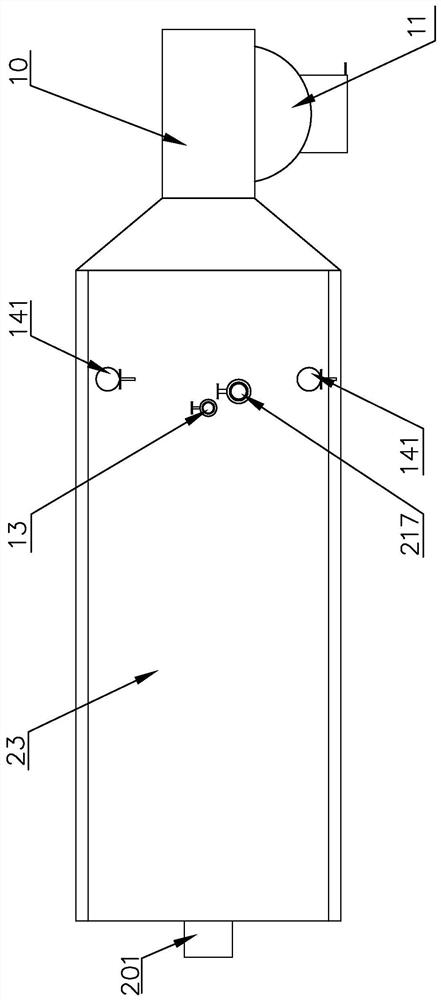

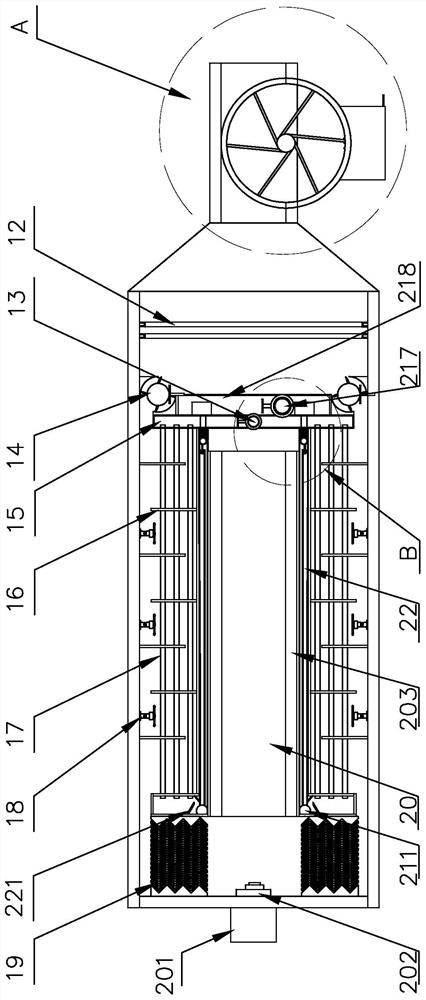

[0023]To facilitate the understanding of those skilled in the art, the following is attachedFigure 1-7, The technical scheme of the present invention is further explained in detail.

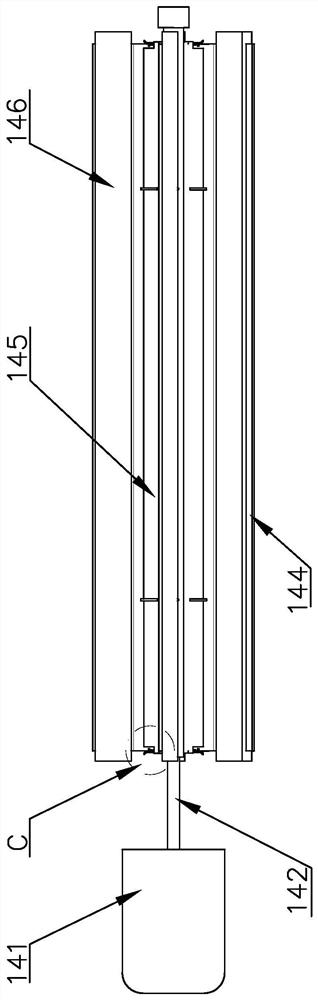

[0024]A catalytic combustion device for industrial waste gas treatment, including an air intake pipe 10, a dust removal device 11, a filter plate 12, a flow sharing mechanism 14, a heat exchange pipe 17, a baffle plate 16, a spoiler fan 18, a plate catalyst 19, and a combustion chamber 20 , Air duct 22, dust baffle 221, recoil air device 21, buffer chamber 15, air outlet pipe 13, the air inlet pipe 10 is arranged on the side of the box body 23, and the air inlet pipe 10 is provided with a dust removal device 11, the dust removal The device 11 includes a housing 117, a dust filter 112, a rotating shaft 116, a gear 115, a vent 111, a dust storage box 113, and a baffle 114. The two sides of the housing 117 are provided with vents 111, and a rotating shaft 116 is provided inside, and the rotating shaft 116 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com