A high-efficiency voc treatment system using a new type of heat exchanger and its treatment process

A processing system and heat exchanger technology, applied in the direction of combustion type, machine/engine, lighting and heating equipment, etc., can solve the problems of difficult implementation, low heat exchange efficiency, human health damage, etc., to achieve energy self-supply, The effect of improving processing efficiency and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

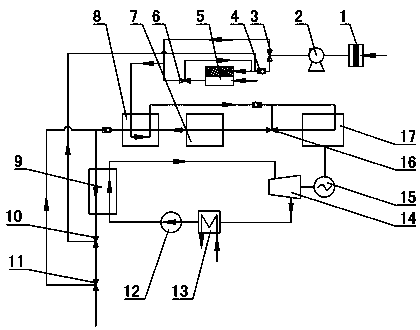

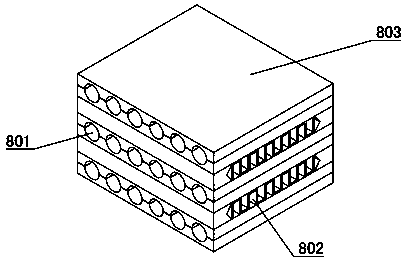

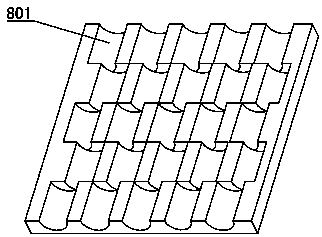

[0038] Figure 1~7 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0039] A high-efficiency VOC treatment system using a new type of heat exchanger, characterized in that it includes a pretreatment module, a catalytic combustion module, a power generation module and a control unit, the outlet end of the pretreatment module is connected to the inlet end of the catalytic combustion module, and the catalytic combustion The outlet of the module is connected to the atmosphere, and a heat exchange unit is installed between the power generation module and the outlet of the catalytic combustion module. The power generation module is connected to the catalytic combustion module through a wire, and supplies power to the catalytic combustion module. The gas enters from the gas end and is discharged into the atmosphere after being burned by the catalytic combustion module. The power gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com